engine YAMAHA YZ250F 2015 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: YZ250F, Model: YAMAHA YZ250F 2015Pages: 356, PDF Size: 11.39 MB

Page 268 of 356

RADIATOR

6-1

EAS1SM5296

TIP

This section is intended for those who have basic knowledge and skill concerning the servicing of

Yamaha motorcycles (e.g., Yamaha dealers, service engineers, etc.). Those who have little knowl-

edge and skill concerning servicing are requested not to undertake inspection, adjustment, disas-

sembly, or reassembly only by reference to this manual. It may lead to servicing trouble and

mechanical damage.

EAS1SM5297

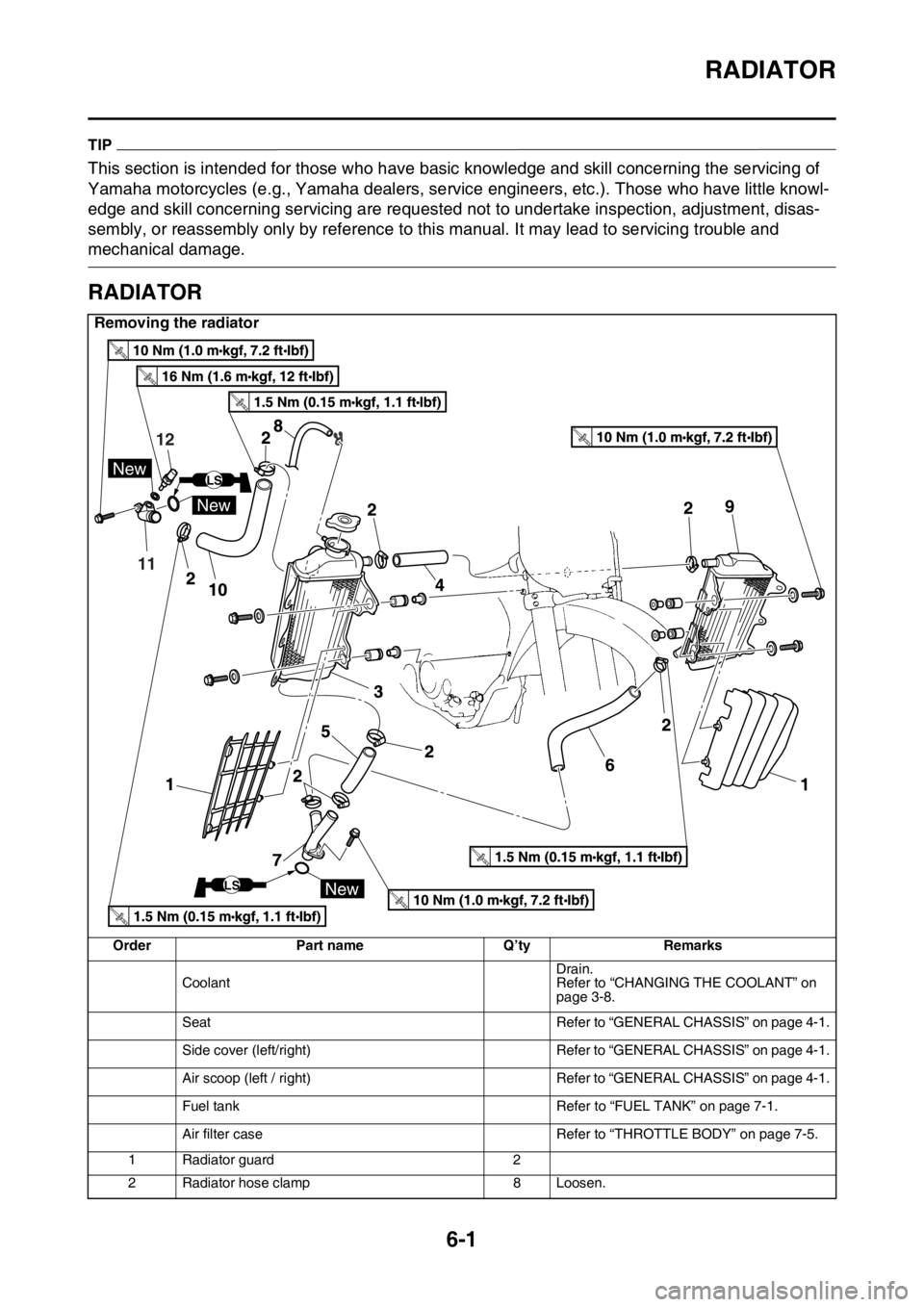

RADIATOR

Removing the radiator

Order Part name Q’ty Remarks

CoolantDrain.

Refer to “CHANGING THE COOLANT” on

page 3-8.

Seat Refer to “GENERAL CHASSIS” on page 4-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left / right) Refer to “GENERAL CHASSIS” on page 4-1.

Fuel tank Refer to “FUEL TANK” on page 7-1.

Air filter case Refer to “THROTTLE BODY” on page 7-5.

1 Radiator guard 2

2 Radiator hose clamp 8 Loosen.

11

12

New

New

New

LS

LS

Page 271 of 356

WATER PUMP

6-4

EAS1SM5300

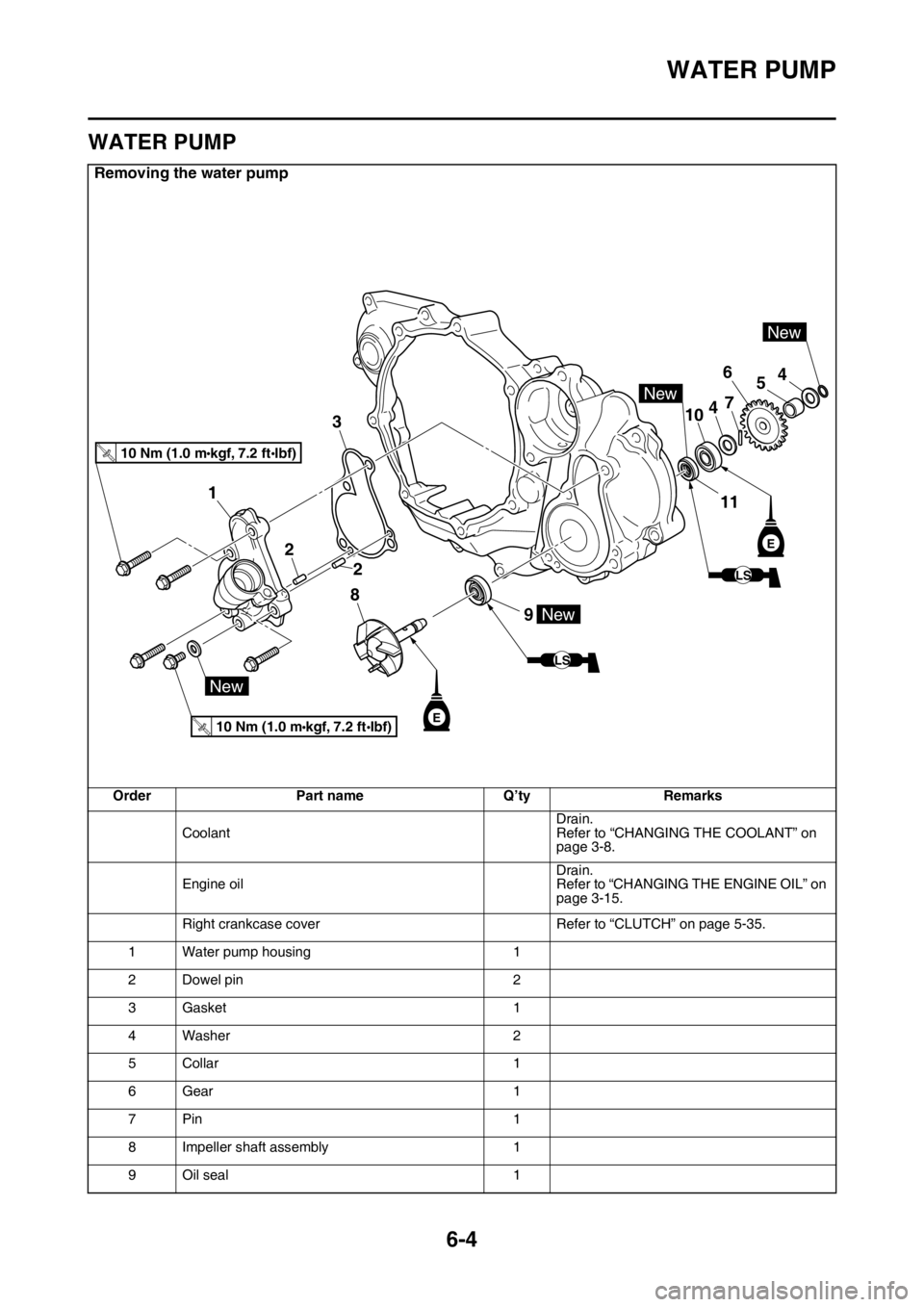

WATER PUMP

Removing the water pump

Order Part name Q’ty Remarks

CoolantDrain.

Refer to “CHANGING THE COOLANT” on

page 3-8.

Engine oilDrain.

Refer to “CHANGING THE ENGINE OIL” on

page 3-15.

Right crankcase cover Refer to “CLUTCH” on page 5-35.

1 Water pump housing 1

2 Dowel pin 2

3Gasket 1

4Washer 2

5Collar 1

6Gear 1

7Pin 1

8 Impeller shaft assembly 1

9 Oil seal 1

9

8

2

2

3

1

10

6

7

5

4

4

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

New

New

New

E

11

New

E

LS

LS

Page 273 of 356

WATER PUMP

6-6

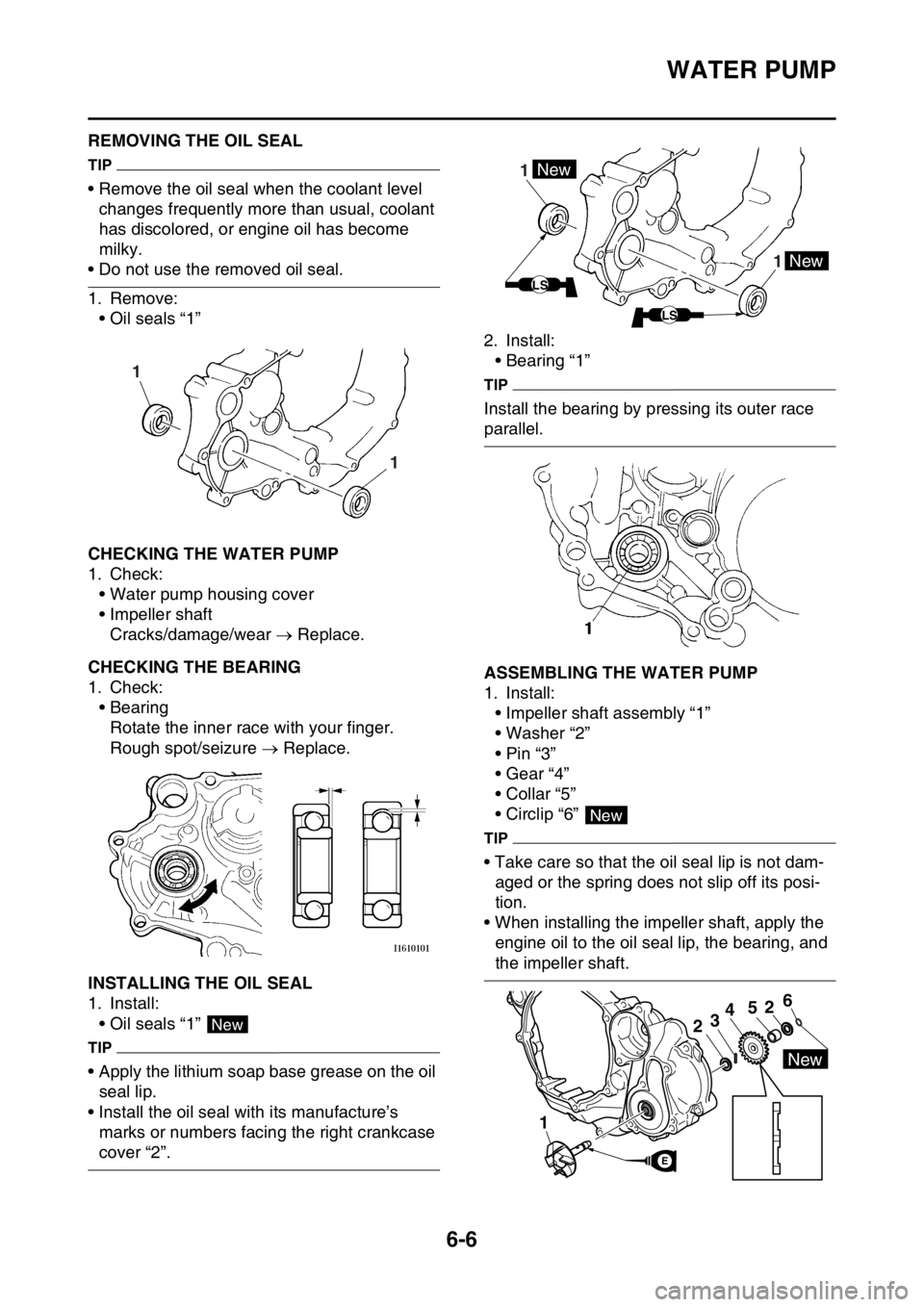

EAS1SM5301REMOVING THE OIL SEAL

TIP

• Remove the oil seal when the coolant level

changes frequently more than usual, coolant

has discolored, or engine oil has become

milky.

• Do not use the removed oil seal.

1. Remove:

• Oil seals “1”

EAS1SM5302CHECKING THE WATER PUMP

1. Check:

• Water pump housing cover

• Impeller shaft

Cracks/damage/wear Replace.

EAS1SM5303CHECKING THE BEARING

1. Check:

• Bearing

Rotate the inner race with your finger.

Rough spot/seizure Replace.

EAS1SM5304INSTALLING THE OIL SEAL

1. Install:

• Oil seals “1”

TIP

• Apply the lithium soap base grease on the oil

seal lip.

• Install the oil seal with its manufacture’s

marks or numbers facing the right crankcase

cover “2”.2. Install:

• Bearing “1”

TIP

Install the bearing by pressing its outer race

parallel.

EAS1SM5305ASSEMBLING THE WATER PUMP

1. Install:

• Impeller shaft assembly “1”

• Washer “2”

•Pin “3”

• Gear “4”

• Collar “5”

• Circlip “6”

TIP

• Take care so that the oil seal lip is not dam-

aged or the spring does not slip off its posi-

tion.

• When installing the impeller shaft, apply the

engine oil to the oil seal lip, the bearing, and

the impeller shaft.

1 1

New

1 1New

New

LS

LS

New

1

2

52346

New

E

Page 276 of 356

FUEL TANK

7-1

EAS1SM5306

TIP

This section is intended for those who have basic knowledge and skill concerning the servicing of

Yamaha motorcycles (e.g., Yamaha dealers, service engineers, etc.). Those who have little knowl-

edge and skill concerning servicing are requested not to undertake inspection, adjustment, disas-

sembly, or reassembly only by reference to this manual. It may lead to servicing trouble and

mechanical damage.

EAS1SM5307

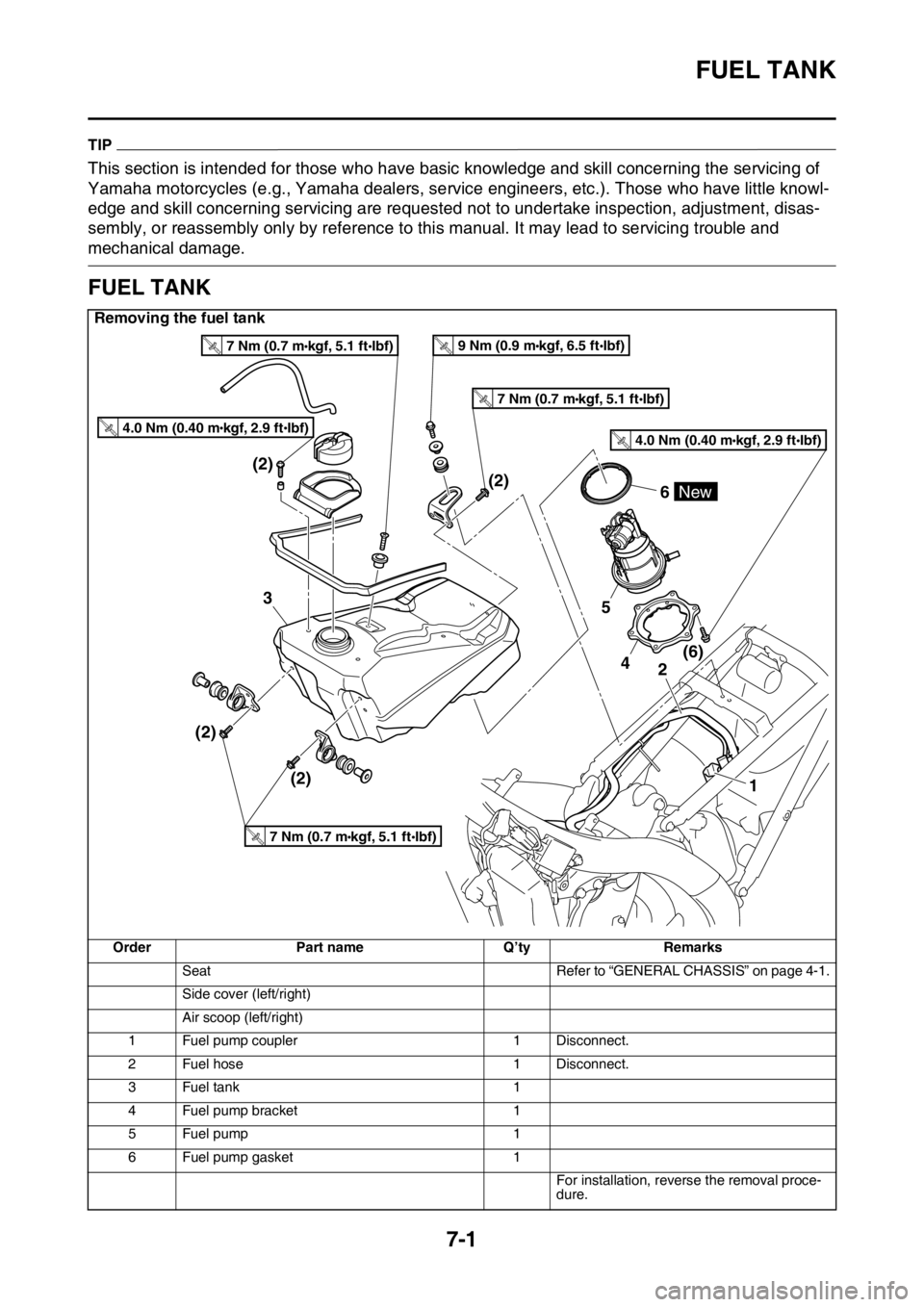

FUEL TANK

Removing the fuel tank

Order Part name Q’ty Remarks

Seat Refer to “GENERAL CHASSIS” on page 4-1.

Side cover (left/right)

Air scoop (left/right)

1 Fuel pump coupler 1 Disconnect.

2 Fuel hose 1 Disconnect.

3Fuel tank 1

4 Fuel pump bracket 1

5 Fuel pump 1

6 Fuel pump gasket 1

For installation, reverse the removal proce-

dure.

4(6) (2)

(2) (2)(2)2

5

6

3

1

New

4.0 Nm (0.40 mkgf, 2.9 ftIbf)T.R.

7 Nm (0.7 mkgf, 5.1 ftIbf)T.R.

7 Nm (0.7 mkgf, 5.1 ftIbf)T.R.

7 Nm (0.7 mkgf, 5.1 ftIbf)T.R.

9 Nm (0.9 mkgf, 6.5 ftIbf)T.R.

4.0 Nm (0.40 mkgf, 2.9 ftIbf)T.R.

Page 279 of 356

FUEL TANK

7-4

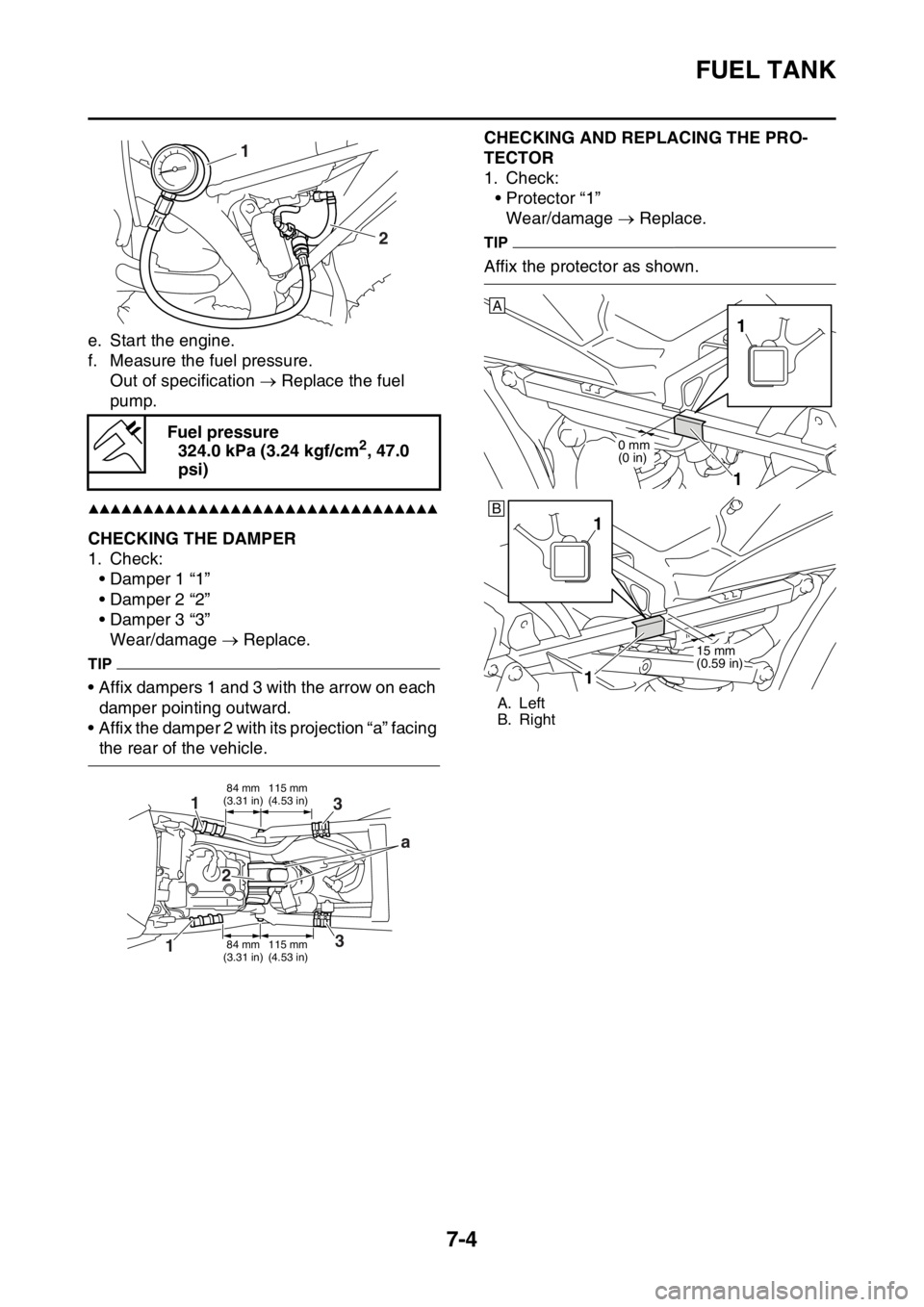

e. Start the engine.

f. Measure the fuel pressure.

Out of specification Replace the fuel

pump.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SM5314CHECKING THE DAMPER

1. Check:

• Damper 1 “1”

• Damper 2 “2”

• Damper 3 “3”

Wear/damage Replace.

TIP

• Affix dampers 1 and 3 with the arrow on each

damper pointing outward.

• Affix the damper 2 with its projection “a” facing

the rear of the vehicle.

EAS1SM5315

CHECKING AND REPLACING THE PRO-

TECTOR

1. Check:

• Protector “1”

Wear/damage Replace.

TIP

Affix the protector as shown.

Fuel pressure

324.0 kPa (3.24 kgf/cm

2, 47.0

psi)

1

2

84 mm

(3.31 in)115 mm

(4.53 in)

84 mm

(3.31 in)115 mm

(4.53 in)

3 1

13a

2

A. Left

B. Right

1

1

0 mm

(0 in)

A

B

1

15 mm

(0.59 in)

1

Page 280 of 356

THROTTLE BODY

7-5

EAS1SM5316

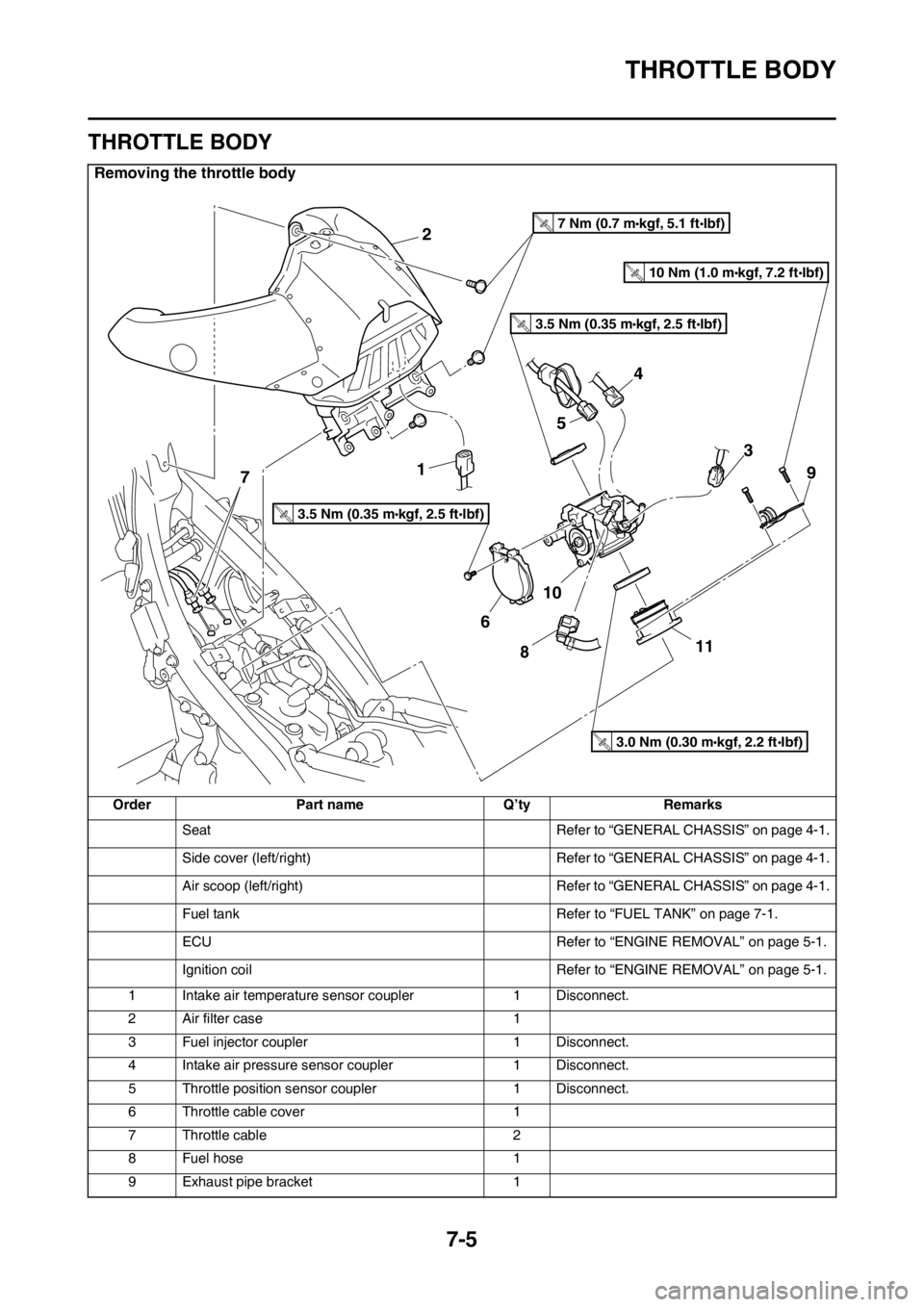

THROTTLE BODY

Removing the throttle body

Order Part name Q’ty Remarks

Seat Refer to “GENERAL CHASSIS” on page 4-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left/right) Refer to “GENERAL CHASSIS” on page 4-1.

Fuel tank Refer to “FUEL TANK” on page 7-1.

ECU Refer to “ENGINE REMOVAL” on page 5-1.

Ignition coil Refer to “ENGINE REMOVAL” on page 5-1.

1 Intake air temperature sensor coupler 1 Disconnect.

2 Air filter case 1

3 Fuel injector coupler 1 Disconnect.

4 Intake air pressure sensor coupler 1 Disconnect.

5 Throttle position sensor coupler 1 Disconnect.

6 Throttle cable cover 1

7 Throttle cable 2

8 Fuel hose 1

9 Exhaust pipe bracket 1

2

1

6

10

11

9

8

3

7

5

4

3.5 Nm (0.35 mkgf, 2.5 ftIbf)T.R

.

3.5 Nm (0.35 mkgf, 2.5 ftIbf)T.R

.

7 Nm (0.7 mkgf, 5.1 ftIbf)T.R.

3.0 Nm (0.30 mkgf, 2.2 ftIbf)T.R

.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

Page 283 of 356

THROTTLE BODY

7-8

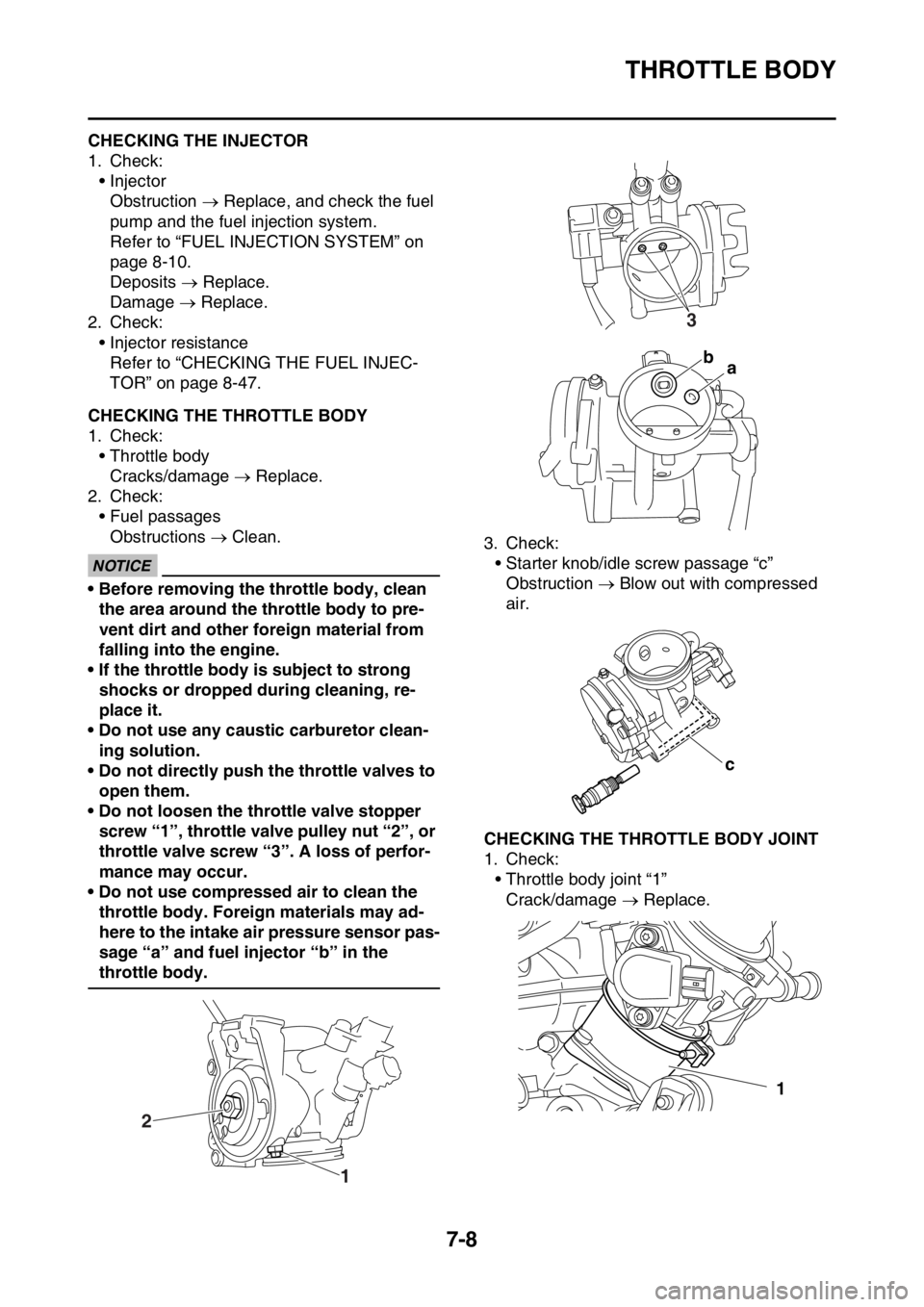

EAS1SM5317CHECKING THE INJECTOR

1. Check:

• Injector

Obstruction Replace, and check the fuel

pump and the fuel injection system.

Refer to “FUEL INJECTION SYSTEM” on

page 8-10.

Deposits Replace.

Damage Replace.

2. Check:

• Injector resistance

Refer to “CHECKING THE FUEL INJEC-

TOR” on page 8-47.

EAS1SM5318CHECKING THE THROTTLE BODY

1. Check:

• Throttle body

Cracks/damage Replace.

2. Check:

• Fuel passages

Obstructions Clean.

ECA1DX1027

NOTICE

• Before removing the throttle body, clean

the area around the throttle body to pre-

vent dirt and other foreign material from

falling into the engine.

• If the throttle body is subject to strong

shocks or dropped during cleaning, re-

place it.

• Do not use any caustic carburetor clean-

ing solution.

• Do not directly push the throttle valves to

open them.

• Do not loosen the throttle valve stopper

screw “1”, throttle valve pulley nut “2”, or

throttle valve screw “3”. A loss of perfor-

mance may occur.

• Do not use compressed air to clean the

throttle body. Foreign materials may ad-

here to the intake air pressure sensor pas-

sage “a” and fuel injector “b” in the

throttle body.3. Check:

• Starter knob/idle screw passage “c”

Obstruction Blow out with compressed

air.

EAS1SM5319CHECKING THE THROTTLE BODY JOINT

1. Check:

• Throttle body joint “1”

Crack/damage Replace.

1 2

3

ba

c

1

Page 287 of 356

8-1

EAS1SM5321

TIP

This section is intended for those who have basic knowledge and skill concerning the servicing of

Yamaha motorcycles (e.g., Yamaha dealers, service engineers, etc.). Those who have little knowl-

edge and skill concerning servicing are requested not to undertake inspection, adjustment, disas-

sembly, or reassembly only by reference to this manual. It may lead to servicing trouble and

mechanical damage.

Page 289 of 356

IGNITION SYSTEM

8-3

1. Crankshaft position sensor

2. AC magneto

3. Rectifier/regulator

4. Joint connector

5. Condenser

7. Engine stop switch

9. ECU

10.Ignition coil

11.Spark plug

Page 290 of 356

IGNITION SYSTEM

8-4

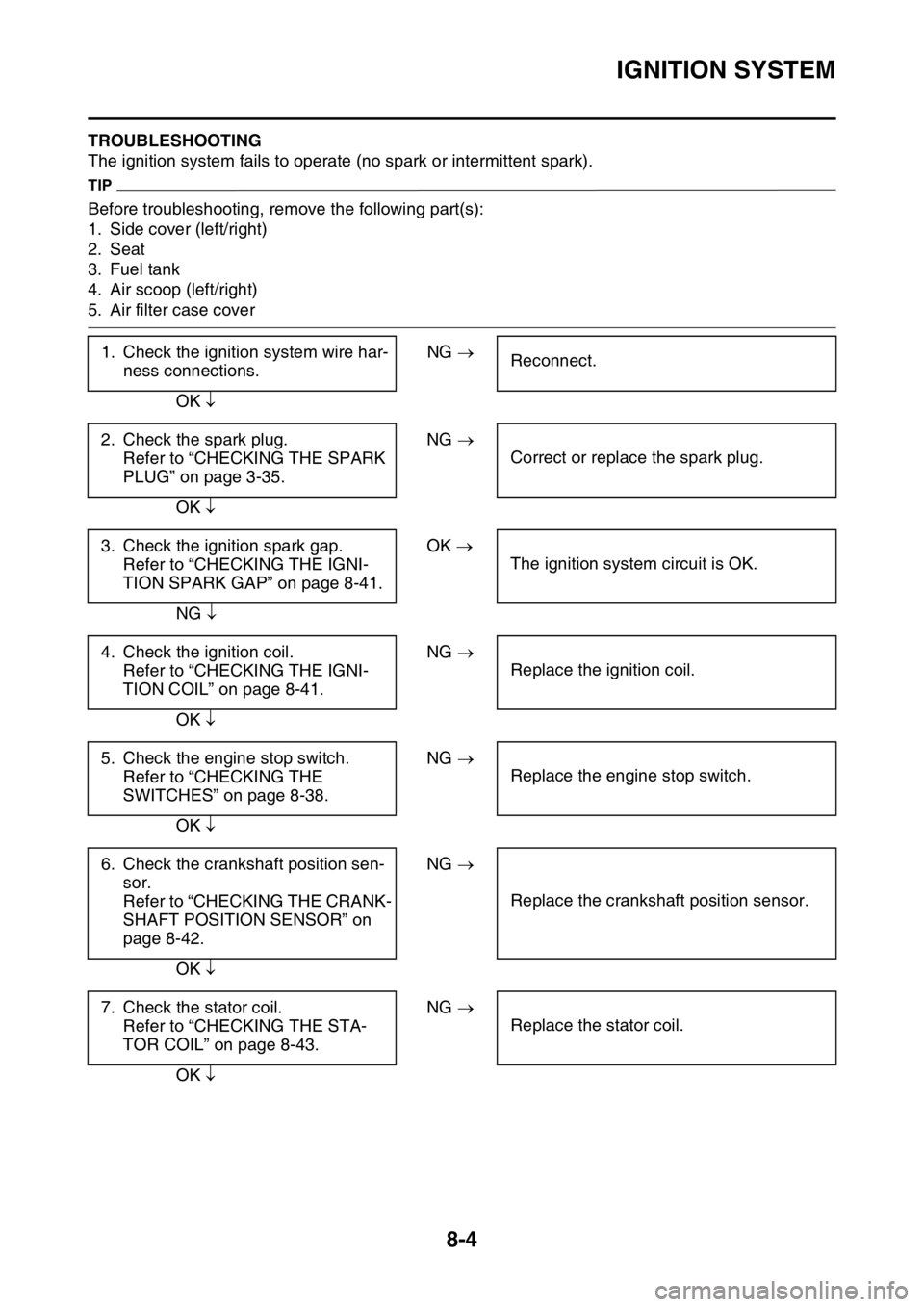

EAS1SM5324TROUBLESHOOTING

The ignition system fails to operate (no spark or intermittent spark).

TIP

Before troubleshooting, remove the following part(s):

1. Side cover (left/right)

2. Seat

3. Fuel tank

4. Air scoop (left/right)

5. Air filter case cover

1. Check the ignition system wire har-

ness connections.NG

Reconnect.

OK

2. Check the spark plug.

Refer to “CHECKING THE SPARK

PLUG” on page 3-35.NG

Correct or replace the spark plug.

OK

3. Check the ignition spark gap.

Refer to “CHECKING THE IGNI-

TION SPARK GAP” on page 8-41.OK

The ignition system circuit is OK.

NG

4. Check the ignition coil.

Refer to “CHECKING THE IGNI-

TION COIL” on page 8-41.NG

Replace the ignition coil.

OK

5. Check the engine stop switch.

Refer to “CHECKING THE

SWITCHES” on page 8-38.NG

Replace the engine stop switch.

OK

6. Check the crankshaft position sen-

sor.

Refer to “CHECKING THE CRANK-

SHAFT POSITION SENSOR” on

page 8-42.NG

Replace the crankshaft position sensor.

OK

7. Check the stator coil.

Refer to “CHECKING THE STA-

TOR COIL” on page 8-43.NG

Replace the stator coil.

OK