brake YAMAHA YZ250LC 2002 Manuale duso (in Italian)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: YZ250LC, Model: YAMAHA YZ250LC 2002Pages: 584, PDF Dimensioni: 14.59 MB

Page 22 of 584

CHAPTER 4

ENGINE

SEAT, FUEL TANK AND SIDE

COVERS.....................................................4-1

EXHAUST PIPE AND SILENCER..............4-3

RADIATOR..................................................4-4

CARBURETOR AND REED VALVE...........4-7

CYLINDER HEAD , CYLINDER AND

PISTON.....................................................4-18

CLUTCH AND PRIMARY DRIVEN

GEAR.......................................................4-33

KICK AXLE, SHIFT SHAFT AND

PRIMARY DRIVE GEAR...........................4-40

YPVS GOVERNOR...................................4-49

WATER PUMP..........................................4-52

CDI MAGNETO.........................................4-56

ENGINE REMOVAL..................................4-60

CRANKCASE AND CRANKSHAFT.........4-65

TRANSMISSION, SHIFT CAM AND

SHIFT FORK.............................................4-72

CHAPTER 5

CHASSIS

FRONT WHEEL AND REAR WHEEL........5-1

FRONT BRAKE AND REAR BRAKE.......5-10

FRONT FORK...........................................5-27

HANDLEBAR............................................5-40

STEERING................................................5-47

SWINGARM..............................................5-52

REAR SHOCK ABSORBER.....................5-59

5NX-9-30-0 6/5/01 3:49 PM Page 20

Page 26 of 584

1-1

DESCRIPTION

GEN

INFO

EC100000

GENERAL INFORMATION

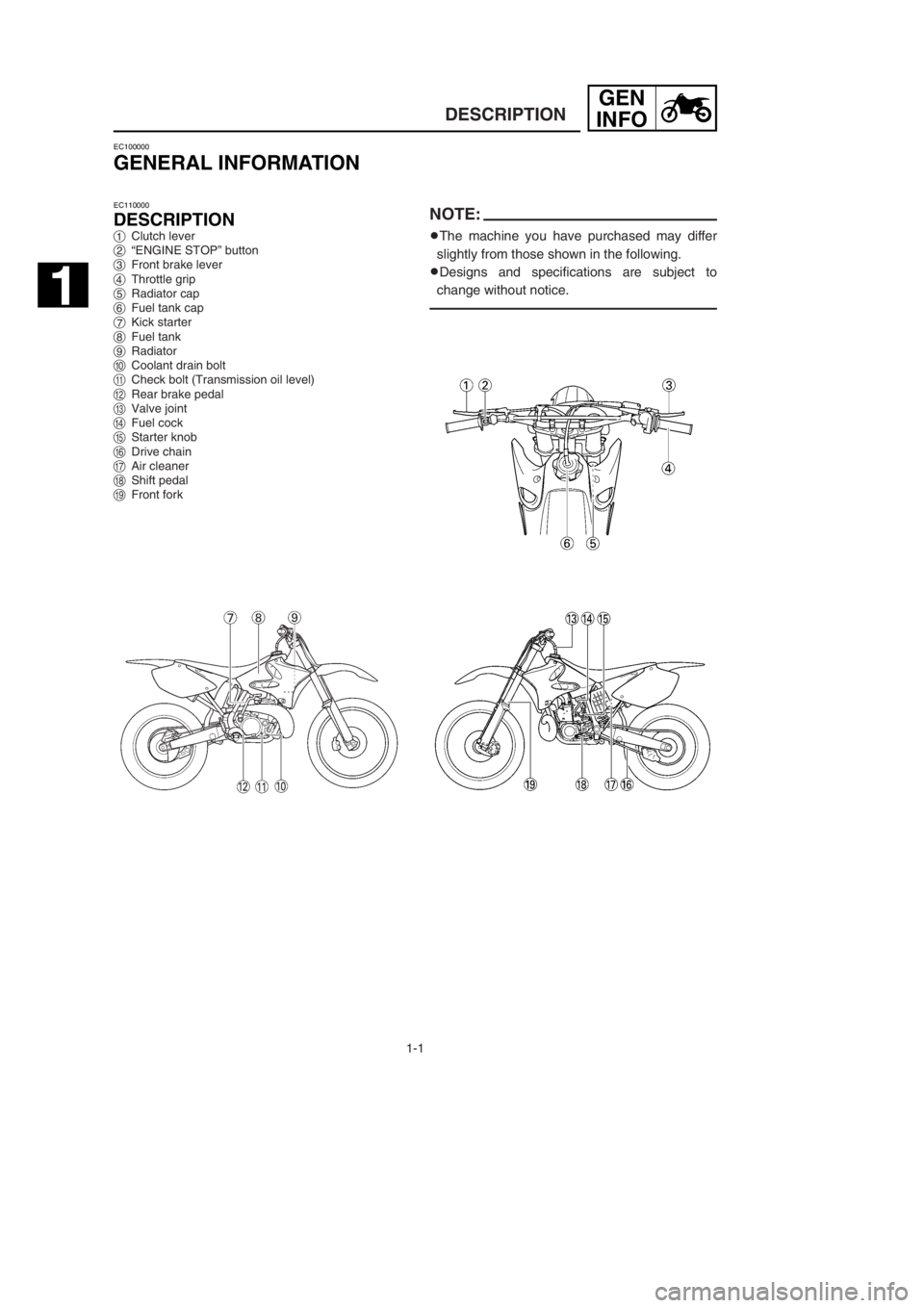

EC110000

DESCRIPTION

1Clutch lever

2“ENGINE STOP” button

3Front brake lever

4Throttle grip

5Radiator cap

6Fuel tank cap

7Kick starter

8Fuel tank

9Radiator

0Coolant drain bolt

qCheck bolt (Transmission oil level)

wRear brake pedal

eValve joint

rFuel cock

tStarter knob

yDrive chain

uAir cleaner

iShift pedal

oFront fork

NOTE:

9The machine you have purchased may differ

slightly from those shown in the following.

9Designs and specifications are subject to

change without notice.

1

5NX-9-30-1 6/5/01 3:53 PM Page 2

Page 48 of 584

1-10

CONTROL FUNCTIONS

GEN

INFO

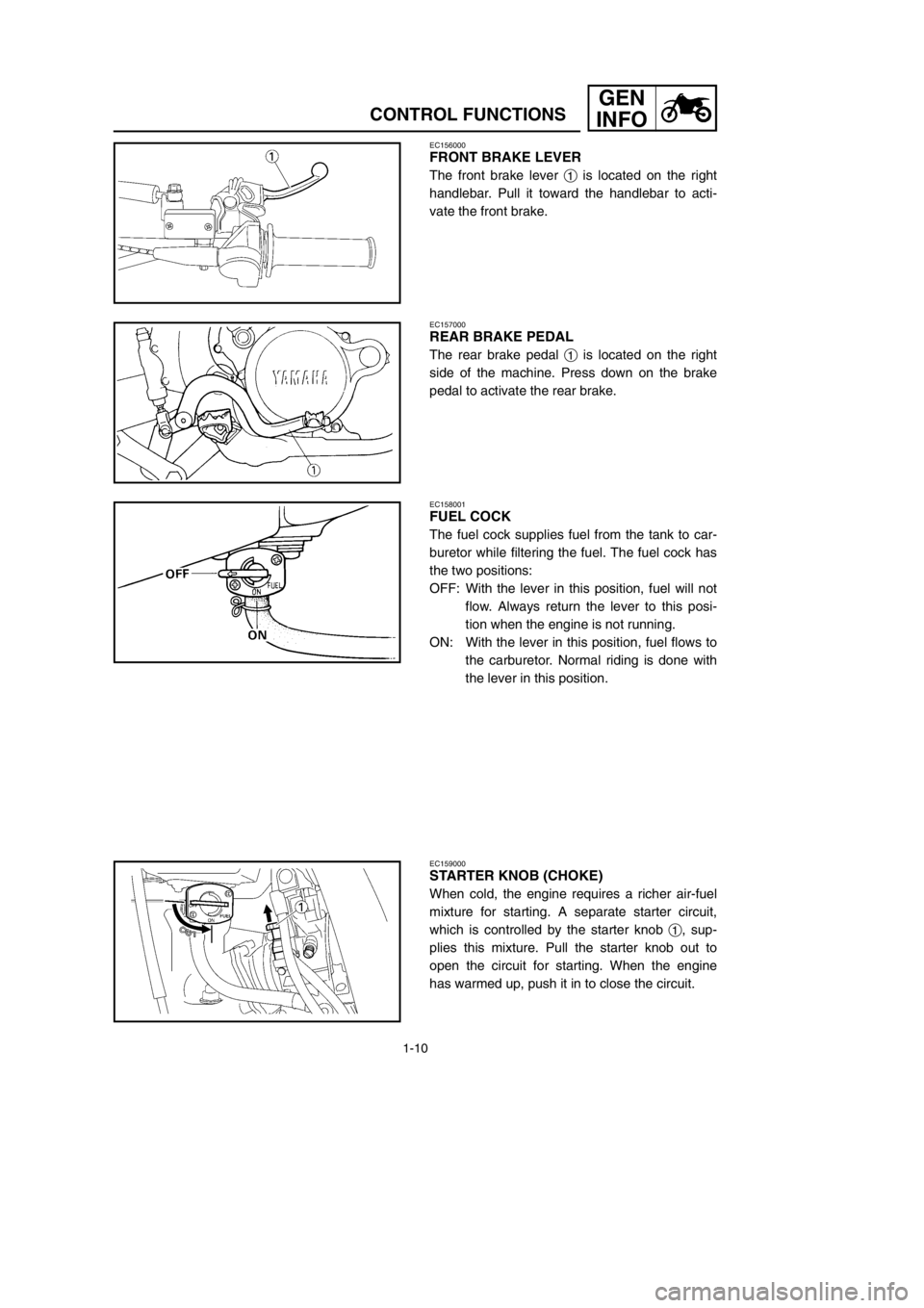

EC156000

FRONT BRAKE LEVER

The front brake lever 1is located on the right

handlebar. Pull it toward the handlebar to acti-

vate the front brake.

EC157000

REAR BRAKE PEDAL

The rear brake pedal 1is located on the right

side of the machine. Press down on the brake

pedal to activate the rear brake.

EC158001

FUEL COCK

The fuel cock supplies fuel from the tank to car-

buretor while filtering the fuel. The fuel cock has

the two positions:

OFF: With the lever in this position, fuel will not

flow. Always return the lever to this posi-

tion when the engine is not running.

ON: With the lever in this position, fuel flows to

the carburetor. Normal riding is done with

the lever in this position.

EC159000

STARTER KNOB (CHOKE)

When cold, the engine requires a richer air-fuel

mixture for starting. A separate starter circuit,

which is controlled by the starter knob 1, sup-

plies this mixture. Pull the starter knob out to

open the circuit for starting. When the engine

has warmed up, push it in to close the circuit.

5NX-9-30-1 6/5/01 3:53 PM Page 24

Page 60 of 584

1-16

TORQUE-CHECK POINTS

GEN

INFO

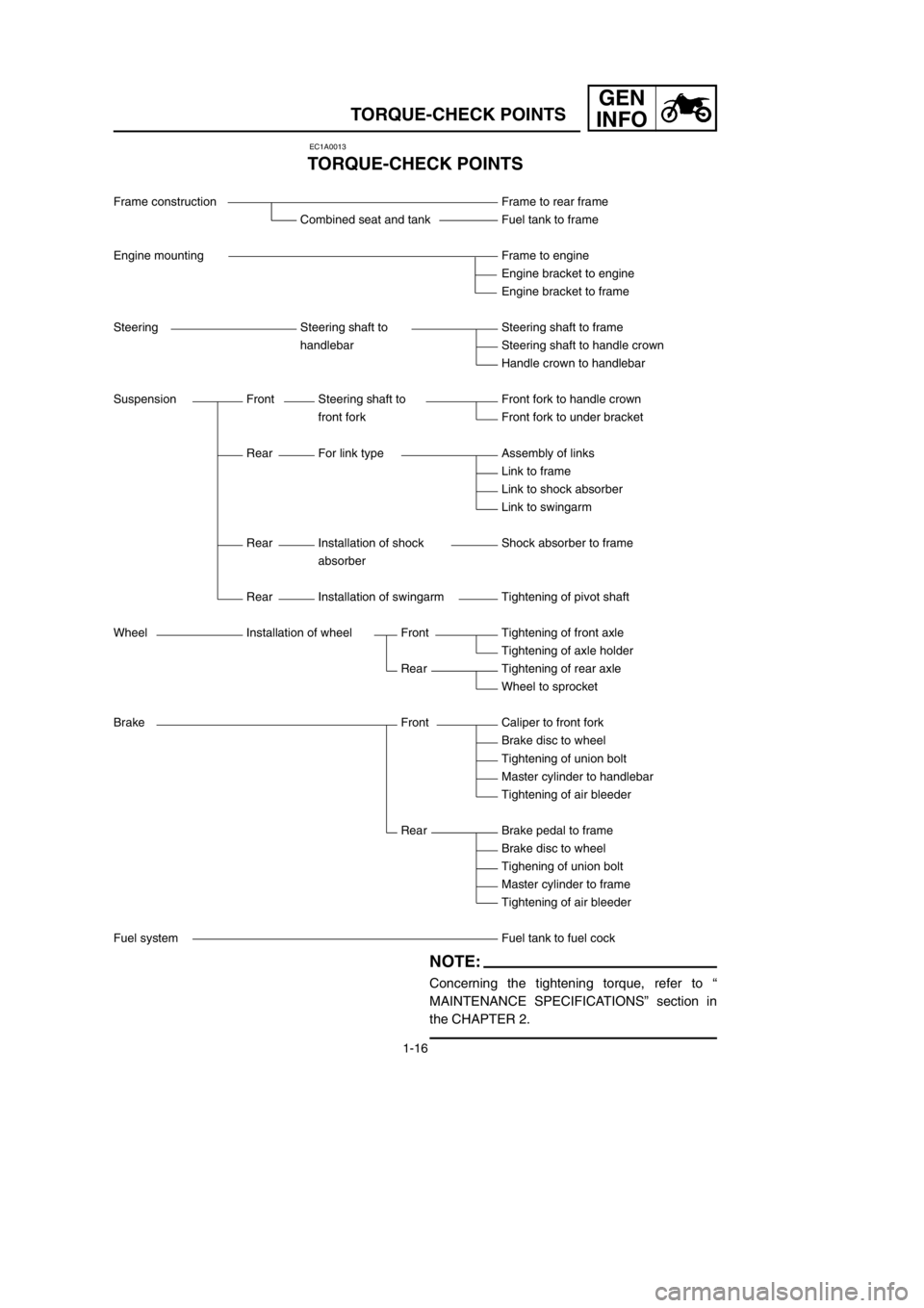

EC1A0013

TORQUE-CHECK POINTS

Frame construction Frame to rear frame

Combined seat and tank Fuel tank to frame

Engine mounting Frame to engine

Engine bracket to engine

Engine bracket to frame

Steering Steering shaft to Steering shaft to frame

handlebar Steering shaft to handle crown

Handle crown to handlebar

Suspension Front Steering shaft to Front fork to handle crown

front fork Front fork to under bracket

Rear For link type Assembly of links

Link to frame

Link to shock absorber

Link to swingarm

Rear Installation of shock Shock absorber to frame

absorber

Rear Installation of swingarm Tightening of pivot shaft

Wheel Installation of wheel Front Tightening of front axle

Tightening of axle holder

Rear Tightening of rear axle

Wheel to sprocket

Brake Front Caliper to front fork

Brake disc to wheel

Tightening of union bolt

Master cylinder to handlebar

Tightening of air bleeder

Rear Brake pedal to frame

Brake disc to wheel

Tighening of union bolt

Master cylinder to frame

Tightening of air bleeder

Fuel system Fuel tank to fuel cock

NOTE:

Concerning the tightening torque, refer to “

MAINTENANCE SPECIFICATIONS” section in

the CHAPTER 2.

5NX-9-30-1 6/5/01 3:54 PM Page 36

Page 64 of 584

1-17

CLEANING AND STORAGE

GEN

INFO

EC1B0000

CLEANING AND STORAGE

EC1B1000

CLEANING

Frequent cleaning of your machine will enhance

its appearance, maintain good overall perfor-

mance, and extend the life of many components.

1. Before washing the machine, block off the

end of the exhaust pipe to prevent water

from entering. A plastic bag secured with a

rubber band may be used for this purpose.

2. If the engine is excessively greasy, apply

some degreaser to it with a paint brush. Do

not apply degreaser to the chain, sprockets,

or wheel axles.

3. Rinse the dirt and degreaser off with a gar-

den hose; use only enough pressure to do

the job.

cC

Excessive hose pressure may cause water

seepage and contamination of wheel bear-

ings, front forks, brakes and transmission

seals. Many expensive repair bills have

resulted from improper high pressure

detergent applications such as those avail-

able in coin-operated car washers.

4. After the majority of the dirt has been hosed

off, wash all surfaces with warm water and a

mild detergent. Use an old toothbrush to

clean hard-to-reach places.

5. Rinse the machine off immediately with

clean water, and dry all surfaces with a soft

towel or cloth.

6. Immediately after washing, remove excess

water from the chain with a paper towel and

lubricate the chain to prevent rust.

7. Clean the seat with a vinyl upholstery clean-

er to keep the cover pliable and glossy.

8. Automotive wax may be applied to all paint-

ed or chromed surfaces. Avoid combination

cleaner-waxes, as they may contain abra-

sives.

9. After completing the above, start the engine

and allow it to idle for several minutes.

5NX-9-30-1 6/5/01 3:54 PM Page 40

Page 69 of 584

2-2

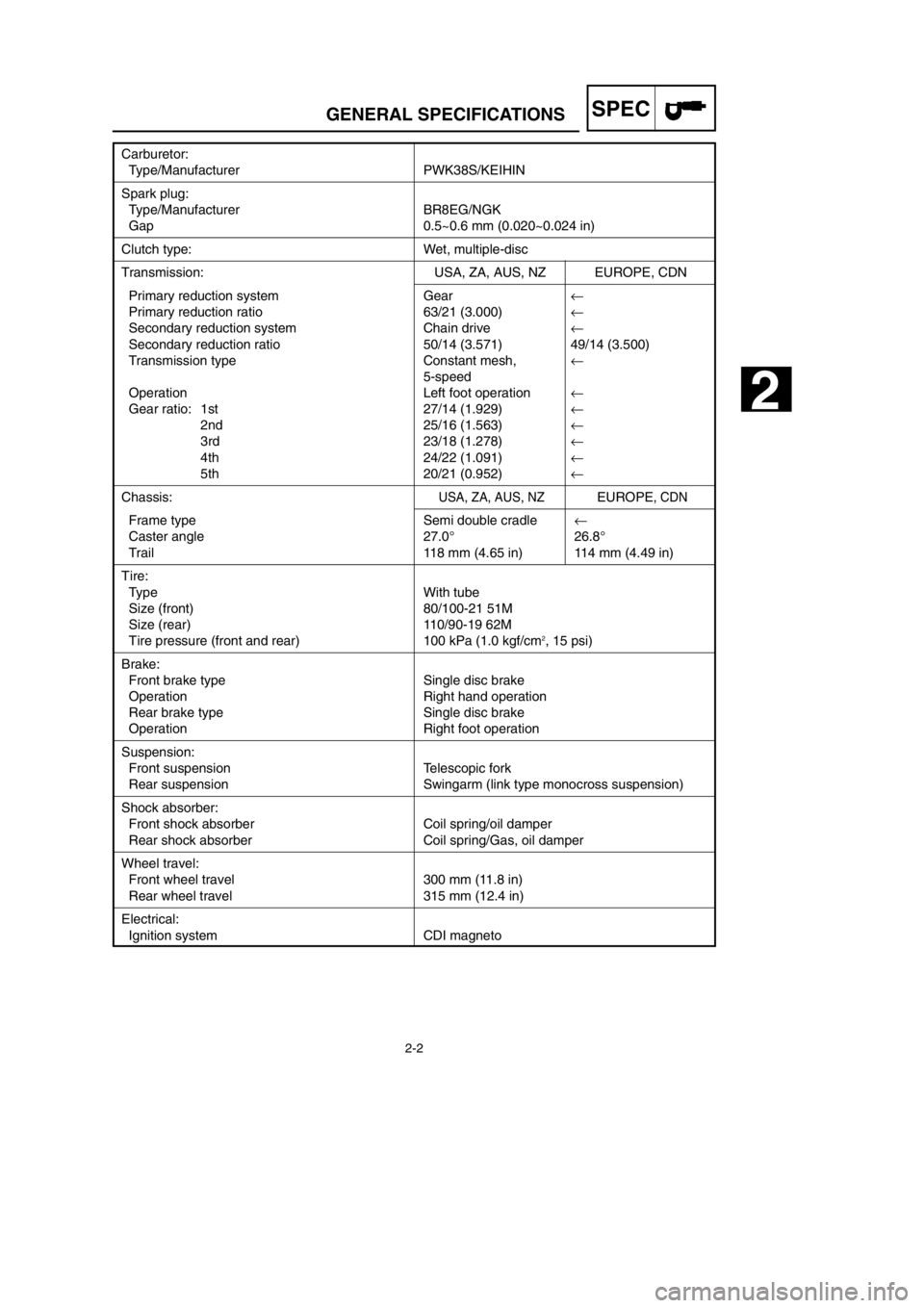

GENERAL SPECIFICATIONSSPEC

Carburetor:

Type/Manufacturer PWK38S/KEIHIN

Spark plug:

Type/Manufacturer BR8EG/NGK

Gap 0.5~0.6 mm (0.020~0.024 in)

Clutch type: Wet, multiple-disc

Transmission: USA, ZA, AUS, NZ EUROPE, CDN

Primary reduction system Gear←

Primary reduction ratio 63/21 (3.000)←

Secondary reduction system Chain drive←

Secondary reduction ratio 50/14 (3.571) 49/14 (3.500)

Transmission type Constant mesh,←

5-speed

Operation Left foot operation←

Gear ratio: 1st 27/14 (1.929)←

2nd 25/16 (1.563)←

3rd 23/18 (1.278)←

4th 24/22 (1.091)←

5th 20/21 (0.952)←

Chassis:USA, ZA, AUS, NZEUROPE, CDN

Frame type Semi double cradle←

Caster angle 27.0° 26.8°

Trail 118 mm (4.65 in) 114 mm (4.49 in)

Tire:

Type With tube

Size (front) 80/100-21 51M

Size (rear) 110/90-19 62M

Tire pressure (front and rear) 100 kPa (1.0 kgf/cm2, 15 psi)

Brake:

Front brake type Single disc brake

Operation Right hand operation

Rear brake type Single disc brake

Operation Right foot operation

Suspension:

Front suspension Telescopic fork

Rear suspension Swingarm (link type monocross suspension)

Shock absorber:

Front shock absorber Coil spring/oil damper

Rear shock absorber Coil spring/Gas, oil damper

Wheel travel:

Front wheel travel 300 mm (11.8 in)

Rear wheel travel 315 mm (12.4 in)

Electrical:

Ignition system CDI magneto

2

5NX-9-30-2 6/7/01 1:57 PM Page 3

Page 75 of 584

2-8

MAINTENANCE SPECIFICATIONSSPEC

Item Standard Limit

Wheel:

Front wheel type Spoke wheel…

Rear wheel type Spoke wheel…

Front rim size/Material 21 ×1.60/Aluminum…

Rear rim size/Material 19 ×2.15/Aluminum…

Rim runout limit:

Radial…

2.0 mm (0.08 in)

Lateral…

2.0 mm (0.08 in)

Drive chain

Type/Manufacturer DID520DMA2 SDH/DAIDO…

Number of links 113 links + joint…

Chain slack 40~50 mm (1.6~2.0 in)…

Chain length (10 links)…

152.5 mm (6.004 in)

Front disc brake:

Disc outside dia. ×Thickness 250 ×3.0 mm (9.84 ×0.12 in)…

Pad thickness 4.4 mm (0.17 in) 1.0 mm (0.04 in)

Master cylinder inside dia. 11.0 mm (0.433 in)…

Caliper cylinder inside dia. 27.0 mm (1.063 in) ×2…

Brake fluid type DOT #4…

Rear disc brake:

Disc outside dia. ×Thickness 245 ×4.0 mm (9.65 ×0.16 in)…

Deflection limit…

0.15 mm (0.006 in)

Pad thickness 6.4 mm (0.25 in) 1.0 mm (0.04 in)

Master cylinder inside dia. 12.7 mm (0.500 in)…

Caliper cylinder insdie dia. 27.0 mm (1.063 in)…

Brake fluid type DOT #4…

Brake lever & brake pedal:

Brake lever position 95 mm (3.74 in)…

Brake pedal height Zero mm (Zero in)…

(vertical height above footrest top)

Clutch lever free play (lever end) 8~13 mm (0.31~0.51 in)…

Throttle grip free play 3~5 mm (0.12~0.20 in)…

5NX-9-30-2 6/7/01 1:57 PM Page 9

Page 76 of 584

2-9

MAINTENANCE SPECIFICATIONSSPEC

17

14

105

20

22

40

21

0.7

7.2

7.2

11

5.1

0.7

2.9

1.4

2.9

6.5

1.4

4.3

4.3

3.6

2.9

22

22

17

2.2

13

4.3

75

17

8.7

10

19

7.2M 8 × 1.25

M 8 × 1.25

M24 × 1.0

M 8 × 1.25

M28 × 1.0

M48 × 1.0

M30 × 1.0

M12 × 1.25

M 5 × 0.8

M 6 × 1.0

M 6 × 1.0

M 8 × 1.25

M 6 × 1.0

M 4 × 0.7

M 6 × 1.0

M 6 × 1.0

M 5 × 0.8

M 6 × 1.0

M 4 × 0.7

M 6 × 1.0

M 6 × 1.0

M 6 × 1.0

M 5 × 0.8

M10 × 1.25

M10 × 1.25

M 8 × 1.25

M10 × 1.0

M10 × 1.0

M 8 × 1.25

M16 × 1.5

M 8 × 1.25

M 6 × 1.0

M 6 × 1.0

M 8 × 1.25

M 6 × 1.0 Handle crown and outer tube

Under bracket and outer tube

Handle crown and steering shaft

Handlebar holder (upper)

Steering ring nut

Front fork and cap bolt

Front fork and base valve

Cap bolt and damper rod (front fork)

Bleed screw (front fork) and cap bolt

Front fork and protector

Front fork and brake hose holder

Front fork and hose cover

Front fork and hose cover

Throttle cable cap

Grip cap upper and lower

Clutch lever (bolt)

Clutch lever holder

Front brake master cylinder and bracket

Front brake master cylinder cap

Brake lever mounting (bolt)

Brake lever mounting (nut)

Brake lever position locknut

Cable guide (front brake hose) and guide stay

Front brake hose union bolt (master cylinder)

Front brake hose union bolt (caliper)

Front brake caliper and front fork

Brake caliper (front and rear) and pad pin plug

Brake caliper (front and rear) and pad pin

Brake caliper (front and rear) and bleed screw

Front wheel axle and nut

Front wheel axle holder

Front brake disc and wheel hub

Rear brake disc and wheel hub

Brake pedal mounting

Rear brake master cylinder and framePart to be tightened Thread size Q’tyTightening torque

Nm m•kg ft•lb

4

4

1

4

1

2

2

2

2

6

2

1

1

2

2

1

2

2

2

1

1

1

1

1

1

2

1

1

1

1

4

6

6

1

223

20

145

28

30

55

29

1

10

10

16

7

1

4

2

4

9

2

6

6

5

4

30

30

23

3

18

6

105

23

12

14

26

102.3

2.0

14.5

2.8

3.0

5.5

2.9

0.1

1.0

1.0

1.6

0.7

0.1

0.4

0.2

0.4

0.9

0.2

0.6

0.6

0.5

0.4

3.0

3.0

2.3

0.3

1.8

0.6

10.5

2.3

1.2

1.4

2.6

1.0

NOTE:

1. First, tighten the ring nut approximately 38 Nm (3.8 m•kg, 27 ft•lb) by using the ring nut wrench,

then loosen the ring nut one turn.

2. Retighten the ring nut 7 Nm (0.7 m•kg, 5.1 ft•lb).

Refer to NOTE

5NX-9-30-2 6/7/01 1:57 PM Page 10

Page 77 of 584

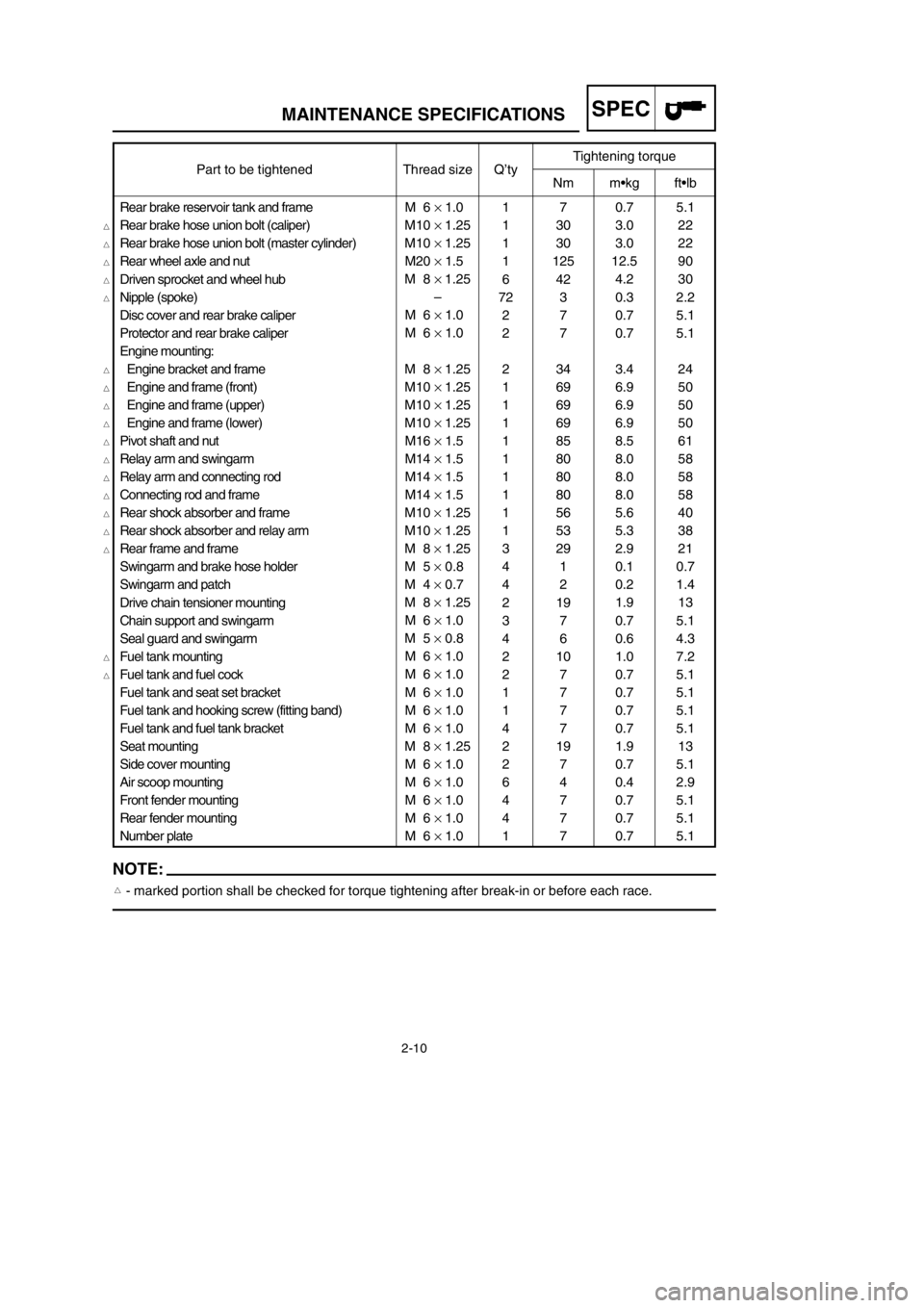

2-10

MAINTENANCE SPECIFICATIONSSPEC

M 6 × 1.0

M10 × 1.25

M10 × 1.25

M20 × 1.5

M 8 × 1.25

–

M 6 × 1.0

M 6 × 1.0

M 8 × 1.25

M10 × 1.25

M10 × 1.25

M10 × 1.25

M16 × 1.5

M14 × 1.5

M14 × 1.5

M14 × 1.5

M10 × 1.25

M10 × 1.25

M 8 × 1.25

M 5 ×0.8

M 4 ×0.7

M 8 × 1.25

M 6 × 1.0

M 5 ×0.8

M 6 × 1.0

M 6 × 1.0

M 6 × 1.0

M 6 × 1.0

M 6 × 1.0

M 8 × 1.25

M 6 × 1.0

M 6 × 1.0

M 6 × 1.0

M 6 × 1.0

M 6 × 1.0 Rear brake reservoir tank and frame

Rear brake hose union bolt (caliper)

Rear brake hose union bolt (master cylinder)

Rear wheel axle and nut

Driven sprocket and wheel hub

Nipple (spoke)

Disc cover and rear brake caliper

Protector and rear brake caliper

Engine mounting:

Engine bracket and frame

Engine and frame (front)

Engine and frame (upper)

Engine and frame (lower)

Pivot shaft and nut

Relay arm and swingarm

Relay arm and connecting rod

Connecting rod and frame

Rear shock absorber and frame

Rear shock absorber and relay arm

Rear frame and frame

Swingarm and brake hose holder

Swingarm and patch

Drive chain tensioner mounting

Chain support and swingarm

Seal guard and swingarm

Fuel tank mounting

Fuel tank and fuel cock

Fuel tank and seat set bracket

Fuel tank and hooking screw (fitting band)

Fuel tank and fuel tank bracket

Seat mounting

Side cover mounting

Air scoop mounting

Front fender mounting

Rear fender mounting

Number platePart to be tightened Thread size Q’tyTightening torque

Nm m•kg ft•lb

1

1

1

1

6

72

2

2

2

1

1

1

1

1

1

1

1

1

3

4

4

2

3

4

2

2

1

1

4

2

2

6

4

4

17

30

30

125

42

3

7

7

34

69

69

69

85

80

80

80

56

53

29

1

2

19

7

6

10

7

7

7

7

19

7

4

7

7

70.7

3.0

3.0

12.5

4.2

0.3

0.7

0.7

3.4

6.9

6.9

6.9

8.5

8.0

8.0

8.0

5.6

5.3

2.9

0.1

0.2

1.9

0.7

0.6

1.0

0.7

0.7

0.7

0.7

1.9

0.7

0.4

0.7

0.7

0.75.1

22

22

90

30

2.2

5.1

5.1

24

50

50

50

61

58

58

58

40

38

21

0.7

1.4

13

5.1

4.3

7.2

5.1

5.1

5.1

5.1

13

5.1

2.9

5.1

5.1

5.1

NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race.

5NX-9-30-2 6/7/01 1:57 PM Page 11

Page 118 of 584

2-14

CABLE ROUTING DIAGRAMSPEC

1Ground lead

2Ignition coil lead

3Clamp

4Wireharness

5CDI magneto lead

6YPVS breather hose

7Radiator breather hose

8Cable guide

9“ENGINE STOP” button lead

0Brake hose

APass the “ENGINE STOP” but-

ton lead on the inside of the

ignition coil lead and ground

lead.BClamp the “ENGINE STOP” but-

ton lead, ground lead, ignition

coil lead, wireharness and CDI

magneto lead with the clamp

ends downward.

In so doing, clamp the “ENGINE

STOP” button lead at its coupler

and do not allow the CDI mag-

neto lead to slacken.

CPass the radiator breather hose

outside the engine bracket and

inside the down-tube.Pass the

radiator breather hose inside

the CDI magneto lead.

DClamp the CDI magneto lead,

radiator breather hose and

YPVS breather hose. In so

doing, clamp the CDI magneto

lead at the rear of the down-

tube with the clamp ends for-

ward.EClamp the radiator breather

hose and CDI magneto lead at

the rear of the down-tube with

the clamp ends outward.

FPass the radiator breather hose

and CDI magneto lead in front

of the radiator hose.

GPass the radiator breather hose

between the frame and radiator.

HAlign the top of the brake hose

neck with the brake hose holder

bottom.

IPass the brake hose in front of

the axle boss,then fit it into the

hose groove so that the brake

hose does not contact the nut

(wheel axle).

JFit the brake hose into the guide

on the protector.

5NX-9-30-2 6/7/01 1:57 PM Page 52