drain bolt YAMAHA YZ250F 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZ250F, Model: YAMAHA YZ250F 2016Pages: 356, PDF Size: 11.25 MB

Page 137 of 356

FRONT BRAKE

4-13

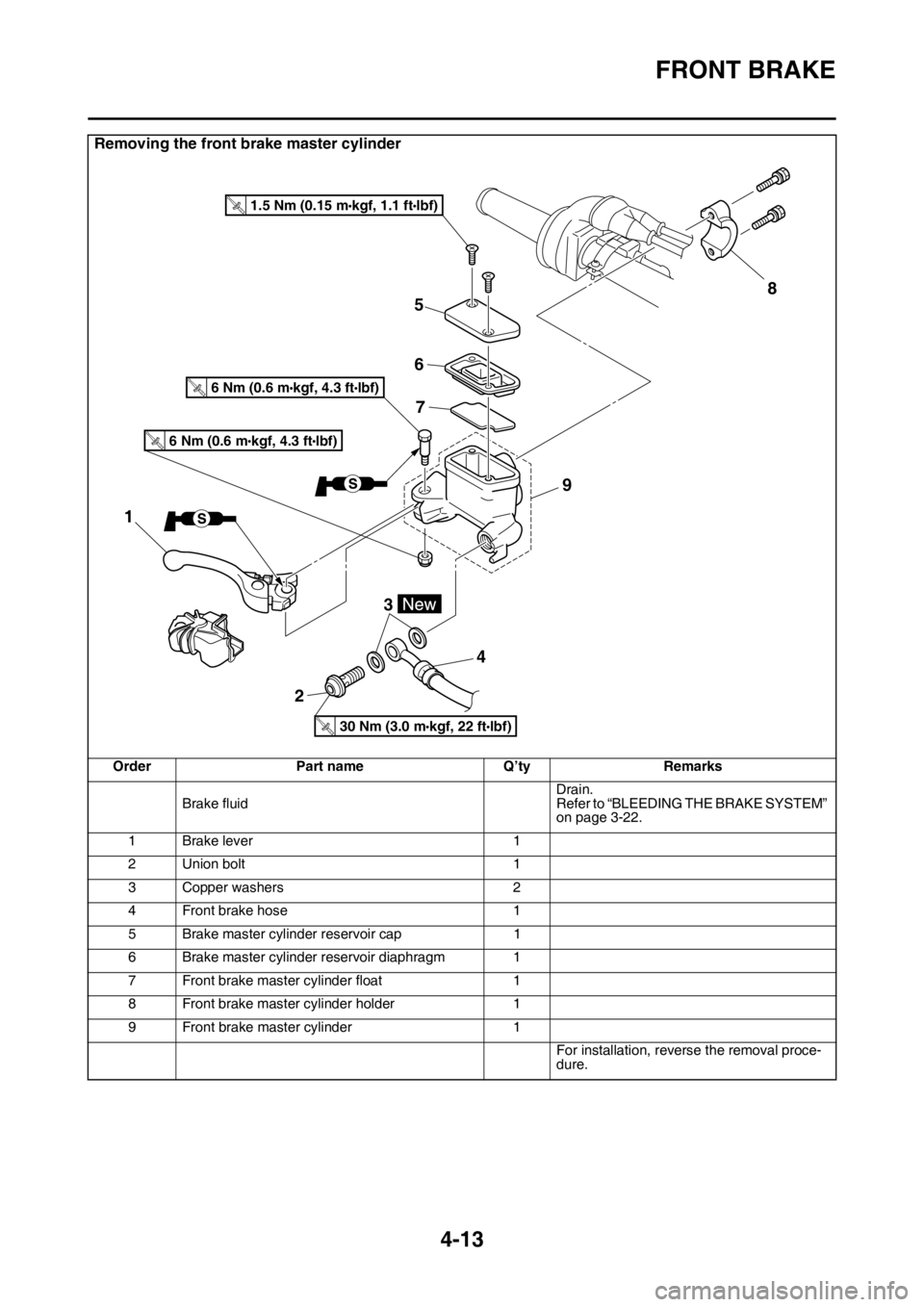

Removing the front brake master cylinder

Order Part name Q’ty Remarks

Brake fluidDrain.

Refer to “BLEEDING THE BRAKE SYSTEM”

on page 3-22.

1 Brake lever 1

2 Union bolt 1

3 Copper washers 2

4 Front brake hose 1

5 Brake master cylinder reservoir cap 1

6 Brake master cylinder reservoir diaphragm 1

7 Front brake master cylinder float 1

8 Front brake master cylinder holder 1

9 Front brake master cylinder 1

For installation, reverse the removal proce-

dure.

5

6

7

23

48

9

1

T.R.30 Nm (3.0 mlbf) kgf, 22 ft

T.R.1.5 Nm (0.15 mlbf) kgf, 1.1 ft

T.R.6 Nm (0.6 mlbf) kgf, 4.3 ft

T.R.6 Nm (0.6 mlbf) kgf, 4.3 ft

Page 139 of 356

FRONT BRAKE

4-15

EAS1SM9134INTRODUCTIONEWA

WARNING

If you need to disassemble the disc brake

components, observe the following precau-

tions.

• Never disassemble the brake components

unless absolutely necessary.

• If there is any problem with connections

on the hydraulic brake system, perform

the following jobs.

Disassemble the brake system, drain the

brake fluid, and clean it. After that, add a

suitable amount of brake fluid. Then, bleed

it after reassembly.

• Use only brake fluid for washing brake

components.

• Use new brake fluid for cleaning the brake

components.

• Immediately wipe off the spilled brake fluid

to avoid damage to painted surfaces or

plastic parts.

• Handle brake fluid with special care not to

let it enter your eyes so that you may not

lost your eyesight.

• FIRST AID FOR BRAKE FLUID ENTERING

THE EYES:

• Flush with water for 15 minutes and get

immediate medical attention.

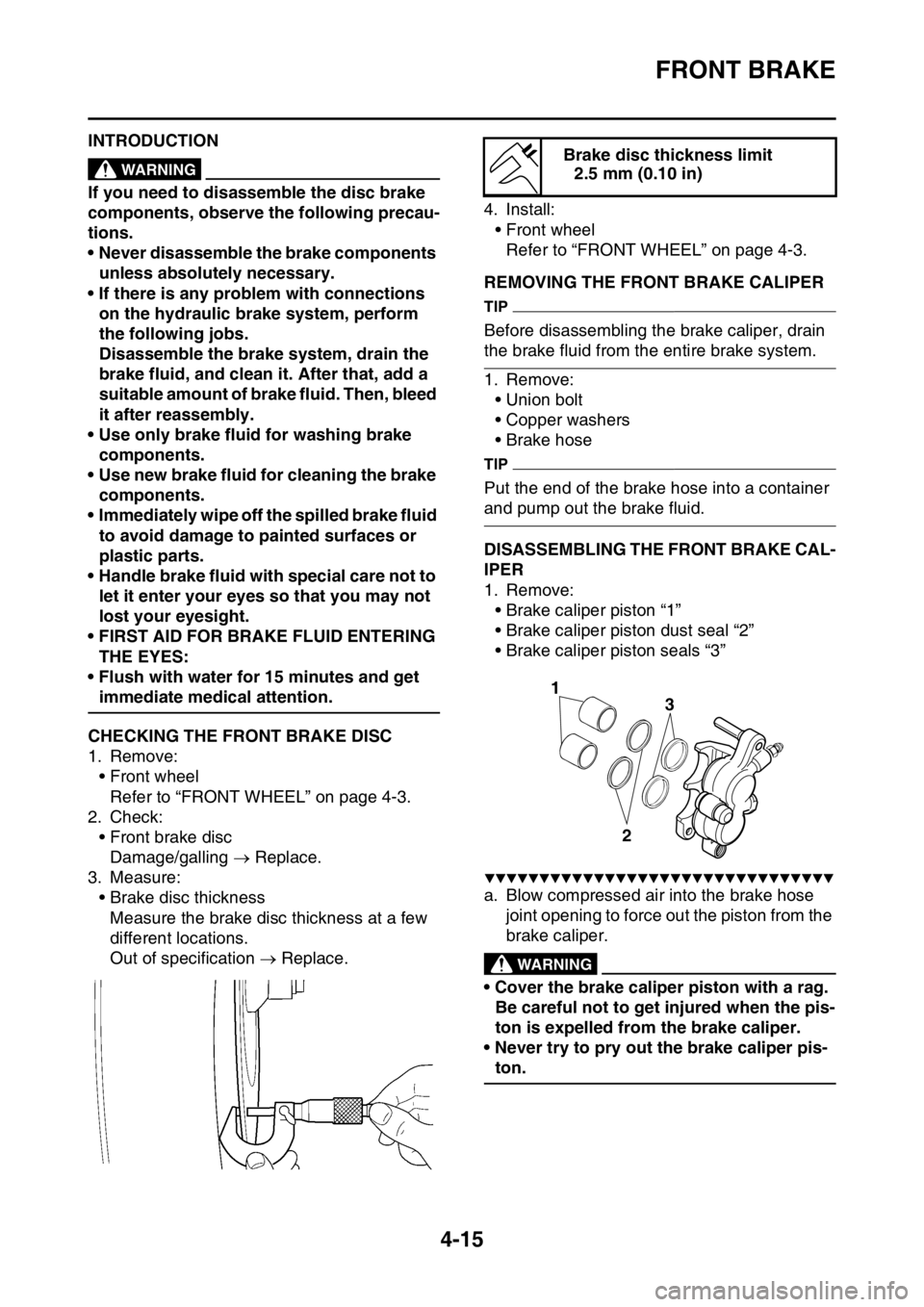

EAS1SM9135CHECKING THE FRONT BRAKE DISC

1. Remove:

• Front wheel

Refer to “FRONT WHEEL” on page 4-3.

2. Check:

• Front brake disc

Damage/galling Replace.

3. Measure:

• Brake disc thickness

Measure the brake disc thickness at a few

different locations.

Out of specification Replace.4. Install:

• Front wheel

Refer to “FRONT WHEEL” on page 4-3.

EAS1SM9136REMOVING THE FRONT BRAKE CALIPER

TIP

Before disassembling the brake caliper, drain

the brake fluid from the entire brake system.

1. Remove:

• Union bolt

• Copper washers

• Brake hose

TIP

Put the end of the brake hose into a container

and pump out the brake fluid.

EAS1SM9137DISASSEMBLING THE FRONT BRAKE CAL-

IPER

1. Remove:

• Brake caliper piston “1”

• Brake caliper piston dust seal “2”

• Brake caliper piston seals “3”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Blow compressed air into the brake hose

joint opening to force out the piston from the

brake caliper.

EWA

WARNING

• Cover the brake caliper piston with a rag.

Be careful not to get injured when the pis-

ton is expelled from the brake caliper.

• Never try to pry out the brake caliper pis-

ton.

Brake disc thickness limit

2.5 mm (0.10 in)

3

2

1

Page 142 of 356

FRONT BRAKE

4-18

NOTICE

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean

up any spilt brake fluid immediately.

5. Bleed:

• Brake system

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-22.

6. Check:

• Brake fluid level

The minimum level mark or below Add.

Refer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-27.

7. Check:

• Brake lever free play

Refer to “ADJUSTING THE FRONT

BRAKE” on page 3-23.

• Brake lever operation

A softy or spongy feeling Bleed the brake

system.

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-22.

EAS1SM9142REMOVING THE FRONT BRAKE MASTER

CYLINDER

TIP

Before removing the front brake master cylin-

der, drain the brake fluid from the entire brake

system.

1. Remove:

• Union bolt

• Copper washers

• Brake hoses

TIP

To drain any remaining brake fluid, place a con-

tainer under the master cylinder and the end of

the brake hose.

EAS1SM9143CHECKING THE FRONT BRAKE MASTER

CYLINDER

1. Check:

• Brake master cylinder “1”

Damage/scratches/wear Replace.

• Brake fluid delivery passages “2”

(brake master cylinder body)

Obstruction Blow out with compressed

air.2. Check:

• Brake master cylinder kit

Damage/scratches/wear Replace.

3. Check:

• Brake master cylinder reservoir cap

4. Check:

• Brake hoses

Cracks/damage/wear Replace.

EAS1SM9144ASSEMBLING THE FRONT BRAKE MAS-

TER CYLINDER

EWAWARNING

• Before installation, all internal brake com-

ponents should be cleaned and lubricated

with clean or new brake fluid.

• Never use solvents on internal brake com-

ponents.

1. Wash the brake master cylinder and the

brake master cylinder kit with brake fluid.

2. Install:

• Primary cylinder cup “1”

• Secondary cylinder cup “2”

Install to the brake master cylinder piston

“3”.

EWAWARNING

Apply brake fluid to the cylinder cups and

install them as shown. Wrong orientation in

installation causes poor braking perfor-

mance.Specified brake fluid

DOT 4

1

2

12

3

Page 145 of 356

REAR BRAKE

4-21

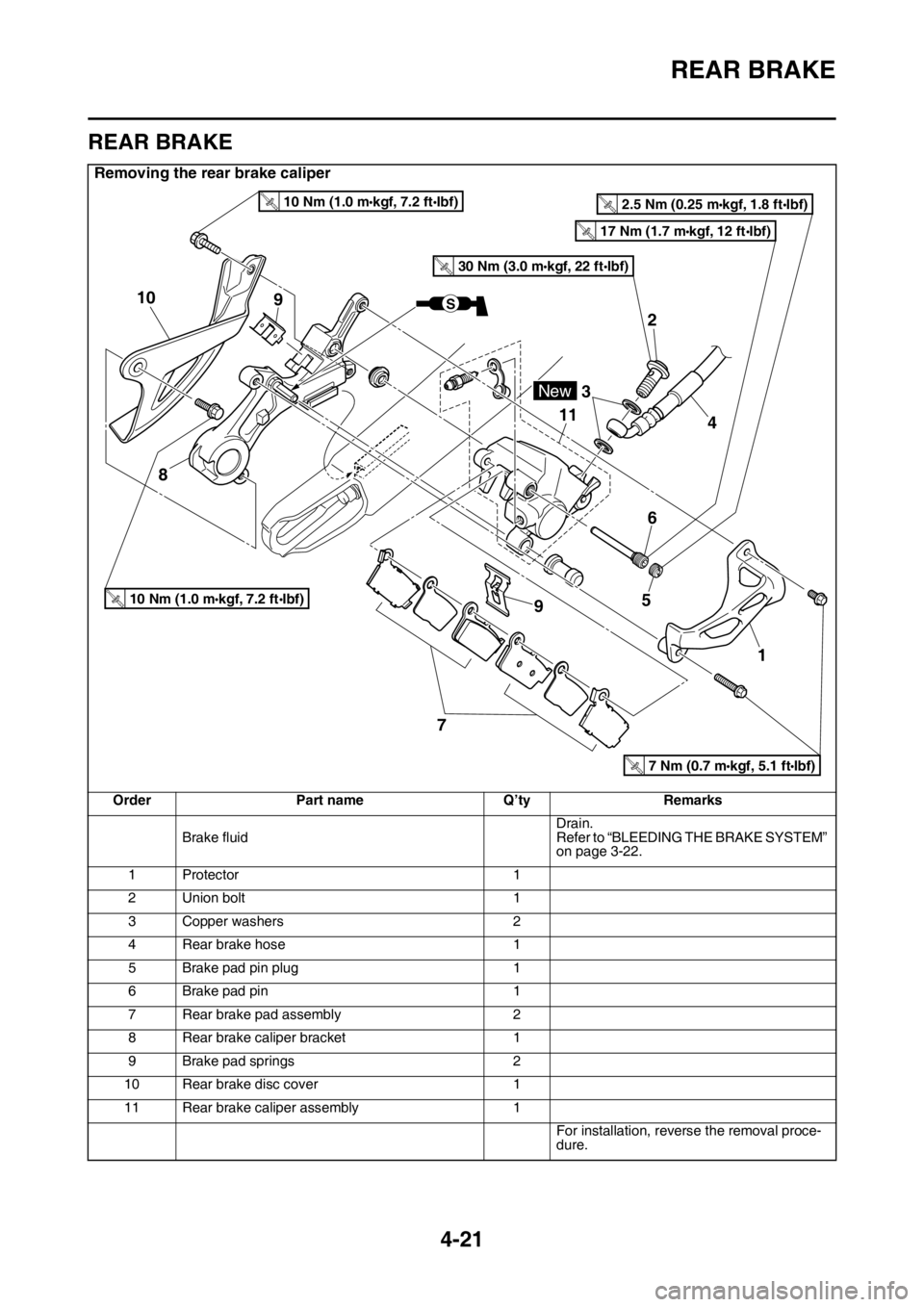

EAS1SM9146

REAR BRAKE

Removing the rear brake caliper

Order Part name Q’ty Remarks

Brake fluidDrain.

Refer to “BLEEDING THE BRAKE SYSTEM”

on page 3-22.

1 Protector 1

2 Union bolt 1

3 Copper washers 2

4 Rear brake hose 1

5 Brake pad pin plug 1

6 Brake pad pin 1

7 Rear brake pad assembly 2

8 Rear brake caliper bracket 1

9 Brake pad springs 2

10 Rear brake disc cover 1

11 Rear brake caliper assembly 1

For installation, reverse the removal proce-

dure.

2

3

4 11

56

79

1

8

9 10

2.5 Nm (0.25 m•kgf, 1.8 ft•Ibf)T.R.

10 Nm (1.0 m•kgf, 7.2 ft•Ibf)T.R.

10 Nm (1.0 m•kgf, 7.2 ft•Ibf)T.R.

17 Nm (1.7 m•kgf, 12 ft•Ibf)T.R.

30 Nm (3.0 m•kgf, 22 ft•Ibf)T.R.

New

S

7 Nm (0.7 m•kgf, 5.1 ft•Ibf)T.R.

Page 147 of 356

REAR BRAKE

4-23

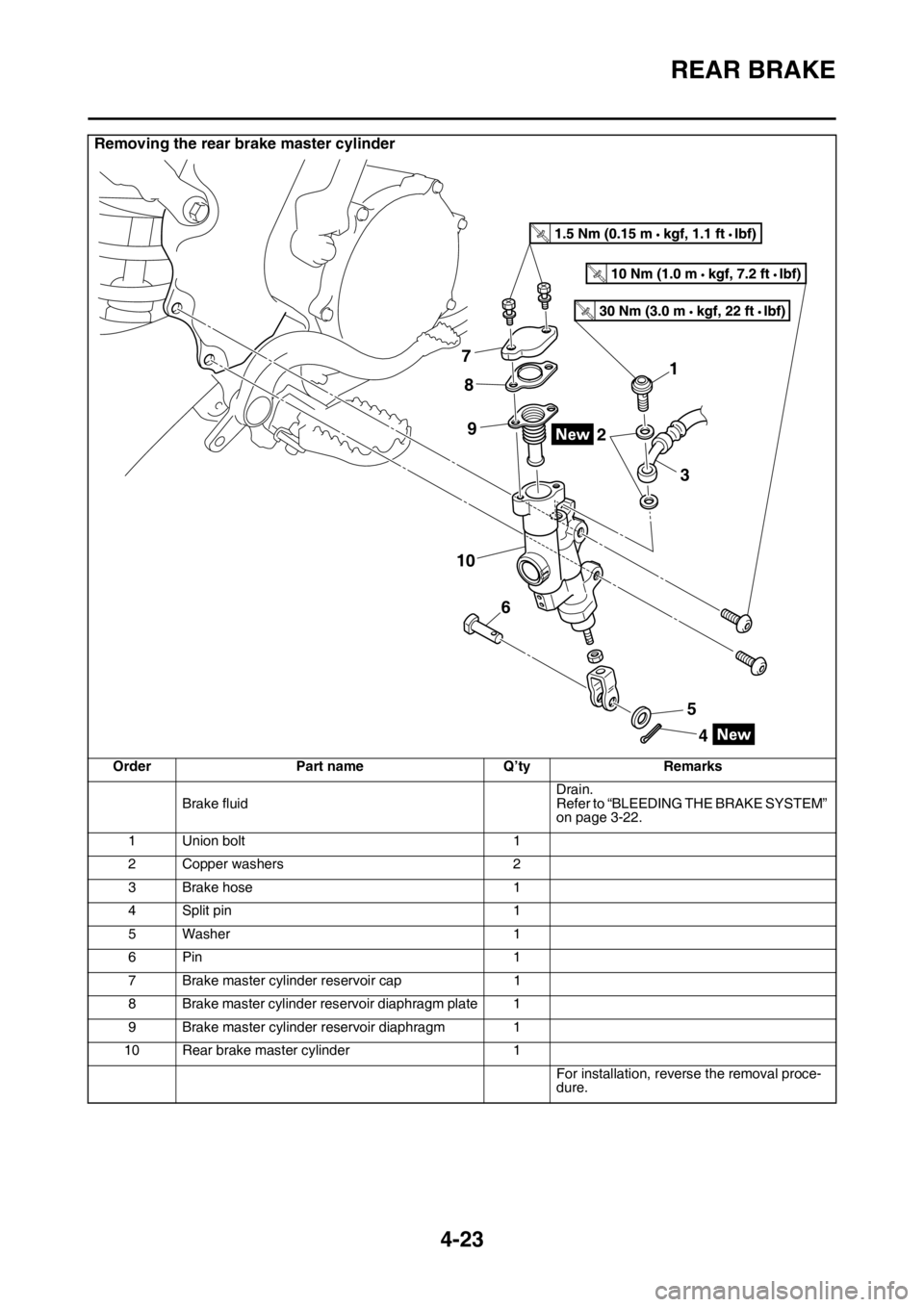

Removing the rear brake master cylinder

Order Part name Q’ty Remarks

Brake fluidDrain.

Refer to “BLEEDING THE BRAKE SYSTEM”

on page 3-22.

1 Union bolt 1

2 Copper washers 2

3 Brake hose 1

4 Split pin 1

5Washer 1

6Pin 1

7 Brake master cylinder reservoir cap 1

8 Brake master cylinder reservoir diaphragm plate 1

9 Brake master cylinder reservoir diaphragm 1

10 Rear brake master cylinder 1

For installation, reverse the removal proce-

dure.

1

2

3

4 7

5 8

6 9

T R..

T R..

10

T R..

Page 149 of 356

REAR BRAKE

4-25

EAS1SM9147INTRODUCTIONEWA

WARNING

If you need to disassemble the disc brake

components, observe the following precau-

tions.

• Never disassemble the brake components

unless absolutely necessary.

• If there is any problem with connections

on the hydraulic brake system, perform

the following jobs.

Disassemble the brake system, drain the

brake fluid, and clean it. After that, add a

suitable amount of brake fluid. Then, bleed

it after reassembly.

• Use only brake fluid for washing internal

brake components.

• Use new brake fluid for cleaning the brake

components.

• Immediately wipe off the spilled brake fluid

to avoid damage to painted surfaces or

plastic parts.

• Handle brake fluid with special care not to

let it enter your eyes so that you may not

lost your eyesight.

• FIRST AID FOR BRAKE FLUID ENTERING

THE EYES:

• Flush with water for 15 minutes and get

immediate medical attention.

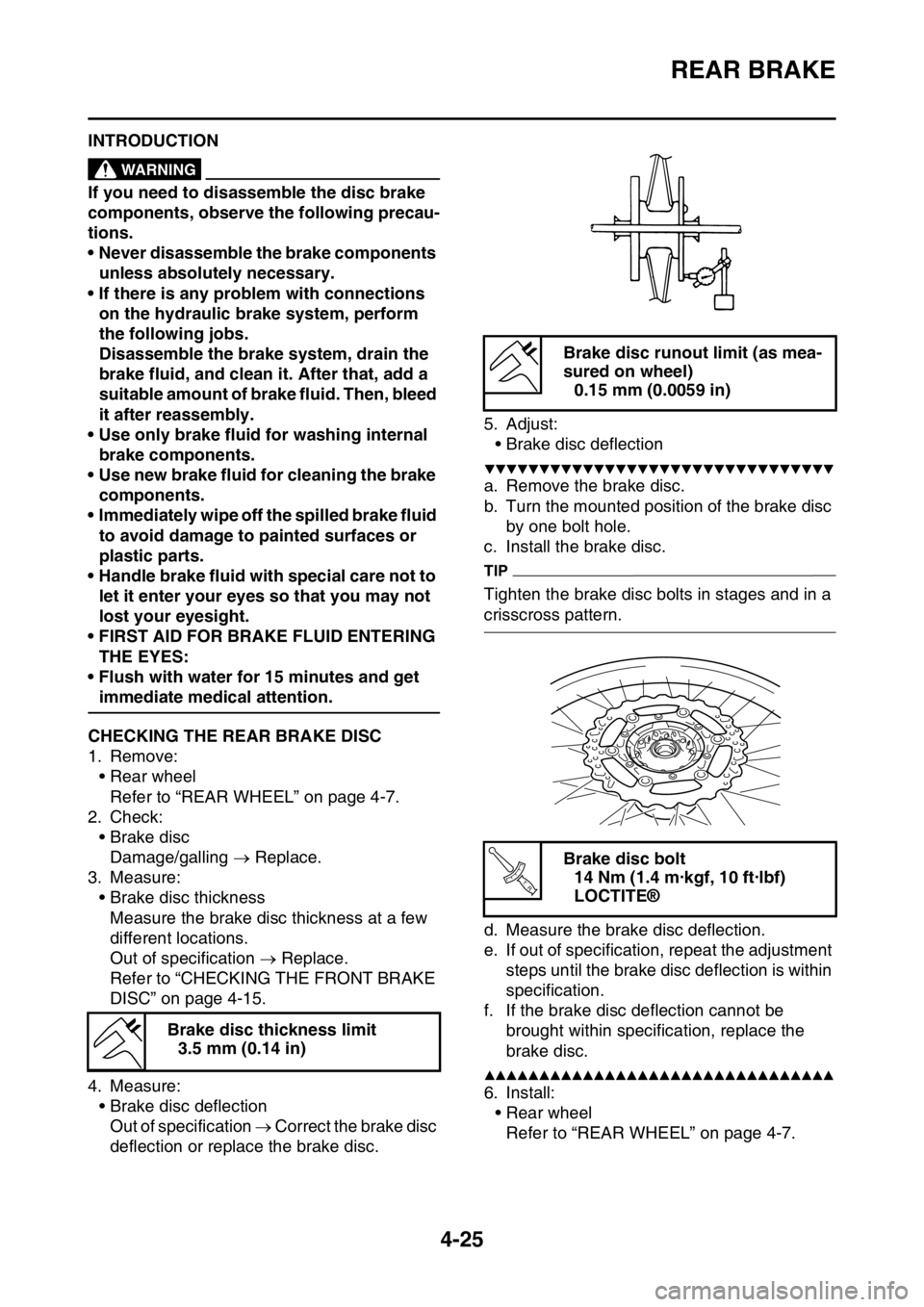

EAS1SM9148CHECKING THE REAR BRAKE DISC

1. Remove:

• Rear wheel

Refer to “REAR WHEEL” on page 4-7.

2. Check:

• Brake disc

Damage/galling Replace.

3. Measure:

• Brake disc thickness

Measure the brake disc thickness at a few

different locations.

Out of specification Replace.

Refer to “CHECKING THE FRONT BRAKE

DISC” on page 4-15.

4. Measure:

• Brake disc deflection

Out of specification Correct the brake disc

deflection or replace the brake disc.5. Adjust:

• Brake disc deflection

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the brake disc.

b. Turn the mounted position of the brake disc

by one bolt hole.

c. Install the brake disc.

TIP

Tighten the brake disc bolts in stages and in a

crisscross pattern.

d. Measure the brake disc deflection.

e. If out of specification, repeat the adjustment

steps until the brake disc deflection is within

specification.

f. If the brake disc deflection cannot be

brought within specification, replace the

brake disc.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

6. Install:

• Rear wheel

Refer to “REAR WHEEL” on page 4-7. Brake disc thickness limit

3.5 mm (0.14 in)

Brake disc runout limit (as mea-

sured on wheel)

0.15 mm (0.0059 in)

Brake disc bolt

14 Nm (1.4 m·kgf, 10 ft·lbf)

LOCTITE®

T R..

Page 150 of 356

REAR BRAKE

4-26

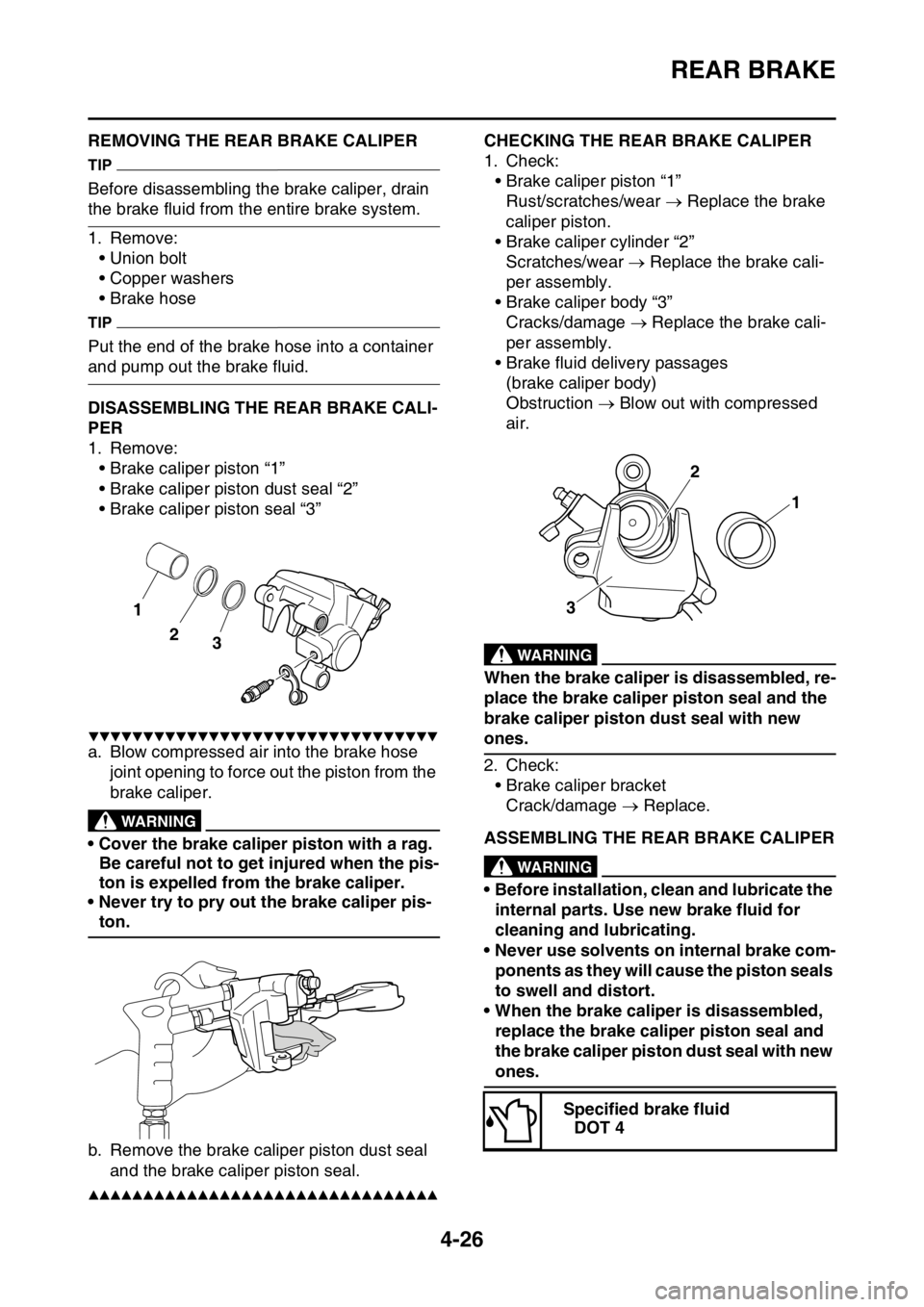

EAS1SM9149REMOVING THE REAR BRAKE CALIPER

TIP

Before disassembling the brake caliper, drain

the brake fluid from the entire brake system.

1. Remove:

• Union bolt

• Copper washers

• Brake hose

TIP

Put the end of the brake hose into a container

and pump out the brake fluid.

EAS1SM9150DISASSEMBLING THE REAR BRAKE CALI-

PER

1. Remove:

• Brake caliper piston “1”

• Brake caliper piston dust seal “2”

• Brake caliper piston seal “3”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Blow compressed air into the brake hose

joint opening to force out the piston from the

brake caliper.

EWA

WARNING

• Cover the brake caliper piston with a rag.

Be careful not to get injured when the pis-

ton is expelled from the brake caliper.

• Never try to pry out the brake caliper pis-

ton.

b. Remove the brake caliper piston dust seal

and the brake caliper piston seal.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SM9151CHECKING THE REAR BRAKE CALIPER

1. Check:

• Brake caliper piston “1”

Rust/scratches/wear Replace the brake

caliper piston.

• Brake caliper cylinder “2”

Scratches/wear Replace the brake cali-

per assembly.

• Brake caliper body “3”

Cracks/damage Replace the brake cali-

per assembly.

• Brake fluid delivery passages

(brake caliper body)

Obstruction Blow out with compressed

air.

EWA

WARNING

When the brake caliper is disassembled, re-

place the brake caliper piston seal and the

brake caliper piston dust seal with new

ones.

2. Check:

• Brake caliper bracket

Crack/damage Replace.

EAS1SM9152ASSEMBLING THE REAR BRAKE CALIPEREWA

WARNING

• Before installation, clean and lubricate the

internal parts. Use new brake fluid for

cleaning and lubricating.

• Never use solvents on internal brake com-

ponents as they will cause the piston seals

to swell and distort.

• When the brake caliper is disassembled,

replace the brake caliper piston seal and

the brake caliper piston dust seal with new

ones.

2

3

1

Specified brake fluid

DOT 4

1 2

3

Page 152 of 356

REAR BRAKE

4-28

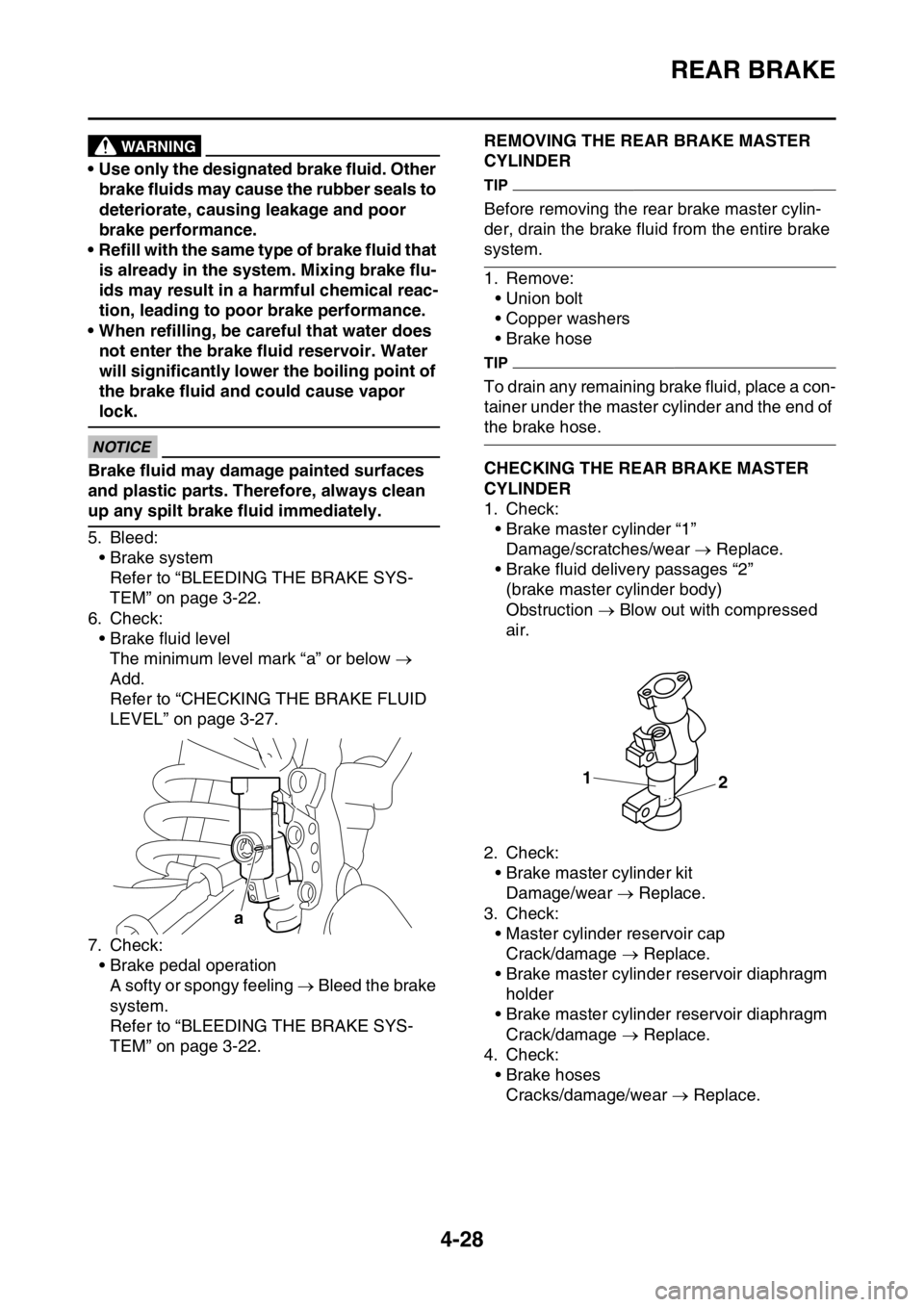

EWA

WARNING

• Use only the designated brake fluid. Other

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that

is already in the system. Mixing brake flu-

ids may result in a harmful chemical reac-

tion, leading to poor brake performance.

• When refilling, be careful that water does

not enter the brake fluid reservoir. Water

will significantly lower the boiling point of

the brake fluid and could cause vapor

lock.

ECA

NOTICE

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean

up any spilt brake fluid immediately.

5. Bleed:

• Brake system

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-22.

6. Check:

• Brake fluid level

The minimum level mark “a” or below

Add.

Refer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-27.

7. Check:

• Brake pedal operation

A softy or spongy feeling Bleed the brake

system.

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-22.

EAS1SM9155REMOVING THE REAR BRAKE MASTER

CYLINDER

TIP

Before removing the rear brake master cylin-

der, drain the brake fluid from the entire brake

system.

1. Remove:

• Union bolt

• Copper washers

• Brake hose

TIP

To drain any remaining brake fluid, place a con-

tainer under the master cylinder and the end of

the brake hose.

EAS1SM9156CHECKING THE REAR BRAKE MASTER

CYLINDER

1. Check:

• Brake master cylinder “1”

Damage/scratches/wear Replace.

• Brake fluid delivery passages “2”

(brake master cylinder body)

Obstruction Blow out with compressed

air.

2. Check:

• Brake master cylinder kit

Damage/wear Replace.

3. Check:

• Master cylinder reservoir cap

Crack/damage Replace.

• Brake master cylinder reservoir diaphragm

holder

• Brake master cylinder reservoir diaphragm

Crack/damage Replace.

4. Check:

• Brake hoses

Cracks/damage/wear Replace.

a

1

2

Page 163 of 356

FRONT FORK

4-39

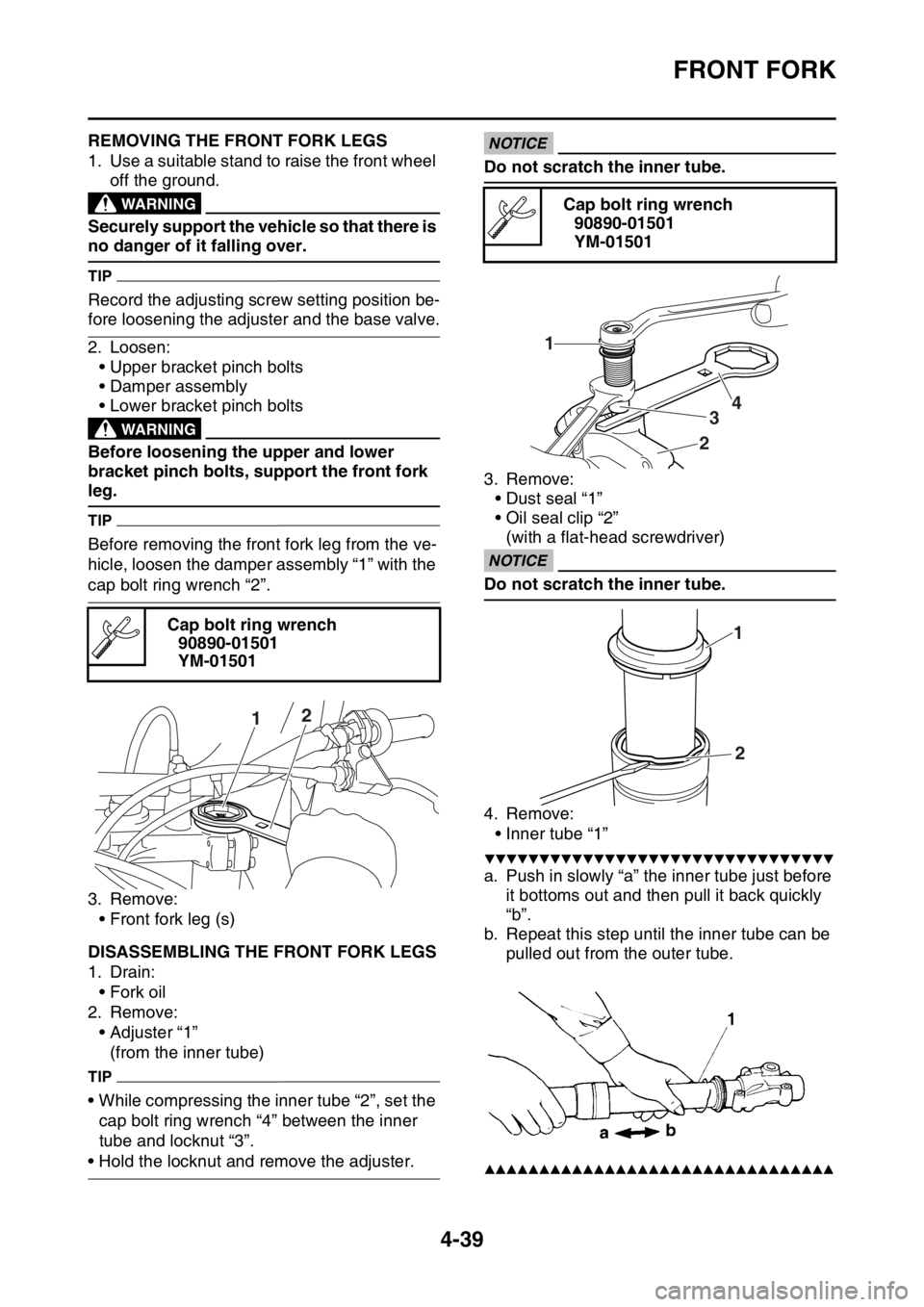

EAS1SM9164REMOVING THE FRONT FORK LEGS

1. Use a suitable stand to raise the front wheel

off the ground.

EWAWARNING

Securely support the vehicle so that there is

no danger of it falling over.

TIP

Record the adjusting screw setting position be-

fore loosening the adjuster and the base valve.

2. Loosen:

• Upper bracket pinch bolts

• Damper assembly

• Lower bracket pinch bolts

EWAWARNING

Before loosening the upper and lower

bracket pinch bolts, support the front fork

leg.

TIP

Before removing the front fork leg from the ve-

hicle, loosen the damper assembly “1” with the

cap bolt ring wrench “2”.

3. Remove:

• Front fork leg (s)

EAS1SM9165DISASSEMBLING THE FRONT FORK LEGS

1. Drain:

• Fork oil

2. Remove:

• Adjuster “1”

(from the inner tube)

TIP

• While compressing the inner tube “2”, set the

cap bolt ring wrench “4” between the inner

tube and locknut “3”.

• Hold the locknut and remove the adjuster.

ECA

NOTICE

Do not scratch the inner tube.

3. Remove:

• Dust seal “1”

• Oil seal clip “2”

(with a flat-head screwdriver)

ECANOTICE

Do not scratch the inner tube.

4. Remove:

• Inner tube “1”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Push in slowly “a” the inner tube just before

it bottoms out and then pull it back quickly

“b”.

b. Repeat this step until the inner tube can be

pulled out from the outer tube.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Cap bolt ring wrench

90890-01501

YM-01501

12

Cap bolt ring wrench

90890-01501

YM-01501

1

234

1

2

Page 274 of 356

WATER PUMP

6-7

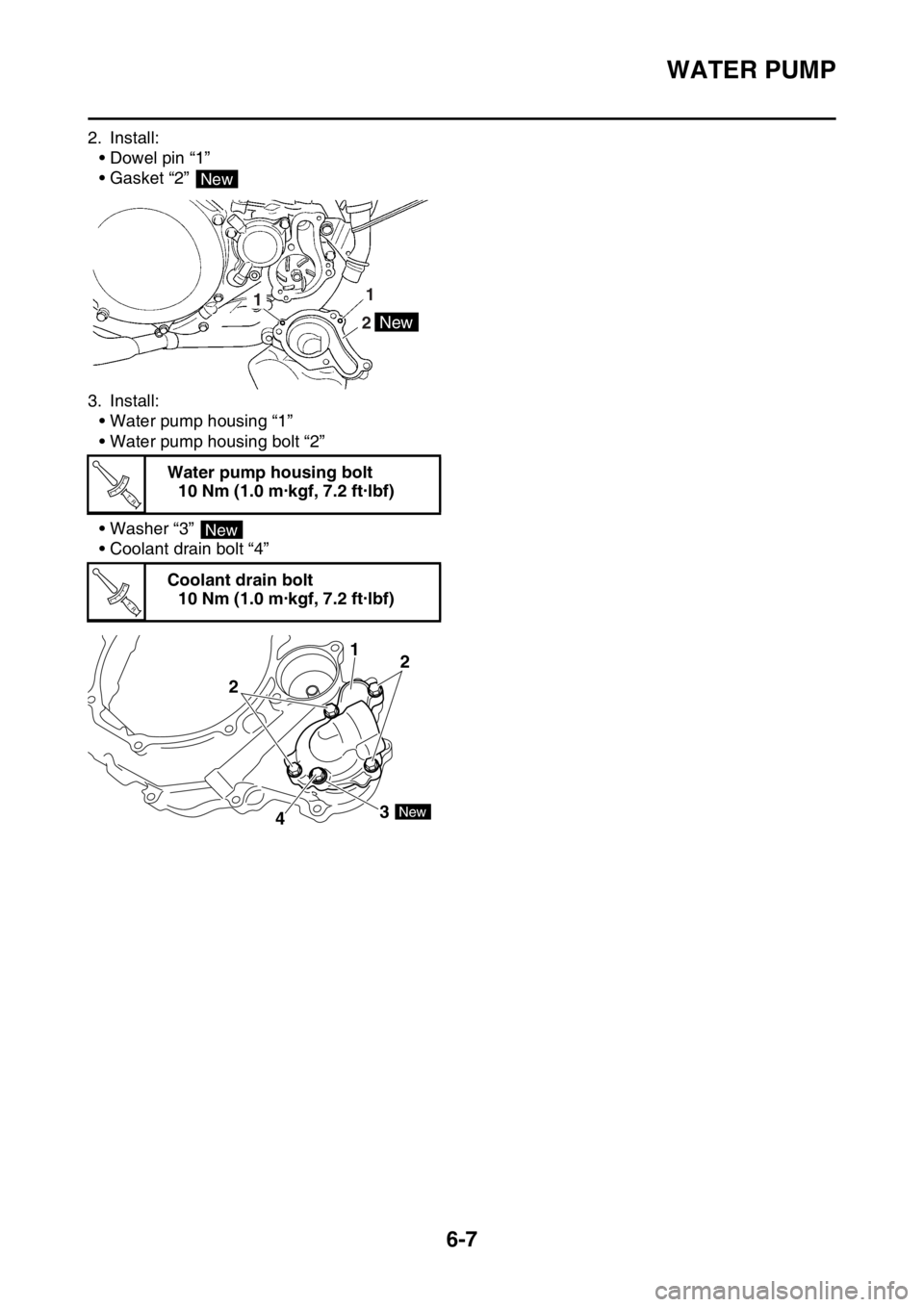

2. Install:

• Dowel pin “1”

• Gasket “2”

3. Install:

• Water pump housing “1”

• Water pump housing bolt “2”

• Washer “3”

• Coolant drain bolt “4”Water pump housing bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Coolant drain bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

New

21

1New

T R..

New

T R..

2

2

43 1

New