engine oil YAMAHA YZ250F 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZ250F, Model: YAMAHA YZ250F 2016Pages: 356, PDF Size: 11.25 MB

Page 45 of 356

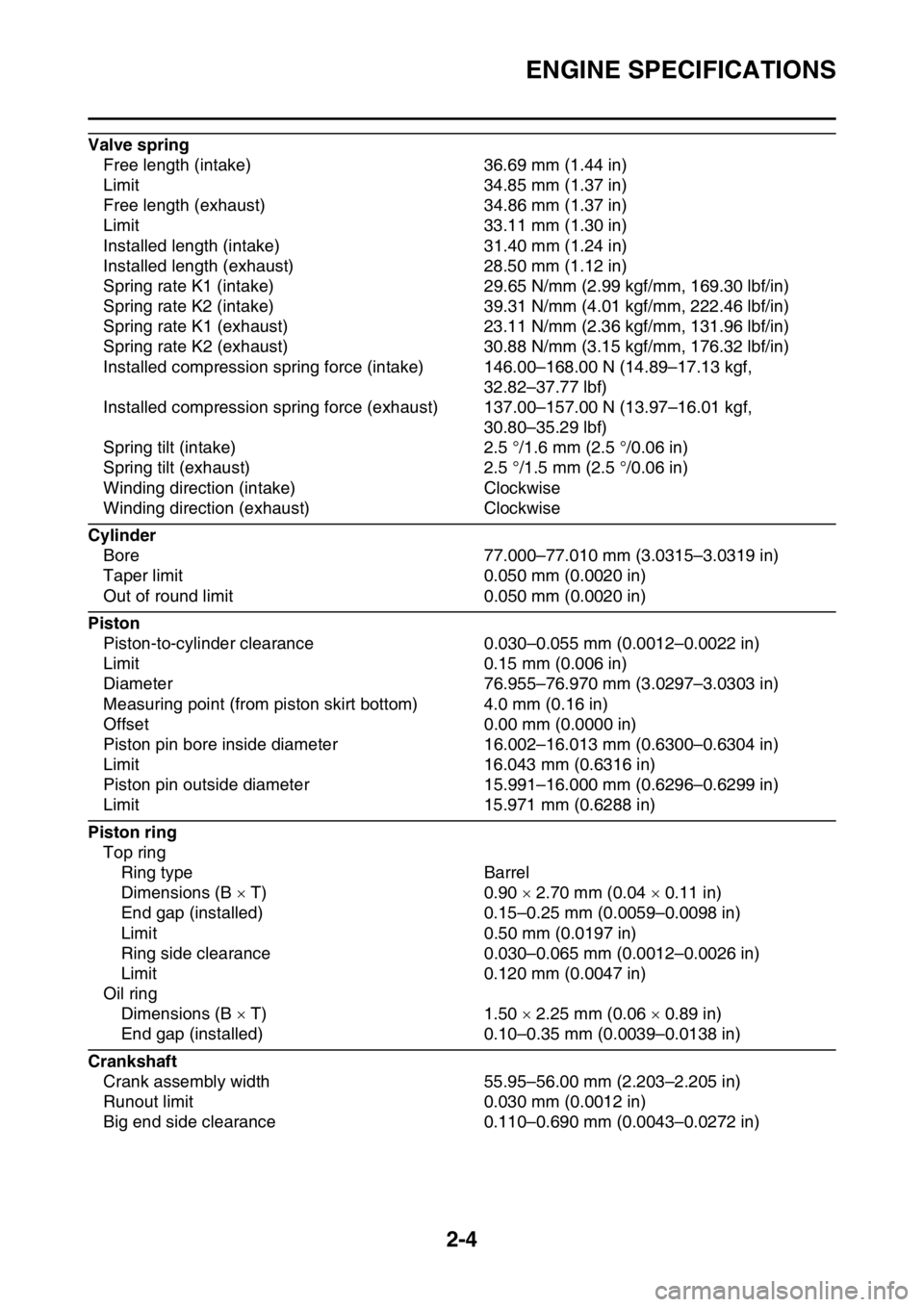

ENGINE SPECIFICATIONS

2-4

Valve spring

Free length (intake) 36.69 mm (1.44 in)

Limit 34.85 mm (1.37 in)

Free length (exhaust) 34.86 mm (1.37 in)

Limit 33.11 mm (1.30 in)

Installed length (intake) 31.40 mm (1.24 in)

Installed length (exhaust) 28.50 mm (1.12 in)

Spring rate K1 (intake) 29.65 N/mm (2.99 kgf/mm, 169.30 lbf/in)

Spring rate K2 (intake) 39.31 N/mm (4.01 kgf/mm, 222.46 lbf/in)

Spring rate K1 (exhaust) 23.11 N/mm (2.36 kgf/mm, 131.96 lbf/in)

Spring rate K2 (exhaust) 30.88 N/mm (3.15 kgf/mm, 176.32 lbf/in)

Installed compression spring force (intake) 146.00–168.00 N (14.89–17.13 kgf,

32.82–37.77 lbf)

Installed compression spring force (exhaust) 137.00–157.00 N (13.97–16.01 kgf,

30.80–35.29 lbf)

Spring tilt (intake) 2.5 °/1.6 mm (2.5 °/0.06 in)

Spring tilt (exhaust) 2.5 °/1.5 mm (2.5 °/0.06 in)

Winding direction (intake) Clockwise

Winding direction (exhaust) Clockwise

Cylinder

Bore 77.000–77.010 mm (3.0315–3.0319 in)

Taper limit 0.050 mm (0.0020 in)

Out of round limit 0.050 mm (0.0020 in)

Piston

Piston-to-cylinder clearance 0.030–0.055 mm (0.0012–0.0022 in)

Limit 0.15 mm (0.006 in)

Diameter 76.955–76.970 mm (3.0297–3.0303 in)

Measuring point (from piston skirt bottom) 4.0 mm (0.16 in)

Offset 0.00 mm (0.0000 in)

Piston pin bore inside diameter 16.002–16.013 mm (0.6300–0.6304 in)

Limit 16.043 mm (0.6316 in)

Piston pin outside diameter 15.991–16.000 mm (0.6296–0.6299 in)

Limit 15.971 mm (0.6288 in)

Piston ring

Top ring

Ring type Barrel

Dimensions (B T) 0.90 2.70 mm (0.04 0.11 in)

End gap (installed) 0.15–0.25 mm (0.0059–0.0098 in)

Limit 0.50 mm (0.0197 in)

Ring side clearance 0.030–0.065 mm (0.0012–0.0026 in)

Limit 0.120 mm (0.0047 in)

Oil ring

Dimensions (B T) 1.50 2.25 mm (0.06 0.89 in)

End gap (installed) 0.10–0.35 mm (0.0039–0.0138 in)

Crankshaft

Crank assembly width 55.95–56.00 mm (2.203–2.205 in)

Runout limit 0.030 mm (0.0012 in)

Big end side clearance 0.110–0.690 mm (0.0043–0.0272 in)

Page 46 of 356

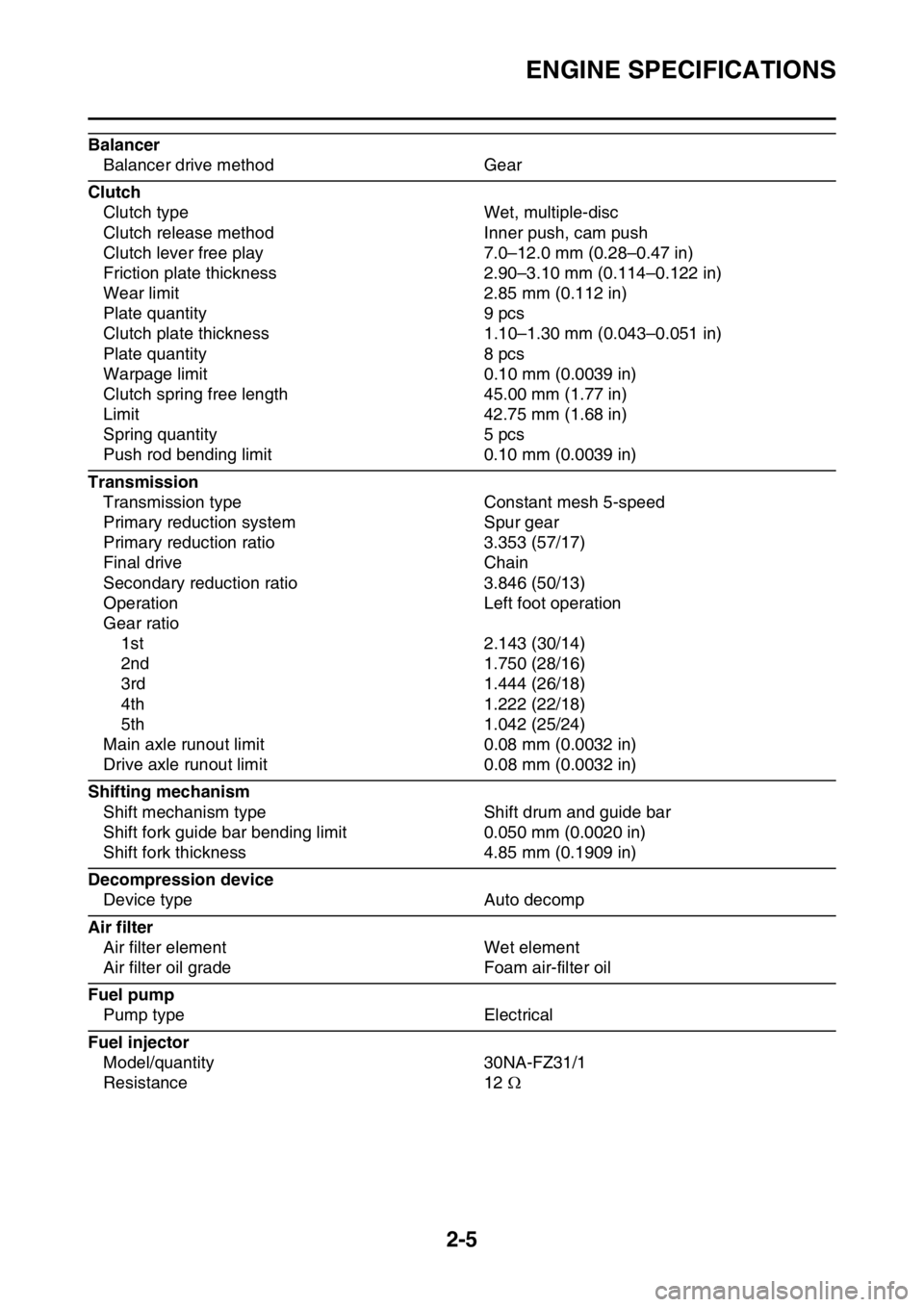

ENGINE SPECIFICATIONS

2-5

Balancer

Balancer drive method Gear

Clutch

Clutch type Wet, multiple-disc

Clutch release method Inner push, cam push

Clutch lever free play 7.0–12.0 mm (0.28–0.47 in)

Friction plate thickness 2.90–3.10 mm (0.114–0.122 in)

Wear limit 2.85 mm (0.112 in)

Plate quantity 9 pcs

Clutch plate thickness 1.10–1.30 mm (0.043–0.051 in)

Plate quantity 8 pcs

Warpage limit 0.10 mm (0.0039 in)

Clutch spring free length 45.00 mm (1.77 in)

Limit 42.75 mm (1.68 in)

Spring quantity 5 pcs

Push rod bending limit 0.10 mm (0.0039 in)

Transmission

Transmission type Constant mesh 5-speed

Primary reduction system Spur gear

Primary reduction ratio 3.353 (57/17)

Final drive Chain

Secondary reduction ratio 3.846 (50/13)

Operation Left foot operation

Gear ratio

1st 2.143 (30/14)

2nd 1.750 (28/16)

3rd 1.444 (26/18)

4th 1.222 (22/18)

5th 1.042 (25/24)

Main axle runout limit 0.08 mm (0.0032 in)

Drive axle runout limit 0.08 mm (0.0032 in)

Shifting mechanism

Shift mechanism type Shift drum and guide bar

Shift fork guide bar bending limit 0.050 mm (0.0020 in)

Shift fork thickness 4.85 mm (0.1909 in)

Decompression device

Device type Auto decomp

Air filter

Air filter element Wet element

Air filter oil grade Foam air-filter oil

Fuel pump

Pump type Electrical

Fuel injector

Model/quantity 30NA-FZ31/1

Resistance 12

Page 47 of 356

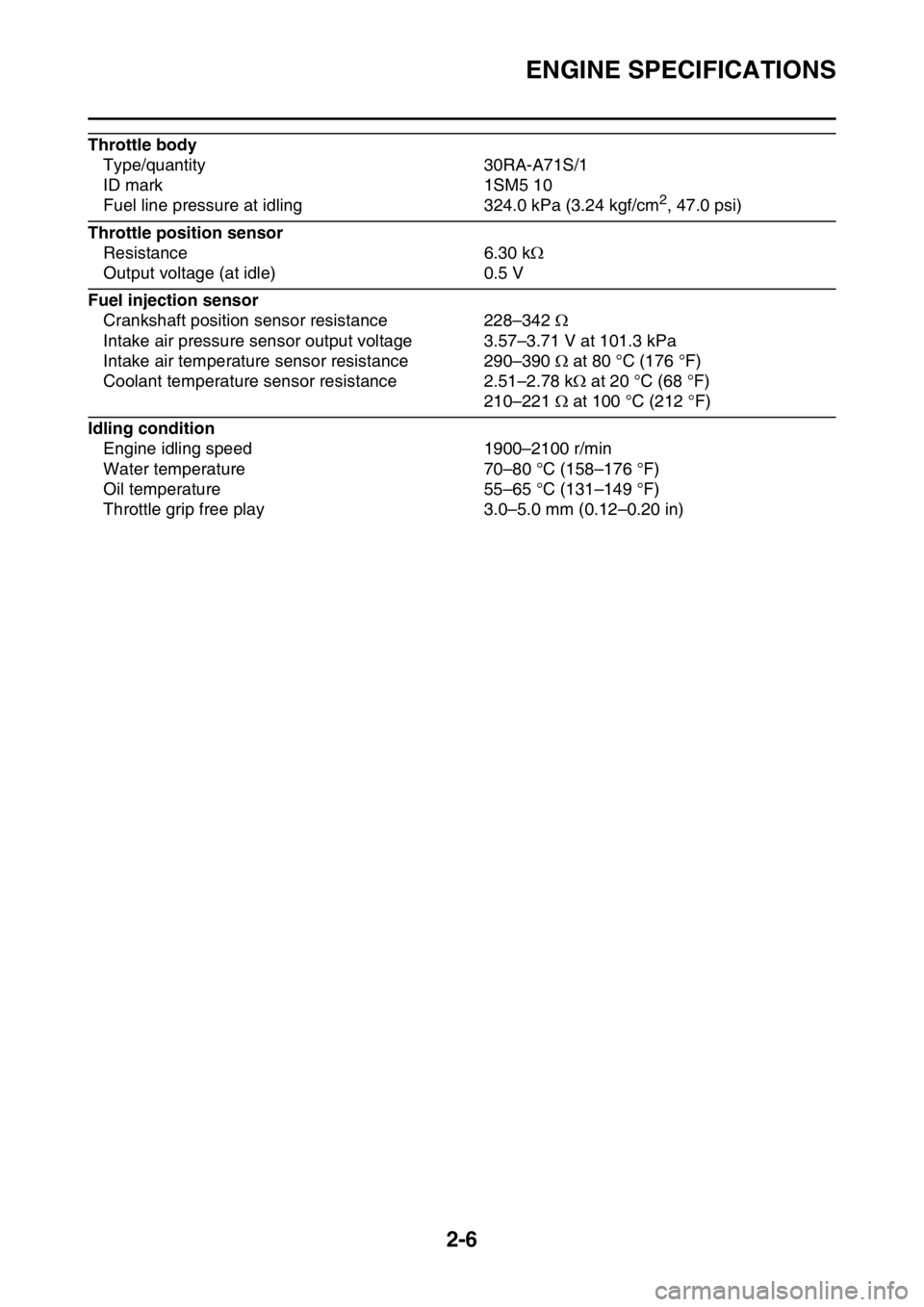

ENGINE SPECIFICATIONS

2-6

Throttle body

Type/quantity 30RA-A71S/1

ID mark 1SM5 10

Fuel line pressure at idling 324.0 kPa (3.24 kgf/cm

2, 47.0 psi)

Throttle position sensor

Resistance 6.30 k

Output voltage (at idle) 0.5 V

Fuel injection sensor

Crankshaft position sensor resistance 228–342

Intake air pressure sensor output voltage 3.57–3.71 V at 101.3 kPa

Intake air temperature sensor resistance 290–390 at 80 °C (176 °F)

Coolant temperature sensor resistance 2.51–2.78 k at 20 °C (68 °F)

210–221 at 100 °C (212 °F)

Idling condition

Engine idling speed 1900–2100 r/min

Water temperature 70–80 °C (158–176 °F)

Oil temperature 55–65 °C (131–149 °F)

Throttle grip free play 3.0–5.0 mm (0.12–0.20 in)

Page 51 of 356

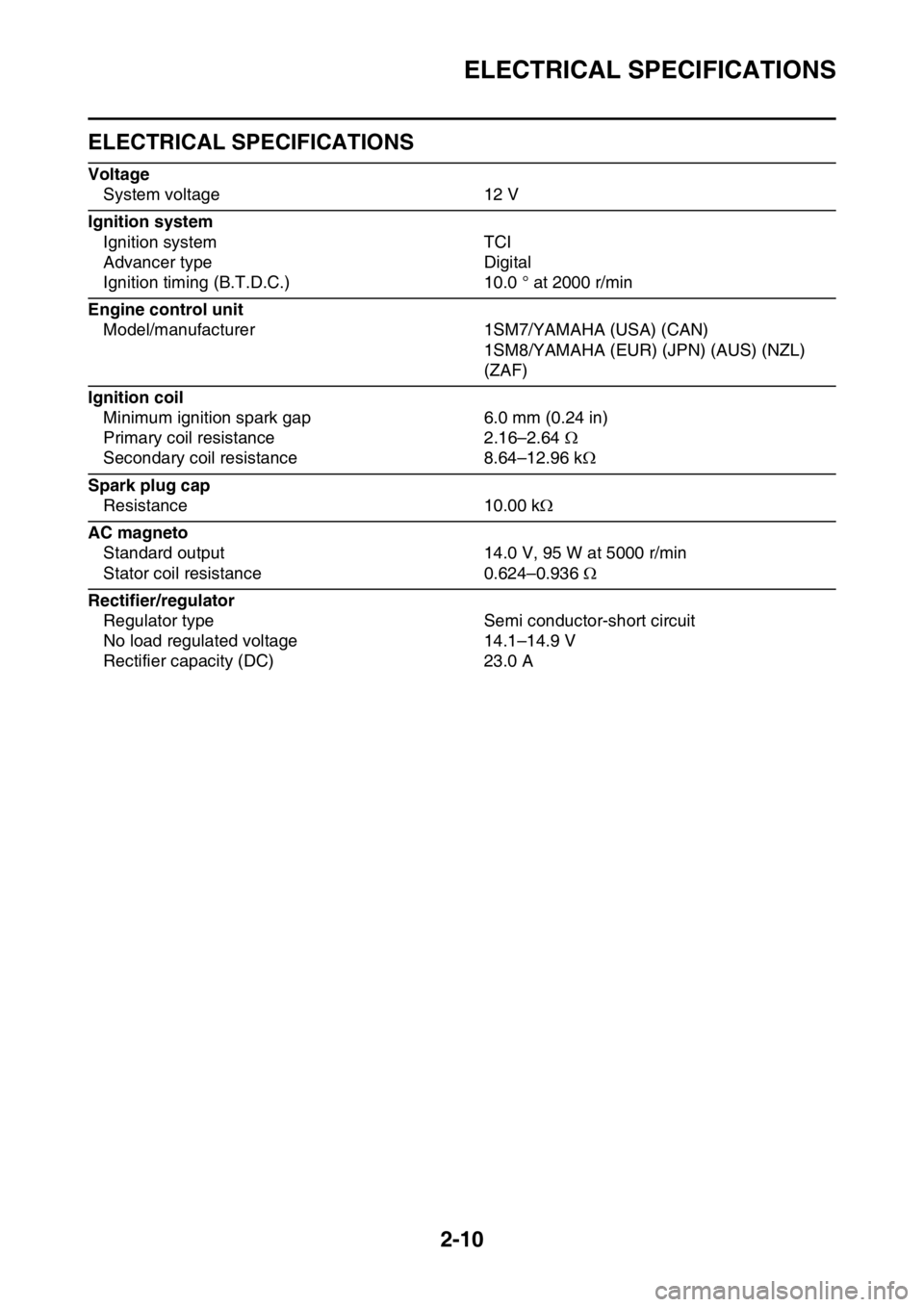

ELECTRICAL SPECIFICATIONS

2-10

EAS1SM9053

ELECTRICAL SPECIFICATIONS

Voltage

System voltage 12 V

Ignition system

Ignition system TCI

Advancer type Digital

Ignition timing (B.T.D.C.) 10.0 ° at 2000 r/min

Engine control unit

Model/manufacturer 1SM7/YAMAHA (USA) (CAN)

1SM8/YAMAHA (EUR) (JPN) (AUS) (NZL)

(ZAF)

Ignition coil

Minimum ignition spark gap 6.0 mm (0.24 in)

Primary coil resistance 2.16–2.64

Secondary coil resistance 8.64–12.96 k

Spark plug cap

Resistance 10.00 k

AC magneto

Standard output 14.0 V, 95 W at 5000 r/min

Stator coil resistance 0.624–0.936

Rectifier/regulator

Regulator type Semi conductor-short circuit

No load regulated voltage 14.1–14.9 V

Rectifier capacity (DC) 23.0 A

Page 53 of 356

TIGHTENING TORQUES

2-12

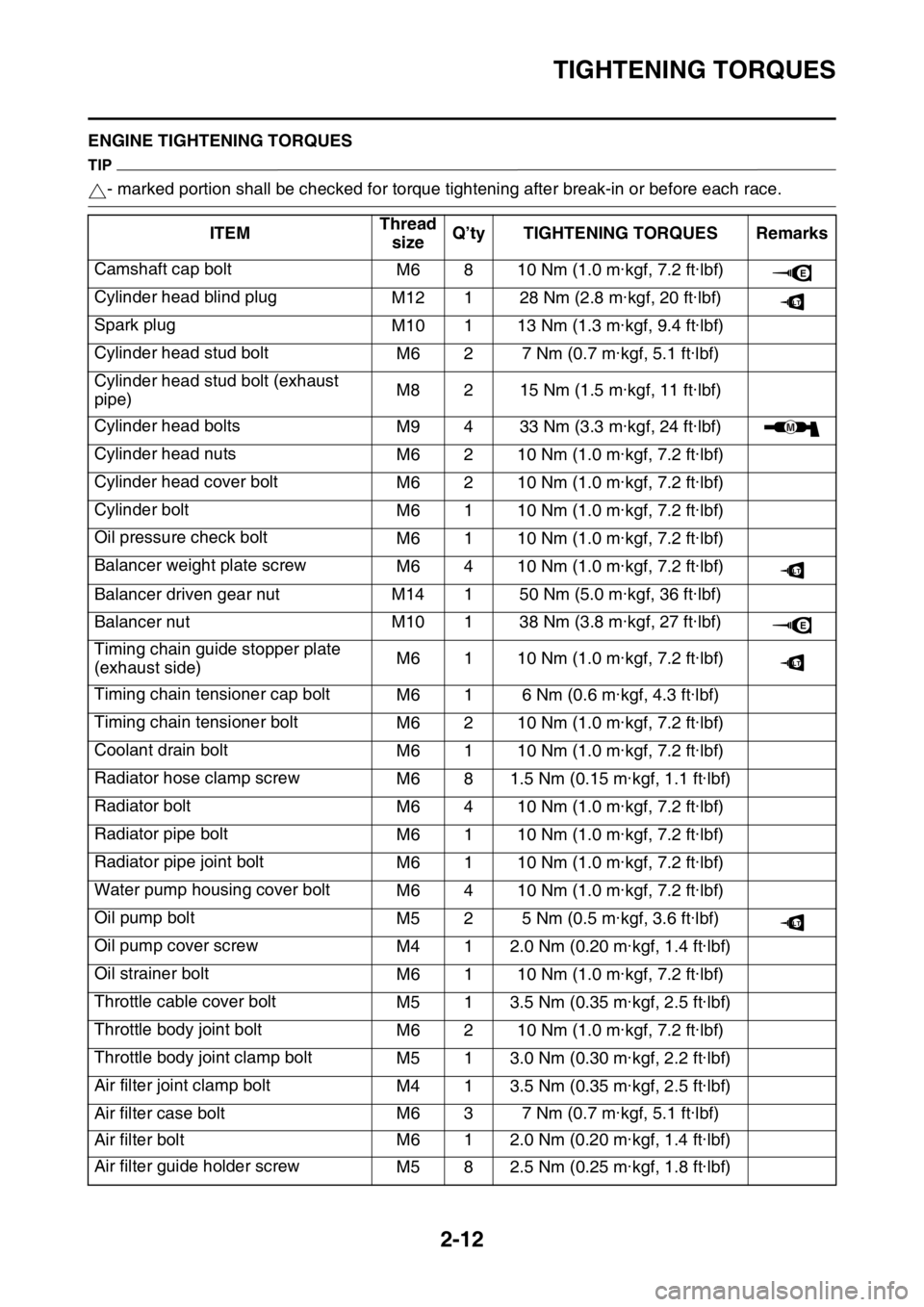

EAS1SM9055ENGINE TIGHTENING TORQUES

TIP

- marked portion shall be checked for torque tightening after break-in or before each race.

ITEMThread

sizeQ’ty TIGHTENING TORQUES Remarks

Camshaft cap bolt

M6 8 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Cylinder head blind plug

M12 1 28 Nm (2.8 m·kgf, 20 ft·lbf)

Spark plug

M10 1 13 Nm (1.3 m·kgf, 9.4 ft·lbf)

Cylinder head stud bolt

M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Cylinder head stud bolt (exhaust

pipe)M8 2 15 Nm (1.5 m·kgf, 11 ft·lbf)

Cylinder head bolts

M9 4 33 Nm (3.3 m·kgf, 24 ft·lbf)

Cylinder head nuts

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Cylinder head cover bolt

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Cylinder bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil pressure check bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Balancer weight plate screw

M6 4 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Balancer driven gear nut M14 1 50 Nm (5.0 m·kgf, 36 ft·lbf)

Balancer nut M10 1 38 Nm (3.8 m·kgf, 27 ft·lbf)

Timing chain guide stopper plate

(exhaust side)M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Timing chain tensioner cap bolt

M6 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Timing chain tensioner bolt

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Coolant drain bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Radiator hose clamp screw

M6 8 1.5 Nm (0.15 m·kgf, 1.1 ft·lbf)

Radiator bolt

M6 4 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Radiator pipe bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Radiator pipe joint bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Water pump housing cover bolt

M6 4 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil pump bolt

M5 2 5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Oil pump cover screw

M4 1 2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Oil strainer bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Throttle cable cover bolt

M5 1 3.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

Throttle body joint bolt

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Throttle body joint clamp bolt

M5 1 3.0 Nm (0.30 m·kgf, 2.2 ft·lbf)

Air filter joint clamp bolt

M4 1 3.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

Air filter case bolt M6 3 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Air filter bolt M6 1 2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Air filter guide holder screw

M5 8 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

E

LT

M

LT

E

LT

LT

Page 54 of 356

TIGHTENING TORQUES

2-13

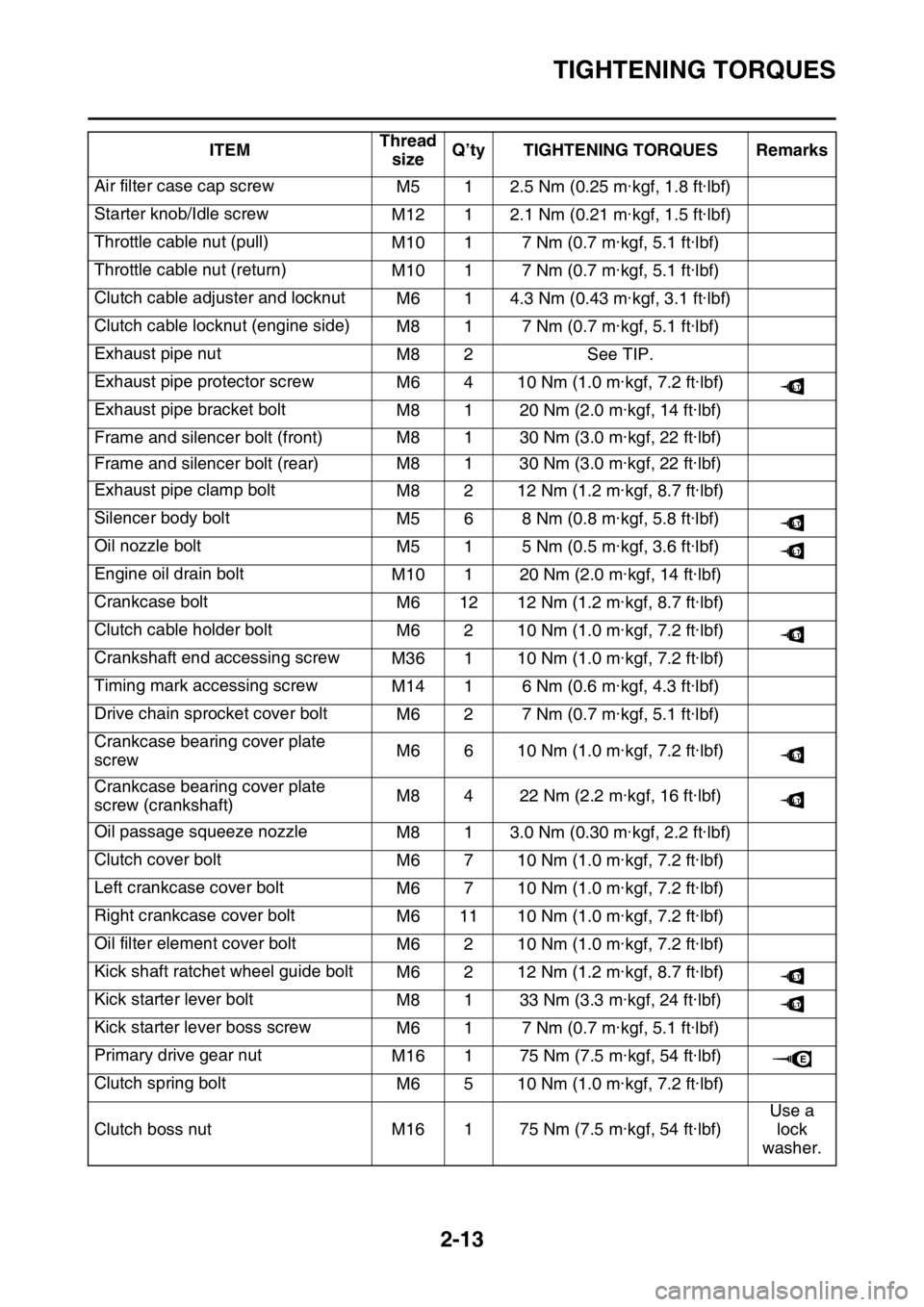

Air filter case cap screw

M5 1 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Starter knob/Idle screw

M12 1 2.1 Nm (0.21 m·kgf, 1.5 ft·lbf)

Throttle cable nut (pull)

M10 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Throttle cable nut (return)

M10 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Clutch cable adjuster and locknut

M6 1 4.3 Nm (0.43 m·kgf, 3.1 ft·lbf)

Clutch cable locknut (engine side)

M8 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Exhaust pipe nut

M8 2 See TIP.

Exhaust pipe protector screw

M6 4 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Exhaust pipe bracket bolt

M8 1 20 Nm (2.0 m·kgf, 14 ft·lbf)

Frame and silencer bolt (front) M8 1 30 Nm (3.0 m·kgf, 22 ft·lbf)

Frame and silencer bolt (rear) M8 1 30 Nm (3.0 m·kgf, 22 ft·lbf)

Exhaust pipe clamp bolt

M8 2 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Silencer body bolt

M5 6 8 Nm (0.8 m·kgf, 5.8 ft·lbf)

Oil nozzle bolt

M5 1 5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Engine oil drain bolt

M10 1 20 Nm (2.0 m·kgf, 14 ft·lbf)

Crankcase bolt

M6 12 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Clutch cable holder bolt

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Crankshaft end accessing screw

M36 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Timing mark accessing screw

M14 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Drive chain sprocket cover bolt

M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Crankcase bearing cover plate

screwM6 6 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Crankcase bearing cover plate

screw (crankshaft)M8 4 22 Nm (2.2 m·kgf, 16 ft·lbf)

Oil passage squeeze nozzle

M8 1 3.0 Nm (0.30 m·kgf, 2.2 ft·lbf)

Clutch cover bolt

M6 7 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Left crankcase cover bolt

M6 7 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Right crankcase cover bolt

M6 11 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil filter element cover bolt

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Kick shaft ratchet wheel guide bolt

M6 2 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Kick starter lever bolt

M8 1 33 Nm (3.3 m·kgf, 24 ft·lbf)

Kick starter lever boss screw

M6 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Primary drive gear nut

M16 1 75 Nm (7.5 m·kgf, 54 ft·lbf)

Clutch spring bolt

M6 5 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Clutch boss nut M16 1 75 Nm (7.5 m·kgf, 54 ft·lbf)Use a

lock

washer. ITEMThread

sizeQ’ty TIGHTENING TORQUES Remarks

LT

LT

LT

LT

LT

LT

LT

LT

E

Page 59 of 356

LUBRICATION POINTS AND LUBRICANT TYPES

2-18

EAS1SM9057

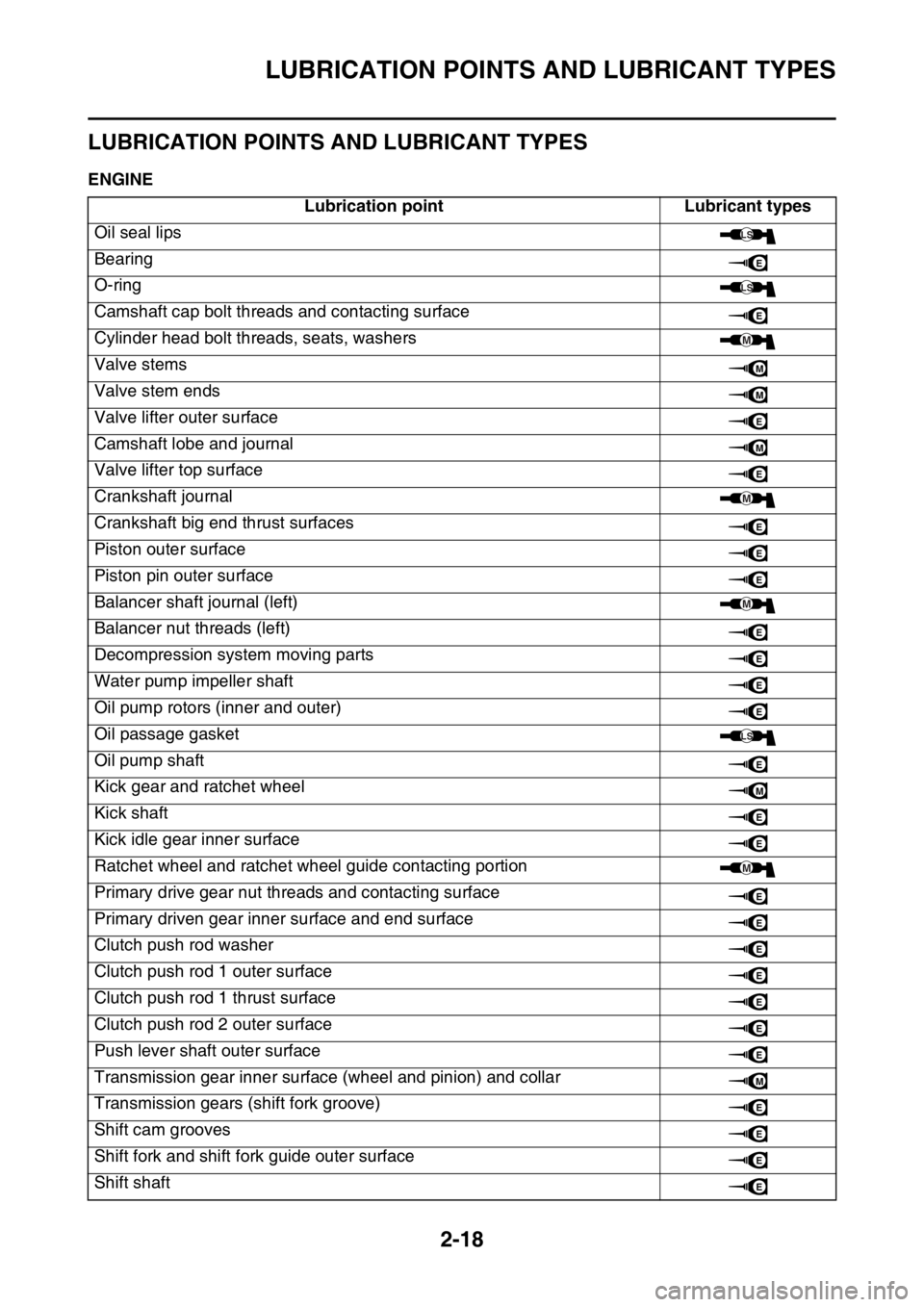

LUBRICATION POINTS AND LUBRICANT TYPES

EAS1SM9058ENGINE

Lubrication point Lubricant types

Oil seal lips

Bearing

O-ring

Camshaft cap bolt threads and contacting surface

Cylinder head bolt threads, seats, washers

Valve stems

Valve stem ends

Valve lifter outer surface

Camshaft lobe and journal

Valve lifter top surface

Crankshaft journal

Crankshaft big end thrust surfaces

Piston outer surface

Piston pin outer surface

Balancer shaft journal (left)

Balancer nut threads (left)

Decompression system moving parts

Water pump impeller shaft

Oil pump rotors (inner and outer)

Oil passage gasket

Oil pump shaft

Kick gear and ratchet wheel

Kick shaft

Kick idle gear inner surface

Ratchet wheel and ratchet wheel guide contacting portion

Primary drive gear nut threads and contacting surface

Primary driven gear inner surface and end surface

Clutch push rod washer

Clutch push rod 1 outer surface

Clutch push rod 1 thrust surface

Clutch push rod 2 outer surface

Push lever shaft outer surface

Transmission gear inner surface (wheel and pinion) and collar

Transmission gears (shift fork groove)

Shift cam grooves

Shift fork and shift fork guide outer surface

Shift shaft

LS

E

LS

E

M

M

M

E

M

E

M

E

E

E

M

E

E

E

E

LS

E

M

E

E

M

E

E

E

E

E

E

E

M

E

E

E

E

Page 83 of 356

3

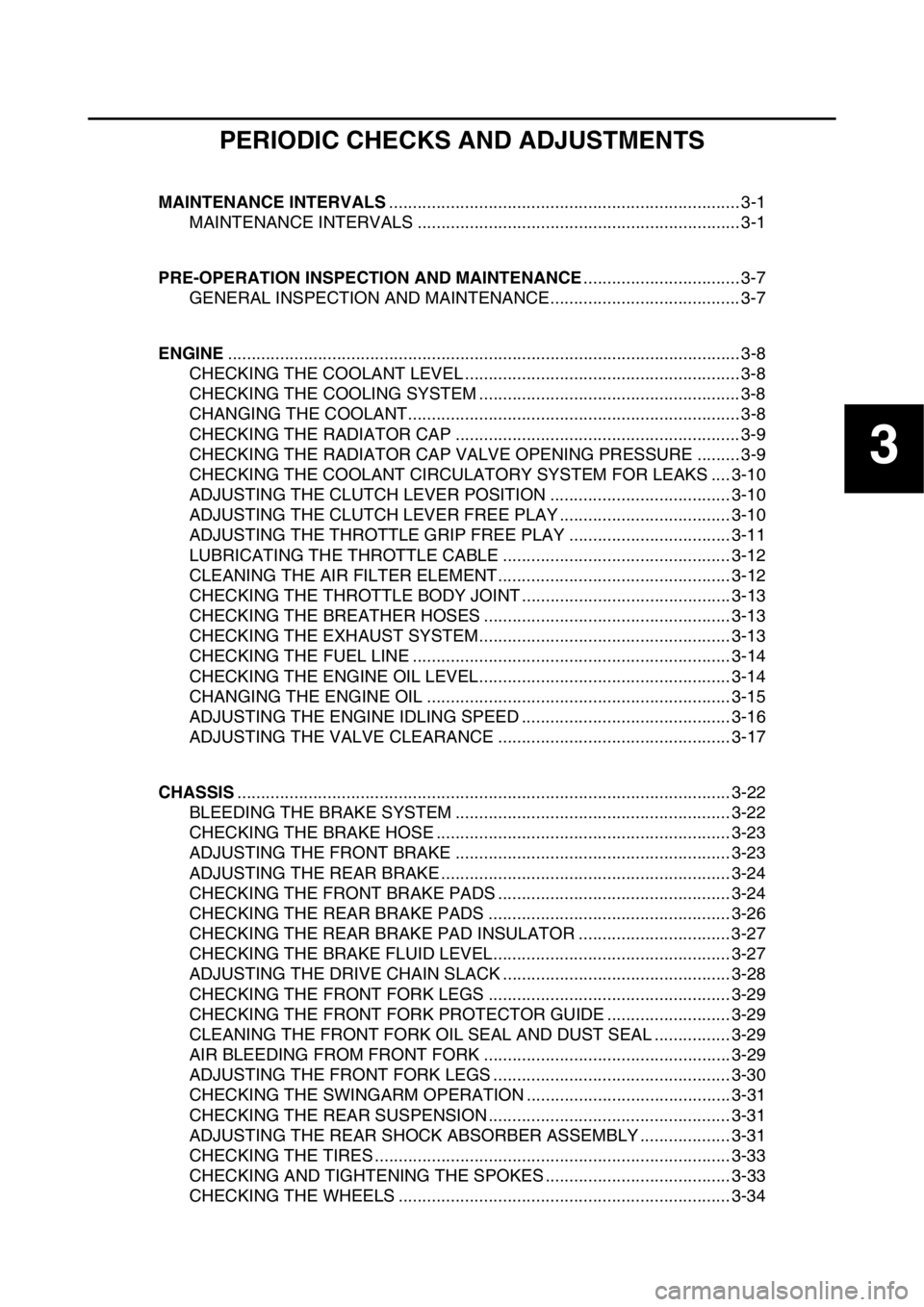

PERIODIC CHECKS AND ADJUSTMENTS

MAINTENANCE INTERVALS.......................................................................... 3-1

MAINTENANCE INTERVALS .................................................................... 3-1

PRE-OPERATION INSPECTION AND MAINTENANCE................................. 3-7

GENERAL INSPECTION AND MAINTENANCE........................................ 3-7

ENGINE............................................................................................................ 3-8

CHECKING THE COOLANT LEVEL .......................................................... 3-8

CHECKING THE COOLING SYSTEM ....................................................... 3-8

CHANGING THE COOLANT...................................................................... 3-8

CHECKING THE RADIATOR CAP ............................................................ 3-9

CHECKING THE RADIATOR CAP VALVE OPENING PRESSURE ......... 3-9

CHECKING THE COOLANT CIRCULATORY SYSTEM FOR LEAKS .... 3-10

ADJUSTING THE CLUTCH LEVER POSITION ...................................... 3-10

ADJUSTING THE CLUTCH LEVER FREE PLAY .................................... 3-10

ADJUSTING THE THROTTLE GRIP FREE PLAY .................................. 3-11

LUBRICATING THE THROTTLE CABLE ................................................ 3-12

CLEANING THE AIR FILTER ELEMENT................................................. 3-12

CHECKING THE THROTTLE BODY JOINT ............................................ 3-13

CHECKING THE BREATHER HOSES .................................................... 3-13

CHECKING THE EXHAUST SYSTEM..................................................... 3-13

CHECKING THE FUEL LINE ................................................................... 3-14

CHECKING THE ENGINE OIL LEVEL..................................................... 3-14

CHANGING THE ENGINE OIL ................................................................ 3-15

ADJUSTING THE ENGINE IDLING SPEED ............................................ 3-16

ADJUSTING THE VALVE CLEARANCE ................................................. 3-17

CHASSIS........................................................................................................ 3-22

BLEEDING THE BRAKE SYSTEM .......................................................... 3-22

CHECKING THE BRAKE HOSE .............................................................. 3-23

ADJUSTING THE FRONT BRAKE .......................................................... 3-23

ADJUSTING THE REAR BRAKE ............................................................. 3-24

CHECKING THE FRONT BRAKE PADS ................................................. 3-24

CHECKING THE REAR BRAKE PADS ................................................... 3-26

CHECKING THE REAR BRAKE PAD INSULATOR ................................ 3-27

CHECKING THE BRAKE FLUID LEVEL.................................................. 3-27

ADJUSTING THE DRIVE CHAIN SLACK ................................................ 3-28

CHECKING THE FRONT FORK LEGS ................................................... 3-29

CHECKING THE FRONT FORK PROTECTOR GUIDE .......................... 3-29

CLEANING THE FRONT FORK OIL SEAL AND DUST SEAL ................ 3-29

AIR BLEEDING FROM FRONT FORK .................................................... 3-29

ADJUSTING THE FRONT FORK LEGS .................................................. 3-30

CHECKING THE SWINGARM OPERATION ........................................... 3-31

CHECKING THE REAR SUSPENSION ................................................... 3-31

ADJUSTING THE REAR SHOCK ABSORBER ASSEMBLY ................... 3-31

CHECKING THE TIRES ........................................................................... 3-33

CHECKING AND TIGHTENING THE SPOKES ....................................... 3-33

CHECKING THE WHEELS ...................................................................... 3-34

Page 86 of 356

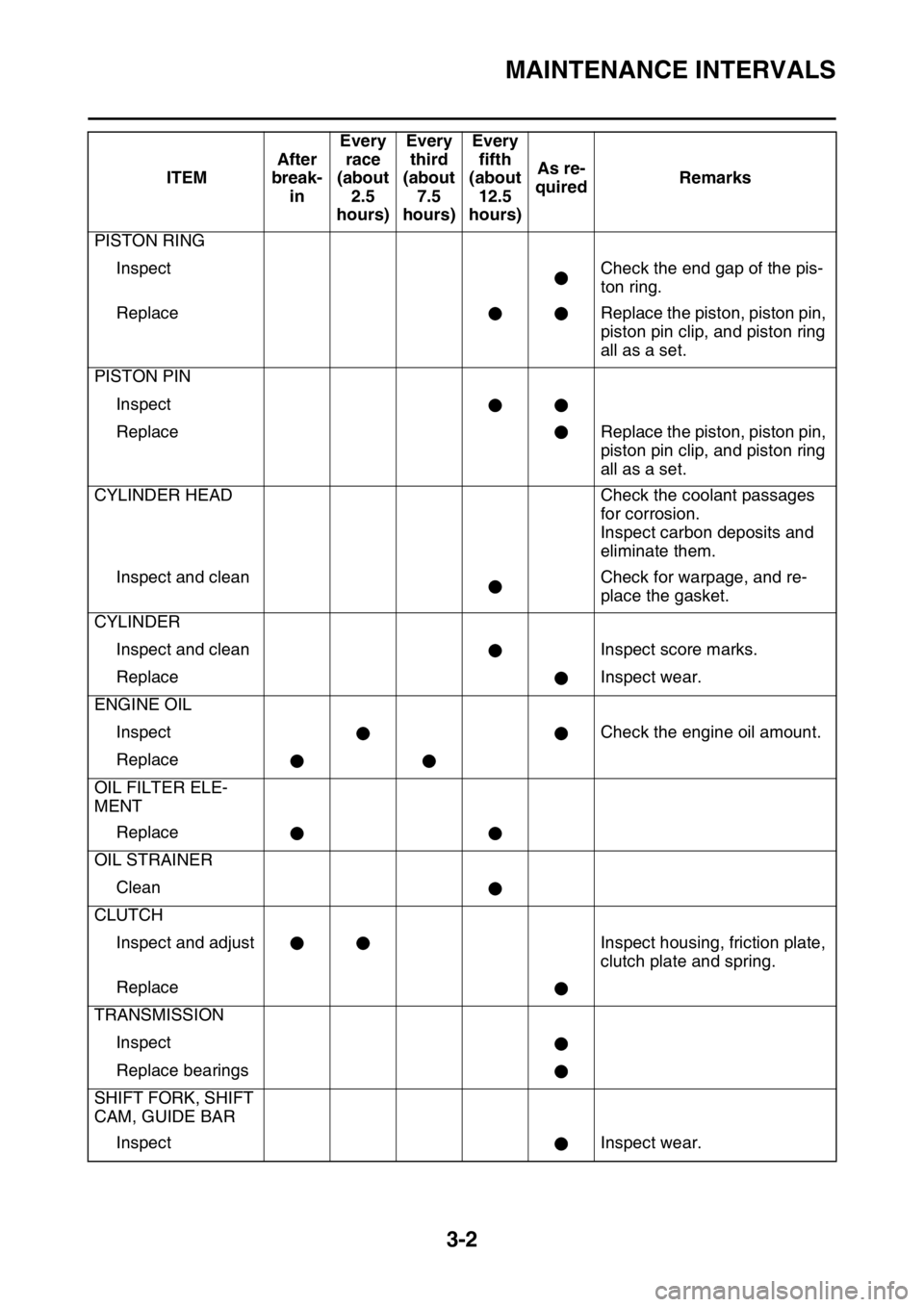

MAINTENANCE INTERVALS

3-2

PISTON RING

Inspect Check the end gap of the pis-

ton ring.

Replace Replace the piston, piston pin,

piston pin clip, and piston ring

all as a set.

PISTON PIN

Inspect

Replace Replace the piston, piston pin,

piston pin clip, and piston ring

all as a set.

CYLINDER HEAD Check the coolant passages

for corrosion.

Inspect carbon deposits and

eliminate them.

Inspect and clean Check for warpage, and re-

place the gasket.

CYLINDER

Inspect and clean Inspect score marks.

Replace Inspect wear.

ENGINE OIL

Inspect Check the engine oil amount.

Replace

OIL FILTER ELE-

MENT

Replace

OIL STRAINER

Clean

CLUTCH

Inspect and adjust Inspect housing, friction plate,

clutch plate and spring.

Replace

TRANSMISSION

Inspect

Replace bearings

SHIFT FORK, SHIFT

CAM, GUIDE BAR

Inspect Inspect wear.ITEMAfter

break-

inEvery

race

(about

2.5

hours)Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)As re-

quiredRemarks

Page 87 of 356

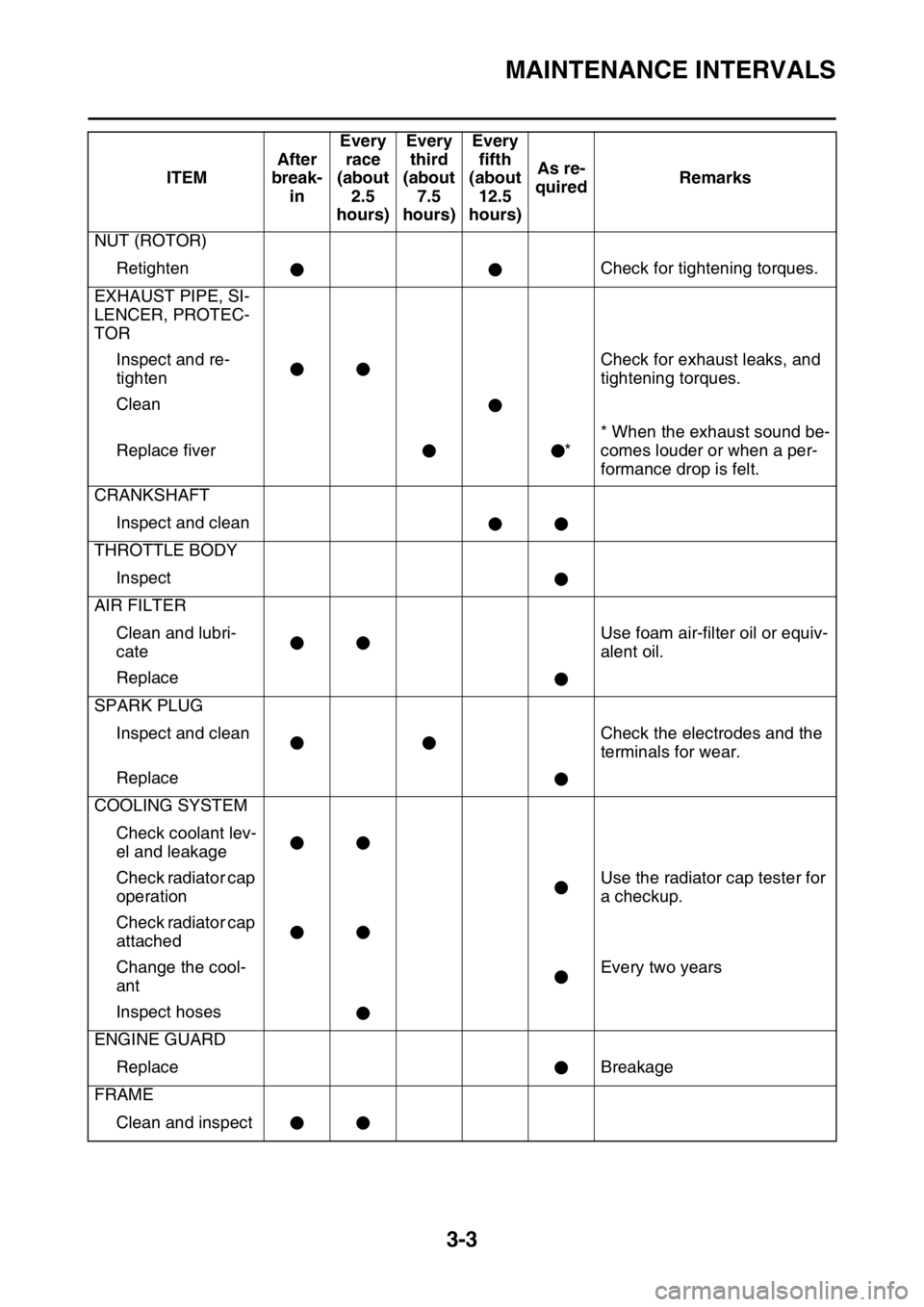

MAINTENANCE INTERVALS

3-3

NUT (ROTOR)

Retighten Check for tightening torques.

EXHAUST PIPE, SI-

LENCER, PROTEC-

TOR

Inspect and re-

tightenCheck for exhaust leaks, and

tightening torques.

Clean

Replace fiver ** When the exhaust sound be-

comes louder or when a per-

formance drop is felt.

CRANKSHAFT

Inspect and clean

THROTTLE BODY

Inspect

AIR FILTER

Clean and lubri-

cateUse foam air-filter oil or equiv-

alent oil.

Replace

SPARK PLUG

Inspect and clean Check the electrodes and the

terminals for wear.

Replace

COOLING SYSTEM

Check coolant lev-

el and leakage

Check radiator cap

operationUse the radiator cap tester for

a checkup.

Check radiator cap

attached

Change the cool-

antEvery two years

Inspect hoses

ENGINE GUARD

Replace Breakage

FRAME

Clean and inspectITEMAfter

break-

inEvery

race

(about

2.5

hours)Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)As re-

quiredRemarks