torque YAMAHA YZ250LC 2001 Manuale duso (in Italian)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ250LC, Model: YAMAHA YZ250LC 2001Pages: 578, PDF Dimensioni: 14.12 MB

Page 20 of 578

EC0A0000

CONTENTS

CHAPTER 1

GENERAL INFORMATION

DESCRIPTION............................................1-1

MACHINE IDENTIFICATION......................1-2

IMPORTANT INFORMATION.....................1-3

CHECKING OF CONNECTION..................1-6

SPECIAL TOOLS........................................1-7

CONTROL FUNCTIONS.............................1-9

FUEL AND ENGINE MIXING OIL.............1-12

STARTING AND BREAK-IN.....................1-13

TORQUE-CHECK POINTS.......................1-16

CLEANING AND STORAGE....................1-17

CHAPTER 2

SPECIFICATIONS

GENERAL SPECIFICATIONS....................2-1

MAINTENANCE SPECIFICATIONS...........2-3

GENERAL TORQUE SPECIFICATIONS..2-12

DEFINITION OF UNITS............................2-12

CABLE ROUTING DIAGRAM...................2-13

CHAPTER 3

REGULAR INSPECTION

AND ADJUSTMENTS

MAINTENANCE INTERVALS.....................3-1

PRE-OPERATION INSPECTION AND

MAINTENANCE..........................................3-4

ENGINE.......................................................3-5

CHASSIS...................................................3-17

ELECTRICAL............................................3-38

5MW-9-30-0 7/5/00 2:15 PM Page 18

Page 58 of 578

1-15

STARTING AND BREAK-IN

GEN

INFO

cC

9After the break-in or before each race, you

must check the entire machine for loose fit-

tings and fasteners as per “TORQUE-

CHECK POINTS”.

Tighten all such fasteners as required.

9When any of the following parts have been

replaced, they must be broken in.

CYLINDER AND CRANKSHAFT:

About one hour of break-in operation is

necessary.

PISTON, RING AND GEARS:

These parts require about 30 minutes of

break-in operation at half-throttle or less.

Observe the condition of the engine careful-

ly during operation.

5MW-9-30-1 7/3/00 1:48 PM Page 34

Page 60 of 578

1-16

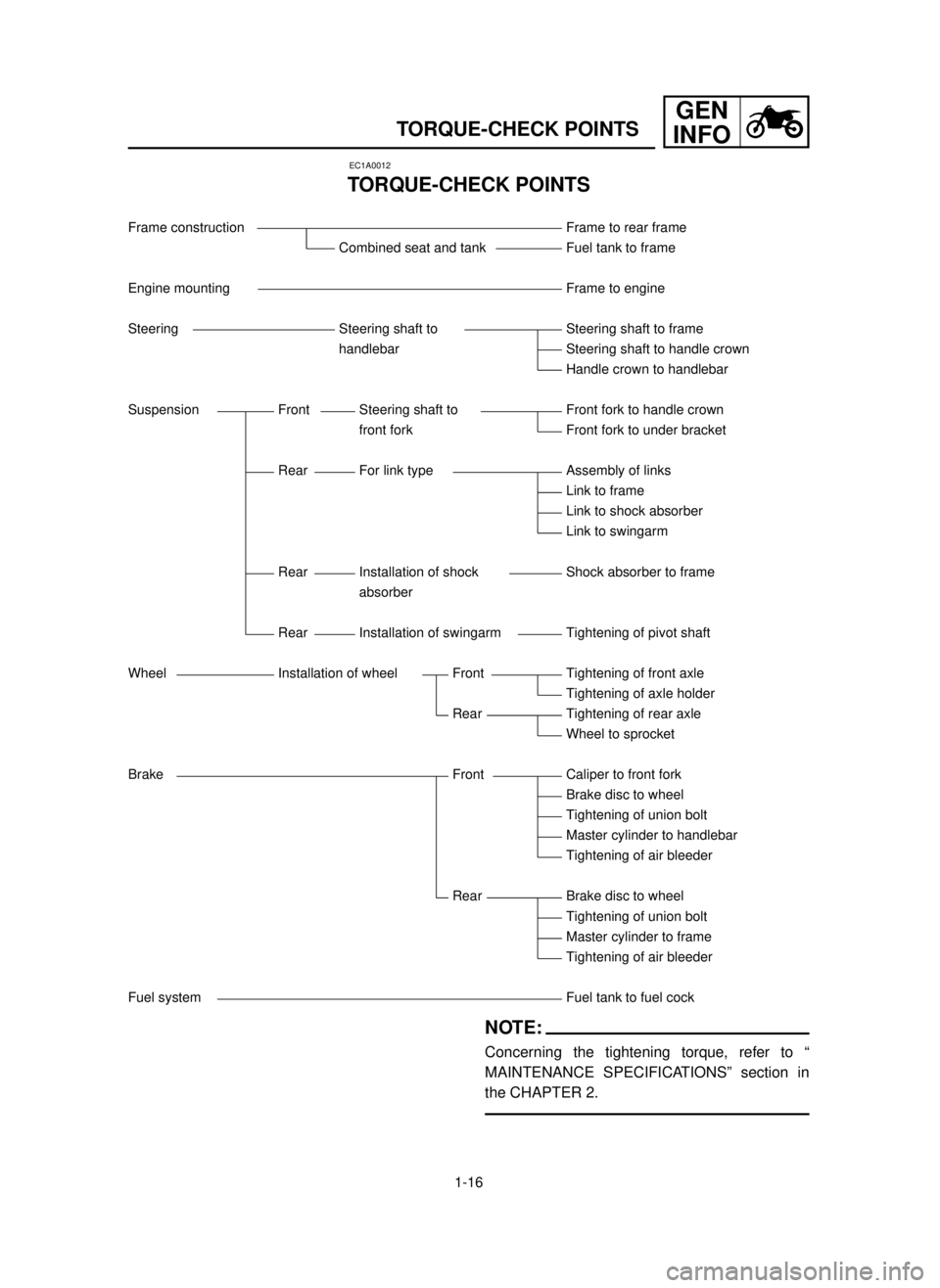

TORQUE-CHECK POINTS

GEN

INFO

EC1A0012

TORQUE-CHECK POINTS

Frame construction Frame to rear frame

Combined seat and tank Fuel tank to frame

Engine mounting Frame to engine

Steering Steering shaft to Steering shaft to frame

handlebar Steering shaft to handle crown

Handle crown to handlebar

Suspension Front Steering shaft to Front fork to handle crown

front fork Front fork to under bracket

Rear For link type Assembly of links

Link to frame

Link to shock absorber

Link to swingarm

Rear Installation of shock Shock absorber to frame

absorber

Rear Installation of swingarm Tightening of pivot shaft

Wheel Installation of wheel Front Tightening of front axle

Tightening of axle holder

Rear Tightening of rear axle

Wheel to sprocket

Brake Front Caliper to front fork

Brake disc to wheel

Tightening of union bolt

Master cylinder to handlebar

Tightening of air bleeder

Rear Brake disc to wheel

Tightening of union bolt

Master cylinder to frame

Tightening of air bleeder

Fuel system Fuel tank to fuel cock

NOTE:

Concerning the tightening torque, refer to “

MAINTENANCE SPECIFICATIONS” section in

the CHAPTER 2.

5MW-9-30-1 7/3/00 1:49 PM Page 36

Page 72 of 578

2-5

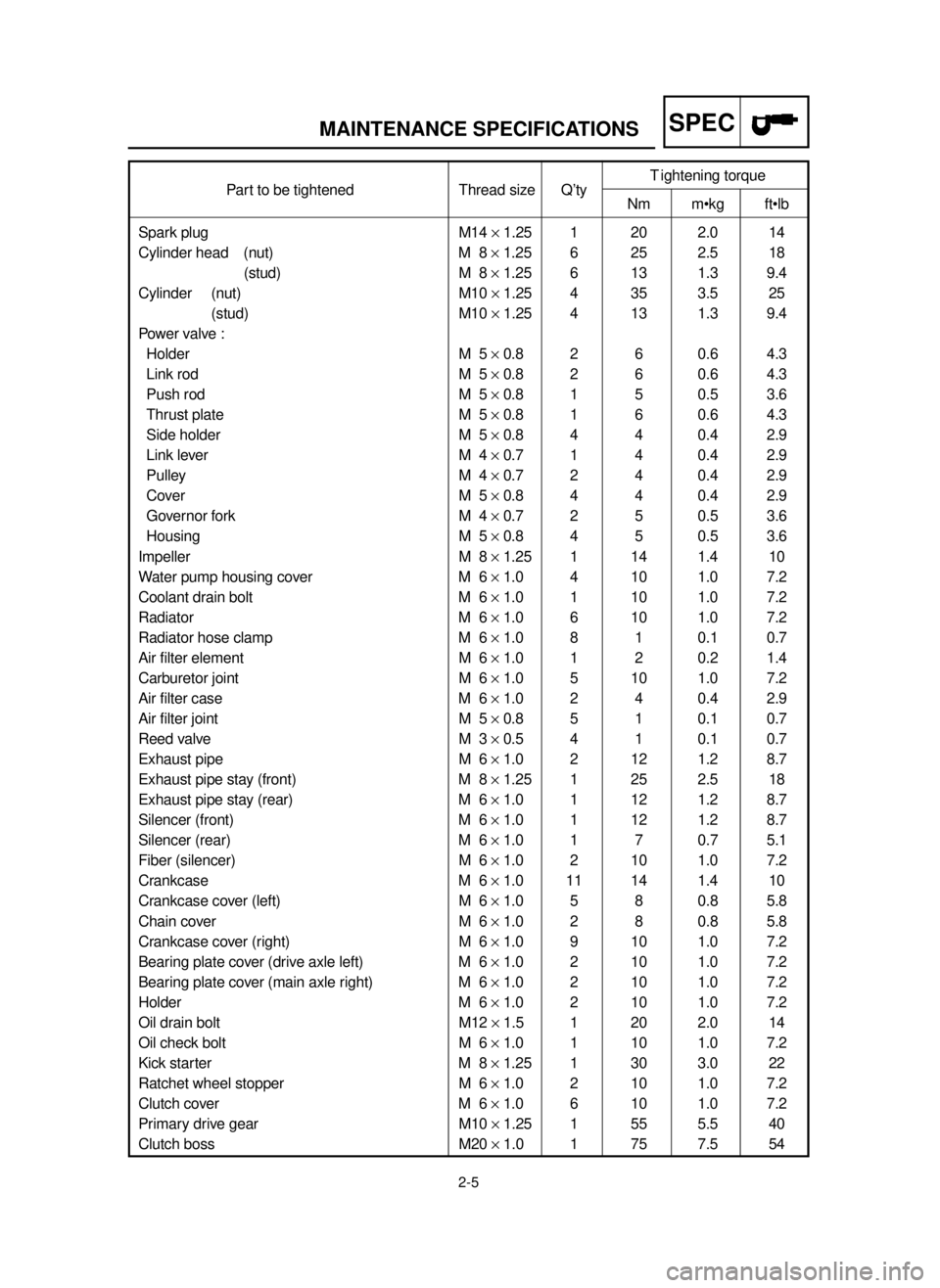

MAINTENANCE SPECIFICATIONSSPEC

Part to be tightened Thread size Q’tyT ightening torqueNm m•kg ft•lb

Spark plug M14 ´1.25 1 20 2.0 14

Cylinder head (nut) M 8 ´1.25 6 25 2.5 18

(stud) M 8 ´1.25 6 13 1.3 9.4

Cylinder (nut) M10 ´1.25 4 35 3.5 25

(stud) M10 ´1.25 4 13 1.3 9.4

Power valve :

Holder M 5 ´0.8 2 6 0.6 4.3

Link rod M 5 ´0.8 2 6 0.6 4.3

Push rod M 5 ´0.8 1 5 0.5 3.6

Thrust plate M 5 ´0.8 1 6 0.6 4.3

Side holder M 5 ´0.8 4 4 0.4 2.9

Link lever M 4 ´0.7 1 4 0.4 2.9

Pulley M 4 ´0.7 2 4 0.4 2.9

Cover M 5 ´0.8 4 4 0.4 2.9

Governor fork M 4 ´0.7 2 5 0.5 3.6

Housing M 5 ´0.8 4 5 0.5 3.6

Impeller M 8 ´1.25 1 14 1.4 10

Water pump housing cover M 6 ´1.0 4 10 1.0 7.2

Coolant drain bolt M 6 ´1.0 1 10 1.0 7.2

Radiator M 6 ´1.0 6 10 1.0 7.2

Radiator hose clamp M 6 ´1.0 8 1 0.1 0.7

Air filter element M 6 ´1.0 1 2 0.2 1.4

Carburetor joint M 6 ´1.0 5 10 1.0 7.2

Air filter case M 6 ´1.0 2 4 0.4 2.9

Air filter joint M 5 ´0.8 5 1 0.1 0.7

Reed valve M 3 ´0.5 4 1 0.1 0.7

Exhaust pipe M 6 ´1.0 2 12 1.2 8.7

Exhaust pipe stay (front) M 8 ´1.25 1 25 2.5 18

Exhaust pipe stay (rear) M 6 ´1.0 1 12 1.2 8.7

Silencer (front) M 6 ´1.0 1 12 1.2 8.7

Silencer (rear) M 6 ´1.0 1 7 0.7 5.1

Fiber (silencer) M 6 ´1.0 2 10 1.0 7.2

Crankcase M 6 ´1.0 11 14 1.4 10

Crankcase cover (left) M 6 ´1.0 5 8 0.8 5.8

Chain cover M 6 ´1.0 2 8 0.8 5.8

Crankcase cover (right) M 6 ´1.0 9 10 1.0 7.2

Bearing plate cover (drive axle left) M 6 ´1.0 2 10 1.0 7.2

Bearing plate cover (main axle right) M 6 ´1.0 2 10 1.0 7.2

Holder M 6 ´1.0 2 10 1.0 7.2

Oil drain bolt M12 ´1.5 1 20 2.0 14

Oil check bolt M 6 ´1.0 1 10 1.0 7.2

Kick starter M 8 ´1.25 1 30 3.0 22

Ratchet wheel stopper M 6 ´1.0 2 10 1.0 7.2

Clutch cover M 6 ´1.0 6 10 1.0 7.2

Primary drive gear M10 ´1.25 1 55 5.5 40

Clutch boss M20 ´1.0 1 75 7.5 54

5MW-9-30-2 7/3/00 2:20 PM Page 6

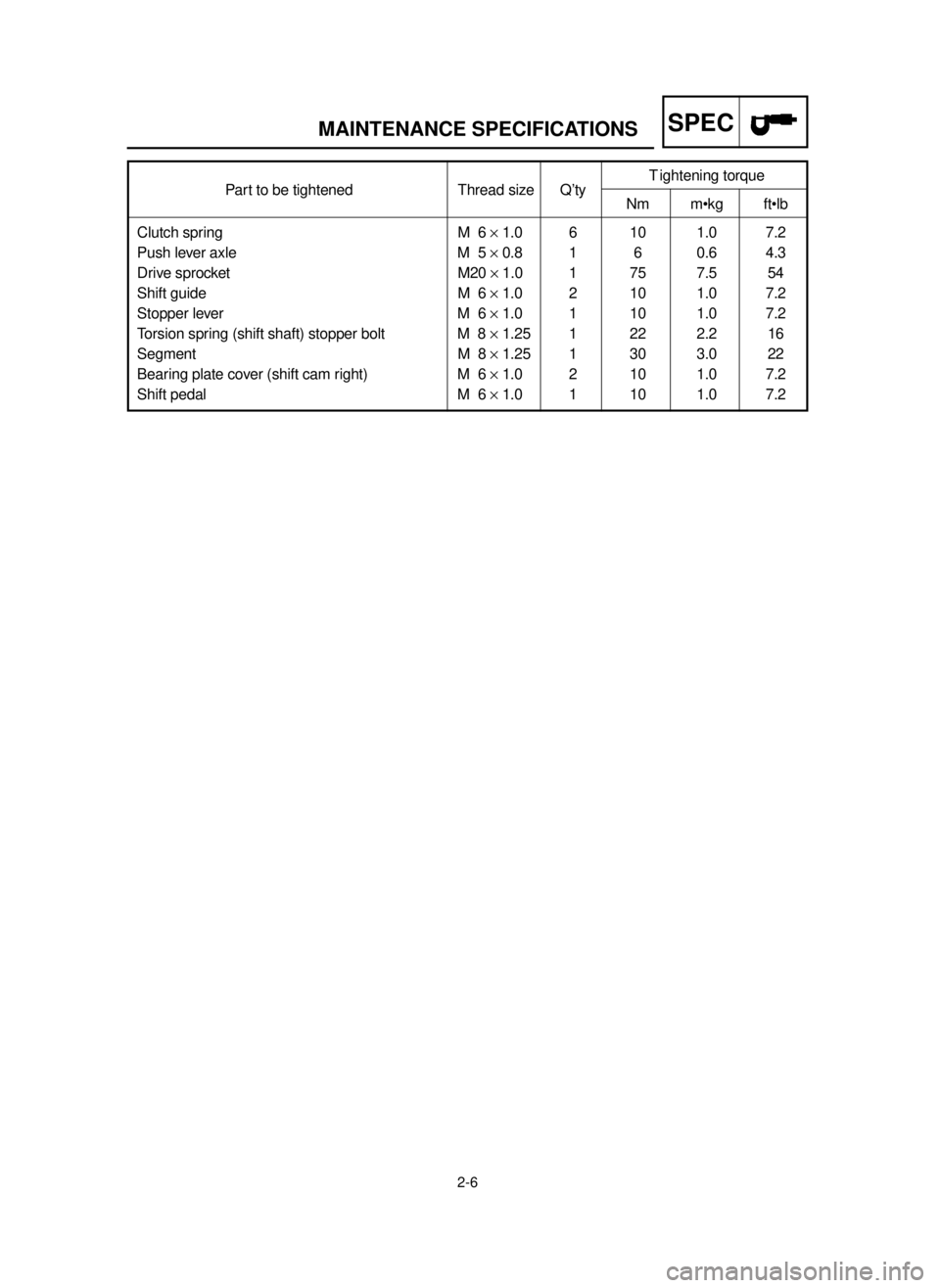

Page 73 of 578

2-6

MAINTENANCE SPECIFICATIONSSPEC

Part to be tightened Thread size Q’tyT ightening torqueNm m•kg ft•lb

Clutch spring M 6 ´1.0 6 10 1.0 7.2

Push lever axle M 5 ´0.8 1 6 0.6 4.3

Drive sprocket M20 ´1.0 1 75 7.5 54

Shift guide M 6 ´1.0 2 10 1.0 7.2

Stopper lever M 6 ´1.0 1 10 1.0 7.2

Torsion spring (shift shaft) stopper bolt M 8 ´1.25 1 22 2.2 16

Segment M 8 ´1.25 1 30 3.0 22

Bearing plate cover (shift cam right) M 6 ´1.0 2 10 1.0 7.2

Shift pedal M 6 ´1.0 1 10 1.0 7.2

5MW-9-30-2 7/3/00 2:20 PM Page 7

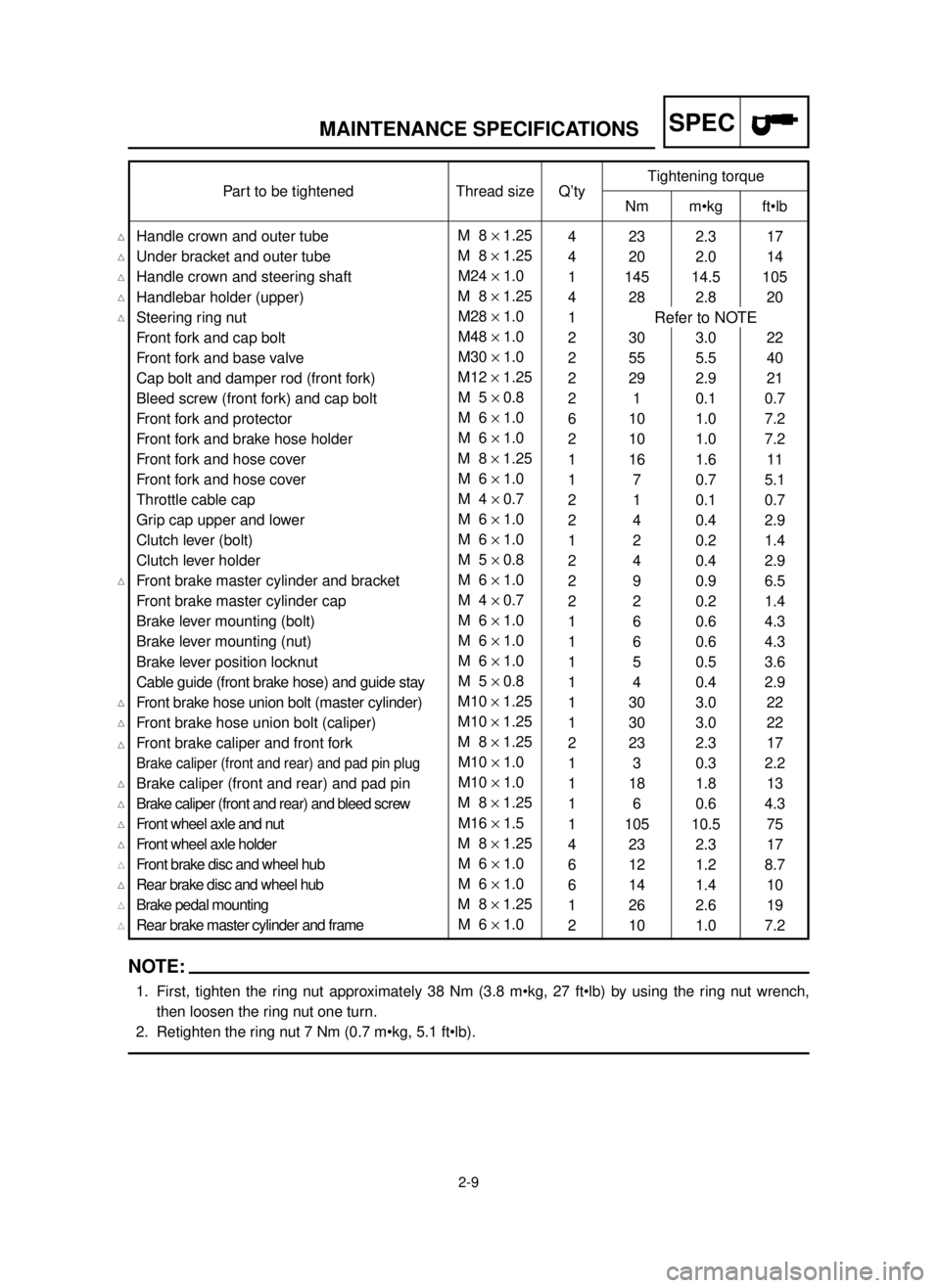

Page 76 of 578

2-9

MAINTENANCE SPECIFICATIONSSPEC

17

14

105

20

22

40

21

0.7

7.2

7.2

11

5.1

0.7

2.9

1.4

2.9

6.5

1.4

4.3

4.3

3.6

2.9

22

22

17

2.2

13

4.3

75

17

8.7

10

19

7.2M 8 ´ 1.25

M 8 ´ 1.25

M24 ´ 1.0

M 8 ´ 1.25

M28 ´ 1.0

M48 ´ 1.0

M30 ´ 1.0

M12 ´ 1.25

M 5 ´ 0.8

M 6 ´ 1.0

M 6 ´ 1.0

M 8 ´ 1.25

M 6 ´ 1.0

M 4 ´ 0.7

M 6 ´ 1.0

M 6 ´ 1.0

M 5 ´ 0.8

M 6 ´ 1.0

M 4 ´ 0.7

M 6 ´ 1.0

M 6 ´ 1.0

M 6 ´ 1.0

M 5 ´ 0.8

M10 ´ 1.25

M10 ´ 1.25

M 8 ´ 1.25

M10 ´ 1.0

M10 ´ 1.0

M 8 ´ 1.25

M16 ´ 1.5

M 8 ´ 1.25

M 6 ´ 1.0

M 6 ´ 1.0

M 8 ´ 1.25

M 6 ´ 1.0 Handle crown and outer tube

Under bracket and outer tube

Handle crown and steering shaft

Handlebar holder (upper)

Steering ring nut

Front fork and cap bolt

Front fork and base valve

Cap bolt and damper rod (front fork)

Bleed screw (front fork) and cap bolt

Front fork and protector

Front fork and brake hose holder

Front fork and hose cover

Front fork and hose cover

Throttle cable cap

Grip cap upper and lower

Clutch lever (bolt)

Clutch lever holder

Front brake master cylinder and bracket

Front brake master cylinder cap

Brake lever mounting (bolt)

Brake lever mounting (nut)

Brake lever position locknut

Cable guide (front brake hose) and guide stay

Front brake hose union bolt (master cylinder)

Front brake hose union bolt (caliper)

Front brake caliper and front fork

Brake caliper (front and rear) and pad pin plug

Brake caliper (front and rear) and pad pin

Brake caliper (front and rear) and bleed screw

Front wheel axle and nut

Front wheel axle holder

Front brake disc and wheel hub

Rear brake disc and wheel hub

Brake pedal mounting

Rear brake master cylinder and framePart to be tightened Thread size Q’tyTightening torque

Nm m•kg ft•lb

4

4

1

4

1

2

2

2

2

6

2

1

1

2

2

1

2

2

2

1

1

1

1

1

1

2

1

1

1

1

4

6

6

1

223

20

145

28

30

55

29

1

10

10

16

7

1

4

2

4

9

2

6

6

5

4

30

30

23

3

18

6

105

23

12

14

26

102.3

2.0

14.5

2.8

3.0

5.5

2.9

0.1

1.0

1.0

1.6

0.7

0.1

0.4

0.2

0.4

0.9

0.2

0.6

0.6

0.5

0.4

3.0

3.0

2.3

0.3

1.8

0.6

10.5

2.3

1.2

1.4

2.6

1.0

NOTE:

1. First, tighten the ring nut approximately 38 Nm (3.8 m•kg, 27 ft•lb) by using the ring nut wrench,

then loosen the ring nut one turn.

2. Retighten the ring nut 7 Nm (0.7 m•kg, 5.1 ft•lb).

Refer to NOTE

5MW-9-30-2 7/3/00 2:20 PM Page 10

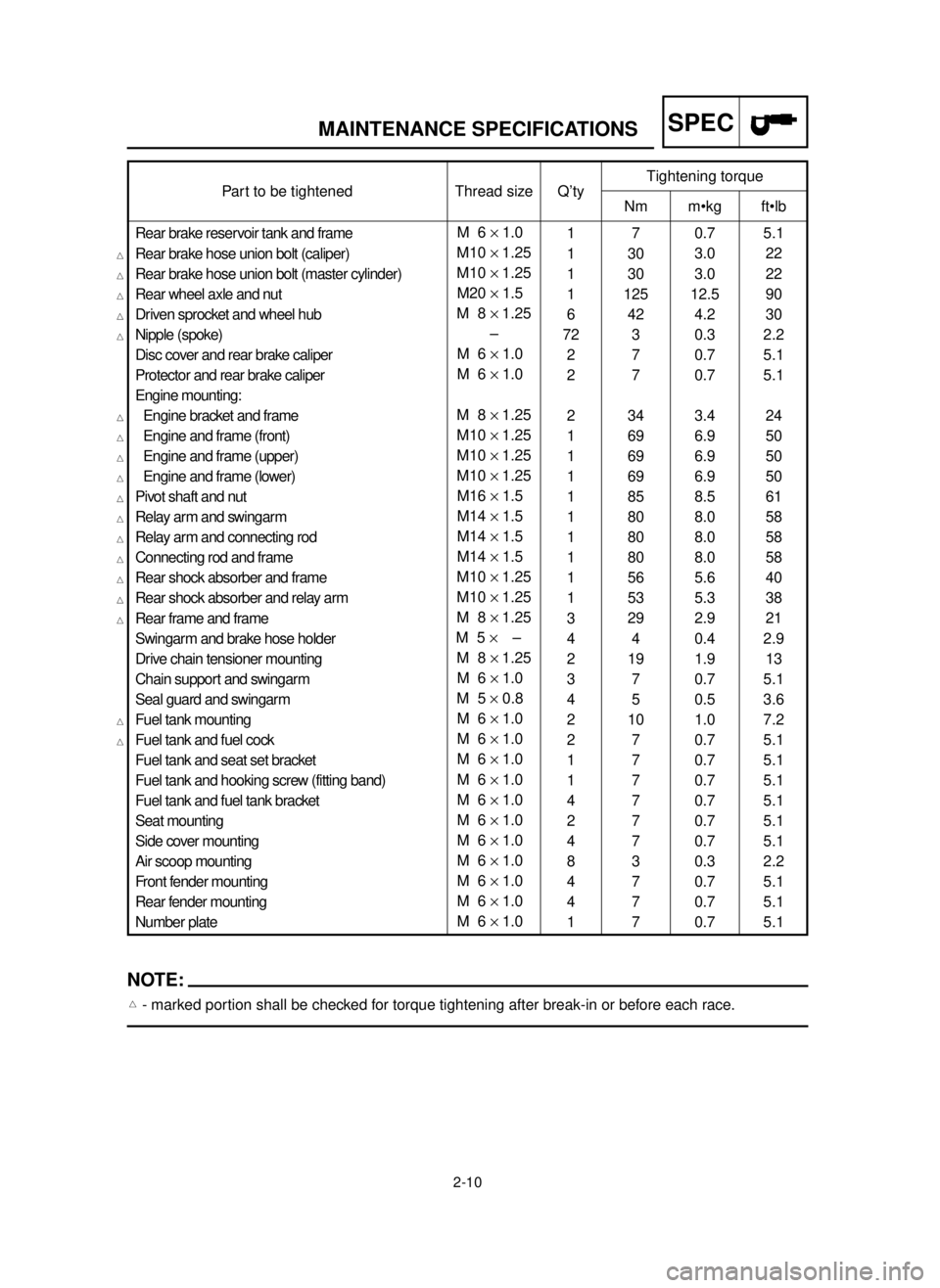

Page 77 of 578

2-10

MAINTENANCE SPECIFICATIONSSPEC

M 6 ´ 1.0

M10 ´ 1.25

M10 ´ 1.25

M20 ´ 1.5

M 8 ´ 1.25

–

M 6 ´ 1.0

M 6 ´ 1.0

M 8 ´ 1.25

M10 ´ 1.25

M10 ´ 1.25

M10 ´ 1.25

M16 ´ 1.5

M14 ´ 1.5

M14 ´ 1.5

M14 ´ 1.5

M10 ´ 1.25

M10 ´ 1.25

M 8 ´ 1.25

M 5 ´ –

M 8 ´ 1.25

M 6 ´ 1.0

M 5 ´0.8

M 6 ´ 1.0

M 6 ´ 1.0

M 6 ´ 1.0

M 6 ´ 1.0

M 6 ´ 1.0

M 6 ´ 1.0

M 6 ´ 1.0

M 6 ´ 1.0

M 6 ´ 1.0

M 6 ´ 1.0

M 6 ´ 1.0 Rear brake reservoir tank and frame

Rear brake hose union bolt (caliper)

Rear brake hose union bolt (master cylinder)

Rear wheel axle and nut

Driven sprocket and wheel hub

Nipple (spoke)

Disc cover and rear brake caliper

Protector and rear brake caliper

Engine mounting:

Engine bracket and frame

Engine and frame (front)

Engine and frame (upper)

Engine and frame (lower)

Pivot shaft and nut

Relay arm and swingarm

Relay arm and connecting rod

Connecting rod and frame

Rear shock absorber and frame

Rear shock absorber and relay arm

Rear frame and frame

Swingarm and brake hose holder

Drive chain tensioner mounting

Chain support and swingarm

Seal guard and swingarm

Fuel tank mounting

Fuel tank and fuel cock

Fuel tank and seat set bracket

Fuel tank and hooking screw (fitting band)

Fuel tank and fuel tank bracket

Seat mounting

Side cover mounting

Air scoop mounting

Front fender mounting

Rear fender mounting

Number platePart to be tightened Thread size Q’tyTightening torque

Nm m•kg ft•lb

1

1

1

1

6

72

2

2

2

1

1

1

1

1

1

1

1

1

3

4

2

3

4

2

2

1

1

4

2

4

8

4

4

17

30

30

125

42

3

7

7

34

69

69

69

85

80

80

80

56

53

29

4

19

7

5

10

7

7

7

7

7

7

3

7

7

70.7

3.0

3.0

12.5

4.2

0.3

0.7

0.7

3.4

6.9

6.9

6.9

8.5

8.0

8.0

8.0

5.6

5.3

2.9

0.4

1.9

0.7

0.5

1.0

0.7

0.7

0.7

0.7

0.7

0.7

0.3

0.7

0.7

0.75.1

22

22

90

30

2.2

5.1

5.1

24

50

50

50

61

58

58

58

40

38

21

2.9

13

5.1

3.6

7.2

5.1

5.1

5.1

5.1

5.1

5.1

2.2

5.1

5.1

5.1

NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race.

5MW-9-30-2 7/3/00 2:20 PM Page 11

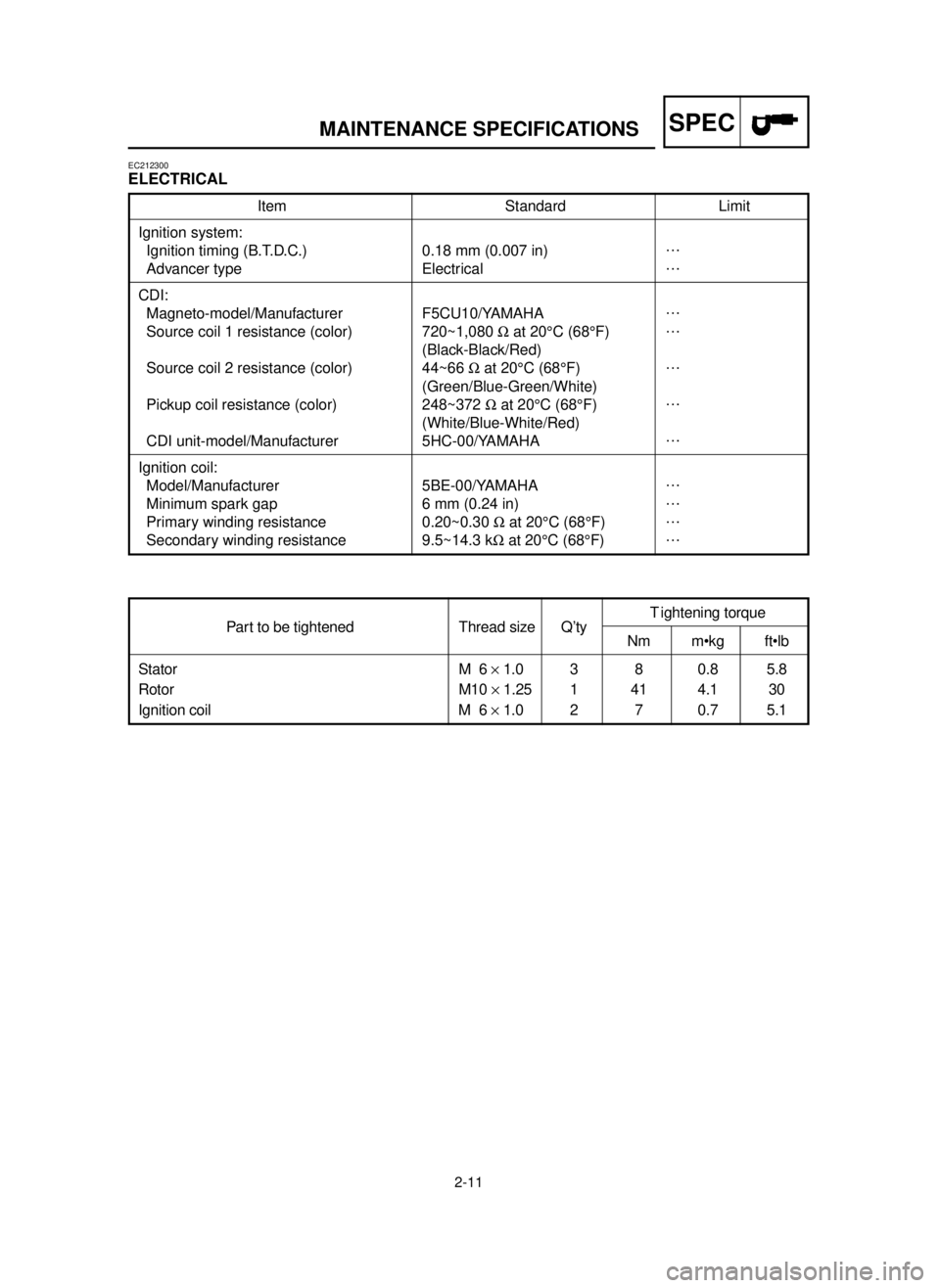

Page 78 of 578

2-11

MAINTENANCE SPECIFICATIONSSPEC

EC212300

ELECTRICAL

Part to be tightened Thread size Q’tyT ightening torqueNm m•kg ft•lb

Stator M 6 ´1.0 3 8 0.8 5.8

Rotor M10 ´1.25 1 41 4.1 30

Ignition coil M 6 ´1.0 2 7 0.7 5.1

Item Standard Limit

Ignition system:

Ignition timing (B.T.D.C.) 0.18 mm (0.007 in)…

Advancer type Electrical…

CDI:

Magneto-model/Manufacturer F5CU10/YAMAHA…

Source coil 1 resistance (color) 720~1,080 ½at 20°C (68°F)…

(Black-Black/Red)

Source coil 2 resistance (color) 44~66 ½at 20°C (68°F)…

(Green/Blue-Green/White)

Pickup coil resistance (color) 248~372 ½at 20°C (68°F)…

(White/Blue-White/Red)

CDI unit-model/Manufacturer 5HC-00/YAMAHA…

Ignition coil:

Model/Manufacturer 5BE-00/YAMAHA…

Minimum spark gap 6 mm (0.24 in)…

Primary winding resistance 0.20~0.30 ½at 20°C (68°F)…

Secondary winding resistance 9.5~14.3 k½at 20°C (68°F)…

5MW-9-30-2 7/3/00 2:20 PM Page 12

Page 79 of 578

2-12

GENERAL TORQUE SPECIFICATIONS/

DEFINITION OF UNITS

SPEC

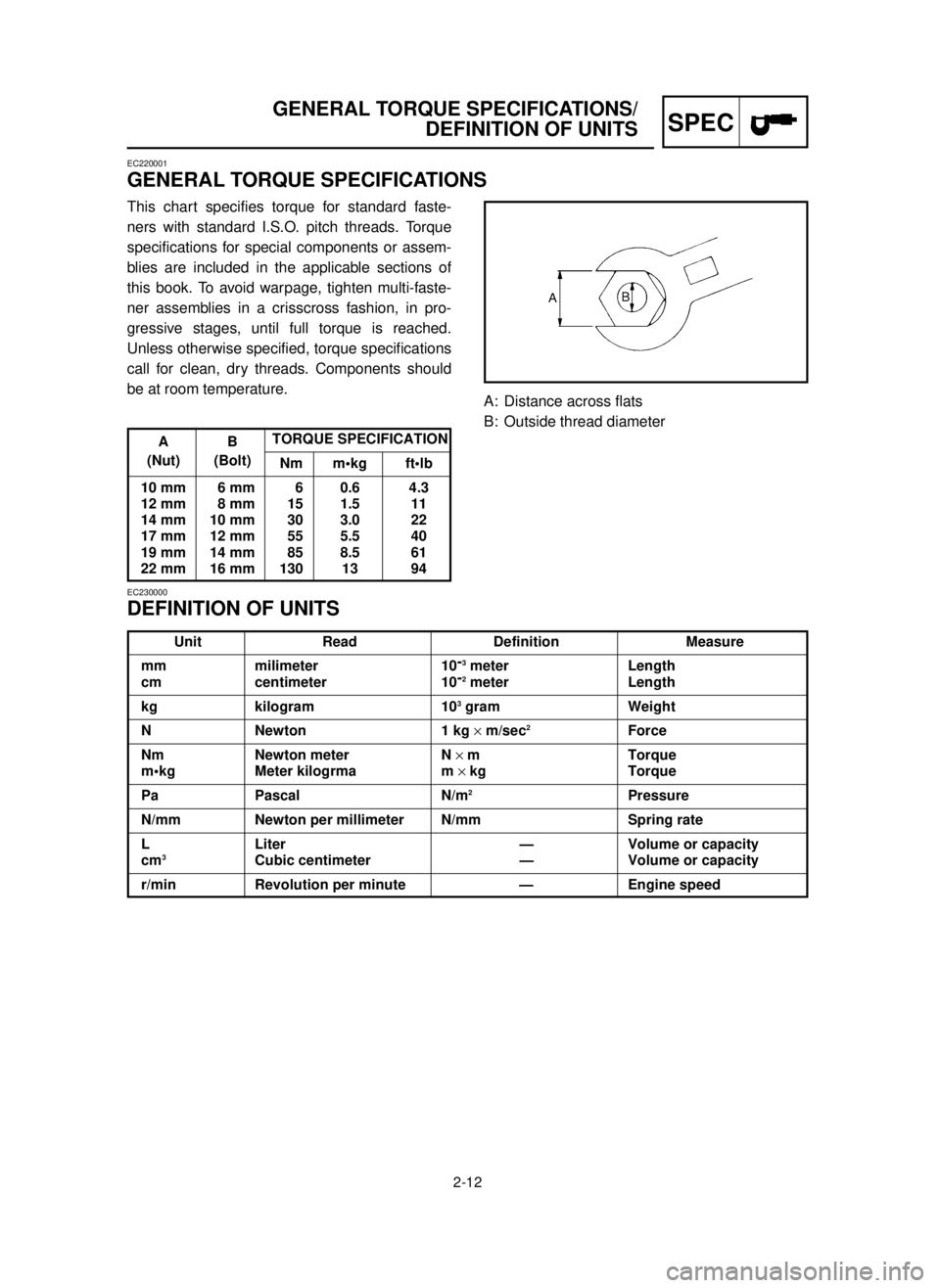

This chart specifies torque for standard faste-

ners with standard I.S.O. pitch threads. Torque

specifications for special components or assem-

blies are included in the applicable sections of

this book. To avoid warpage, tighten multi-faste-

ner assemblies in a crisscross fashion, in pro-

gressive stages, until full torque is reached.

Unless otherwise specified, torque specifications

call for clean, dry threads. Components should

be at room temperature.

A: Distance across flats

B: Outside thread diameter

EC230000

DEFINITION OF UNITS

EC220001

GENERAL TORQUE SPECIFICATIONS

ABTORQUE SPECIFICATION

(Nut) (Bolt)

Nm m•kg ft•lb

10 mm 6 mm 6 0.6 4.3

12 mm 8 mm 15 1.5 11

14 mm 10 mm 30 3.0 22

17 mm 12 mm 55 5.5 40

19 mm 14 mm 85 8.5 61

22 mm 16 mm 130 13 94

Unit Read Definition Measure

mm milimeter 10-

3meter Length

cm centimeter 10-2meter Length

kg kilogram 103gram Weight

N Newton 1 kg ´m/sec2Force

Nm Newton meter N ´m Torque

m•kg Meter kilogrma m ´kg Torque

Pa Pascal N/m2Pressure

N/mm Newton per millimeter N/mm Spring rate

L Liter — Volume or capacity

cm3Cubic centimeter — Volume or capacity

r/min Revolution per minute — Engine speed

5MW-9-30-2 7/3/00 2:20 PM Page 13

Page 200 of 578

3-35

STEERING HEAD INSPECTION AND ADJUSTMENT

INSP

ADJ

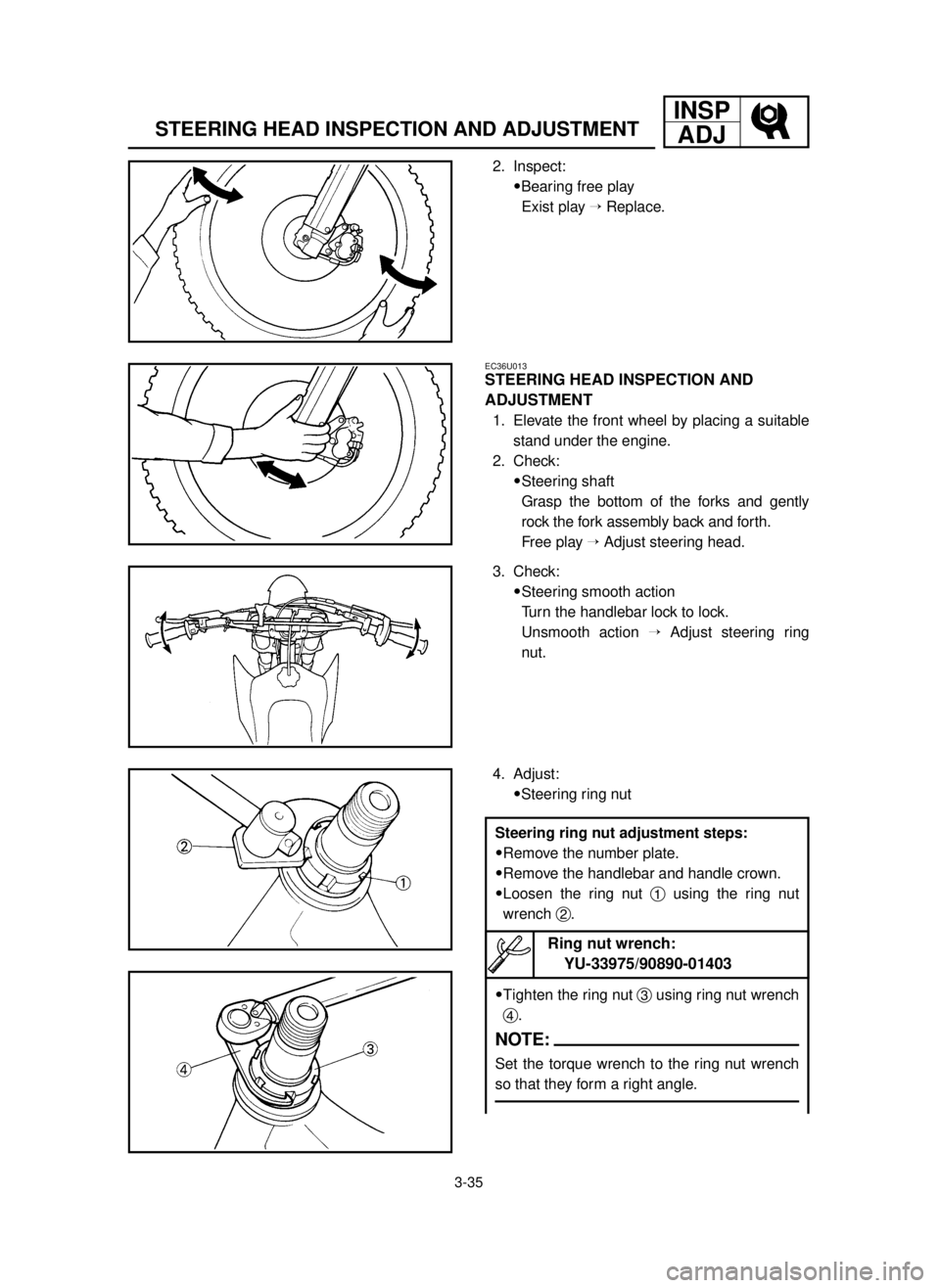

2. Inspect:

9Bearing free play

Exist play ÕReplace.

EC36U013

STEERING HEAD INSPECTION AND

ADJUSTMENT

1. Elevate the front wheel by placing a suitable

stand under the engine.

2. Check:

9Steering shaft

Grasp the bottom of the forks and gently

rock the fork assembly back and forth.

Free play ÕAdjust steering head.

3. Check:

9Steering smooth action

Turn the handlebar lock to lock.

Unsmooth action ÕAdjust steering ring

nut.

4. Adjust:

9Steering ring nut

Steering ring nut adjustment steps:

9Remove the number plate.

9Remove the handlebar and handle crown.

9Loosen the ring nut 1using the ring nut

wrench 2.

9Tighten the ring nut 3using ring nut wrench

4.

NOTE:

Set the torque wrench to the ring nut wrench

so that they form a right angle.

Ring nut wrench:

YU-33975/90890-01403

5MW-9-30-3B 7/3/00 3:28 PM Page 38