washer fluid YAMAHA YZ250F 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ250F, Model: YAMAHA YZ250F 2014Pages: 356, PDF Size: 11.39 MB

Page 152 of 356

REAR BRAKE

4-28

EWA13090

WARNING

• Use only the designated brake fluid. Other

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that

is already in the system. Mixing brake flu-

ids may result in a harmful chemical reac-

tion, leading to poor brake performance.

• When pouring the brake fluid, be careful

that water does not enter the reservoir.

Water will significantly lower the boiling

point of the brake fluid and could cause

vapor lock.

ECA13540

NOTICE

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean

up any spilt brake fluid immediately.

5. Bleed:

• Brake system

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-21.

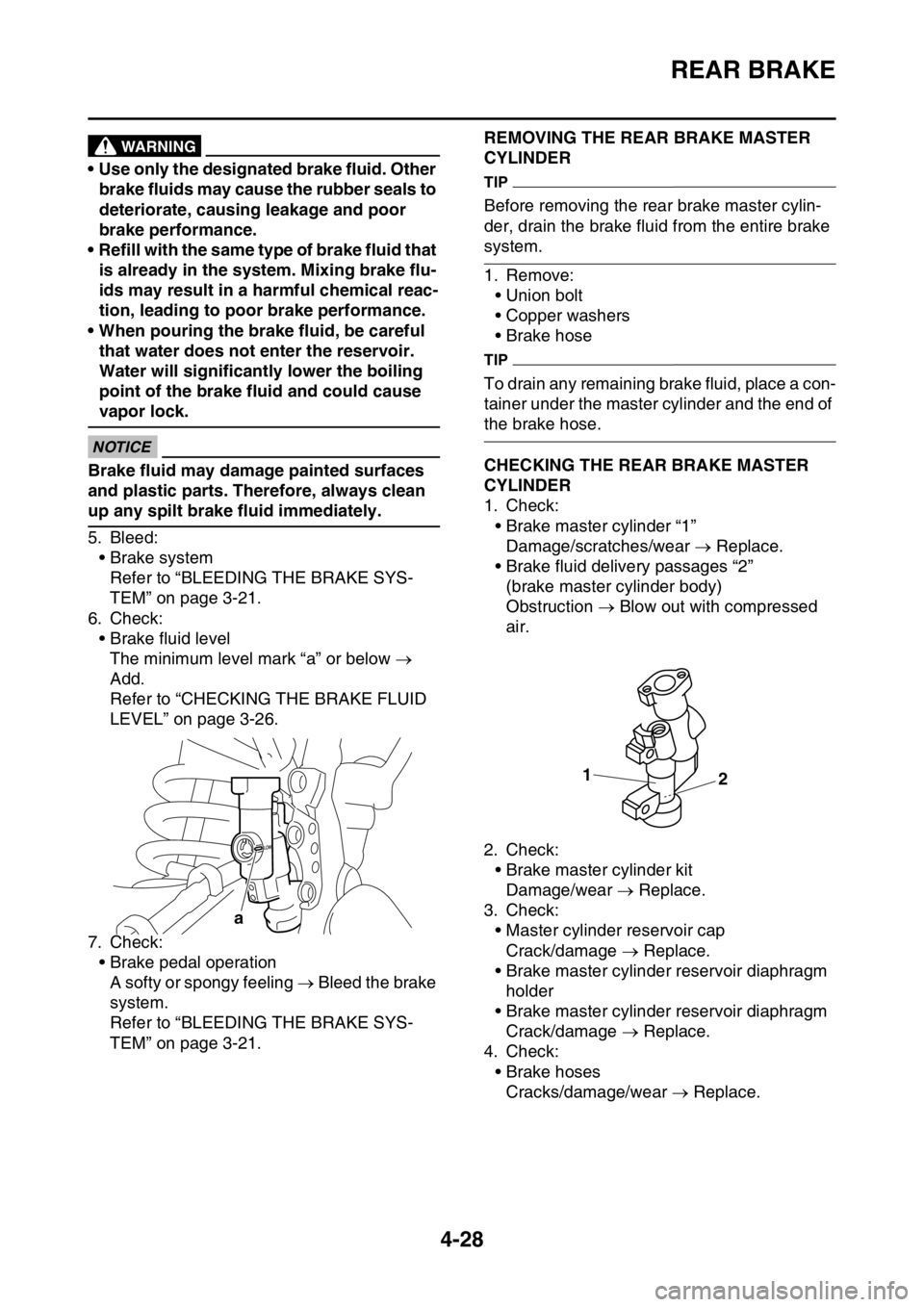

6. Check:

• Brake fluid level

The minimum level mark “a” or below 

Add.

Refer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-26.

7. Check:

• Brake pedal operation

A softy or spongy feeling ď‚® Bleed the brake

system.

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-21.

EAS1SM1157

REMOVING THE REAR BRAKE MASTER

CYLINDER

TIP

Before removing the rear brake master cylin-

der, drain the brake fluid from the entire brake

system.

1. Remove:

• Union bolt

• Copper washers

• Brake hose

TIP

To drain any remaining brake fluid, place a con-

tainer under the master cylinder and the end of

the brake hose.

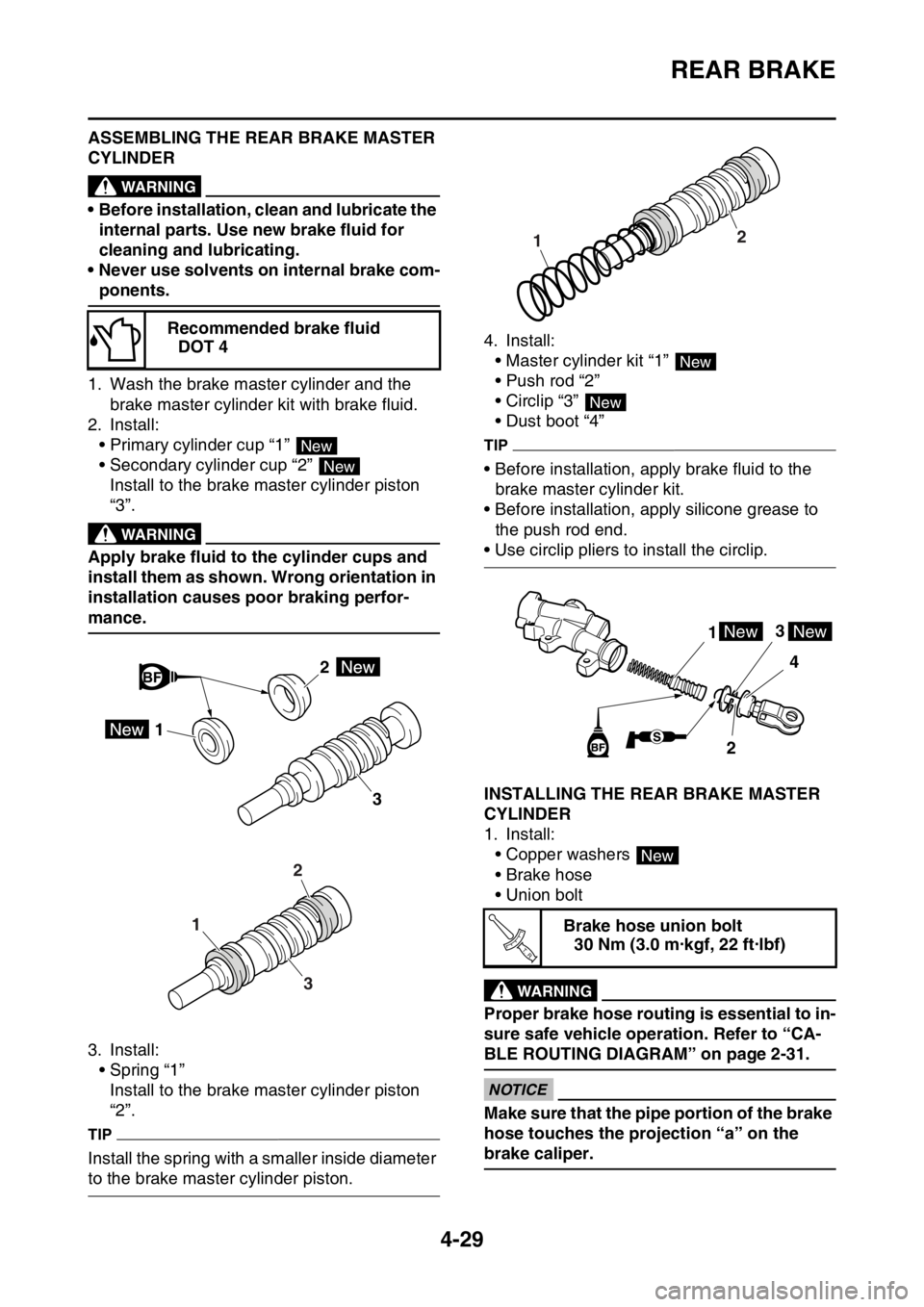

EAS1SM1158CHECKING THE REAR BRAKE MASTER

CYLINDER

1. Check:

• Brake master cylinder “1”

Damage/scratches/wear ď‚® Replace.

• Brake fluid delivery passages “2”

(brake master cylinder body)

Obstruction ď‚® Blow out with compressed

air.

2. Check:

• Brake master cylinder kit

Damage/wear ď‚® Replace.

3. Check:

• Master cylinder reservoir cap

Crack/damage ď‚® Replace.

• Brake master cylinder reservoir diaphragm

holder

• Brake master cylinder reservoir diaphragm

Crack/damage ď‚® Replace.

4. Check:

• Brake hoses

Cracks/damage/wear ď‚® Replace.

EAS1SM1159

a

1

2

Page 153 of 356

REAR BRAKE

4-29

ASSEMBLING THE REAR BRAKE MASTER

CYLINDER

EWA13520

WARNING

• Before installation, clean and lubricate the

internal parts. Use new brake fluid for

cleaning and lubricating.

• Never use solvents on internal brake com-

ponents.

1. Wash the brake master cylinder and the

brake master cylinder kit with brake fluid.

2. Install:

• Primary cylinder cup “1”

• Secondary cylinder cup “2”

Install to the brake master cylinder piston

“3”.

EWA13520

WARNING

Apply brake fluid to the cylinder cups and

install them as shown. Wrong orientation in

installation causes poor braking perfor-

mance.

3. Install:

• Spring “1”

Install to the brake master cylinder piston

“2”.

TIP

Install the spring with a smaller inside diameter

to the brake master cylinder piston.4. Install:

• Master cylinder kit “1”

• Push rod “2”

• Circlip “3”

• Dust boot “4”

TIP

• Before installation, apply brake fluid to the

brake master cylinder kit.

• Before installation, apply silicone grease to

the push rod end.

• Use circlip pliers to install the circlip.

EAS1SM1160INSTALLING THE REAR BRAKE MASTER

CYLINDER

1. Install:

• Copper washers

• Brake hose

• Union bolt

EWA13530

WARNING

Proper brake hose routing is essential to in-

sure safe vehicle operation. Refer to “CA-

BLE ROUTING DIAGRAM” on page 2-31.

ECA1DX1008

NOTICE

Make sure that the pipe portion of the brake

hose touches the projection “a” on the

brake caliper. Recommended brake fluid

DOT 4

New

New

2

3

1

2

3

1Brake hose union bolt

30 Nm (3.0 m·kgf, 22 ft·lbf)

12

New

New

13

4

2NewNew

New

T R..

Page 338 of 356

TROUBLE SHOOTING

9-3

Fuel system

1. Throttle body

• Damaged or loose throttle body joint

2. Air filter

• Clogged air filter element

Chassis

1. Brake(s)

• Dragging brake

Electrical system

1. Spark plug

• Incorrect spark plug gap

• Incorrect spark plug heat range

2. Ignition system

• Faulty ECU

• Faulty coolant temperature sensor

EAS1SM1360OVERCOOLING

Cooling system

• Faulty coolant temperature sensor

EAS1SM1361POOR BRAKING PERFORMANCE

• Worn brake pad

• Worn brake disc

• Air in hydraulic brake system

• Leaking brake fluid

• Defective master cylinder kit

• Faulty brake caliper kit

• Faulty brake caliper seal

• Loose union bolt

• Damaged brake hose

• Oil or grease on the brake disc

• Oil or grease on the brake pad

• Incorrect brake fluid level

EAS1SM1362FAULTY FRONT FORK LEGS

Leaking oil

• Bent, damaged, or rusty inner tube

• Cracked or damaged outer tube

• Improperly installed oil seal

• Damaged oil seal lip

• Incorrect oil level (high)

• Loose damper rod assembly bolt

• Damaged damper rod assembly bolt copper

washer

• Cracked or damaged cap bolt O-ringMalfunction

• Bent or damaged inner tube

• Bent or damaged outer tube

• Broken fork spring

• Bent or damaged damper rod

• Incorrect oil viscosity

• Incorrect oil level

EAS1SM1363UNSTABLE HANDLING

1. Handlebar

• Bent or improperly installed handlebar

2. Steering head components

• Improperly installed upper bracket

• Improperly installed lower bracket

(improperly tightened ring nut)

• Bent steering stem

• Damaged ball bearing or bearing race

3. Front fork leg (s)

• Uneven oil levels (both front fork legs)

• Unevenly tensioned fork spring (both front

fork legs)

• Broken fork spring

• Bent or damaged inner tube

• Bent or damaged outer tube

4. Swingarm

• Worn bearing or bushing

• Bent or damaged swingarm

5. Rear shock absorber assembly (-ies)

• Faulty rear shock absorber spring

• Leaking oil or gas

6. Tire (s)

• Uneven tire pressures (front and rear)

• Incorrect tire pressure

• Uneven tire wear

7. Wheel (s)

• Incorrect wheel balance

• Broken or loose spoke

• Damaged wheel bearing

• Bent or loose wheel axle

• Excessive wheel runout

8. Frame

• Bent frame

• Damaged steering head pipe

• Improperly installed bearing race