engine YAMAHA YZ250LC 2002 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: YZ250LC, Model: YAMAHA YZ250LC 2002Pages: 584, PDF Size: 14.59 MB

Page 32 of 584

1-4

IMPORTANT INFORMATION

GEN

INFO

EC133000

GASKETS, OIL SEALS AND O-RINGS

1. All gaskets, oil seals, and O-rings should be

replaced when an engine is overhauled. All

gasket surfaces, oil seal lips, and O-rings

must be cleaned.

2. Properly oil all mating parts and bearings

during reassembly. Apply grease to the oil

seal lips.

EC134000

LOCK WASHERS/PLATES AND COTTER

PINS

1. All lock washers/plates 1and cotter pins

must be replaced when they are removed.

Lock tab(s) should be bent along the bolt or

nut flat(s) after the bolt or nut has been

properly tightened.

EC135001

BEARINGS AND OIL SEALS

1. Install the bearing (s) 1and oil seal (s) 2

with their manufacturer’s marks or numbers

facing outward. (In other words, the

stamped letters must be on the side

exposed to view.) When installing oil seal(s),

apply a light coating of light-weight lithium

base grease to the seal lip(s). Oil the bear-

ings liberally when installing.

cC

Do not use compressed air to spin the

bearings dry. This causes damage to the

bearing surfaces.

EC132000

ALL REPLACEMENT PARTS

1. We recommend to use Yamaha genuine

parts for all replacements. Use oil and/or

grease recommended by Yamaha for

assembly and adjustment.

5NX-9-30-1 6/5/01 3:53 PM Page 8

Page 39 of 584

1-8

SPECIAL TOOLS

GEN

INFO

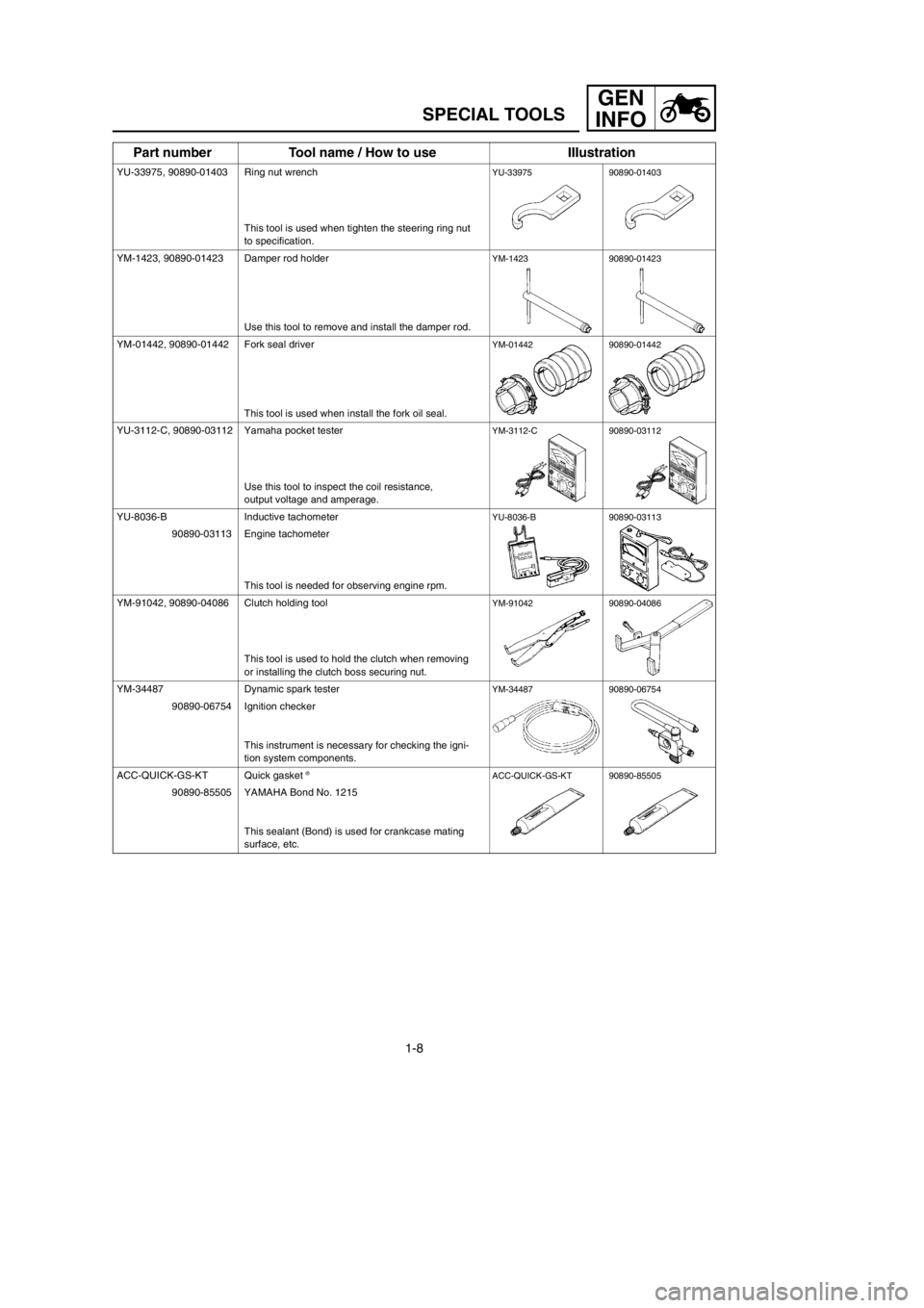

Part number Tool name / How to use IIIustration

YU-33975, 90890-01403 Ring nut wrenchYU-33975 90890-01403

This tool is used when tighten the steering ring nut

to specification.

YM-1423, 90890-01423 Damper rod holder

YM-1423 90890-01423

Use this tool to remove and install the damper rod.

YM-01442, 90890-01442 Fork seal driver

YM-01442 90890-01442

This tool is used when install the fork oil seal.

YU-3112-C, 90890-03112 Yamaha pocket tester

YM-3112-C 90890-03112

Use this tool to inspect the coil resistance,

output voltage and amperage.

YU-8036-B Inductive tachometer

YU-8036-B 90890-03113

90890-03113 Engine tachometer

This tool is needed for observing engine rpm.

YM-91042, 90890-04086 Clutch holding tool

YM-91042 90890-04086

This tool is used to hold the clutch when removing

or installing the clutch boss securing nut.

YM-34487 Dynamic spark tester

YM-34487 90890-06754

90890-06754 Ignition checker

This instrument is necessary for checking the igni-

tion system components.

ACC-QUICK-GS-KT Quick gasket

®ACC-QUICK-GS-KT 90890-85505

90890-85505 YAMAHA Bond No. 1215

This sealant (Bond) is used for crankcase mating

surface, etc.

5NX-9-30-1 6/5/01 3:53 PM Page 15

Page 46 of 584

1-9

CONTROL FUNCTIONS

GEN

INFO

EC150000

CONTROL FUNCTIONS

EC151000

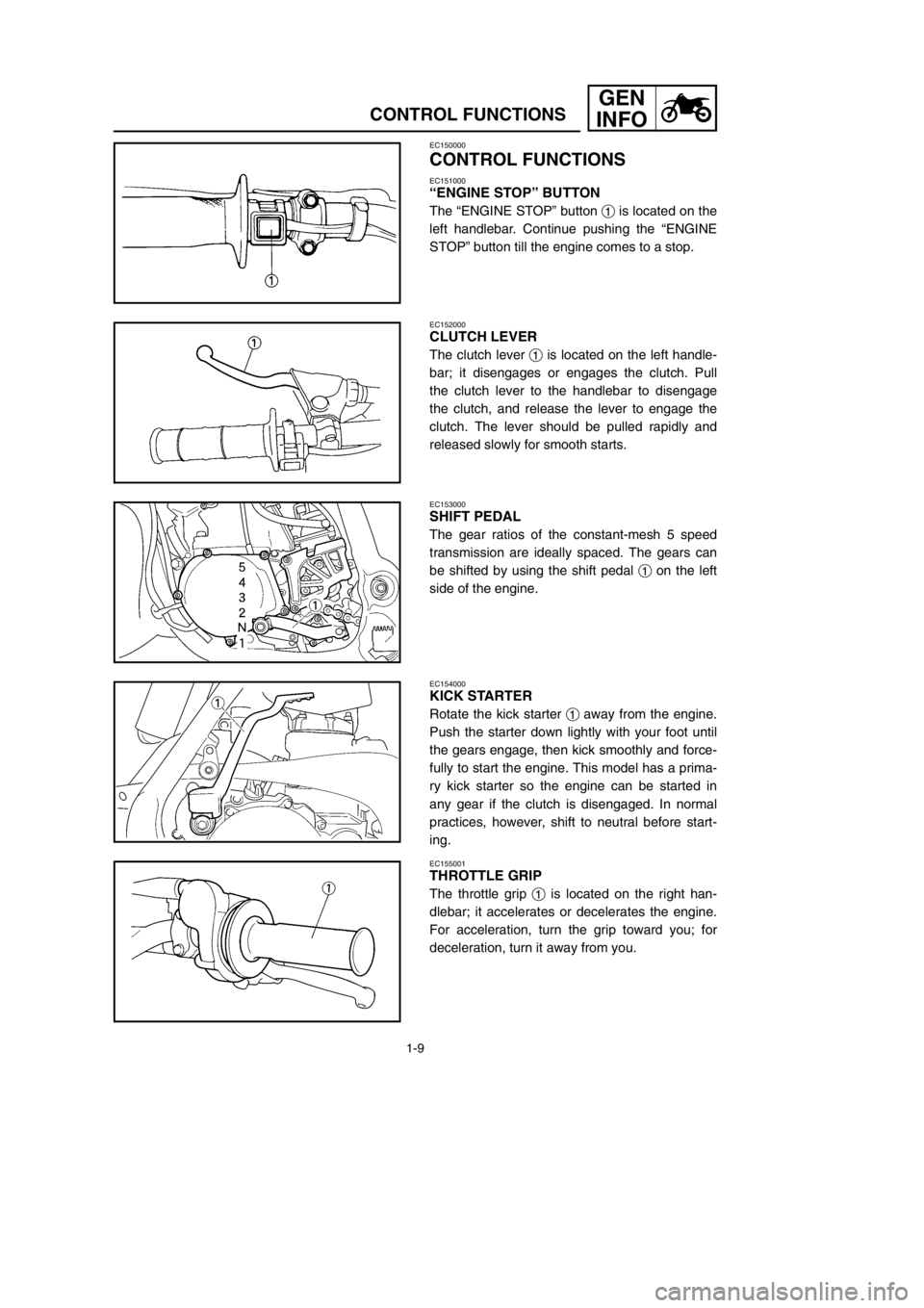

“ENGINE STOP” BUTTON

The “ENGINE STOP” button 1is located on the

left handlebar. Continue pushing the “ENGINE

STOP” button till the engine comes to a stop.

EC152000

CLUTCH LEVER

The clutch lever 1is located on the left handle-

bar; it disengages or engages the clutch. Pull

the clutch lever to the handlebar to disengage

the clutch, and release the lever to engage the

clutch. The lever should be pulled rapidly and

released slowly for smooth starts.

EC153000

SHIFT PEDAL

The gear ratios of the constant-mesh 5 speed

transmission are ideally spaced. The gears can

be shifted by using the shift pedal 1on the left

side of the engine.

EC154000

KICK STARTER

Rotate the kick starter 1away from the engine.

Push the starter down lightly with your foot until

the gears engage, then kick smoothly and force-

fully to start the engine. This model has a prima-

ry kick starter so the engine can be started in

any gear if the clutch is disengaged. In normal

practices, however, shift to neutral before start-

ing.

EC155001

THROTTLE GRIP

The throttle grip 1is located on the right han-

dlebar; it accelerates or decelerates the engine.

For acceleration, turn the grip toward you; for

deceleration, turn it away from you.

5NX-9-30-1 6/5/01 3:53 PM Page 22

Page 47 of 584

1-9

FONCTIONS DES COMMANDES

BEDIENUNGSELEMENTE

FUNZIONI DEI COMANDI

GEN

INFO

FONCTIONS DES

COMMANDES

BOUTON D’ARRET DE MOTEUR

“ENGINE STOP”

Ce bouton d’arrêt de moteur “ENGINE

STOP” 1est situé sur le guidon

gauche. Continuer à appuyer sur le bou-

ton d’arrêt de moteur “ENGINE STOP”

jusqu’a que ce le moteur s’arrête.

LEVIER D’EMBRAYAGE

Le levier d’embrayage 1est situé sur

le guidon gauche et permet d’embrayer

ou de débrayer. Tirer le levier

d’embrayage vers le guidon pour

débrayer et relâcher le levier pour

embrayer. Pour des démarrages doux,

le levier doit être tiré rapidement et

relâché lentement.

PEDALE DE CHANGEMENT DE

VITESSE

Les 5 rapports pour de la boîte de

vitesses à prise constante sont idéale-

ment échelonnés. Le changement de

vitesse est commandé par le sélecteur à

pédale 1situé du côté gauche du

moteur.

KICKSTARTER

Déployer la pédale de démarreur au

pied 1. Appuyer légèrement sur la

pédale jusqu’à ce que les pignons se

mettent en prise puis l’actionner vigou-

reusement pour démarrer le moteur. Ce

modèle est muni d’un démarreur au

pied primaire, de sorte qu’on peut

démarrer sur n’importe quelle vitesse à

condition de débrayer. Toutefois, nor-

malement, on remettra les vitesses au

point mort avant la mise en marche.

POIGNEE DES GAZ

La poignée des gaz 1est située sur le

guidon droit; elle permet d’accélérer ou

de décélérer le moteur. Pour une accé-

lération, tourner la poignée vers soi;

pour une décélération, la tourner de

l’autre côté.

BEDIENUNGSELEMENTE

MOTORSTOPPKNOPF „ENGINE

STOP“

Dieser Motorstoppknopf „ENGINE

STOP“ 1befindet sich am linken

Lenkerrohr.

Den Motorstoppknopf „ENGINE

STOP“ drücken, bis der Motor

abstirbt.

KUPPLUNGSHEBEL

Der Kupplungshebel 1befindet sich

am linken Lenkerrohr und dient zum

Aus- bzw. Einrücken der Kupplung.

Den Kupplungshebel bis zum Lenker-

rohr durchziehen, um die Kupplung

auszurücken; den Hebel wieder frei-

geben, sobald die Kupplung wieder

eingerückt werden soll. Der Hebel

sollte schnell durchgezogen, aber

langsam freigegeben werden, um ein

ruckfreies Anfahren zu gewährleisten.

FUSSSCHALTHEBEL

Das Untersetzungsverhältnis dieses 5

Gang Synchrongetriebes ist optimal

abgestimmt, um bestes Leistungsver-

mögen bei allen Fahrbedingungen zu

garantieren. Das Einlegen der einzel-

nen Gänge erfolgt mittels Fußschalt-

hebel 1, angebrancht an der linken

Seite des Motors.

KICKSTARTER

Den Kickstarter 1vom Motor weg-

schwenken. Den Kickstarter langsam

niedertreten, bis die Zahnräder einra-

sten; danach den Kickstarter

schwungvoll durchtreten, um den

Motor anzulassen. Dieses Modell ist

mit einem Primärkickstarter ausgerü-

stet, d.h. der Motor kann auch bei ein-

gelegtem Gang angelassen werden,

vorausgesetzt, daß die Kupplung aus-

gerückt wird. Normalerweise sollte

jedoch in den Leerlauf geschaltet wer-

den, bevor der Motor gestartet wird.

GASDREHGRIFF

Der Gasdrehgriff 1ist am rechten

Lenkerrohr angeordnet; mit diesem

Gasdrehgriff wird die Drehzahl des

Motors erhöht bzw. reduziert. Für eine

Drehzahlerhöhung (Beschleunigung)

den Gasdrehgriff gegen sich drehen,

wogegen für eine Drehzahlreduzie-

rung der Gasdrehgriff von sich wegge-

dreht werden muß.

IC150000

FUNZIONI DEI COMANDI

IC151000

PULSANTE “ARRESTO

MOTORE”

Il pulsante “ARRESTO MOTORE” 1

è situato sul manubrio sinistro. Conti-

nuare a premere il pulsante “ARRE-

STO MOTORE” finché il motore non

si arresta.

IC152000

LEVA DI COMANDO DELLA

FRIZIONE

La leva di comando della frizione 1è

situata sul manubrio sinistro; disinnesta

o innesta la frizione. Tirare la leva di

comando della frizione verso il manu-

brio per disinnestare la frizione e lascia-

re andare la leva per innestare la frizio-

ne. La leva dovrebbe essere tirata rapi-

damente e lasciata andare lentamente

per partenze dolci.

IC153000

PEDALE DI COMANDO DEL

CAMBIO

I rapporti di trasmissione della trasmis-

sione a 5 marce a ingranamento costan-

te sono distanziati in maniera ideale. Si

possono cambiare le marce usando il

pedale di comando del cambio 1sul

lato sinistro del motore.

IC154000

PEDIVELLA DELLA MESSA IN

MOTO

Ruotare la pedivella della messa in

moto 1allontanandola dal motore.

Spingere leggermente la pedivella verso

il basso con il piede finché le marce

non si innestano, quindi scalciare senza

strappi e con forza per avviare il moto-

re. Questo modello ha una pedivella

primaria della messa in moto, quindi il

motore può essere avviato in qualsiasi

marcia se la frizione è disinnestata.

Nella prassi normale, però, mettere in

folle prima di avviare.

IC155001

MANOPOLA DELL’ACCELERA-

TORE

La manopola dell’acceleratore 1è

situata sul manubrio destro; accelera o

decelera il motore. Per l’accelerazione,

ruotare la manopola verso il guidatore;

per la decelerazione, ruotarla lontano

dal guidatore.

5NX-9-30-1 6/5/01 3:53 PM Page 23

Page 48 of 584

1-10

CONTROL FUNCTIONS

GEN

INFO

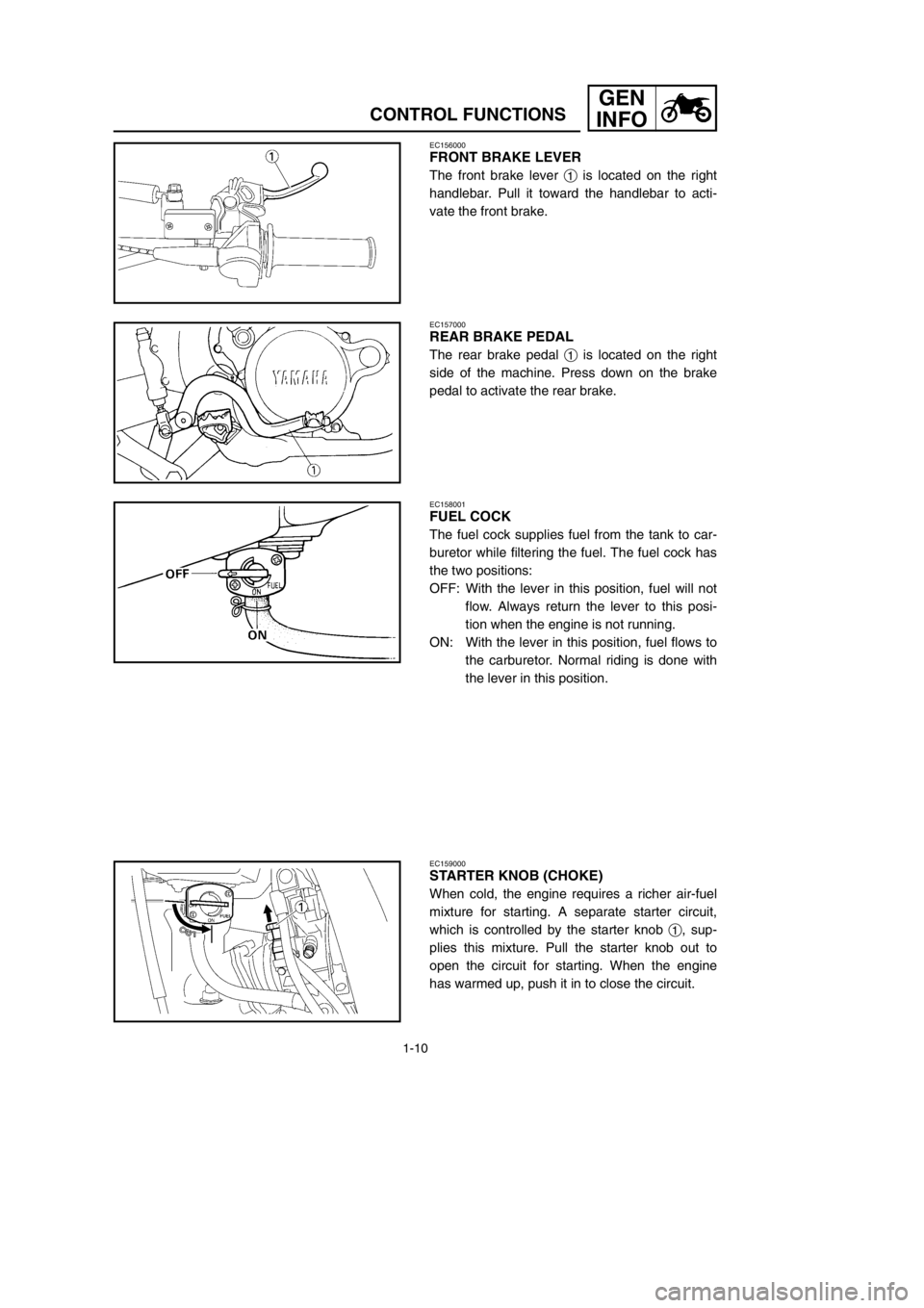

EC156000

FRONT BRAKE LEVER

The front brake lever 1is located on the right

handlebar. Pull it toward the handlebar to acti-

vate the front brake.

EC157000

REAR BRAKE PEDAL

The rear brake pedal 1is located on the right

side of the machine. Press down on the brake

pedal to activate the rear brake.

EC158001

FUEL COCK

The fuel cock supplies fuel from the tank to car-

buretor while filtering the fuel. The fuel cock has

the two positions:

OFF: With the lever in this position, fuel will not

flow. Always return the lever to this posi-

tion when the engine is not running.

ON: With the lever in this position, fuel flows to

the carburetor. Normal riding is done with

the lever in this position.

EC159000

STARTER KNOB (CHOKE)

When cold, the engine requires a richer air-fuel

mixture for starting. A separate starter circuit,

which is controlled by the starter knob 1, sup-

plies this mixture. Pull the starter knob out to

open the circuit for starting. When the engine

has warmed up, push it in to close the circuit.

5NX-9-30-1 6/5/01 3:53 PM Page 24

Page 52 of 584

1-12

FUEL AND ENGINE MIXING OIL

GEN

INFO

EC160051

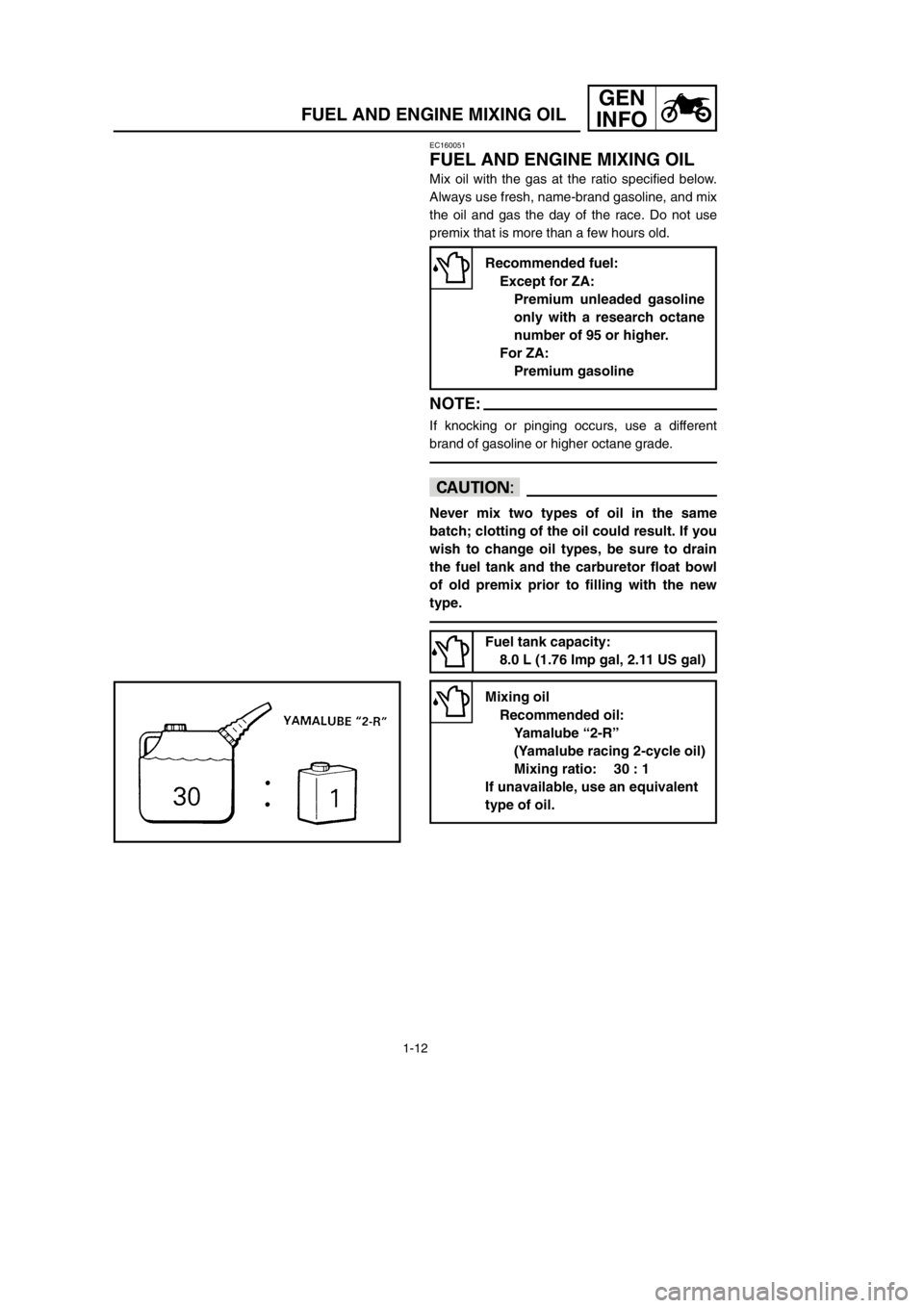

FUEL AND ENGINE MIXING OIL

Mix oil with the gas at the ratio specified below.

Always use fresh, name-brand gasoline, and mix

the oil and gas the day of the race. Do not use

premix that is more than a few hours old.

NOTE:

If knocking or pinging occurs, use a different

brand of gasoline or higher octane grade.

cC

Never mix two types of oil in the same

batch; clotting of the oil could result. If you

wish to change oil types, be sure to drain

the fuel tank and the carburetor float bowl

of old premix prior to filling with the new

type.

Fuel tank capacity:

8.0 L (1.76 Imp gal, 2.11 US gal)

Mixing oil

Recommended oil:

Yamalube “2-R”

(Yamalube racing 2-cycle oil)

Mixing ratio: 30 : 1

If unavailable, use an equivalent

type of oil.

Recommended fuel:

Except for ZA:

Premium unleaded gasoline

only with a research octane

number of 95 or higher.

For ZA:

Premium gasoline

5NX-9-30-1 6/5/01 3:53 PM Page 28

Page 54 of 584

1-13

STARTING AND BREAK-IN

GEN

INFO

EC190000

STARTING AND BREAK-IN

cC

Before starting the machine, perform the

checks in the pre-operation check list.

w

Never start or run the engine in a closed

area. The exhaust fumes are poisonous;

they can cause loss of consciousness and

death in a very short time. Always operate

the machine in a well-ventilated area.

EC191001

STARTING A COLD ENGINE

1. Shift the transmission into neutral.

2. Turn the fuel cock to “ON” and full open the

starter knob (CHOKE).

3. With the throttle completely closed start the

engine by kicking the kick starter forcefully

with firm stroke.

4. Run the engine at idle or slightly higher until

it warms up: this usually takes about one or

two minutes.

5. The engine is warmed up when it responds

normally to the throttle with the starter knob

(CHOKE) turned off.

cC

Do not warm up the engine for extended peri-

ods.

EC193001

STARTING A WARM ENGINE

Do not operate the starter knob (CHOKE). Open

the throttle slightly and start the engine by kick-

ing the kick starter forcefully with firm stroke.

cC

Observe the following break-in procedures

during initial operation to ensure optimum

performance and avoid engine damage.

5NX-9-30-1 6/5/01 3:53 PM Page 30

Page 56 of 584

1-14

STARTING AND BREAK-IN

GEN

INFO

EC194001

BREAK-IN PROCEDURES

1. Before starting the engine, fill the fuel tank

with a break-in oil-fuel mixture as follows.

2. Perform the pre-operation checks on the

machine.

3. Start and warm up the engine. Check the

idle speed, and check the operation of the

controls and the “ENGINE STOP” button.

4. Operate the machine in the lower gears at

moderate throttle openings for five to eight

minutes. Stop and check the spark plug

condition; it will show a rich condition during

break-in.

5. Allow the engine to cool. Restart the engine

and operate the machine as in the step

above for five minutes. Then, very briefly

shift to the higher gears and check full-throt-

tle response. Stop and check the spark

plug.

6. After again allowing the engine to cool,

restart and run the machine for five more

minutes. Full throttle and the higher gears

may be used, but sustained full-throttle

operation should be avoided. Check the

spark plug condition.

7. Allow the engine to cool, remove the top

end, and inspect the piston and cylinder.

Remove any high spots on the piston with

#600 grit wet sandpaper. Clean all compo-

nents and carefully reassemble the top end.

8. Drain the break-in oil-fuel mixture from the

fuel tank and refill with the specified mix.

9. Restart the engine and check the operation

of the machine throughout its entire operat-

ing range. Stop and check the spark plug

condition. Restart the machine and operate

it for about 10 to 15 more minutes. The

machine will now be ready to race.

Mixing oil: Mixing ratio:

Yamalube “2-R” 15:1

5NX-9-30-1 6/5/01 3:53 PM Page 32

Page 57 of 584

1-14

MISE EN MARCHE ET RODAGE

STARTEN UND EINFAHREN

AVVIAMENTO E RODAGGIO

GEN

INFO

EINFAHRVORGÄNGE

1. Vor dem Starten des Motors, den

Kraftstofftank für das Einfahren mit

einem Benzin/Öl-Gemisch wie dar-

gestellt füllen.

2. Die unter „Prüfungen vor Inbetrieb-

nahme“ aufgeführten Kotrollen aus-

führen.

3. Den Motor starten und warmlaufen

lassen. Die Leerlaufdrehzahl kon-

trollieren und die Funktion der

Bedienungselemente und des

Motorstoppknopfes „ENGINE

STOP“ prüfen.

4. Die Maschine in den unteren Gän-

gen bei gemäßigter Drosselöffnung

füf fünf bis acht Minuten fahren. Den

Motor danach abschalten und den

Zustand der Zündkerze kontrollie-

ren; während des Einfahrens sollte

die Zündkerze leicht verölt (fettes

Gemisch) sein.

5. Den Motor abkühlen lassen. Den

Motor wieder starten und die

Maschine für etwa fünf Minuten

unter den gleichen Bedingungen

betreiben, wie sie oben beschrieben

wurden. Danach jeweils kurz in die

höheren Gänge schalten und das

Ansprechen auf Vollgas kontrollie-

ren. Den Motor wieder abschalten

und nochmals die Zündkerze kon-

trollieren.

6. Den Motor abkühlen lassen, danach

wieder starten und die Maschine

nochmals für fünf Minuten betreiben.

Nun dürfen die höheren Gänge

auch bei Vollgas eingesetzt werden,

wobei jedoch längeres Vollgasfah-

ren zu vermeiden ist. Anschließend

den Zustand der Zündkerze prüfen.

7. Den Motor abkühlen lassen, den

Zylinderkopf ausbauen und Kolben

und Zylinder kontrollieren. Den Kol-

ben ggf. mit Schmirgelleinen der

Körnung 600 glätten. Alle Bauteile

reinigen und vorsichtig wieder ein-

bauen.

8. Das Benzin/Öl-Gemisch für das Ein-

fahren aus dem Kraftstofftank ent-

leeren und das vorgeschriebene

Gemisch einfüllen.

9. Den Motor starten und die Betriebs-

bedingungen der Maschine im

gesamten Betriebsbereich überprü-

fen. Den Motor abschalten und den

Zustand der Zündkerze kontrollie-

ren. Den Motor wieder starten und

die Maschine für etwa 10 bis 15

Minuten betreiben. Danach ist die

Maschine einsatzbereit für Rennen.

PROCEDURE DE RODAGE

1. Avant de lancer le moteur, rem-

plissez le réservoir d’un mélange

essence-huile de rodage de propor-

tion si dessous.

2. Exécutez le contrôle avant utilisa-

tion de la machine.

3. Lancez le moteur et laissez-le se

réchauffer. Vérifiez le régime de

ralenti, le fonctionnement des

commandes et l’efficacité du bou-

ton d’arrêt du moteur “ENGINE

STOP”.

4. Pilotez la machine sur les rapports

inférieurs et à régime modéré

durant les cinq à huit premières

minutes. Arrêtez-vous et vérifiez

l’état de la bougie; elle devrait

donner des indices de richesse

durant le rodage.

5. Laissez le moteur se refroidir.

Remettez le moteur en marche et

pilotez comme ci-dessus pendant

cinq minutes. Passez brièvement

sur les rapports supérieurs et véri-

fiez la réponse à pleine accéléra-

tion. Arrêtez-vous et revérifiez la

bougie.

6. A nouveau, laissez le moteur se

refroidir. Redémarrez et pilotez

pendant cinq nouvelles minutes.

Cette fois, vous pouvez rouler à

pleins gaz sur les rapports supé-

rieurs, mais évitez une marche

soutenue à pleine vitesse. Vérifiez

l’état de la bougie.

7. Laissez le moteur se refroidir,

déposez la culasse et le cylindre, et

examinez piston et cylindre. Elimi-

nez les points élevés au papier de

verre humide No. 600. Nettoyez

tous les éléments puis remontez

soigneusement le moteur.

8. Videz le mélange essence-huile de

rodage du réservoir et remplissez-

le du mélange prescrit.

9. Remettez le moteur en marche et

vérifiez son fonctionnement à tous

les régimes. Arrêtez et vérifiez la

bougie. Relancez le moteur et pilo-

tez la machine pendant 10 à 15

minutes supplémentaires. Elle sera

alors prête pour la course.IC194001PROCEDURE DI RODAGGIO

1. Prima di avviare il motore, riempi-

re il serbatorio del carburante con

una miscela di olio-carburante per

rodaggio come segue.

2. Eseguire i controlli sul veicolo

prima del funzionamento.

3. Avviare e scaldare il motore. Con-

trollare il numero di giri al minimo

e controllare il funzionamento dei

comandi e del pulsante “ARRE-

STO MOTORE”.

4. Azionare il veicolo alle marce

basse con aperture moderate della

valvola a farfalla per cinque-otto

minuti. Arrestarlo e controllare le

condizioni della candela; durante il

rodaggio presenterà condicche.

5. Far raffreddare il motore. Riavvia-

re il motore e far funzionare il vei-

colo come descritto nel punto pre-

cedente per cinque minuti. Quindi,

passare per brevissimo tempo alle

marce alte e controllare la risposta

con la valvola a farfalla completa-

mente aperta. Arrestarlo e control-

lare la candela.

6. Dopo avere fatto raffreddare anco-

ra il motore, riavviare e far girare

il veicolo per altri cinque minuti.

Si possono usare la valvola a far-

falla completamente aperta e le

marce alte, ma si dovrebbe evitare

un funzionamento prolungato con

la valvola a farfalla completamen-

te aperta. Controllare le condizioni

della candela.

7. Far raffreddare il motore, togliere

l’estremità superiore e ispezionare

il pistone e il cilindro. Togliere

eventuali irregolarità sul pistone

con carta vetrata bagnata di grana

No. 600. Pulire tutti i componenti

e rimontare con cautela l’estremità

superiore.

8. Scaricare la miscela di olio-carbu-

rante di rodaggio dal serbatoio del

carburante e riempirlo con la

miscela specificata.

9. Riavviare il motore e controllare il

funzionamento del veicolo per

tutta la gamma di funzionamento.

Arrestarlo e controllare le condi-

zioni della candela. Riavviare il

veicolo e farlo funzionare per altri

10-15 minuti circa. Il veicolo sarà

ora pronto per la gara.

Huile de Proportions

Mélange: de Mélange:

Yamalube

“2-R” 15 : 1Olio per Rapporto di

miscela: miscelazione:

Yamalube

“2-R” 15 : 1Mischöl: Misch-

verhältnis:

Yamalube

„2-R“ 15 : 1

5NX-9-30-1 6/5/01 3:53 PM Page 33

Page 58 of 584

1-15

STARTING AND BREAK-IN

GEN

INFO

cC

9

After the break-in or before each race, you

must check the entire machine for loose fit-

tings and fasteners as per “TORQUE-

CHECK POINTS”.

Tighten all such fasteners as required.

9When any of the following parts have been

replaced, they must be broken in.

CYLINDER AND CRANKSHAFT:

About one hour of break-in operation is

necessary.

PISTON, RING AND GEARS:

These parts require about 30 minutes of

break-in operation at half-throttle or less.

Observe the condition of the engine careful-

ly during operation.

5NX-9-30-1 6/5/01 3:53 PM Page 34