radiator cap YAMAHA YZ250F 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ250F, Model: YAMAHA YZ250F 2014Pages: 356, PDF Size: 11.39 MB

Page 95 of 356

ENGINE

3-9

5. Install:

• Copper washers

• Coolant drain bolt

6. Pour coolant.

EWA13040

WARNING

• If coolant splashes in your eyes, thorough-

ly wash them with water and consult a

doctor.

• If coolant splashes on your clothes, quick-

ly wash it away with water and then with

soap and water.

• If coolant is swallowed, induce vomiting

and get immediate medical attention.

ECA13480

NOTICE

• Adding water instead of coolant lowers the

antifreeze content. If, therefore, water is

used instead of coolant, check, and if nec-

essary, adjust the antifreeze concentra-

tion.

• Use only distilled water. However, if dis-

tilled water is not available, soft water may

be used.

• If coolant comes into contact with painted

surfaces, immediately wash them with wa-

ter.

• Do not mix different types of coolant.

7. Install:

• Radiator cap

8. Start the engine, warm this up for several

minutes, stop it, and then wait for it to cool

down.

9. Check:

• Coolant level

Refer to “CHECKING THE COOLANT LEV-

EL” on page 3-8.

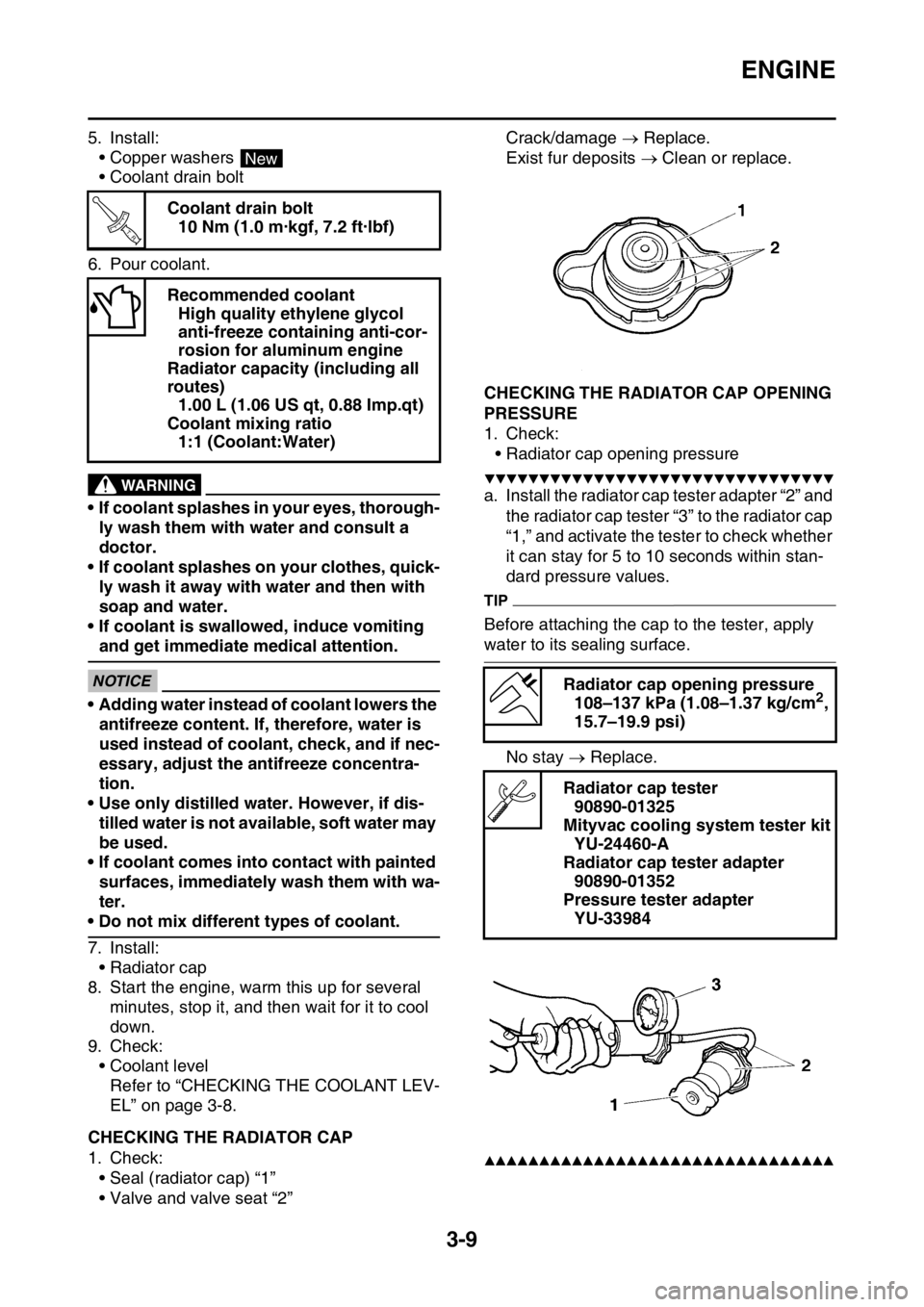

EAS1SM1073CHECKING THE RADIATOR CAP

1. Check:

• Seal (radiator cap) “1”

• Valve and valve seat “2”Crack/damage Replace.

Exist fur deposits Clean or replace.

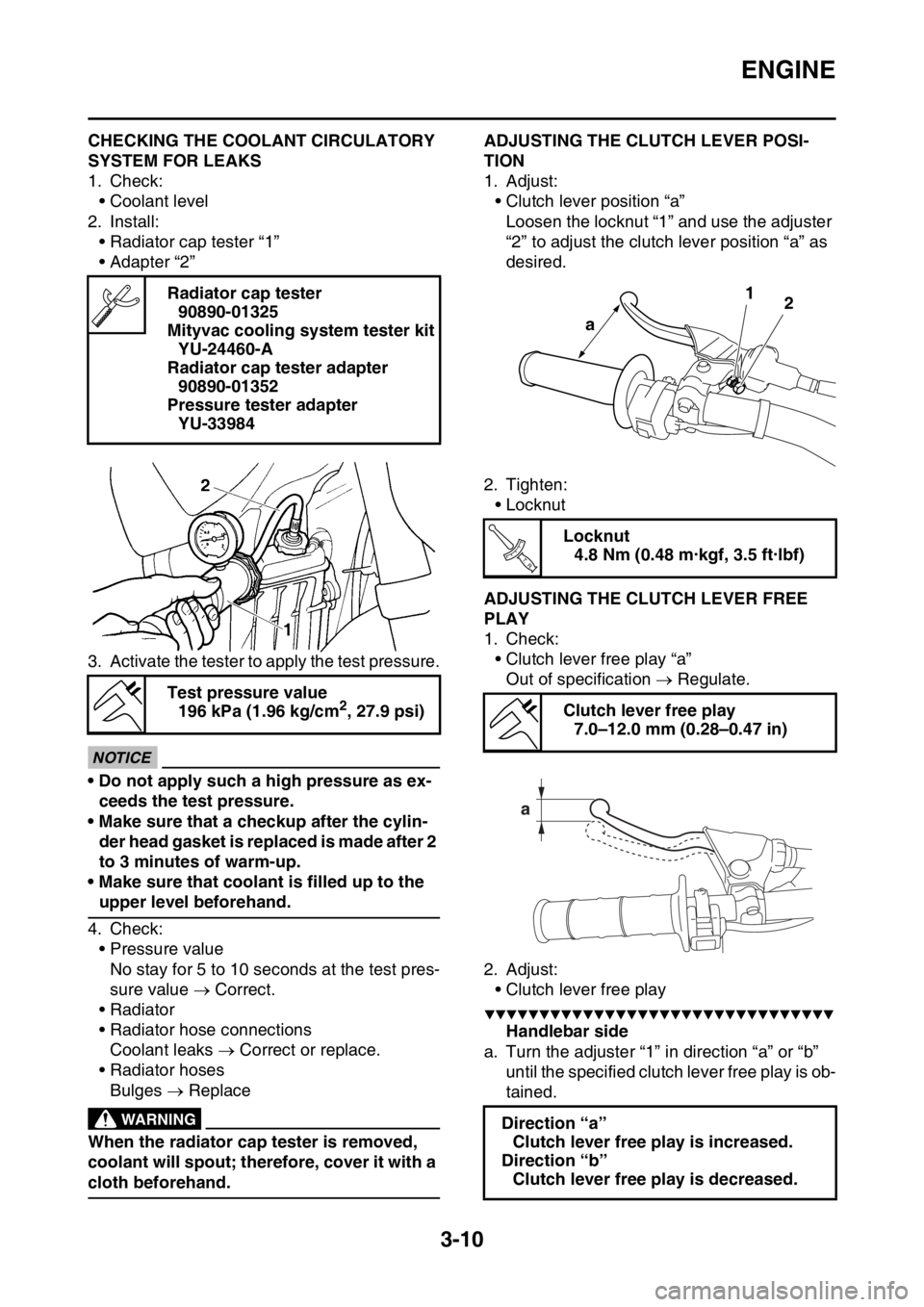

EAS1SM1074CHECKING THE RADIATOR CAP OPENING

PRESSURE

1. Check:

• Radiator cap opening pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Install the radiator cap tester adapter “2” and

the radiator cap tester “3” to the radiator cap

“1,” and activate the tester to check whether

it can stay for 5 to 10 seconds within stan-

dard pressure values.

TIP

Before attaching the cap to the tester, apply

water to its sealing surface.

No stay Replace.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Coolant drain bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Recommended coolant

High quality ethylene glycol

anti-freeze containing anti-cor-

rosion for aluminum engine

Radiator capacity (including all

routes)

1.00 L (1.06 US qt, 0.88 Imp.qt)

Coolant mixing ratio

1:1 (Coolant:Water)

New

T R..

Radiator cap opening pressure

108–137 kPa (1.08–1.37 kg/cm2,

15.7–19.9 psi)

Radiator cap tester

90890-01325

Mityvac cooling system tester kit

YU-24460-A

Radiator cap tester adapter

90890-01352

Pressure tester adapter

YU-33984

Page 96 of 356

ENGINE

3-10

EAS1SM1075CHECKING THE COOLANT CIRCULATORY

SYSTEM FOR LEAKS

1. Check:

• Coolant level

2. Install:

• Radiator cap tester “1”

• Adapter “2”

3. Activate the tester to apply the test pressure.

ECA@

NOTICE

• Do not apply such a high pressure as ex-

ceeds the test pressure.

• Make sure that a checkup after the cylin-

der head gasket is replaced is made after 2

to 3 minutes of warm-up.

• Make sure that coolant is filled up to the

upper level beforehand.

4. Check:

• Pressure value

No stay for 5 to 10 seconds at the test pres-

sure value Correct.

• Radiator

• Radiator hose connections

Coolant leaks Correct or replace.

• Radiator hoses

Bulges Replace

EWA@

WARNING

When the radiator cap tester is removed,

coolant will spout; therefore, cover it with a

cloth beforehand.

EAS1SM1076ADJUSTING THE CLUTCH LEVER POSI-

TION

1. Adjust:

• Clutch lever position “a”

Loosen the locknut “1” and use the adjuster

“2” to adjust the clutch lever position “a” as

desired.

2. Tighten:

• Locknut

EAS1SM1077ADJUSTING THE CLUTCH LEVER FREE

PLAY

1. Check:

• Clutch lever free play “a”

Out of specification Regulate.

2. Adjust:

• Clutch lever free play

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Handlebar side

a. Turn the adjuster “1” in direction “a” or “b”

until the specified clutch lever free play is ob-

tained. Radiator cap tester

90890-01325

Mityvac cooling system tester kit

YU-24460-A

Radiator cap tester adapter

90890-01352

Pressure tester adapter

YU-33984

Test pressure value

196 kPa (1.96 kg/cm

2, 27.9 psi)

Locknut

4.8 Nm (0.48 m·kgf, 3.5 ft·lbf)

Clutch lever free play

7.0–12.0 mm (0.28–0.47 in)

Direction “a”

Clutch lever free play is increased.

Direction “b”

Clutch lever free play is decreased.

1

2

a

T R..

Page 270 of 356

RADIATOR

6-3

EAS1SM1297HANDLING NOTEEWA1DX1007

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

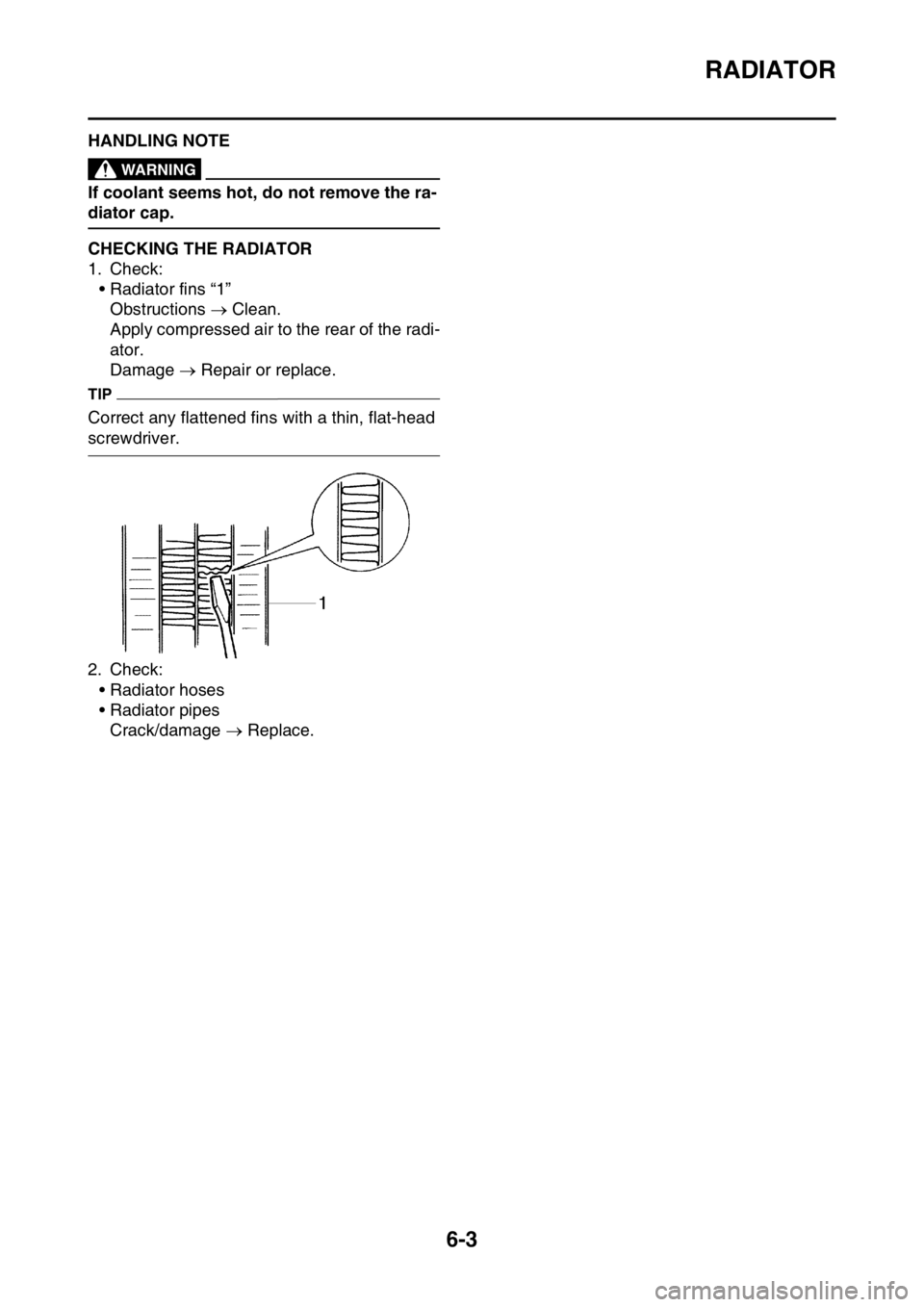

EAS1SM1298CHECKING THE RADIATOR

1. Check:

• Radiator fins “1”

Obstructions Clean.

Apply compressed air to the rear of the radi-

ator.

Damage Repair or replace.

TIP

Correct any flattened fins with a thin, flat-head

screwdriver.

2. Check:

• Radiator hoses

• Radiator pipes

Crack/damage Replace.

Page 337 of 356

TROUBLE SHOOTING

9-2

3. Ignition system

• Faulty ECU

• Faulty crankshaft position sensor

• Broken generator rotor woodruff key

EAS1SM1354POOR MEDIUM-AND-HIGH-SPEED PER-

FORMANCE

Refer to “STARTING FAILURES” on page 9-1.

Engine

1. Air filter

• Clogged air filter element

Fuel system

1. Fuel pump

• Faulty fuel pump

2. Throttle body

• Defective throttle body

3. ECU

• Faulty ECU

EAS1SM1355FAULTY GEAR SHIFTING

Shifting is difficult

Refer to “CLUTCH” on page 5-35.

EAS1SM1356SHIFT PEDAL DOES NOT MOVE

Shift shaft

• Bent shift shaft

Shift drum and shift forks

• Foreign object in a shift drum groove

• Seized shift fork

• Bent shift fork guide bar

Transmission

• Seized transmission gear

• Foreign object between transmission gears

• Improperly assembled transmission

EAS1SM1357JUMPS OUT OF GEAR

Shift shaft

• Incorrect shift pedal position

• Improperly returned stopper lever

Shift forks

• Worn shift fork

Shift drum

• Incorrect axial play

• Worn shift drum groove

Transmission

• Worn gear dog

EAS1SM1358FAULTY CLUTCH

Clutch slips

1. Clutch

• Improperly assembled clutch

• Loose or fatigued clutch spring

• Worn friction plate

• Worn clutch plate

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity (low)

• Deteriorated oil

Clutch drags

1. Clutch

• Unevenly tensioned clutch springs

• Warped pressure plate

• Bent clutch plate

• Swollen friction plate

• Bent clutch push rod

• Damaged clutch boss

• Burnt primary driven gear bushing

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity (high)

• Deteriorated oil

EAS1SM1359OVERHEATING

Engine

1. Cylinder head and piston

• Heavy carbon buildup

• Clogged coolant passages

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity

• Inferior oil quality

Cooling system

1. Coolant

• Low coolant level

2. Radiator

• Damaged or leaking radiator

• Faulty radiator cap

• Bent or damaged radiator fin

3. Water pump

• Damaged or faulty water pump

• Damaged hose

• Improperly connected hose

• Damaged pipe

• Improperly connected pipe