clutch YAMAHA YZ250F 2016 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZ250F, Model: YAMAHA YZ250F 2016Pages: 356, PDF Size: 11.25 MB

Page 155 of 356

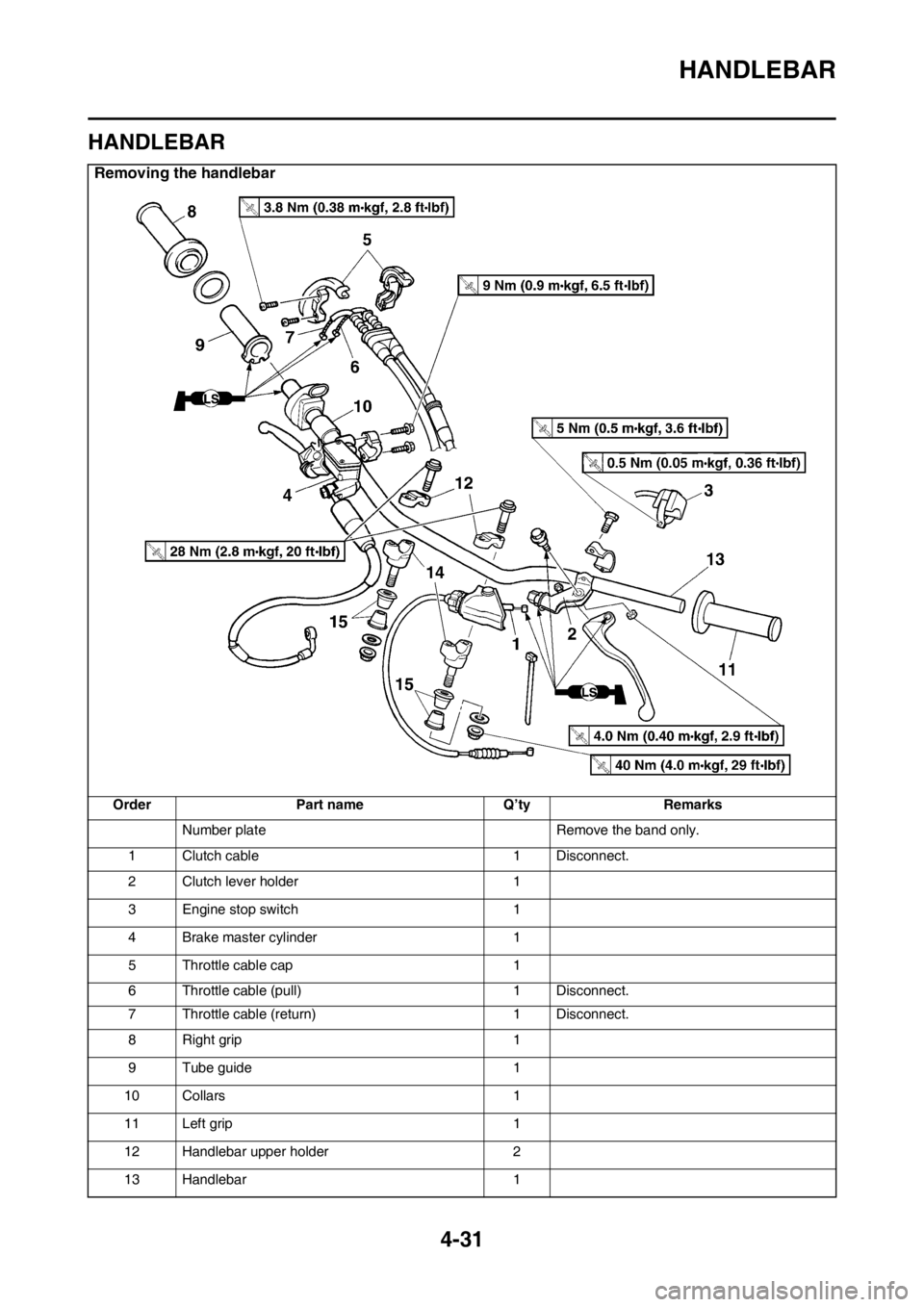

HANDLEBAR

4-31

EAS1SM9159

HANDLEBAR

Removing the handlebar

Order Part name Q’ty Remarks

Number plate Remove the band only.

1 Clutch cable 1 Disconnect.

2 Clutch lever holder 1

3 Engine stop switch 1

4 Brake master cylinder 1

5 Throttle cable cap 1

6 Throttle cable (pull) 1 Disconnect.

7 Throttle cable (return) 1 Disconnect.

8 Right grip 1

9 Tube guide 1

10 Collars 1

11 Left grip 1

12 Handlebar upper holder 2

13 Handlebar 1

Page 158 of 356

HANDLEBAR

4-34

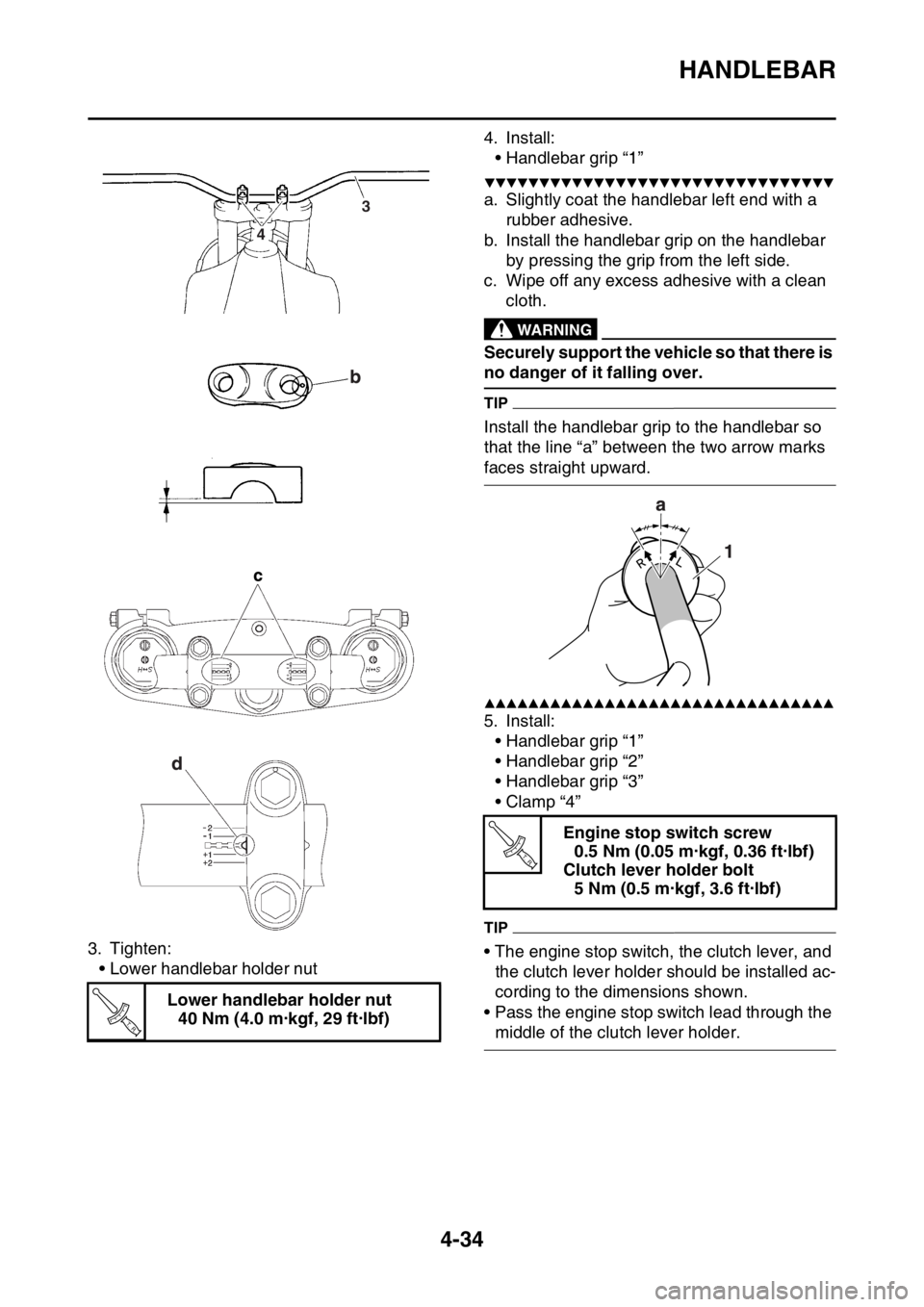

3. Tighten:

• Lower handlebar holder nut4. Install:

• Handlebar grip “1”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Slightly coat the handlebar left end with a

rubber adhesive.

b. Install the handlebar grip on the handlebar

by pressing the grip from the left side.

c. Wipe off any excess adhesive with a clean

cloth.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

TIP

Install the handlebar grip to the handlebar so

that the line “a” between the two arrow marks

faces straight upward.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Install:

• Handlebar grip “1”

• Handlebar grip “2”

• Handlebar grip “3”

•Clamp “4”

TIP

• The engine stop switch, the clutch lever, and

the clutch lever holder should be installed ac-

cording to the dimensions shown.

• Pass the engine stop switch lead through the

middle of the clutch lever holder. Lower handlebar holder nut

40 Nm (4.0 m·kgf, 29 ft·lbf)

3

4

T R..

Engine stop switch screw

0.5 Nm (0.05 m·kgf, 0.36 ft·lbf)

Clutch lever holder bolt

5 Nm (0.5 m·kgf, 3.6 ft·lbf)

T R..

Page 160 of 356

HANDLEBAR

4-36

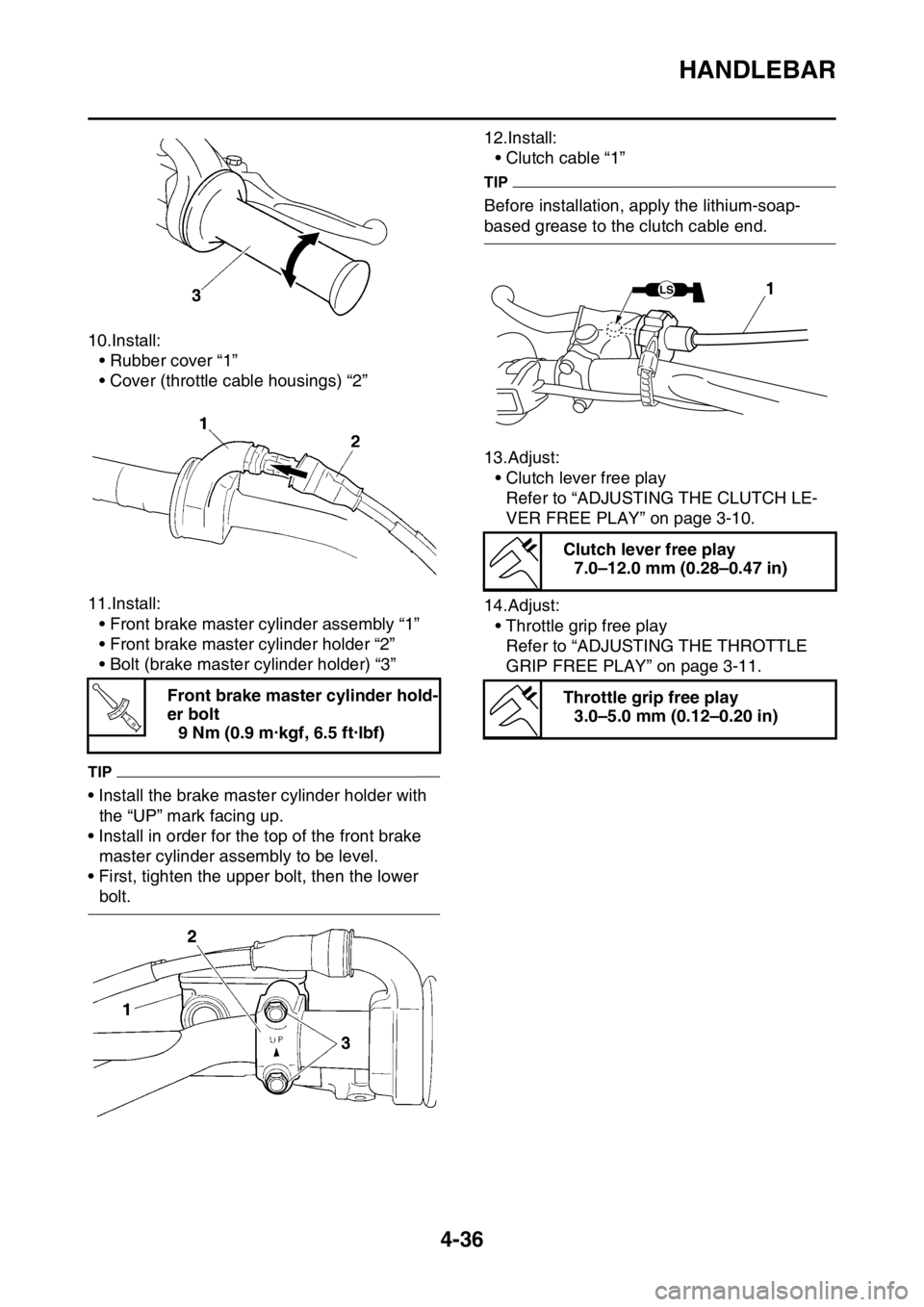

10.Install:

• Rubber cover “1”

• Cover (throttle cable housings) “2”

11.Install:

• Front brake master cylinder assembly “1”

• Front brake master cylinder holder “2”

• Bolt (brake master cylinder holder) “3”

TIP

• Install the brake master cylinder holder with

the “UP” mark facing up.

• Install in order for the top of the front brake

master cylinder assembly to be level.

• First, tighten the upper bolt, then the lower

bolt.12.Install:

• Clutch cable “1”

TIP

Before installation, apply the lithium-soap-

based grease to the clutch cable end.

13.Adjust:

• Clutch lever free play

Refer to “ADJUSTING THE CLUTCH LE-

VER FREE PLAY” on page 3-10.

14.Adjust:

• Throttle grip free play

Refer to “ADJUSTING THE THROTTLE

GRIP FREE PLAY” on page 3-11.

Front brake master cylinder hold-

er bolt

9 Nm (0.9 m·kgf, 6.5 ft·lbf)

T R..

Clutch lever free play

7.0–12.0 mm (0.28–0.47 in)

Throttle grip free play

3.0–5.0 mm (0.12–0.20 in)

1LS

Page 192 of 356

CLUTCH......................................................................................................... 5-35

REMOVING THE CLUTCH ...................................................................... 5-38

CHECKING THE FRICTION PLATES...................................................... 5-38

CHECKING THE CLUTCH PLATES ........................................................ 5-38

CHECKING THE CLUTCH SPRINGS...................................................... 5-38

CHECKING THE CLUTCH HOUSING ..................................................... 5-39

CHECKING THE CLUTCH BOSS ............................................................ 5-39

CHECKING THE PRESSURE PLATE ..................................................... 5-39

CHECKING THE PUSH LEVER SHAFT .................................................. 5-39

CHECKING THE CLUTCH PUSH RODS ................................................ 5-39

CHECKING THE PRIMARY DRIVE GEAR .............................................. 5-39

CHECKING THE PRIMARY DRIVEN GEAR ........................................... 5-40

INSTALLING THE OIL SEAL................................................................... 5-40

INSTALLING THE RIGHT CRANKCASE COVER ................................... 5-40

INSTALLING THE CLUTCH ..................................................................... 5-41

INSTALLING THE KICKSTARTER LEVER ............................................. 5-43

KICKSTATER................................................................................................. 5-44

REMOVING THE KICK SHAFT ASSEMBLY ........................................... 5-45

CHECKING THE KICK SHAFT AND RATCHET WHEEL ........................ 5-45

CHECKING THE KICK GEAR, KICK IDLE GEAR AND

RATCHET WHEEL .................................................................................. 5-45

INSTALLING THE KICK SHAFT ASSEMBLY .......................................... 5-45

INSTALLING THE KICK IDLE GEAR ....................................................... 5-46

SHIFT SHAFT................................................................................................. 5-47

REMOVING THE SHIFT GUIDE AND SHIFT LEVER ASSEMBLY ......... 5-49

REMOVING THE SEGMENT ................................................................... 5-49

CHECKING THE SHIFT SHAFT .............................................................. 5-49

CHECKING THE SHIFT GUIDE AND SHIFT LEVER ASSEMBLY ......... 5-49

CHECKING THE STOPPER LEVER ....................................................... 5-49

INSTALLING THE STOPPER LEVER ..................................................... 5-50

INSTALLING THE SEGMENT.................................................................. 5-50

INSTALLING THE SHIFT GUIDE AND SHIFT LEVER ASSEMBLY ....... 5-50

INSTALLING THE SHIFT SHAFT ............................................................ 5-51

INSTALLING THE SHIFT PEDAL ............................................................ 5-51

OIL PUMP AND BALANCER GEAR............................................................. 5-52

REMOVING THE BALANCER ................................................................. 5-54

CHECKING THE PRIMARY DRIVE GEAR, BALANCER SHAFT DRIVE

GEAR, AND BALANCER WEIGHT GEAR .............................................. 5-54

CHECKING THE BALANCER .................................................................. 5-54

CHECKING THE OIL PUMP .................................................................... 5-54

ASSEMBLING THE OIL PUMP ................................................................ 5-55

INSTALLING THE OIL PUMP AND BALANCER GEAR .......................... 5-55

Page 197 of 356

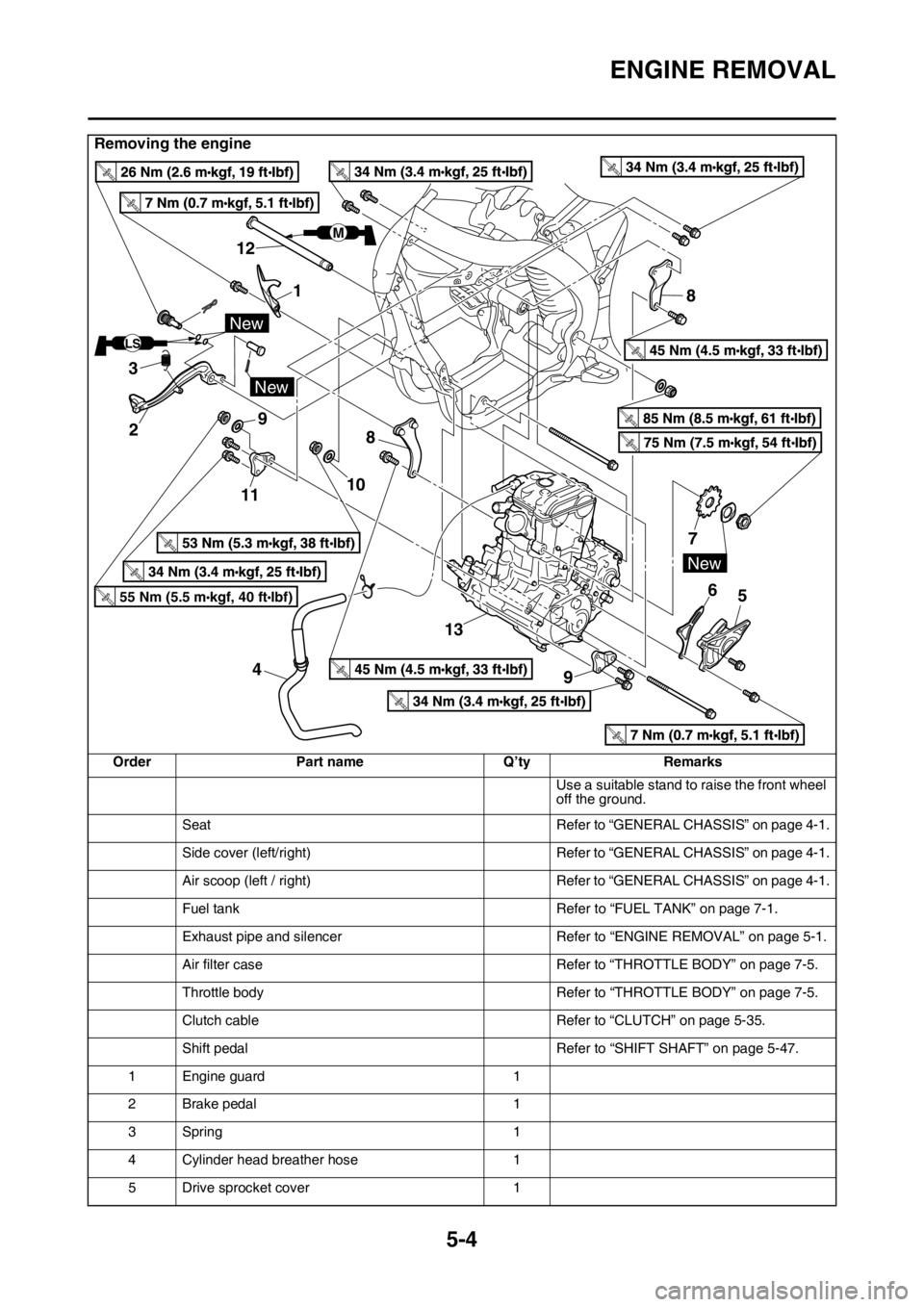

ENGINE REMOVAL

5-4

Removing the engine

Order Part name Q’ty Remarks

Use a suitable stand to raise the front wheel

off the ground.

Seat Refer to “GENERAL CHASSIS” on page 4-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left / right) Refer to “GENERAL CHASSIS” on page 4-1.

Fuel tank Refer to “FUEL TANK” on page 7-1.

Exhaust pipe and silencer Refer to “ENGINE REMOVAL” on page 5-1.

Air filter case Refer to “THROTTLE BODY” on page 7-5.

Throttle body Refer to “THROTTLE BODY” on page 7-5.

Clutch cable Refer to “CLUTCH” on page 5-35.

Shift pedal Refer to “SHIFT SHAFT” on page 5-47.

1 Engine guard 1

2 Brake pedal 1

3Spring 1

4 Cylinder head breather hose 1

5 Drive sprocket cover 1

New

New

LS

M

8

8

7

6

13

45

New

1 12

3

2

1110 9

55 Nm (5.5 mkgf, 40 ftIbf)T.R.

Page 228 of 356

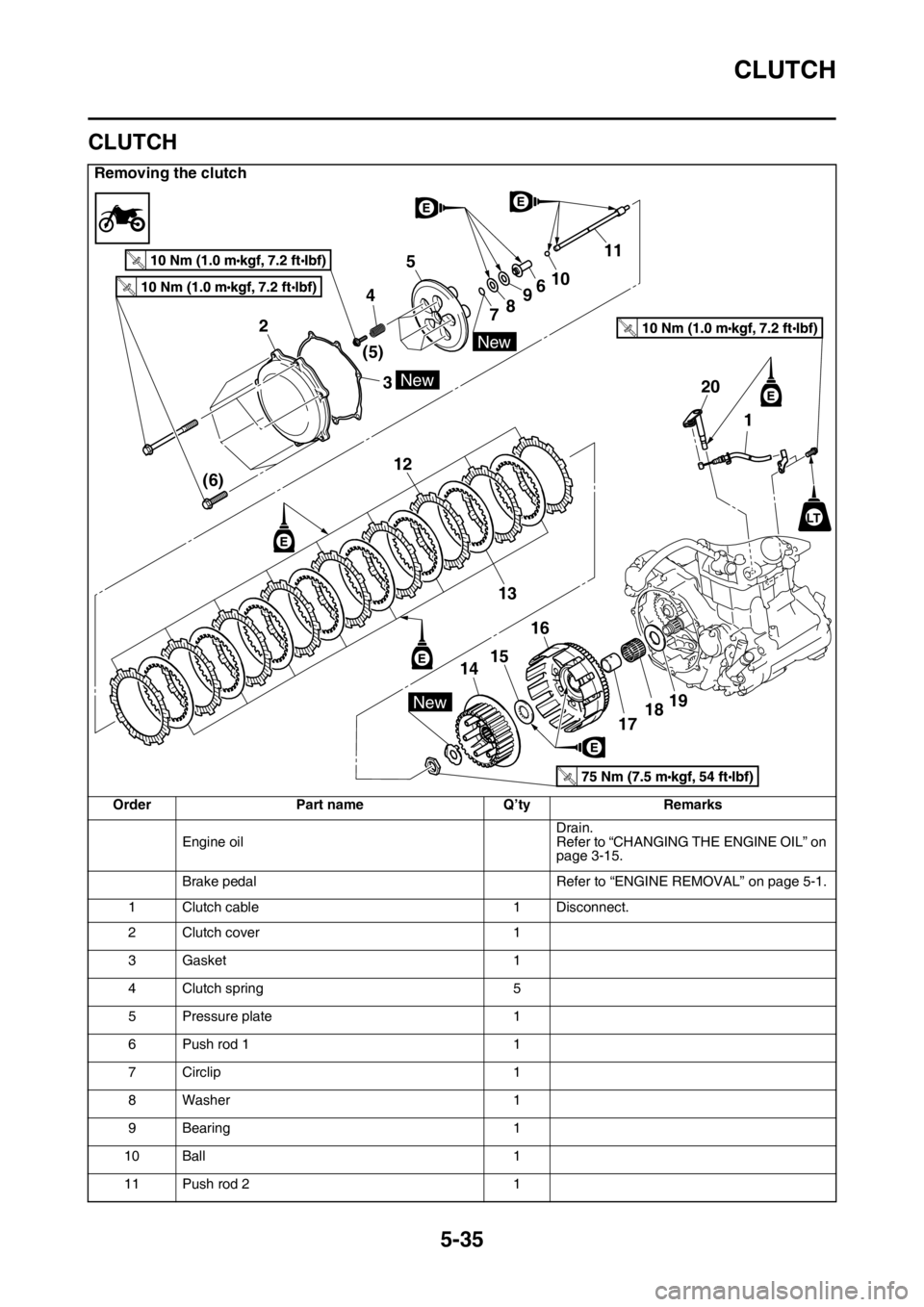

CLUTCH

5-35

EAS1SM9230

CLUTCH

Removing the clutch

Order Part name Q’ty Remarks

Engine oilDrain.

Refer to “CHANGING THE ENGINE OIL” on

page 3-15.

Brake pedal Refer to “ENGINE REMOVAL” on page 5-1.

1 Clutch cable 1 Disconnect.

2 Clutch cover 1

3Gasket 1

4 Clutch spring 5

5 Pressure plate 1

6 Push rod 1 1

7 Circlip 1

8Washer 1

9 Bearing 1

10 Ball 1

11 Push rod 2 1

New

New

New

2

3 45

(5)

(6)78961011

20

1

12

13

16

1718 15

14

T.R.

T.R.

T.R.

T.R.

LT

19

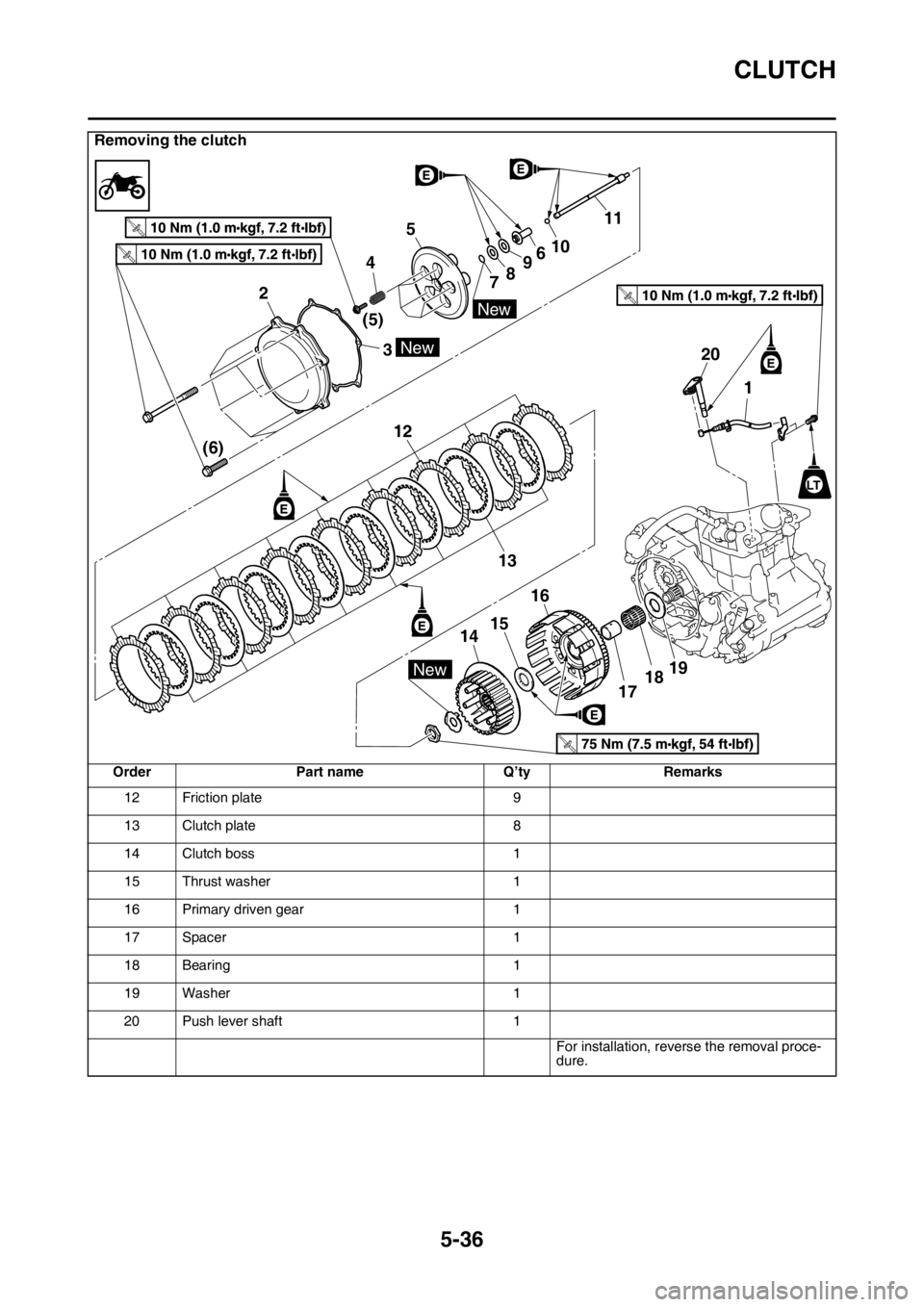

Page 229 of 356

CLUTCH

5-36

12 Friction plate 9

13 Clutch plate 8

14 Clutch boss 1

15 Thrust washer 1

16 Primary driven gear 1

17 Spacer 1

18 Bearing 1

19 Washer 1

20 Push lever shaft 1

For installation, reverse the removal proce-

dure.

Removing the clutch

Order Part name Q’ty Remarks

New

New

New

2

3 45

(5)

(6)78961011

20

1

12

13

16

1718 15

14

T.R.

T.R.

T.R.

T.R.

LT

19

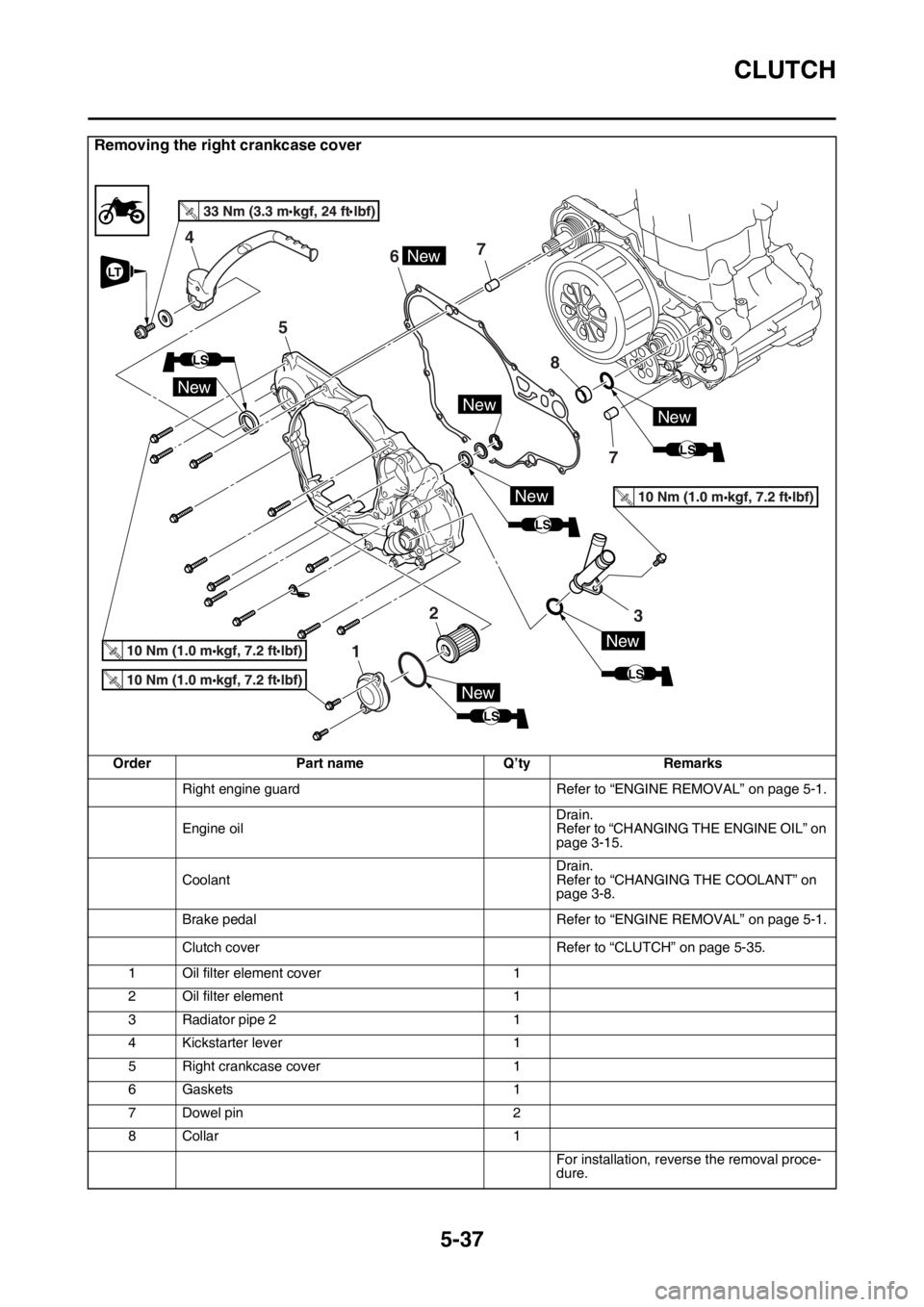

Page 230 of 356

CLUTCH

5-37

Removing the right crankcase cover

Order Part name Q’ty Remarks

Right engine guard Refer to “ENGINE REMOVAL” on page 5-1.

Engine oilDrain.

Refer to “CHANGING THE ENGINE OIL” on

page 3-15.

CoolantDrain.

Refer to “CHANGING THE COOLANT” on

page 3-8.

Brake pedal Refer to “ENGINE REMOVAL” on page 5-1.

Clutch cover Refer to “CLUTCH” on page 5-35.

1 Oil filter element cover 1

2 Oil filter element 1

3 Radiator pipe 2 1

4 Kickstarter lever 1

5 Right crankcase cover 1

6 Gaskets 1

7 Dowel pin 2

8Collar 1

For installation, reverse the removal proce-

dure.

T.R.

LS

New

New

67

2

5

4

1

7 8

New

3

LS

New

New

LS

NewNew

LT

LS

Page 231 of 356

CLUTCH

5-38

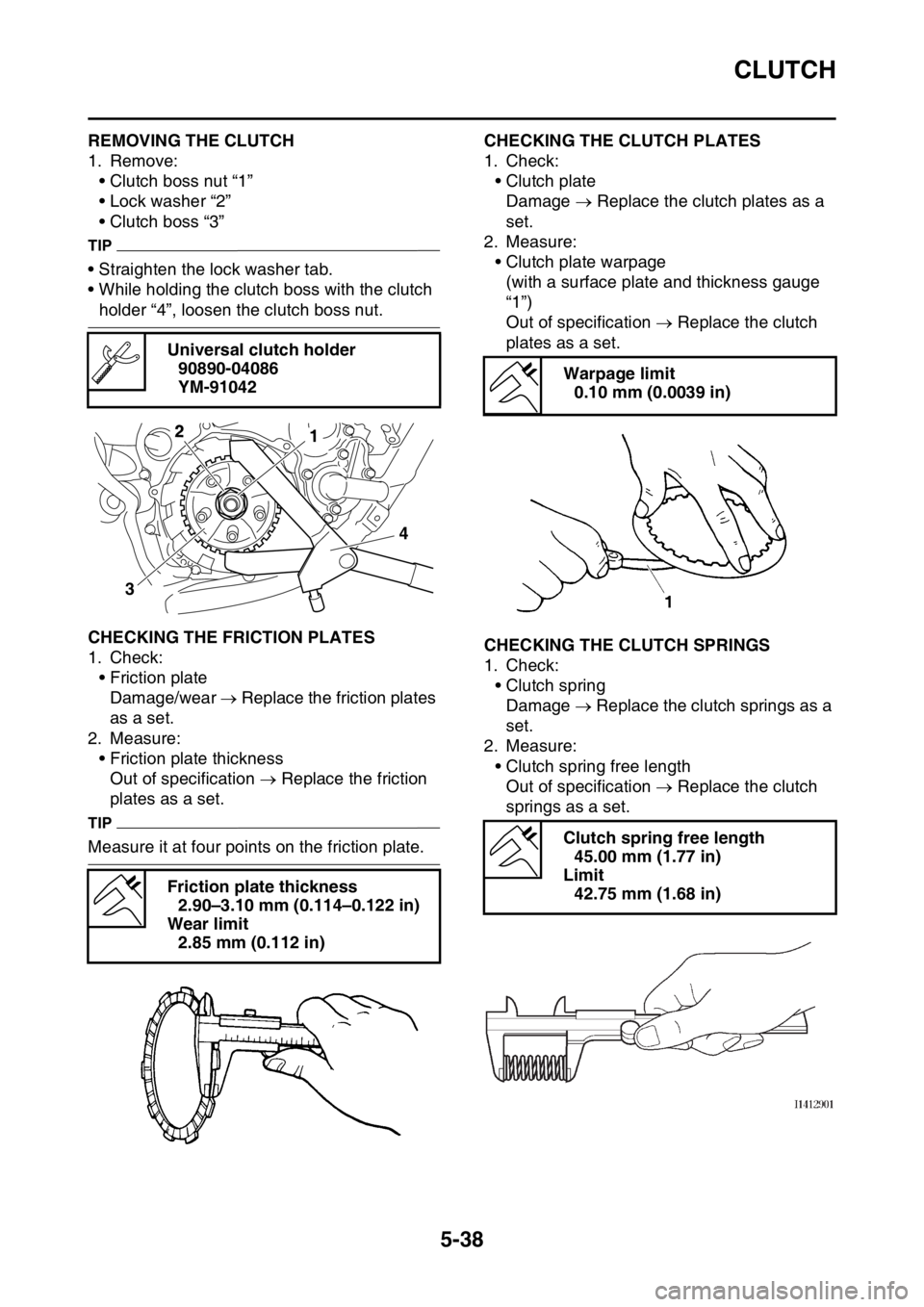

EAS1SM9231REMOVING THE CLUTCH

1. Remove:

• Clutch boss nut “1”

• Lock washer “2”

• Clutch boss “3”

TIP

• Straighten the lock washer tab.

• While holding the clutch boss with the clutch

holder “4”, loosen the clutch boss nut.

EAS1SM9232CHECKING THE FRICTION PLATES

1. Check:

• Friction plate

Damage/wear Replace the friction plates

as a set.

2. Measure:

• Friction plate thickness

Out of specification Replace the friction

plates as a set.

TIP

Measure it at four points on the friction plate.

EAS1SM9233CHECKING THE CLUTCH PLATES

1. Check:

• Clutch plate

Damage Replace the clutch plates as a

set.

2. Measure:

• Clutch plate warpage

(with a surface plate and thickness gauge

“1”)

Out of specification Replace the clutch

plates as a set.

EAS1SM9234CHECKING THE CLUTCH SPRINGS

1. Check:

• Clutch spring

Damage Replace the clutch springs as a

set.

2. Measure:

• Clutch spring free length

Out of specification Replace the clutch

springs as a set. Universal clutch holder

90890-04086

YM-91042

Friction plate thickness

2.90–3.10 mm (0.114–0.122 in)

Wear limit

2.85 mm (0.112 in)

34

12

Warpage limit

0.10 mm (0.0039 in)

Clutch spring free length

45.00 mm (1.77 in)

Limit

42.75 mm (1.68 in)

Page 232 of 356

CLUTCH

5-39

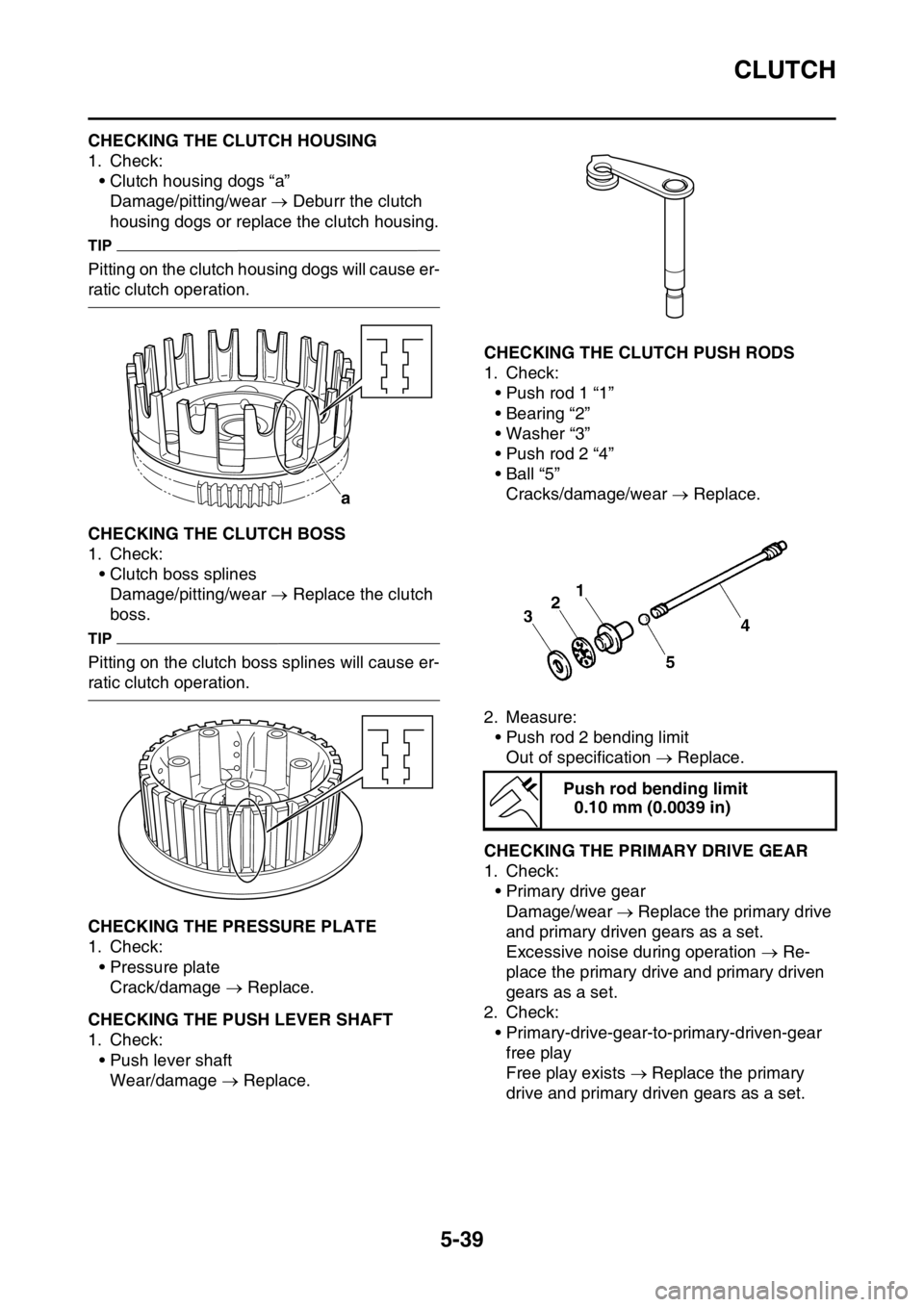

EAS1SM9235CHECKING THE CLUTCH HOUSING

1. Check:

• Clutch housing dogs “a”

Damage/pitting/wear Deburr the clutch

housing dogs or replace the clutch housing.

TIP

Pitting on the clutch housing dogs will cause er-

ratic clutch operation.

EAS1SM9236CHECKING THE CLUTCH BOSS

1. Check:

• Clutch boss splines

Damage/pitting/wear Replace the clutch

boss.

TIP

Pitting on the clutch boss splines will cause er-

ratic clutch operation.

EAS1SM9237CHECKING THE PRESSURE PLATE

1. Check:

• Pressure plate

Crack/damage Replace.

EAS1SM9238CHECKING THE PUSH LEVER SHAFT

1. Check:

• Push lever shaft

Wear/damage Replace.

EAS1SM9239CHECKING THE CLUTCH PUSH RODS

1. Check:

• Push rod 1 “1”

• Bearing “2”

• Washer “3”

• Push rod 2 “4”

•Ball “5”

Cracks/damage/wear Replace.

2. Measure:

• Push rod 2 bending limit

Out of specification Replace.

EAS1SM9240CHECKING THE PRIMARY DRIVE GEAR

1. Check:

• Primary drive gear

Damage/wear Replace the primary drive

and primary driven gears as a set.

Excessive noise during operation Re-

place the primary drive and primary driven

gears as a set.

2. Check:

• Primary-drive-gear-to-primary-driven-gear

free play

Free play exists Replace the primary

drive and primary driven gears as a set.

a

Push rod bending limit

0.10 mm (0.0039 in)