wheel YAMAHA YZ250F 2014 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ250F, Model: YAMAHA YZ250F 2014Pages: 356, PDF Size: 11.39 MB

Page 9 of 356

EAS1SM1007

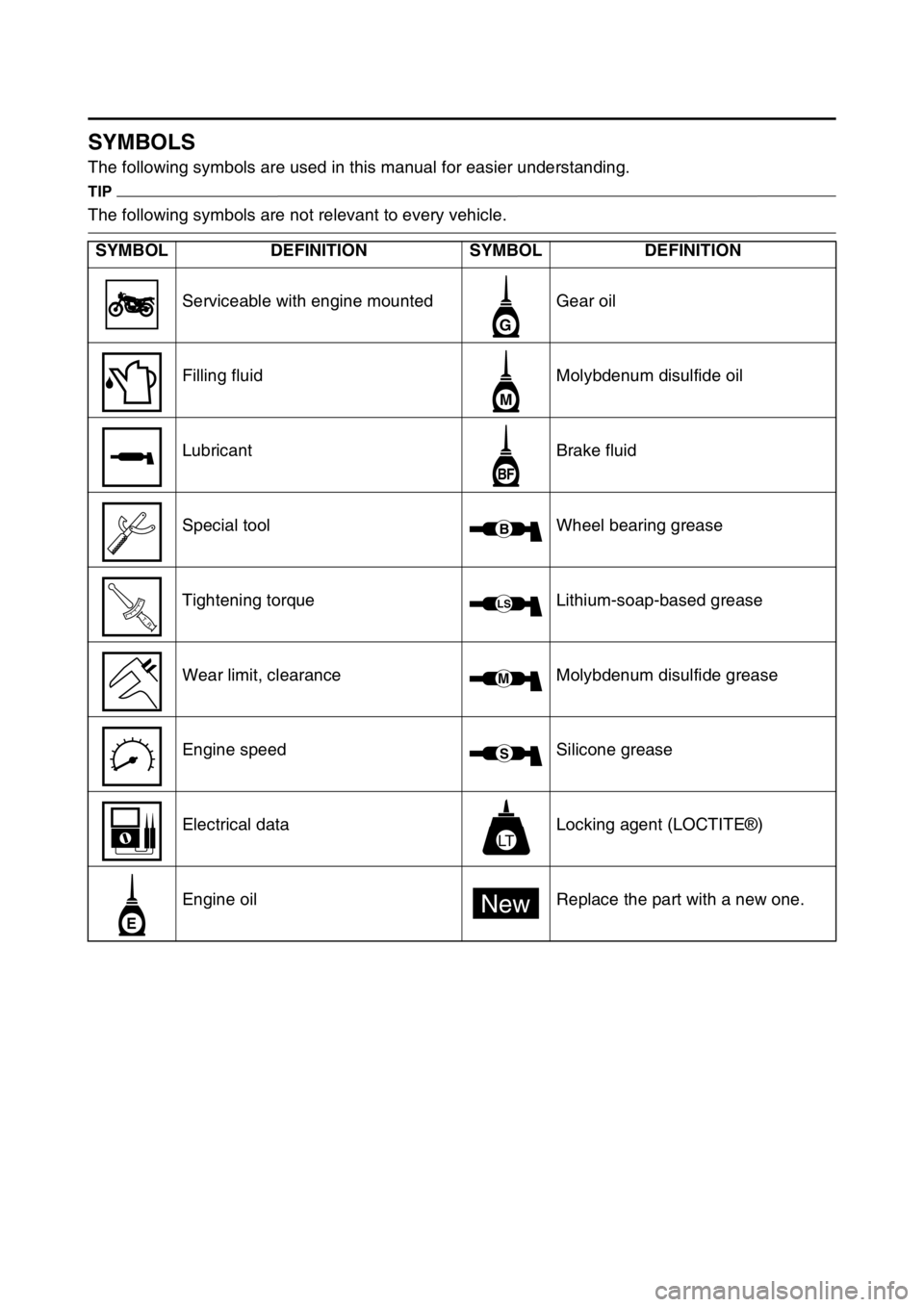

SYMBOLS

The following symbols are used in this manual for easier understanding.

TIP

The following symbols are not relevant to every vehicle.

SYMBOL DEFINITION SYMBOL DEFINITION

Serviceable with engine mounted Gear oil

Filling fluid Molybdenum disulfide oil

Lubricant Brake fluid

Special tool Wheel bearing grease

Tightening torque Lithium-soap-based grease

Wear limit, clearance Molybdenum disulfide grease

Engine speed Silicone grease

Electrical data Locking agent (LOCTITE®)

Engine oil Replace the part with a new one.

G

M

BF

B

T R..

LS

M

S

LT

E

New

Page 38 of 356

MAINTENANCE AFTER BREAK-IN

1-24

EAS1SM1046

MAINTENANCE AFTER BREAK-IN

After a break-in, perform careful maintenance

to get ready for the next practice or race.

Refer to “PRE-OPERATION INSPECTION

AND MAINTENANCE” on page 3-7.

EAS1SM1047MAJOR MAINTENANCE

1. For the engine

• Leaks around the engine

Check for pressure leaks from the cylinder

head or the cylinder, oil leaks from the

crankcase or the case cover, leaks from the

coolant system, and other leaks.

• Check that the valve, the cylinder head, the

cylinder, the piston, and the piston ring fit

one another, and that contact between the

valve and the cylinder head, and that be-

tween the cylinder and the piston are cor-

rect.

• Engine oil change

Drain the oil, and check for dirt and foreign

materials such as metal chips. (If any foreign

material is mixed, disassemble and check

the crankcase.)

Pour the specified amount of the recom-

mended oil.

• AC magneto

Check for looseness in mounted areas of

the rotor and the stator.

Check that the connector is not being dis-

connected.

• Silencer

Check the main body and stay for cracks.

Check for leaks.

• Mounting bolts and nuts

Check for looseness in mounted areas of

parts, as well as engine mounting bolts and

engine brackets.

2. For the chassis

• Check welds and mounted areas of the

frame, the swingarm, the link, the bracket,

and so on, for looseness and cracks.

• Wheel (s)

Check the wheel for runout. Check the

spoke for looseness.

• Brake(s)

Check the brake disc mounting bolt for

looseness.

Check that the reservoir contains the speci-

fied amount of brake fluid. Check for leaks.• Cable

Grease and adjust cables.

•Drive chain

Lubricate the drive chain and adjust its ten-

sion.

• Fuel tank

Clean the inside of the fuel tank. Check for

leaks.

• Suspension

Check for oil leaks in the front fork or the rear

shock absorber. Check that the mounted

conditions are good.

• Sprocket

Check for looseness in the sprocket mount-

ed on the rear wheel.

• Mounting bolts and nuts

Check mounted areas for looseness.

JCA1SL1001

NOTICE

After a break-in or before each race, always

check the points shown in “TORQUE-

CHECK POINTS” for tightening torques and

retighten them. (Refer to “TORQUE-CHECK

POINTS”.)

• Greasing and oiling

Always grease or oil the specified points.

Page 39 of 356

TORQUE-CHECK POINTS

1-25

EAS1SM1048

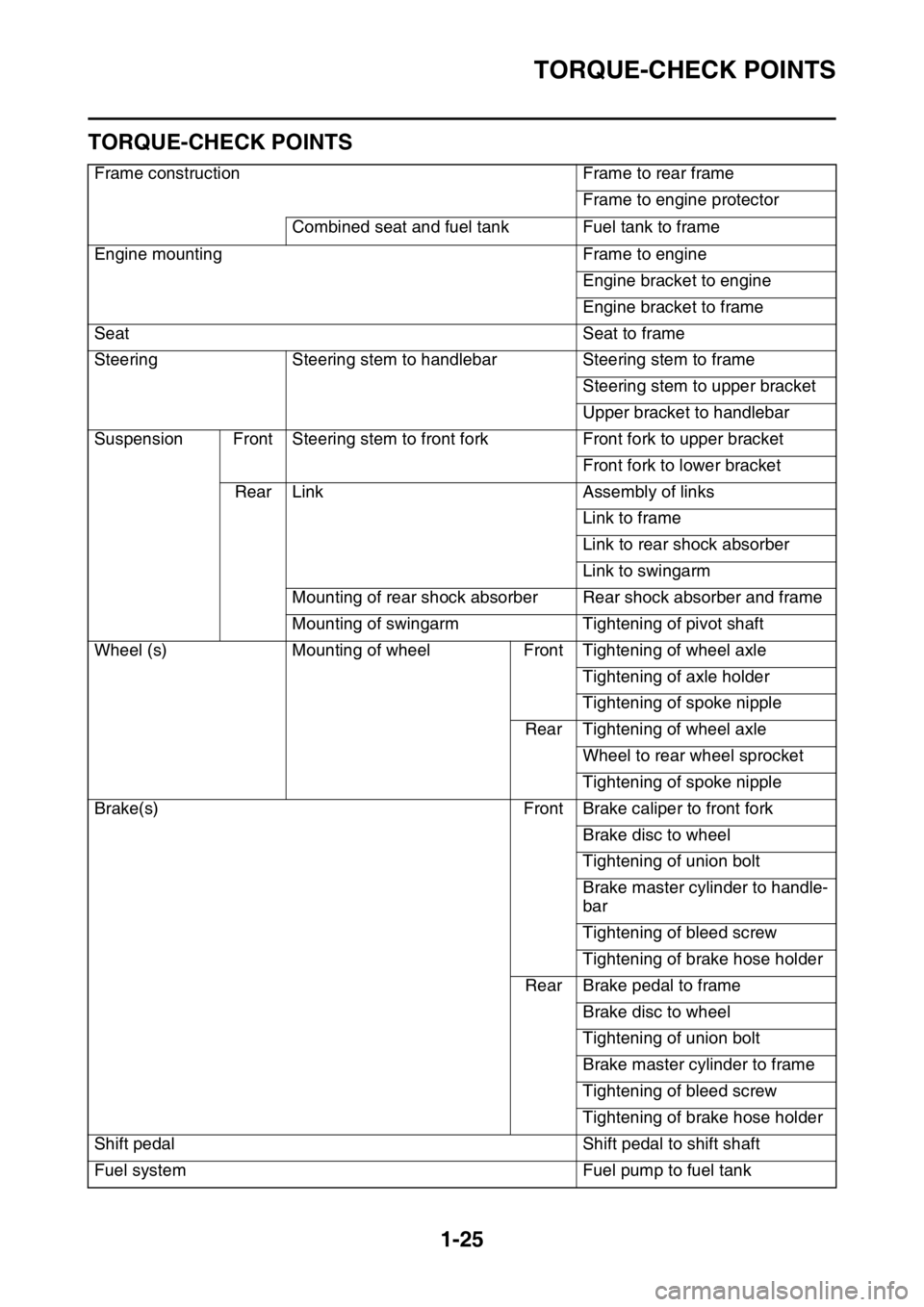

TORQUE-CHECK POINTS

Frame construction Frame to rear frame

Frame to engine protector

Combined seat and fuel tank Fuel tank to frame

Engine mounting Frame to engine

Engine bracket to engine

Engine bracket to frame

Seat Seat to frame

Steering Steering stem to handlebar Steering stem to frame

Steering stem to upper bracket

Upper bracket to handlebar

Suspension Front Steering stem to front fork Front fork to upper bracket

Front fork to lower bracket

Rear Link Assembly of links

Link to frame

Link to rear shock absorber

Link to swingarm

Mounting of rear shock absorber Rear shock absorber and frame

Mounting of swingarm Tightening of pivot shaft

Wheel (s) Mounting of wheel Front Tightening of wheel axle

Tightening of axle holder

Tightening of spoke nipple

Rear Tightening of wheel axle

Wheel to rear wheel sprocket

Tightening of spoke nipple

Brake(s) Front Brake caliper to front fork

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handle-

bar

Tightening of bleed screw

Tightening of brake hose holder

Rear Brake pedal to frame

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Tightening of brake hose holder

Shift pedal Shift pedal to shift shaft

Fuel system Fuel pump to fuel tank

Page 41 of 356

CLEANING AND STORAGE

1-27

EAS1SM1049

CLEANING AND STORAGE

EAS1SM1050CLEANING

Frequent cleaning of your vehicle will enhance

its appearance, maintain performance, and ex-

tend the life of parts.

1. Before cleaning, block the silencer outlet to

prevent water from entering. A plastic bag

secured with a rubber band may be used for

this purpose.

2. If the engine is contaminated with oil, apply

some degreaser to it with a brush. Do not

apply degreaser to the drive chain, the

sprockets, or the wheel axles.

3. Hose off dirt. Use only enough water pres-

sure to do the job.

ECA

NOTICE

Do not use high-pressure washers or steam

cleaners. Otherwise, these may cause a fail-

ure because of the entry of water.

4. After hosing off the dirt, wash all surfaces

with a mild detergent and warm water. Use

a toothbrush to clean hard-to-reach places.

5. Rinse the detergent with clean water, and

dry the surfaces with a soft towel or a cloth.

6. Immediately after cleaning, remove any wa-

ter from the drive chain with a paper towel,

and lubricate it to prevent rust.

7. Clean the seat with a vinyl upholstery clean-

er to keep the cover pliable and glossy.

8. Automotive wax may be applied to all paint-

ed or chromed surfaces. Avoid using such

wax as contains abrasives, because it may

scratch surfaces.

9. After completing the above, start the engine

and allow it to warm up for several minutes.

EAS1SM1051STORAGE

If your vehicle is to be stored for 60 days or

more, some preventive measures must be tak-

en to avoid deterioration. After cleaning the ve-

hicle thoroughly, prepare it for storage as

follows:

1. Fill the fuel tank with gasoline.

2. Remove the spark plug, pour a spoonful of

engine oil (SAE 10W-40) into the spark plug

hole, and reinstall the plug. With the engine

stop switch pushed in, by pushing down the

kickstarter lever, crank the engine to coat

the cylinder walls with oil.3. Remove the drive chain, clean it thoroughly

with solvent, and lubricate it Reinstall the

drive chain or store it in a plastic bag tied to

the frame.

4. Lubricate all cables.

5. Lift up the frame of the vehicle to keep the

wheels off the ground.

6. Tie a plastic bag over the muffler outlet to

prevent moisture from entering.

7. If the vehicle is to be stored in a place that is

humid or exposed to the sea breeze, apply a

light coat of oil to metal surfaces. Do not ap-

ply oil to the seat or rubber parts.

TIP

Make any necessary repairs before the vehicle

is stored.

Page 44 of 356

GENERAL SPECIFICATIONS

2-1

EAS1SM1052

GENERAL SPECIFICATIONS

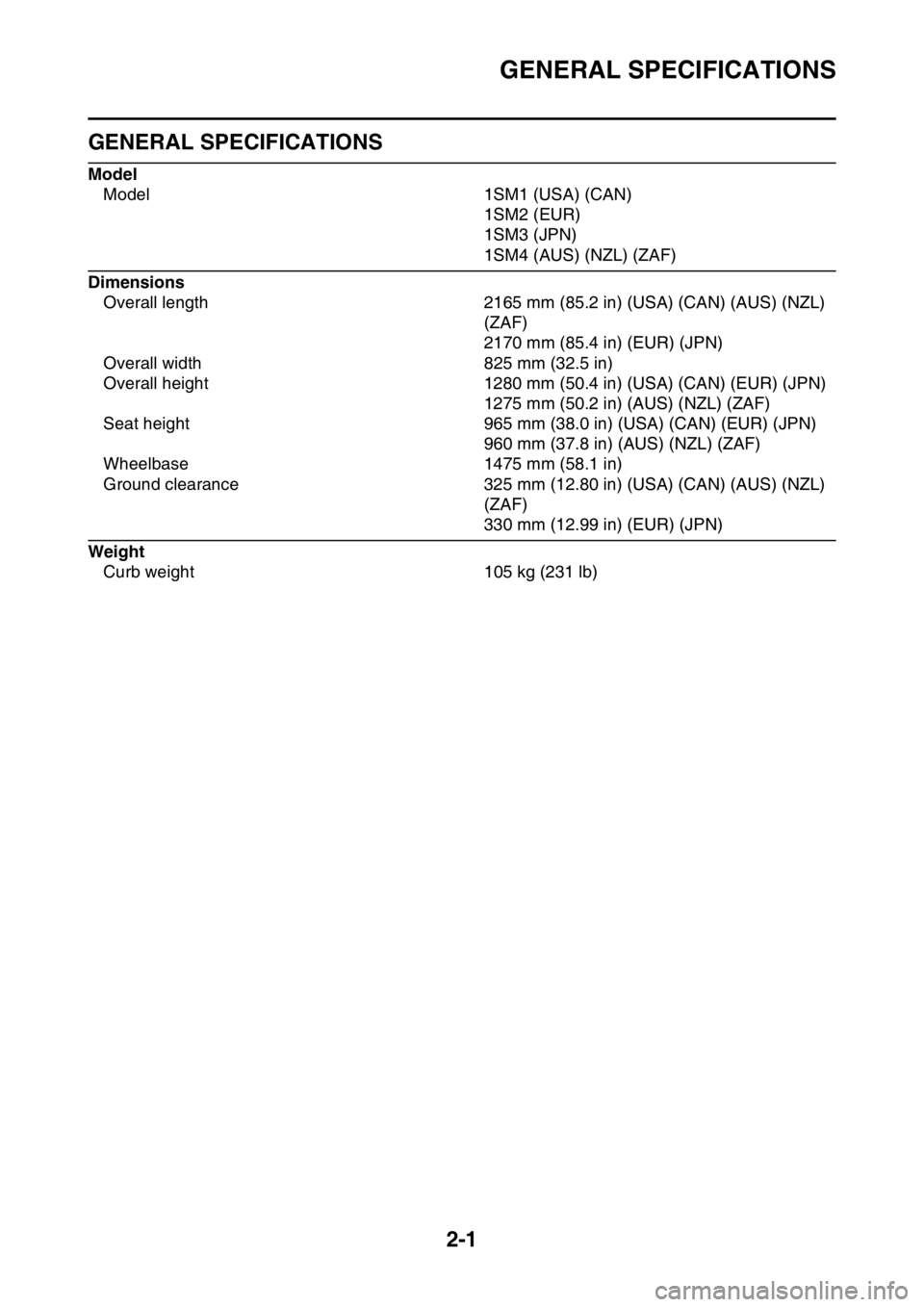

Model

Model 1SM1 (USA) (CAN)

1SM2 (EUR)

1SM3 (JPN)

1SM4 (AUS) (NZL) (ZAF)

Dimensions

Overall length 2165 mm (85.2 in) (USA) (CAN) (AUS) (NZL)

(ZAF)

2170 mm (85.4 in) (EUR) (JPN)

Overall width 825 mm (32.5 in)

Overall height 1280 mm (50.4 in) (USA) (CAN) (EUR) (JPN)

1275 mm (50.2 in) (AUS) (NZL) (ZAF)

Seat height 965 mm (38.0 in) (USA) (CAN) (EUR) (JPN)

960 mm (37.8 in) (AUS) (NZL) (ZAF)

Wheelbase 1475 mm (58.1 in)

Ground clearance 325 mm (12.80 in) (USA) (CAN) (AUS) (NZL)

(ZAF)

330 mm (12.99 in) (EUR) (JPN)

Weight

Curb weight 105 kg (231 lb)

Page 51 of 356

CHASSIS SPECIFICATIONS

2-8

EAS1SM1054

CHASSIS SPECIFICATIONS

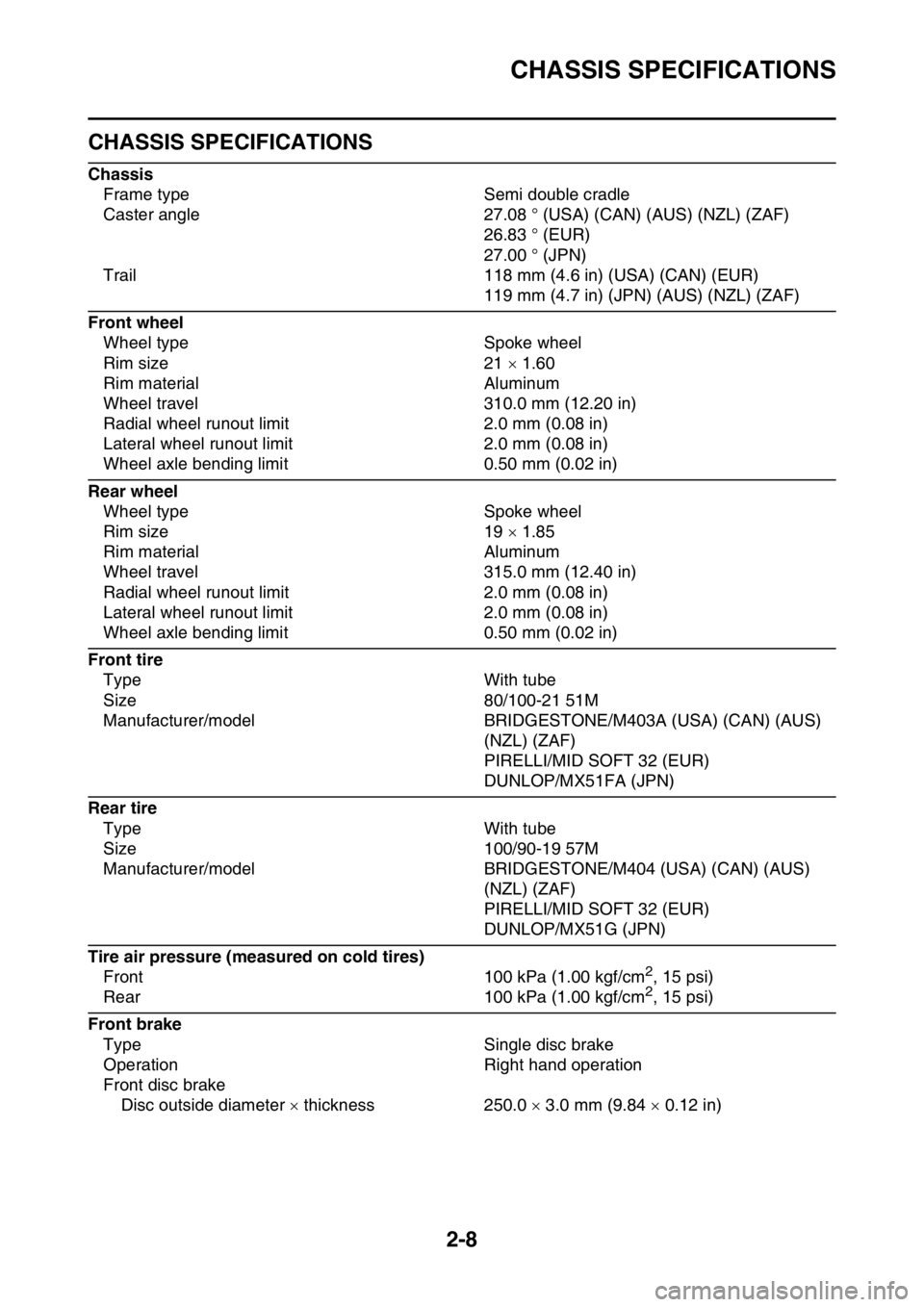

Chassis

Frame type Semi double cradle

Caster angle 27.08 ° (USA) (CAN) (AUS) (NZL) (ZAF)

26.83 ° (EUR)

27.00 ° (JPN)

Trail 118 mm (4.6 in) (USA) (CAN) (EUR)

119 mm (4.7 in) (JPN) (AUS) (NZL) (ZAF)

Front wheel

Wheel type Spoke wheel

Rim size 21 1.60

Rim material Aluminum

Wheel travel 310.0 mm (12.20 in)

Radial wheel runout limit 2.0 mm (0.08 in)

Lateral wheel runout limit 2.0 mm (0.08 in)

Wheel axle bending limit 0.50 mm (0.02 in)

Rear wheel

Wheel type Spoke wheel

Rim size 19 1.85

Rim material Aluminum

Wheel travel 315.0 mm (12.40 in)

Radial wheel runout limit 2.0 mm (0.08 in)

Lateral wheel runout limit 2.0 mm (0.08 in)

Wheel axle bending limit 0.50 mm (0.02 in)

Front tire

Type With tube

Size 80/100-21 51M

Manufacturer/model BRIDGESTONE/M403A (USA) (CAN) (AUS)

(NZL) (ZAF)

PIRELLI/MID SOFT 32 (EUR)

DUNLOP/MX51FA (JPN)

Rear tire

Type With tube

Size 100/90-19 57M

Manufacturer/model BRIDGESTONE/M404 (USA) (CAN) (AUS)

(NZL) (ZAF)

PIRELLI/MID SOFT 32 (EUR)

DUNLOP/MX51G (JPN)

Tire air pressure (measured on cold tires)

Front 100 kPa (1.00 kgf/cm2, 15 psi)

Rear 100 kPa (1.00 kgf/cm2, 15 psi)

Front brake

Type Single disc brake

Operation Right hand operation

Front disc brake

Disc outside diameter thickness 250.0 3.0 mm (9.84 0.12 in)

Page 57 of 356

TIGHTENING TORQUES

2-14

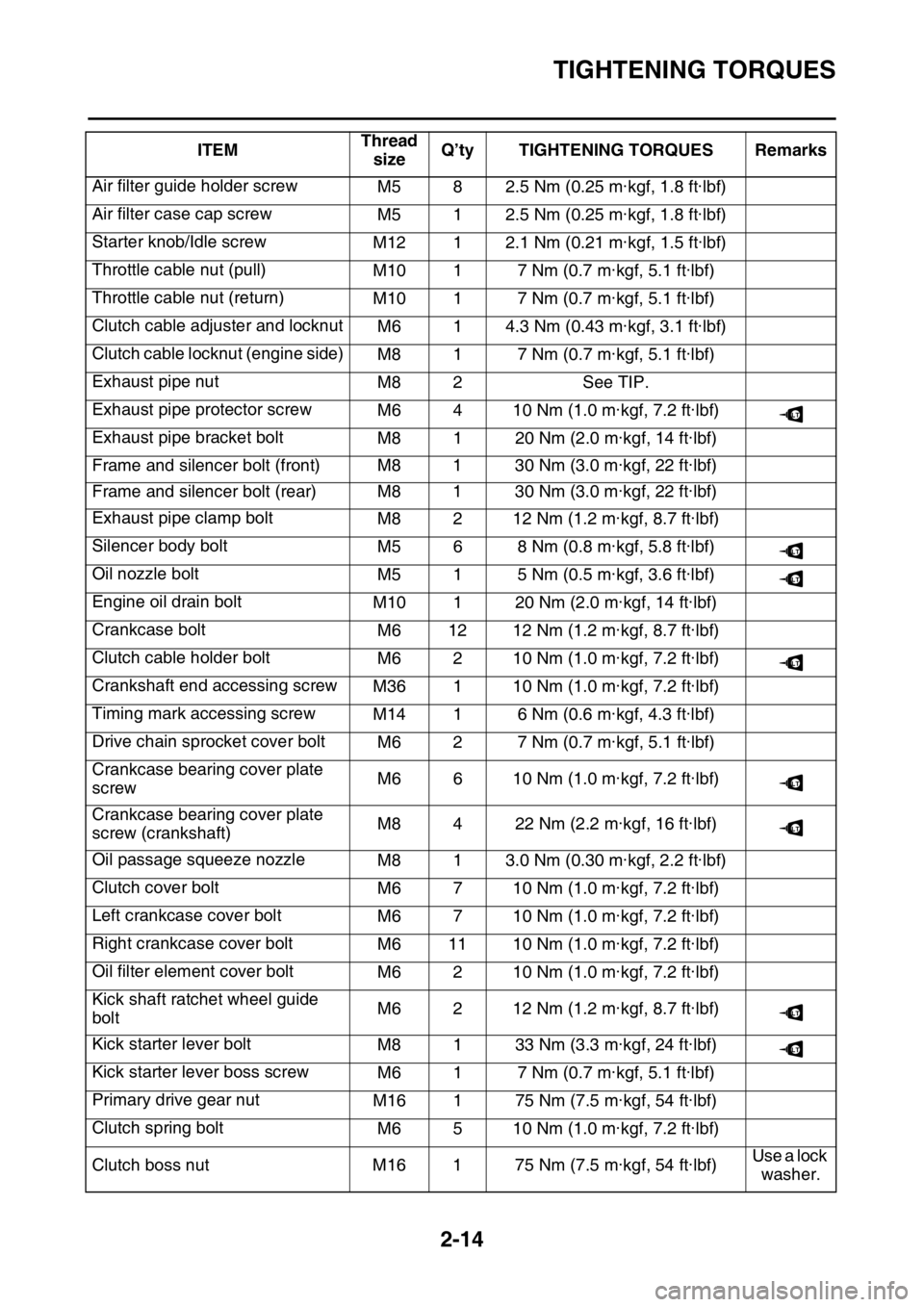

Air filter guide holder screw

M5 8 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Air filter case cap screw

M5 1 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Starter knob/Idle screw

M12 1 2.1 Nm (0.21 m·kgf, 1.5 ft·lbf)

Throttle cable nut (pull)

M10 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Throttle cable nut (return)

M10 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Clutch cable adjuster and locknut

M6 1 4.3 Nm (0.43 m·kgf, 3.1 ft·lbf)

Clutch cable locknut (engine side)

M8 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Exhaust pipe nut

M8 2 See TIP.

Exhaust pipe protector screw

M6 4 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Exhaust pipe bracket bolt

M8 1 20 Nm (2.0 m·kgf, 14 ft·lbf)

Frame and silencer bolt (front) M8 1 30 Nm (3.0 m·kgf, 22 ft·lbf)

Frame and silencer bolt (rear) M8 1 30 Nm (3.0 m·kgf, 22 ft·lbf)

Exhaust pipe clamp bolt

M8 2 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Silencer body bolt

M5 6 8 Nm (0.8 m·kgf, 5.8 ft·lbf)

Oil nozzle bolt

M5 1 5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Engine oil drain bolt

M10 1 20 Nm (2.0 m·kgf, 14 ft·lbf)

Crankcase bolt

M6 12 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Clutch cable holder bolt

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Crankshaft end accessing screw

M36 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Timing mark accessing screw

M14 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Drive chain sprocket cover bolt

M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Crankcase bearing cover plate

screwM6 6 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Crankcase bearing cover plate

screw (crankshaft)M8 4 22 Nm (2.2 m·kgf, 16 ft·lbf)

Oil passage squeeze nozzle

M8 1 3.0 Nm (0.30 m·kgf, 2.2 ft·lbf)

Clutch cover bolt

M6 7 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Left crankcase cover bolt

M6 7 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Right crankcase cover bolt

M6 11 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil filter element cover bolt

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Kick shaft ratchet wheel guide

boltM6 2 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Kick starter lever bolt

M8 1 33 Nm (3.3 m·kgf, 24 ft·lbf)

Kick starter lever boss screw

M6 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Primary drive gear nut

M16 1 75 Nm (7.5 m·kgf, 54 ft·lbf)

Clutch spring bolt

M6 5 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Clutch boss nut M16 1 75 Nm (7.5 m·kgf, 54 ft·lbf)Use a lock

washer. ITEMThread

sizeQ’ty TIGHTENING TORQUES Remarks

LT

LT

LT

LT

LT

LT

LT

LT

Page 59 of 356

TIGHTENING TORQUES

2-16

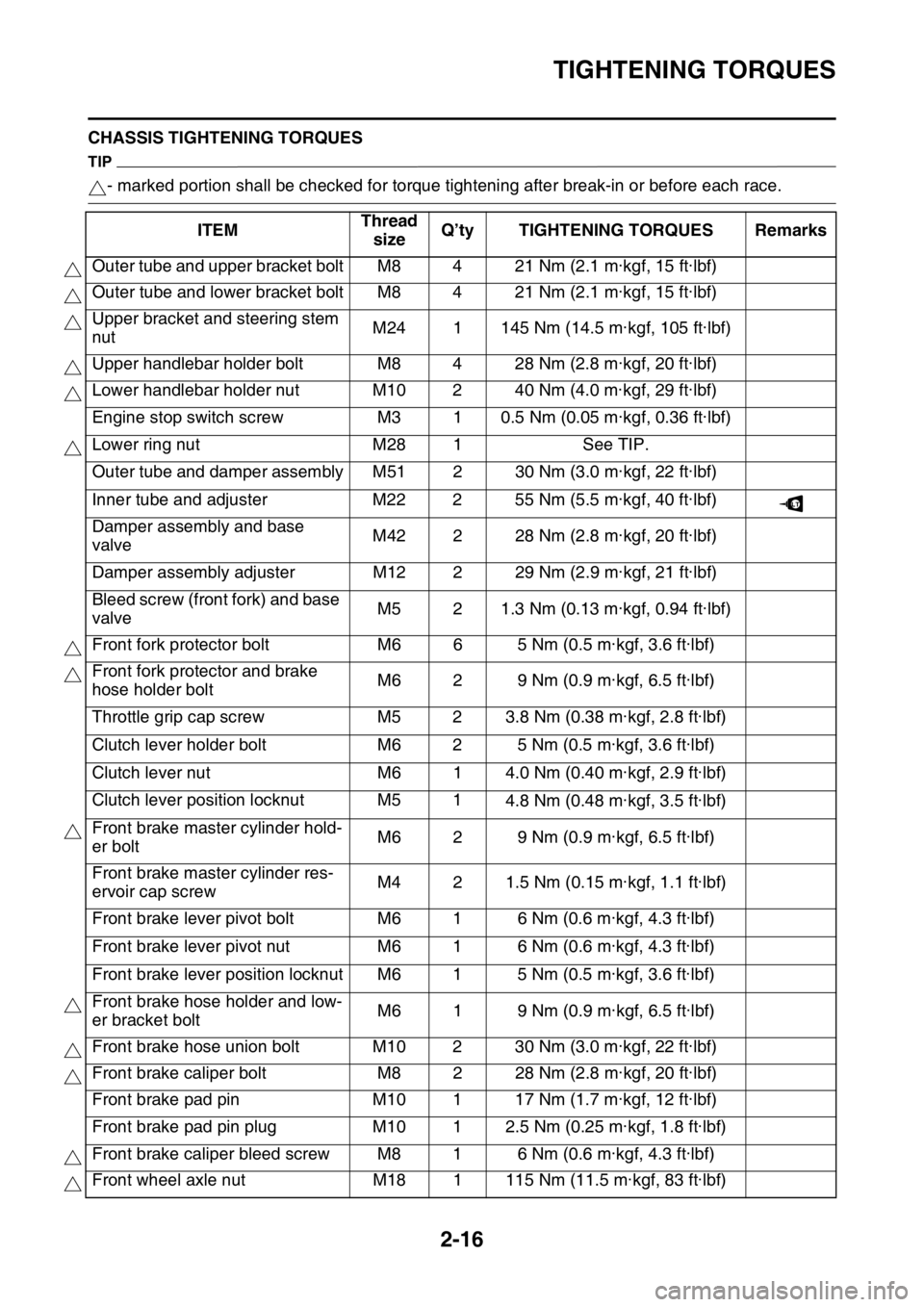

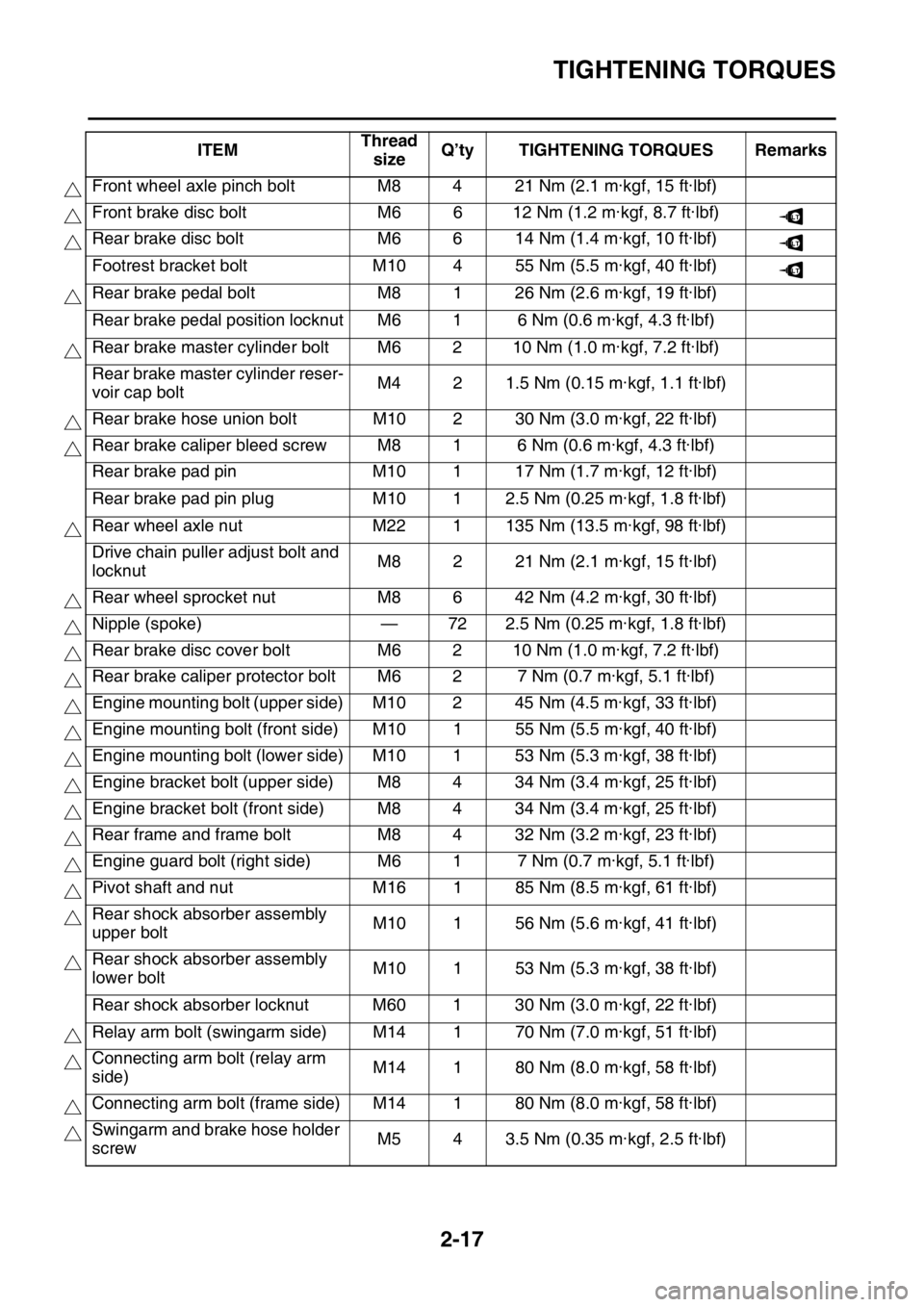

CHASSIS TIGHTENING TORQUES

TIP

- marked portion shall be checked for torque tightening after break-in or before each race.

ITEMThread

sizeQ’ty TIGHTENING TORQUES Remarks

Outer tube and upper bracket bolt M8 4 21 Nm (2.1 m·kgf, 15 ft·lbf)

Outer tube and lower bracket bolt M8 4 21 Nm (2.1 m·kgf, 15 ft·lbf)

Upper bracket and steering stem

nutM24 1 145 Nm (14.5 m·kgf, 105 ft·lbf)

Upper handlebar holder bolt M8 4 28 Nm (2.8 m·kgf, 20 ft·lbf)

Lower handlebar holder nut M10 2 40 Nm (4.0 m·kgf, 29 ft·lbf)

Engine stop switch screw M3 1 0.5 Nm (0.05 m·kgf, 0.36 ft·lbf)

Lower ring nut M28 1 See TIP.

Outer tube and damper assembly M51 2 30 Nm (3.0 m·kgf, 22 ft·lbf)

Inner tube and adjuster M22 2 55 Nm (5.5 m·kgf, 40 ft·lbf)

Damper assembly and base

valveM42 2 28 Nm (2.8 m·kgf, 20 ft·lbf)

Damper assembly adjuster M12 2 29 Nm (2.9 m·kgf, 21 ft·lbf)

Bleed screw (front fork) and base

valveM5 2 1.3 Nm (0.13 m·kgf, 0.94 ft·lbf)

Front fork protector bolt M6 6 5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Front fork protector and brake

hose holder boltM6 2 9 Nm (0.9 m·kgf, 6.5 ft·lbf)

Throttle grip cap screw M5 2 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

Clutch lever holder bolt M6 2 5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Clutch lever nut M6 1 4.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

Clutch lever position locknut M5 1

4.8 Nm (0.48 m·kgf, 3.5 ft·lbf)

Front brake master cylinder hold-

er boltM6 2 9 Nm (0.9 m·kgf, 6.5 ft·lbf)

Front brake master cylinder res-

ervoir cap screwM4 2 1.5 Nm (0.15 m·kgf, 1.1 ft·lbf)

Front brake lever pivot bolt M6 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Front brake lever pivot nut M6 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Front brake lever position locknut M6 1 5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Front brake hose holder and low-

er bracket boltM6 1 9 Nm (0.9 m·kgf, 6.5 ft·lbf)

Front brake hose union bolt M10 2 30 Nm (3.0 m·kgf, 22 ft·lbf)

Front brake caliper bolt M8 2 28 Nm (2.8 m·kgf, 20 ft·lbf)

Front brake pad pin M10 1 17 Nm (1.7 m·kgf, 12 ft·lbf)

Front brake pad pin plug M10 1 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Front brake caliper bleed screw M8 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Front wheel axle nut M18 1 115 Nm (11.5 m·kgf, 83 ft·lbf)

LT

Page 60 of 356

TIGHTENING TORQUES

2-17

Front wheel axle pinch bolt M8 4 21 Nm (2.1 m·kgf, 15 ft·lbf)

Front brake disc bolt M6 6 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Rear brake disc bolt M6 6 14 Nm (1.4 m·kgf, 10 ft·lbf)

Footrest bracket bolt M10 4 55 Nm (5.5 m·kgf, 40 ft·lbf)

Rear brake pedal bolt M8 1 26 Nm (2.6 m·kgf, 19 ft·lbf)

Rear brake pedal position locknut M6 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Rear brake master cylinder bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Rear brake master cylinder reser-

voir cap boltM4 2 1.5 Nm (0.15 m·kgf, 1.1 ft·lbf)

Rear brake hose union bolt M10 2 30 Nm (3.0 m·kgf, 22 ft·lbf)

Rear brake caliper bleed screw M8 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Rear brake pad pin M10 1 17 Nm (1.7 m·kgf, 12 ft·lbf)

Rear brake pad pin plug M10 1 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Rear wheel axle nut M22 1 135 Nm (13.5 m·kgf, 98 ft·lbf)

Drive chain puller adjust bolt and

locknutM8 2 21 Nm (2.1 m·kgf, 15 ft·lbf)

Rear wheel sprocket nut M8 6 42 Nm (4.2 m·kgf, 30 ft·lbf)

Nipple (spoke) — 72 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Rear brake disc cover bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Rear brake caliper protector bolt M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Engine mounting bolt (upper side) M10 2 45 Nm (4.5 m·kgf, 33 ft·lbf)

Engine mounting bolt (front side) M10 1 55 Nm (5.5 m·kgf, 40 ft·lbf)

Engine mounting bolt (lower side) M10 1 53 Nm (5.3 m·kgf, 38 ft·lbf)

Engine bracket bolt (upper side) M8 4 34 Nm (3.4 m·kgf, 25 ft·lbf)

Engine bracket bolt (front side) M8 4 34 Nm (3.4 m·kgf, 25 ft·lbf)

Rear frame and frame bolt M8 4 32 Nm (3.2 m·kgf, 23 ft·lbf)

Engine guard bolt (right side) M6 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Pivot shaft and nut M16 1 85 Nm (8.5 m·kgf, 61 ft·lbf)

Rear shock absorber assembly

upper boltM10 1 56 Nm (5.6 m·kgf, 41 ft·lbf)

Rear shock absorber assembly

lower boltM10 1 53 Nm (5.3 m·kgf, 38 ft·lbf)

Rear shock absorber locknut M60 1 30 Nm (3.0 m·kgf, 22 ft·lbf)

Relay arm bolt (swingarm side) M14 1 70 Nm (7.0 m·kgf, 51 ft·lbf)

Connecting arm bolt (relay arm

side)M14 1 80 Nm (8.0 m·kgf, 58 ft·lbf)

Connecting arm bolt (frame side) M14 1 80 Nm (8.0 m·kgf, 58 ft·lbf)

Swingarm and brake hose holder

screwM5 4 3.5 Nm (0.35 m·kgf, 2.5 ft·lbf) ITEMThread

sizeQ’ty TIGHTENING TORQUES Remarks

LT

LT

LT

Page 62 of 356

LUBRICATION POINTS AND LUBRICANT TYPES

2-19

EAS1SM1059

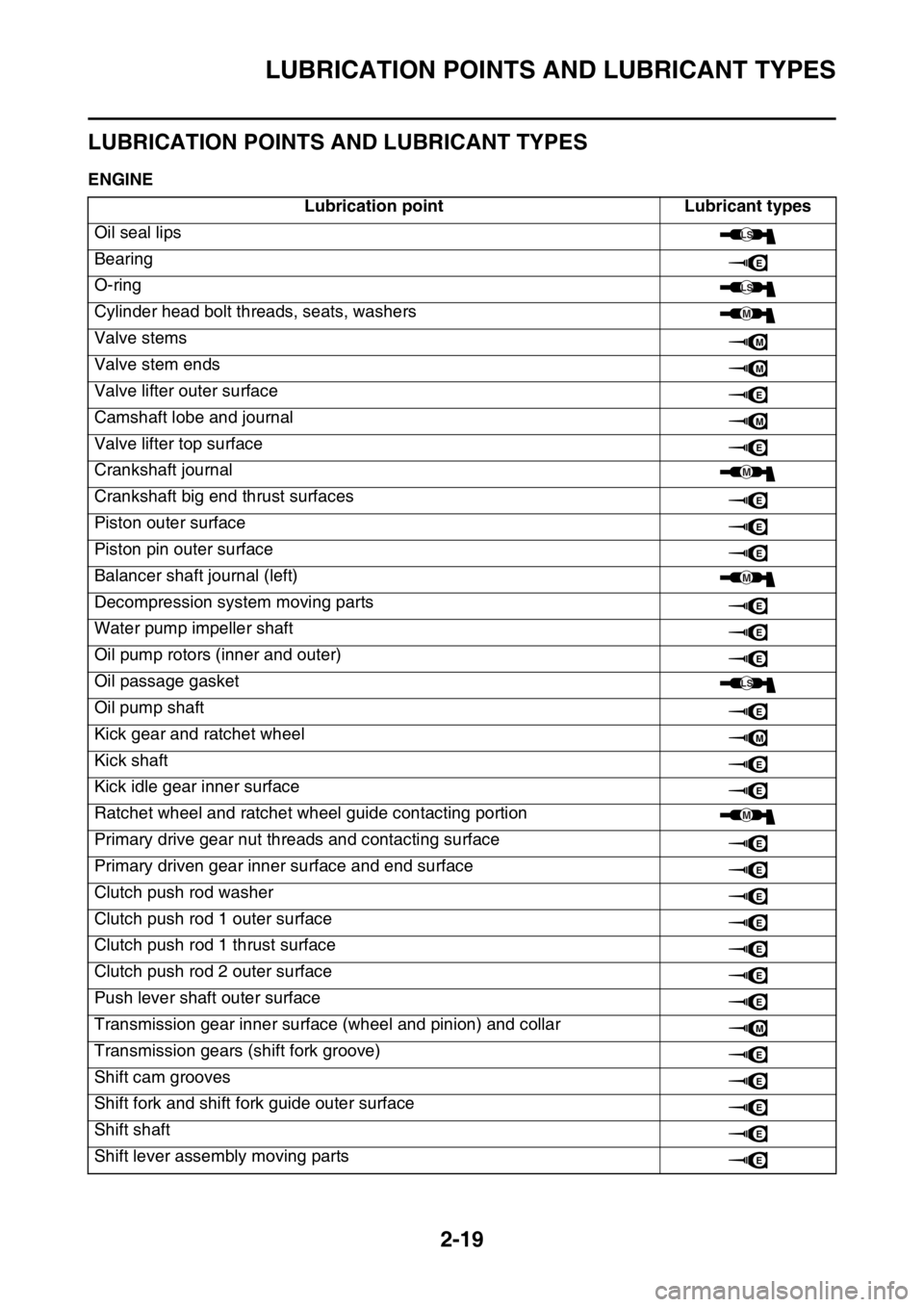

LUBRICATION POINTS AND LUBRICANT TYPES

EAS1SM1060ENGINE

Lubrication point Lubricant types

Oil seal lips

Bearing

O-ring

Cylinder head bolt threads, seats, washers

Valve stems

Valve stem ends

Valve lifter outer surface

Camshaft lobe and journal

Valve lifter top surface

Crankshaft journal

Crankshaft big end thrust surfaces

Piston outer surface

Piston pin outer surface

Balancer shaft journal (left)

Decompression system moving parts

Water pump impeller shaft

Oil pump rotors (inner and outer)

Oil passage gasket

Oil pump shaft

Kick gear and ratchet wheel

Kick shaft

Kick idle gear inner surface

Ratchet wheel and ratchet wheel guide contacting portion

Primary drive gear nut threads and contacting surface

Primary driven gear inner surface and end surface

Clutch push rod washer

Clutch push rod 1 outer surface

Clutch push rod 1 thrust surface

Clutch push rod 2 outer surface

Push lever shaft outer surface

Transmission gear inner surface (wheel and pinion) and collar

Transmission gears (shift fork groove)

Shift cam grooves

Shift fork and shift fork guide outer surface

Shift shaft

Shift lever assembly moving parts

LS

E

LS

M

M

M

E

M

E

M

E

E

E

M

E

E

E

LS

E

M

E

E

M

E

E

E

E

E

E

E

M

E

E

E

E

E