brake YAMAHA YZ250LC 2001 Manuale duso (in Italian)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ250LC, Model: YAMAHA YZ250LC 2001Pages: 578, PDF Dimensioni: 14.12 MB

Page 120 of 578

2-15

CABLE ROUTING DIAGRAMSPEC

1Brake hose holder

2Master cylinder

3Brake hose

4Reservoir hose

5Hose guide

6Clamp

7High tension cord

8Ignition coil

9Clutch cable

0Cable guide

qGround lead

wRadiator breather hose

eCDI magneto lead

rThrottle cable

tCDI unit lead

y“ENGINE STOP” button lead

uFuel tank damper

iEngine bracket

APass the brake hose into the

brake hose holder.BIf the brake hose contacts the

spring (rear shock absorber),

correct its twist.

CInstall the brake hose so that its

pipe portion directs as shown

and lightly touches the projec-

tion on the master cylinder.

DPass the reservoir hose

between the brake hose and

swingarm bracket.

EPass the reservoir hose into the

hose guide.

FClamp the high tension cord,

throttle cable, TPS (throttle posi-

tion sensor) and solenoid valve

lead so that the high tension

cord does not contact the

engine bracket installation nuts.

G

Fasten the ground lead together

with the front installation portion

of the ingnition coil.

HPass the clutch cable into the

cable guide.

IPosition the CDI magneto lead

coupler between the radiators.

JInstall the brake hose to the

caliper with the paint on the pipe

facing the caliper and with the

pipe contacting the caliper pro-

jection.

KPass the radiator breather hose

between the frame and radiator

hose so that it is not kinked or

wedged.

LPass the throttle cable, CDI unit

lead, “ENGINE STOP” button

lead and clutch cable between

the fuel tank damper tube ends.

5MW-9-30-2 7/3/00 2:26 PM Page 54

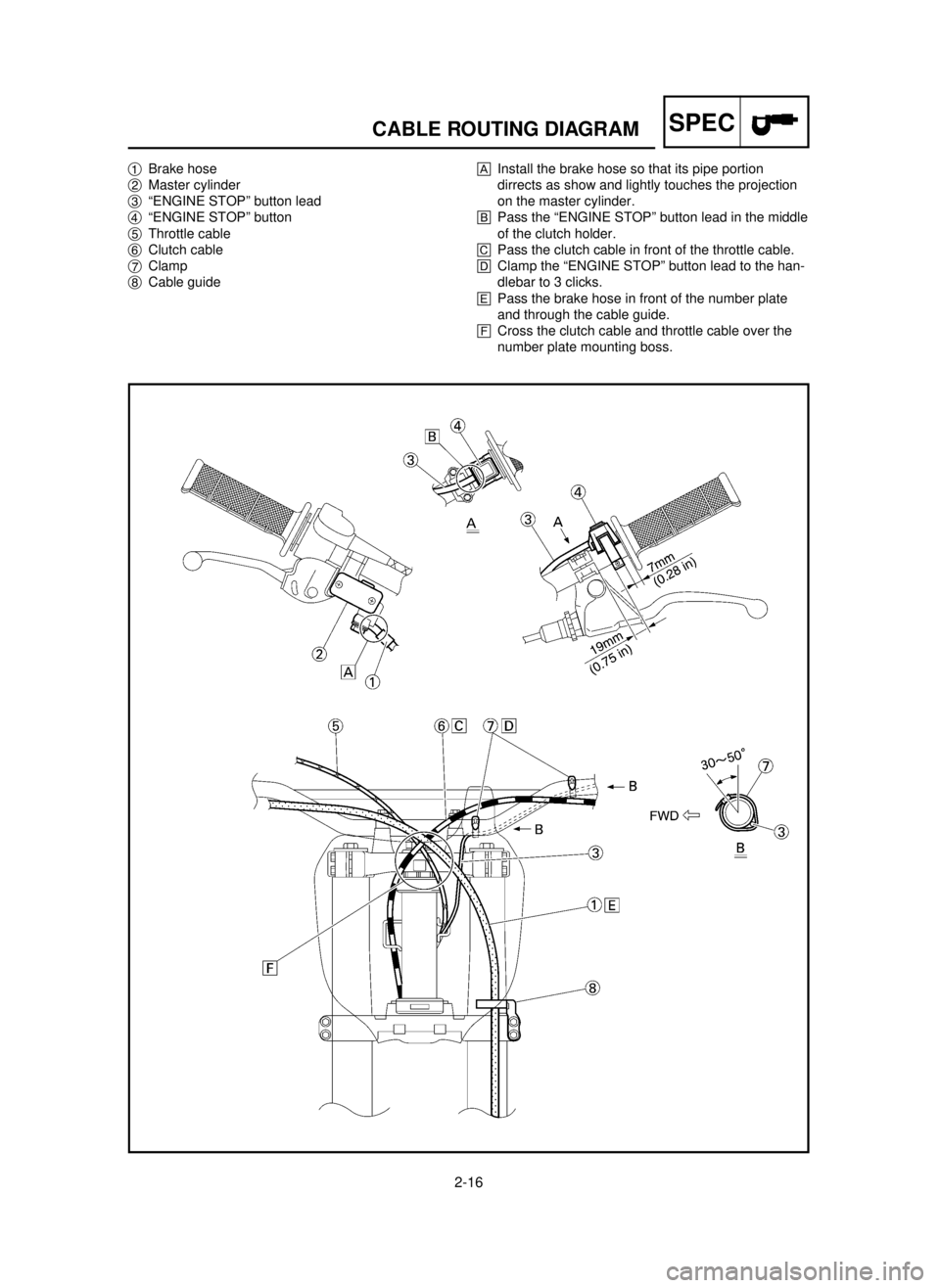

Page 122 of 578

2-16

CABLE ROUTING DIAGRAMSPEC

1Brake hose

2Master cylinder

3“ENGINE STOP” button lead

4“ENGINE STOP” button

5Throttle cable

6Clutch cable

7Clamp

8Cable guideAInstall the brake hose so that its pipe portion

dirrects as show and lightly touches the projection

on the master cylinder.

BPass the “ENGINE STOP” button lead in the middle

of the clutch holder.

CPass the clutch cable in front of the throttle cable.

DClamp the “ENGINE STOP” button lead to the han-

dlebar to 3 clicks.

EPass the brake hose in front of the number plate

and through the cable guide.

FCross the clutch cable and throttle cable over the

number plate mounting boss.

5MW-9-30-2 7/3/00 2:27 PM Page 56

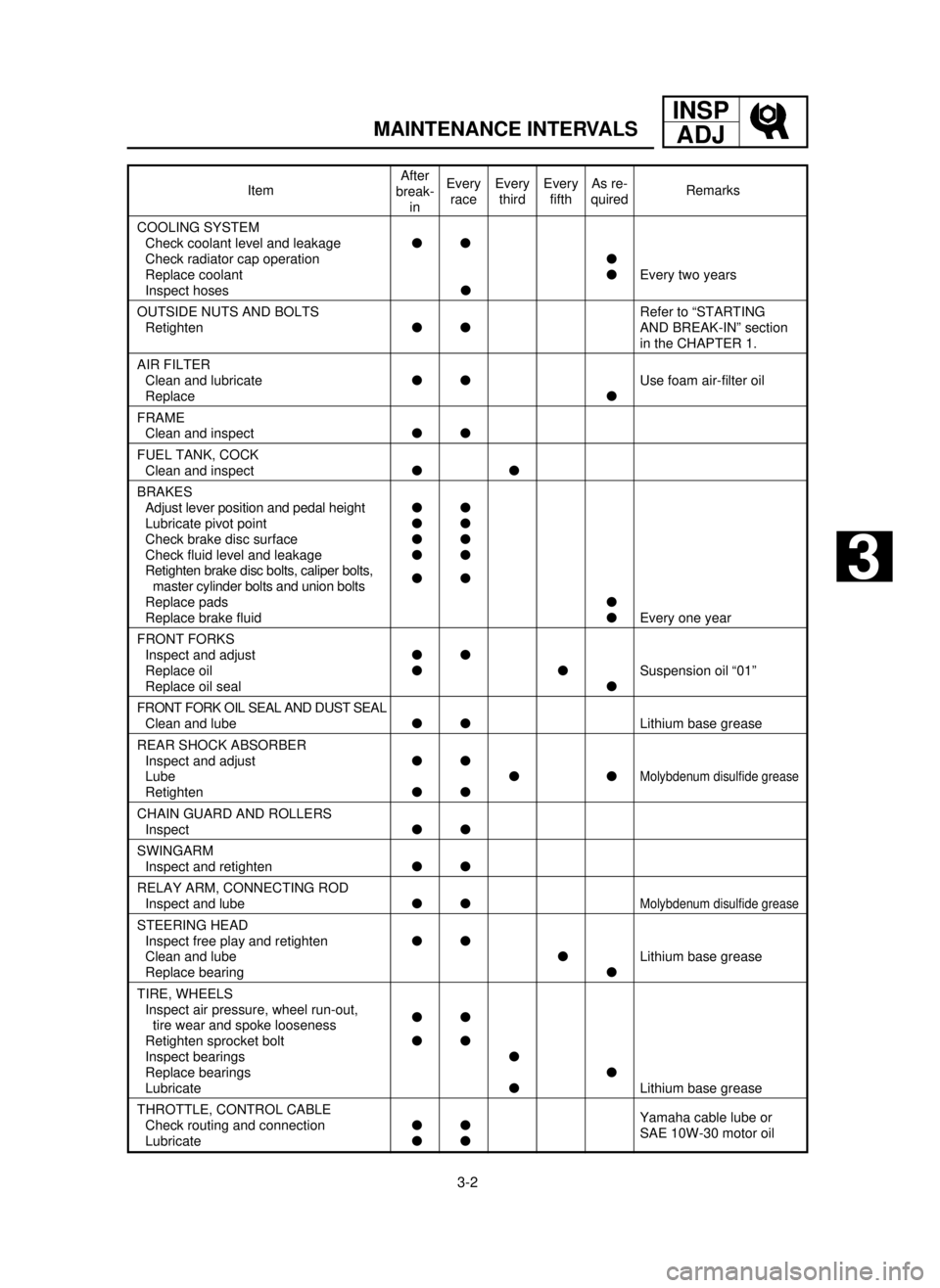

Page 125 of 578

INSP

ADJ

3-2

MAINTENANCE INTERVALS

3

Item Remarks

COOLING SYSTEM

Check coolant level and leakagell

Check radiator cap operationl

Replace coolantlEvery two years

Inspect hosesl

OUTSIDE NUTS AND BOLTS Refer to “STARTING

RetightenllAND BREAK-IN” section

in the CHAPTER 1.

AIR FILTER

Clean and lubricatellUse foam air-filter oil

Replacel

FRAME

Clean and inspectll

FUEL TANK, COCK

Clean and inspectll

BRAKES

Adjust lever position and pedal heightll

Lubricate pivot pointll

Check brake disc surfacell

Check fluid level and leakagell

Retighten brake disc bolts, caliper bolts,

ll

master cylinder bolts and union bolts

Replace padsl

Replace brake fluidlEvery one year

FRONT FORKS

Inspect and adjustll

Replace oilllSuspension oil “01”

Replace oil seall

FRONT FORK OIL SEAL AND DUST SEAL

Clean and lubellLithium base grease

REAR SHOCK ABSORBER

Inspect and adjustll

Lube ll

Molybdenum disulfide grease

Retightenll

CHAIN GUARD AND ROLLERS

Inspectll

SWINGARM

Inspect and retightenll

RELAY ARM, CONNECTING ROD

Inspect and lubellMolybdenum disulfide grease

STEERING HEAD

Inspect free play and retightenll

Clean and lubelLithium base grease

Replace bearingl

TIRE, WHEELS

Inspect air pressure, wheel run-out,

ll

tire wear and spoke looseness

Retighten sprocket boltll

Inspect bearingsl

Replace bearingsl

LubricatelLithium base grease

THROTTLE, CONTROL CABLE

Check routing and connectionllYamaha cable lube or

LubricatellSAE 10W-30 motor oil

After

break-

inEvery

raceEvery

thirdEvery

fifthAs re-

quired

5MW-9-30-3A 7/3/00 2:46 PM Page 3

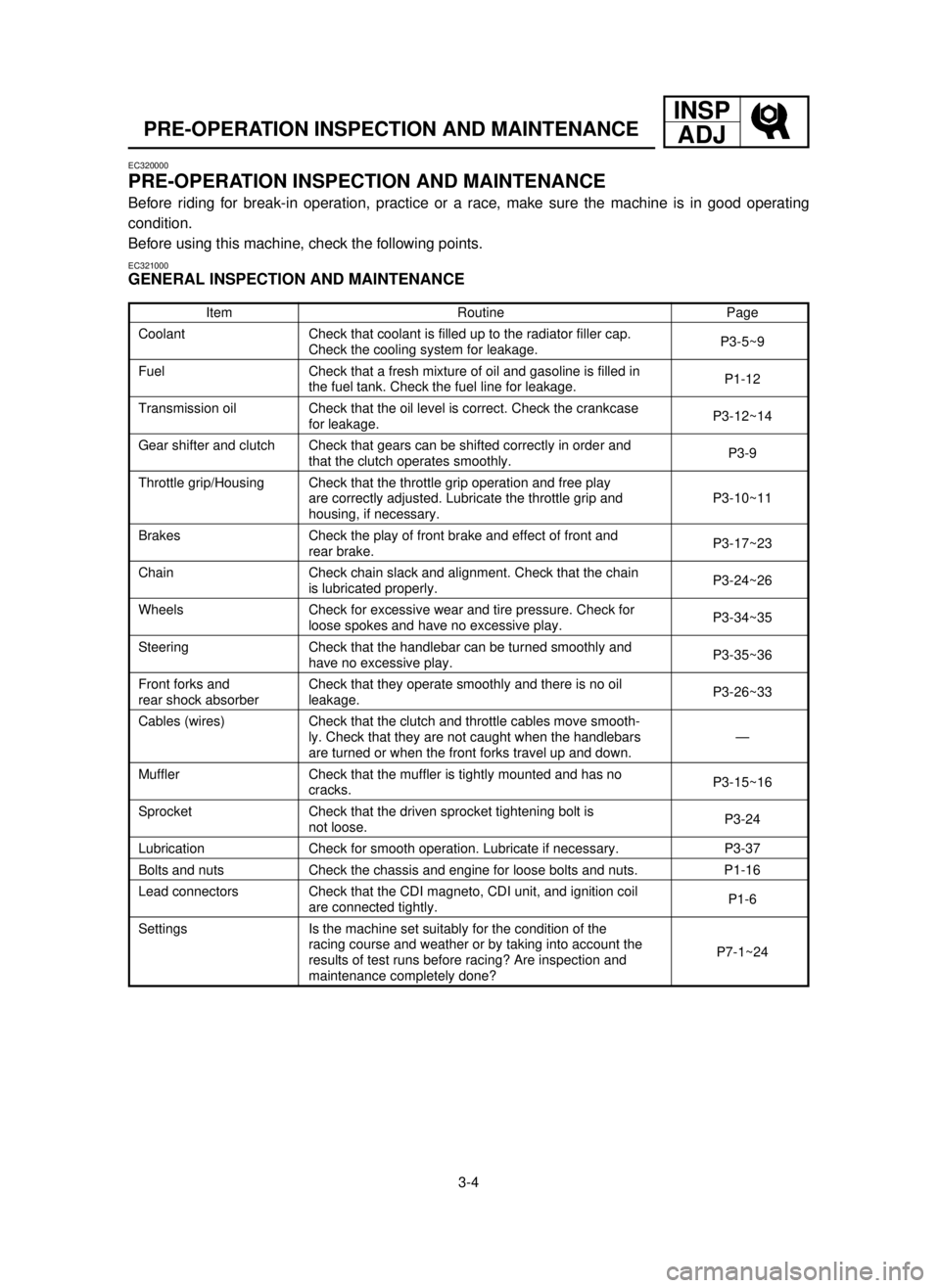

Page 136 of 578

3-4

PRE-OPERATION INSPECTION AND MAINTENANCE

INSP

ADJ

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

EC321000

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

Coolant Check that coolant is filled up to the radiator filler cap.

Check the cooling system for leakage.P3-5~9

Fuel Check that a fresh mixture of oil and gasoline is filled in

the fuel tank. Check the fuel line for leakage.P1-12

Transmission oil Check that the oil level is correct. Check the crankcase

for leakage.P3-12~14

Gear shifter and clutch Check that gears can be shifted correctly in order and

that the clutch operates smoothly.P3-9

Throttle grip/Housing Check that the throttle grip operation and free play

are correctly adjusted. Lubricate the throttle grip and P3-10~11

housing, if necessary.

Brakes Check the play of front brake and effect of front and

rear brake.P3-17~23

Chain Check chain slack and alignment. Check that the chain

is lubricated properly.P3-24~26

Wheels Check for excessive wear and tire pressure. Check for

loose spokes and have no excessive play.P3-34~35

Steering Check that the handlebar can be turned smoothly and

have no excessive play.P3-35~36

Front forks and Check that they operate smoothly and there is no oil

rear shock absorber leakage.P3-26~33

Cables (wires) Check that the clutch and throttle cables move smooth-

ly. Check that they are not caught when the handlebars —

are turned or when the front forks travel up and down.

Muffler Check that the muffler is tightly mounted and has no

cracks.P3-15~16

Sprocket Check that the driven sprocket tightening bolt is

not loose.P3-24

Lubrication Check for smooth operation. Lubricate if necessary. P3-37

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P1-16

Lead connectors Check that the CDI magneto, CDI unit, and ignition coil

are connected tightly.P1-6

Settings Is the machine set suitably for the condition of the

racing course and weather or by taking into account the

P7-1~24

results of test runs before racing? Are inspection and

maintenance completely done?

5MW-9-30-3A 7/3/00 2:47 PM Page 14

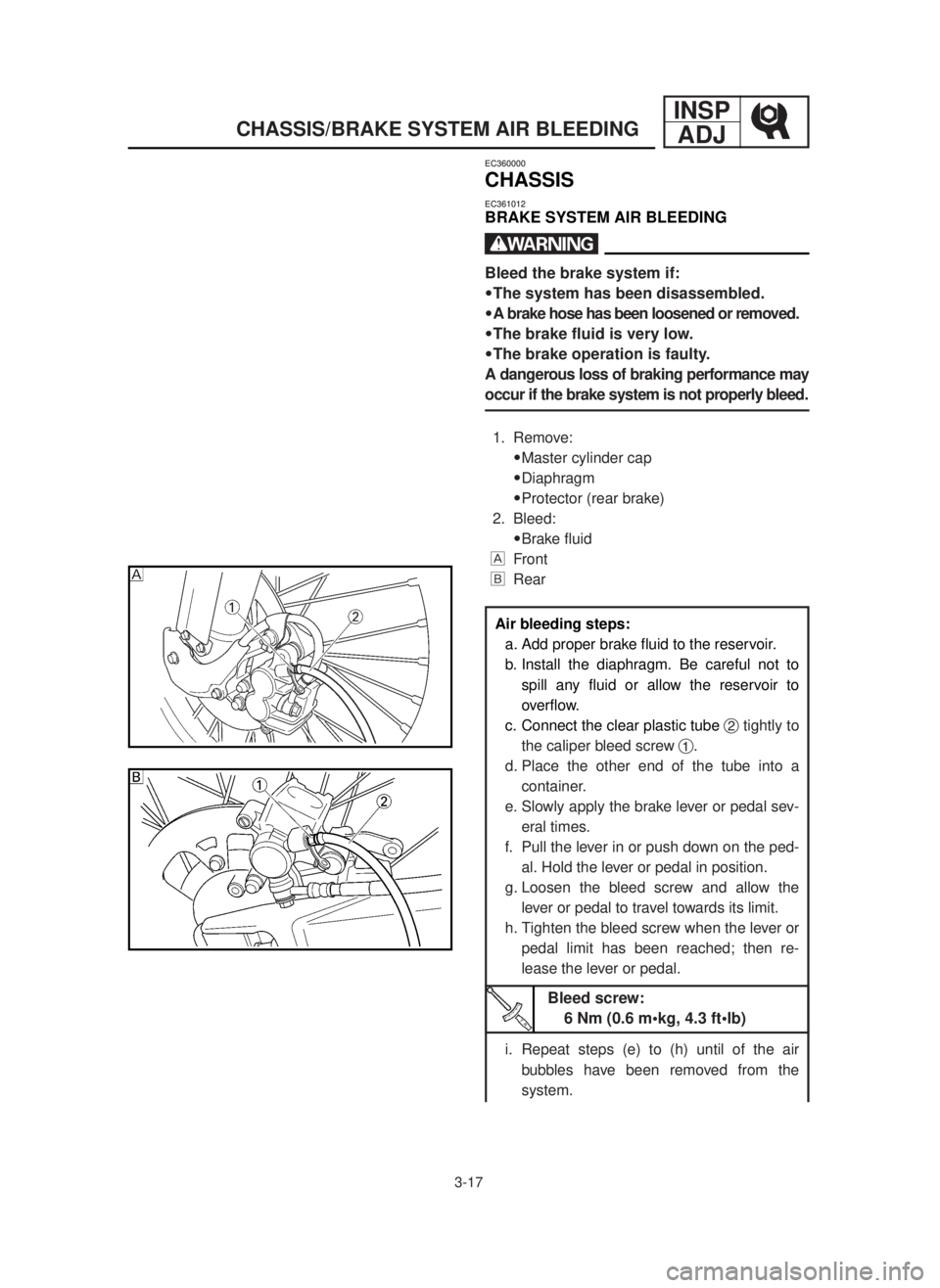

Page 164 of 578

3-17

CHASSIS/BRAKE SYSTEM AIR BLEEDING

INSP

ADJ

EC360000

CHASSIS

EC361012

BRAKE SYSTEM AIR BLEEDING

w

Bleed the brake system if:

9The system has been disassembled.

9A brake hose has been loosened or removed.

9The brake fluid is very low.

9The brake operation is faulty.

A dangerous loss of braking performance may

occur if the brake system is not properly bleed.

1. Remove:

9Master cylinder cap

9Diaphragm

9Protector (rear brake)

2. Bleed:

9Brake fluid

Front

õRear

Air bleeding steps:

a. Add proper brake fluid to the reservoir.

b. Install the diaphragm. Be careful not to

spill any fluid or allow the reservoir to

overflow.

c. Connect the clear plastic tube

2tightly to

the caliper bleed screw 1.

d. Place the other end of the tube into a

container.

e. Slowly apply the brake lever or pedal sev-

eral times.

f. Pull the lever in or push down on the ped-

al. Hold the lever or pedal in position.

g. Loosen the bleed screw and allow the

lever or pedal to travel towards its limit.

h. Tighten the bleed screw when the lever or

pedal limit has been reached; then re-

lease the lever or pedal.

i. Repeat steps (e) to (h) until of the air

bubbles have been removed from the

system.

Bleed screw:

6 Nm (0.6 m•kg, 4.3 ft•lb)

5MW-9-30-3B 7/3/00 3:16 PM Page 2

Page 166 of 578

3-18

FRONT BRAKE ADJUSTMENT

INSP

ADJ

3. Install:

9Protector (rear brake)

9Diaphragm

9Master cylinder cap

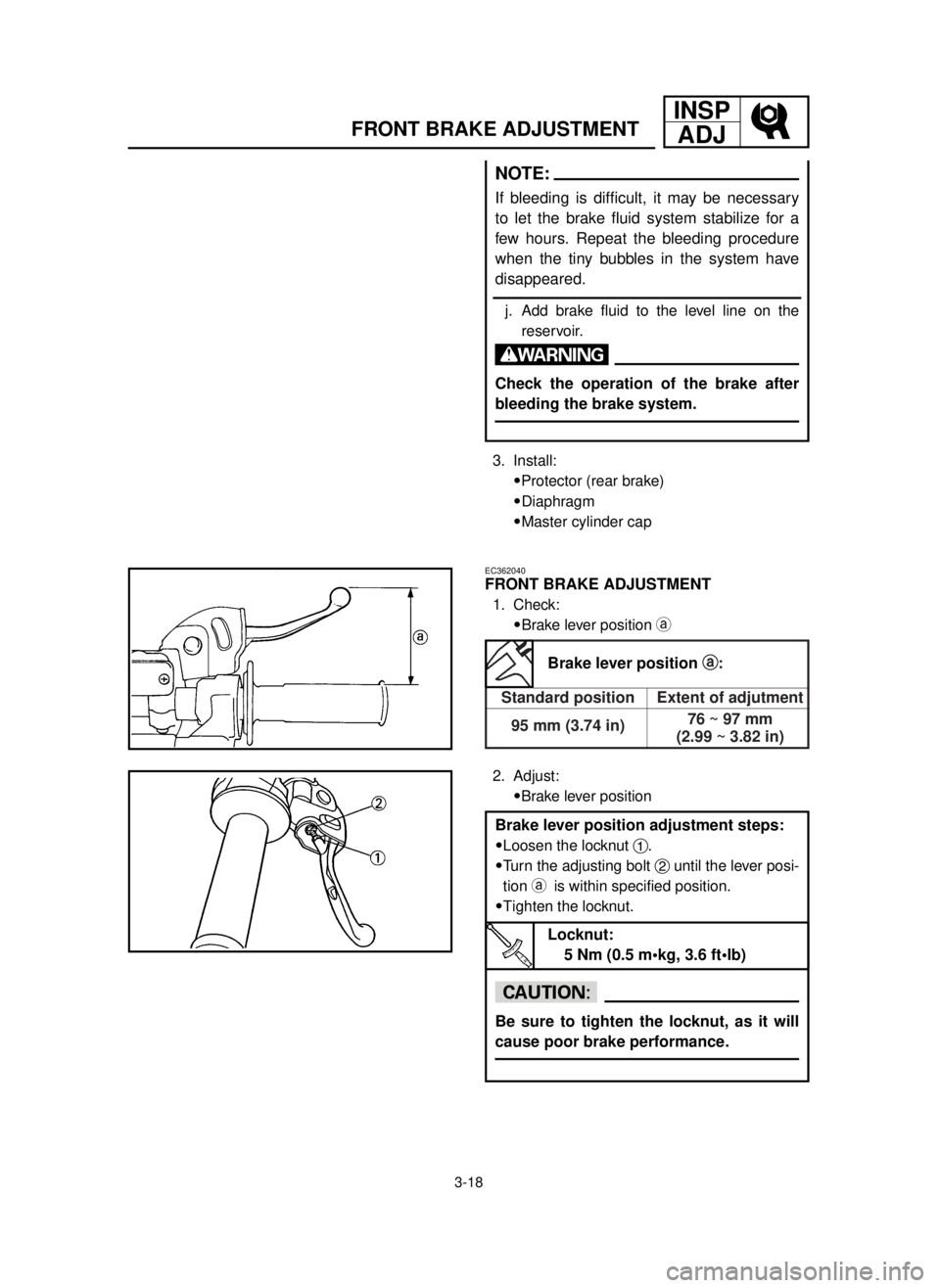

EC362040

FRONT BRAKE ADJUSTMENT

1. Check:

9Brake lever position a

2. Adjust:

9Brake lever position

NOTE:

If bleeding is difficult, it may be necessary

to let the brake fluid system stabilize for a

few hours. Repeat the bleeding procedure

when the tiny bubbles in the system have

disappeared.

j. Add brake fluid to the level line on the

reservoir.

w

Check the operation of the brake after

bleeding the brake system.

Brake lever position a a

:

Standard position Extent of adjutment

95 mm (3.74 in)76 ~ 97 mm

(2.99 ~ 3.82 in)

Brake lever position adjustment steps:

9Loosen the locknut 1.

9Turn the adjusting bolt 2until the lever posi-

tion a is within specified position.

9Tighten the locknut.

cC

Be sure to tighten the locknut, as it will

cause poor brake performance.

Locknut:

5 Nm (0.5 m•kg, 3.6 ft•lb)

5MW-9-30-3B 7/3/00 3:17 PM Page 4

Page 168 of 578

3-19

REAR BRAKE ADJUSTMENT/

FRONT BRAKE PAD INSPECTION AND REPLACEMENTINSP

ADJ

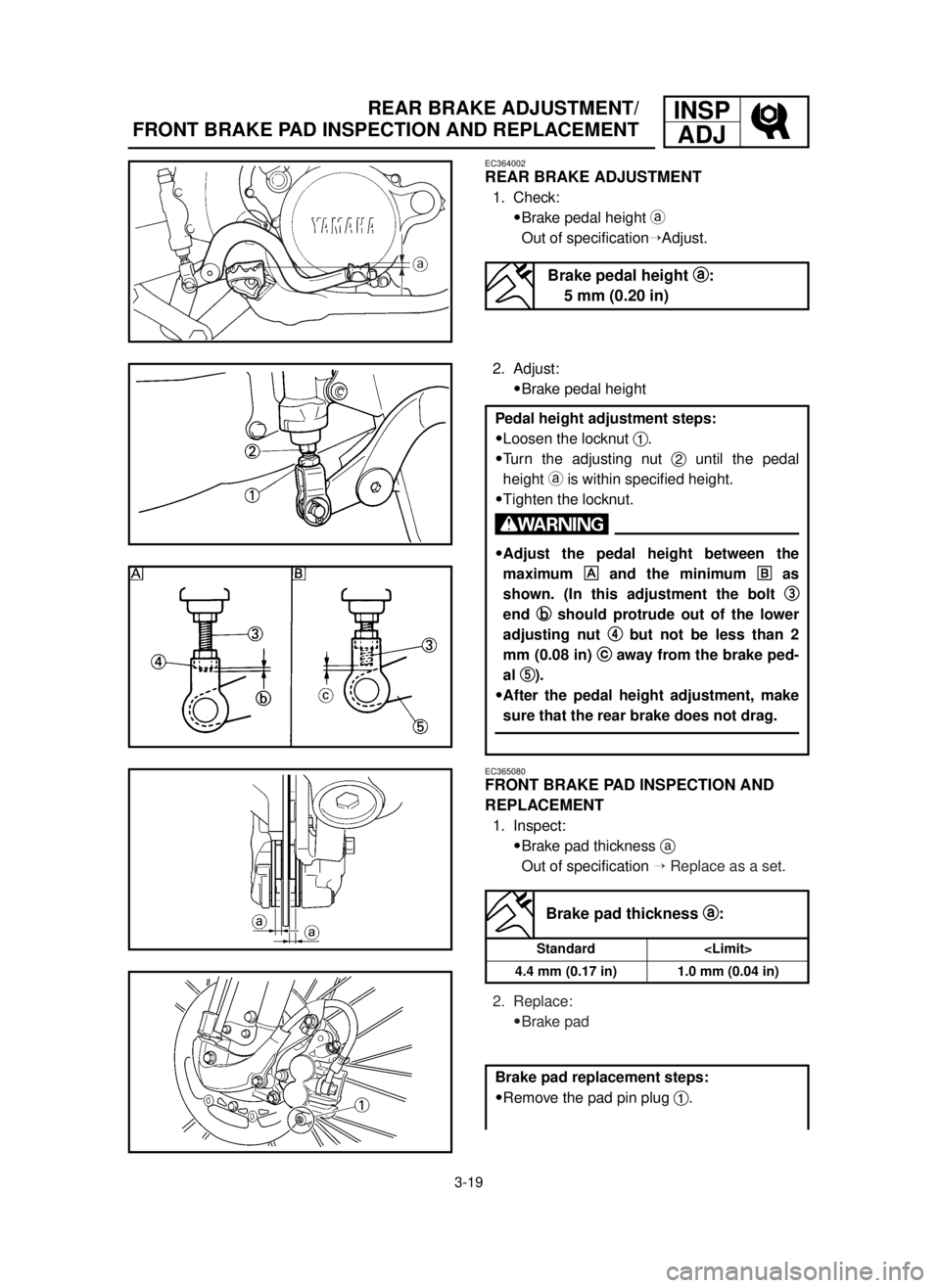

EC365080

FRONT BRAKE PAD INSPECTION AND

REPLACEMENT

1. Inspect:

9Brake pad thickness a

Out of specification ÕReplace as a set.

2. Replace:

9Brake pad

Brake pad thickness a a

:

Standard

4.4 mm (0.17 in)

1.0 mm (0.04 in)

Brake pad replacement steps:

9Remove the pad pin plug 1.

EC364002

REAR BRAKE ADJUSTMENT

1. Check:

9Brake pedal height a

Out of specificationÕAdjust.

2. Adjust:

9Brake pedal height

Brake pedal height a a

:

5 mm (0.20 in)

Pedal height adjustment steps:

9Loosen the locknut 1.

9Turn the adjusting nut 2until the pedal

height ais within specified height.

9Tighten the locknut.

w

9Adjust the pedal height between the

maximum

and the minimum õ õ

as

shown. (In this adjustment the bolt 3 3

end b b

should protrude out of the lower

adjusting nut 4 4

but not be less than 2

mm (0.08 in) c c

away from the brake ped-

al 5 5

).

9After the pedal height adjustment, make

sure that the rear brake does not drag.

5MW-9-30-3B 7/3/00 3:18 PM Page 6

Page 170 of 578

3-20

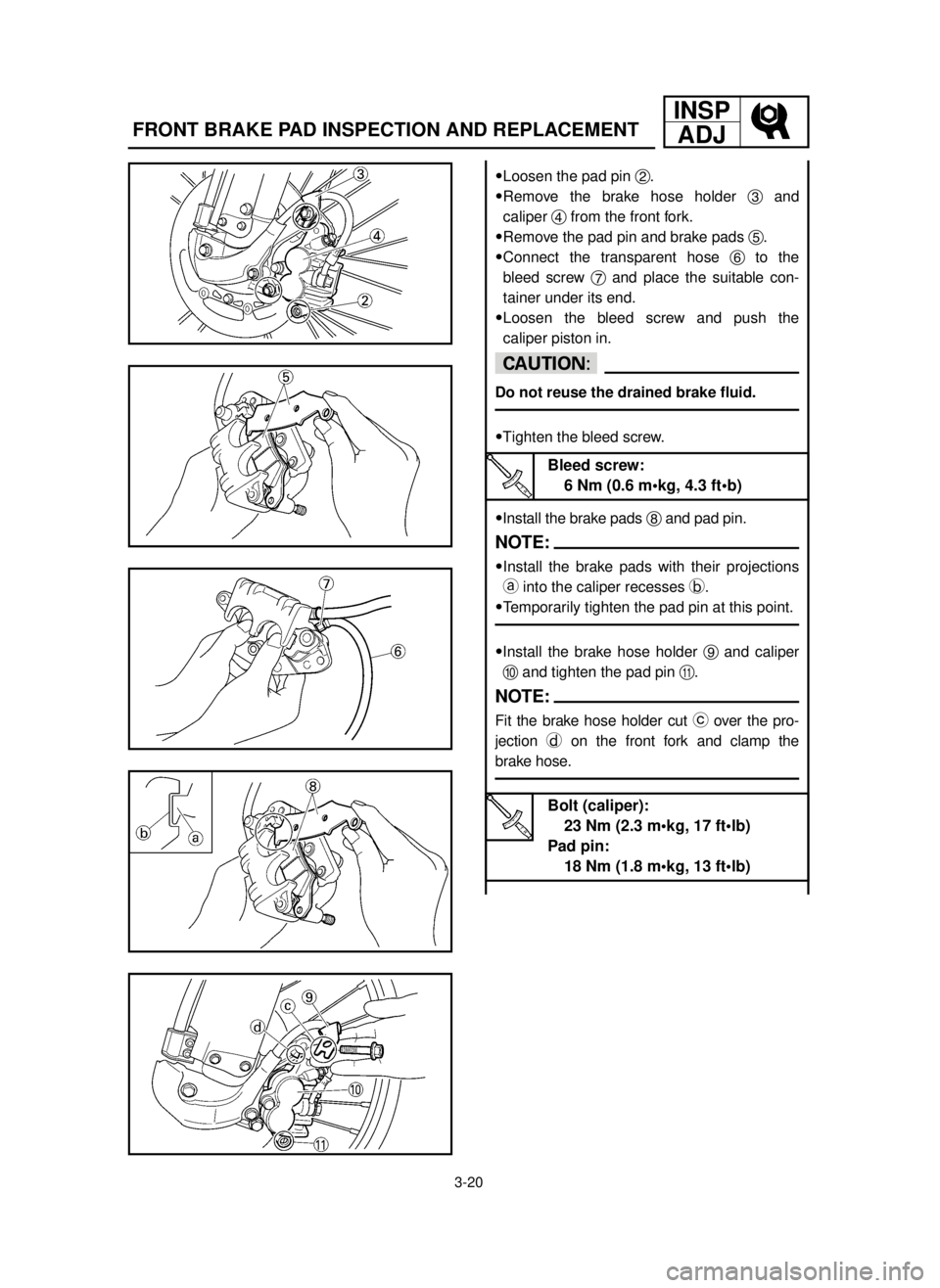

FRONT BRAKE PAD INSPECTION AND REPLACEMENT

INSP

ADJ

9Loosen the pad pin 2.

9Remove the brake hose holder 3and

caliper 4from the front fork.

9Remove the pad pin and brake pads 5.

9Connect the transparent hose 6to the

bleed screw 7and place the suitable con-

tainer under its end.

9Loosen the bleed screw and push the

caliper piston in.

cC

Do not reuse the drained brake fluid.

9Tighten the bleed screw.

9Install the brake pads 8and pad pin.

NOTE:

9Install the brake pads with their projections

ainto the caliper recesses b.

9Temporarily tighten the pad pin at this point.

9Install the brake hose holder 9and caliper

0and tighten the pad pin q.

NOTE:

Fit the brake hose holder cut cover the pro-

jection

don the front fork and clamp the

brake hose.

Bleed screw:

6 Nm (0.6 m•kg, 4.3 ft•b)

Bolt (caliper):

23 Nm (2.3 m•kg, 17 ft•lb)

Pad pin:

18 Nm (1.8 m•kg, 13 ft•lb)

5MW-9-30-3B 7/3/00 3:19 PM Page 8

Page 172 of 578

3-21

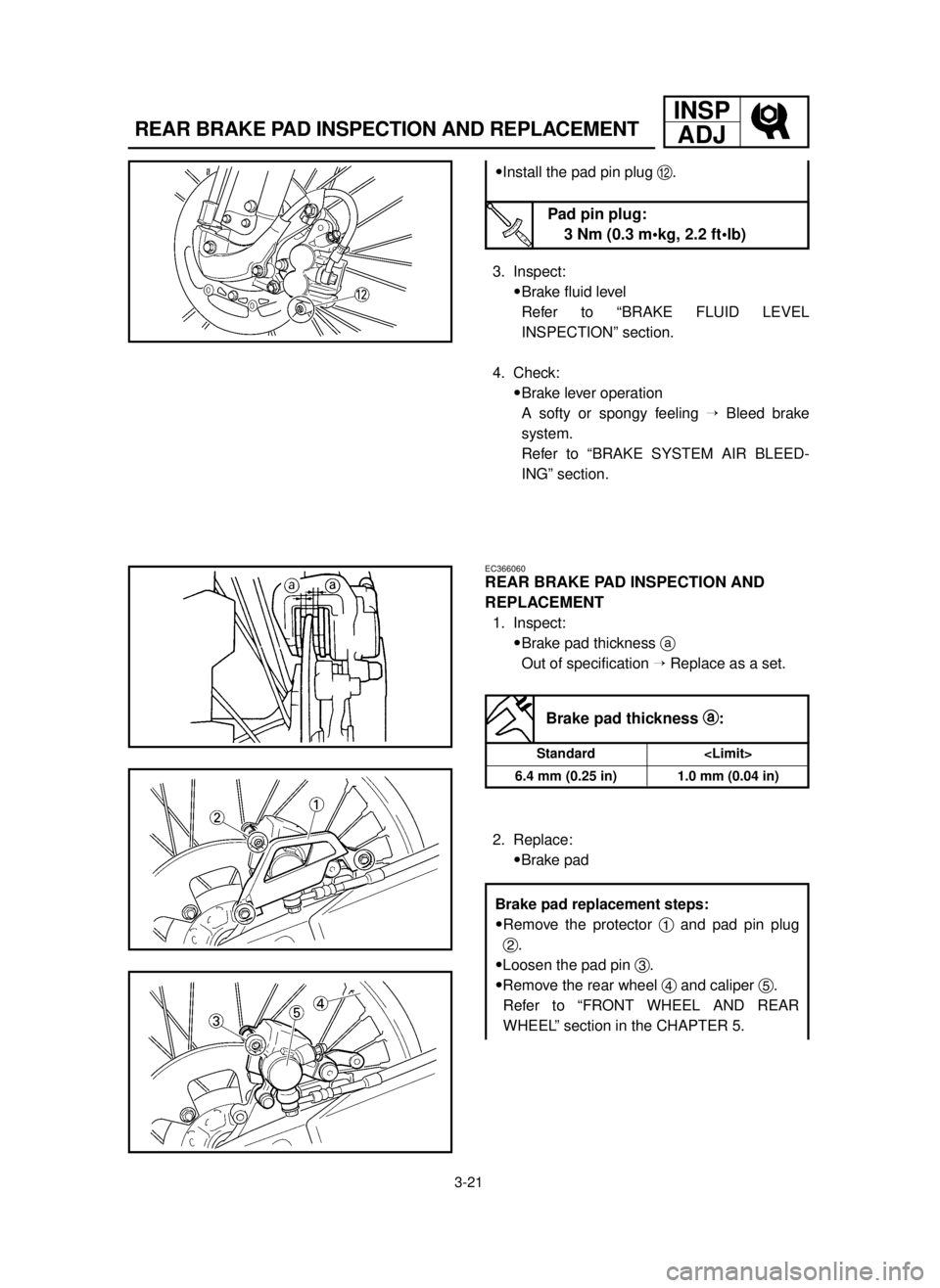

REAR BRAKE PAD INSPECTION AND REPLACEMENT

INSP

ADJ

3. Inspect:

9Brake fluid level

Refer to “BRAKE FLUID LEVEL

INSPECTION” section.

4. Check:

9Brake lever operation

A softy or spongy feeling ÕBleed brake

system.

Refer to “BRAKE SYSTEM AIR BLEED-

ING” section.

EC366060

REAR BRAKE PAD INSPECTION AND

REPLACEMENT

1. Inspect:

9Brake pad thickness a

Out of specification ÕReplace as a set.

2. Replace:

9Brake pad

9Install the pad pin plug w.

Pad pin plug:

3 Nm (0.3 m•kg, 2.2 ft•lb)

Brake pad thickness a a

:

Standard

6.4 mm (0.25 in)

1.0 mm (0.04 in)

Brake pad replacement steps:

9Remove the protector 1and pad pin plug

2.

9Loosen the pad pin 3.

9Remove the rear wheel 4and caliper 5.

Refer to “FRONT WHEEL AND REAR

WHEEL” section in the CHAPTER 5.

5MW-9-30-3B 7/3/00 3:20 PM Page 10

Page 174 of 578

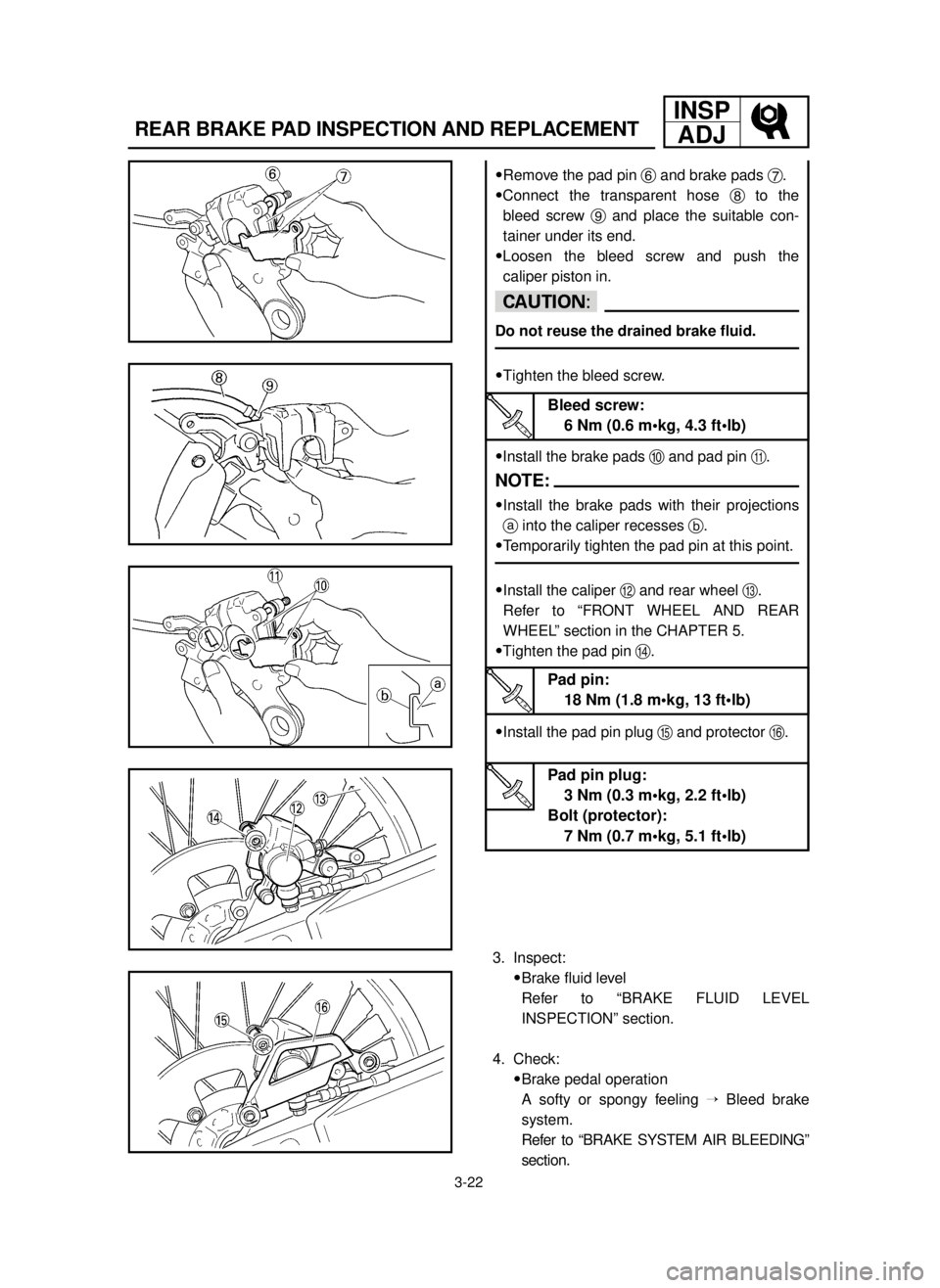

3-22

REAR BRAKE PAD INSPECTION AND REPLACEMENT

INSP

ADJ

9Remove the pad pin 6and brake pads 7.

9Connect the transparent hose 8to the

bleed screw 9and place the suitable con-

tainer under its end.

9Loosen the bleed screw and push the

caliper piston in.

cC

Do not reuse the drained brake fluid.

9Tighten the bleed screw.

9Install the brake pads 0and pad pin q.

NOTE:

9Install the brake pads with their projections

ainto the caliper recesses b.

9Temporarily tighten the pad pin at this point.

9Install the caliper wand rear wheel e.

Refer to “FRONT WHEEL AND REAR

WHEEL” section in the CHAPTER 5.

9Tighten the pad pin r.

9Install the pad pin plug tand protector y.

Bleed screw:

6 Nm (0.6 m•kg, 4.3 ft•lb)

Pad pin:

18 Nm (1.8 m•kg, 13 ft•lb)

Pad pin plug:

3 Nm (0.3 m•kg, 2.2 ft•lb)

Bolt (protector):

7 Nm (0.7 m•kg, 5.1 ft•lb)

3. Inspect:

9Brake fluid level

Refer to “BRAKE FLUID LEVEL

INSPECTION” section.

4. Check:

9Brake pedal operation

A softy or spongy feeling ÕBleed brake

system.

Refer to “BRAKE SYSTEM AIR BLEEDING”

section.

5MW-9-30-3B 7/3/00 3:21 PM Page 12