diagram YAMAHA YZ250LC 2007 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: YZ250LC, Model: YAMAHA YZ250LC 2007Pages: 596, PDF Size: 14.47 MB

Page 124 of 596

2-16

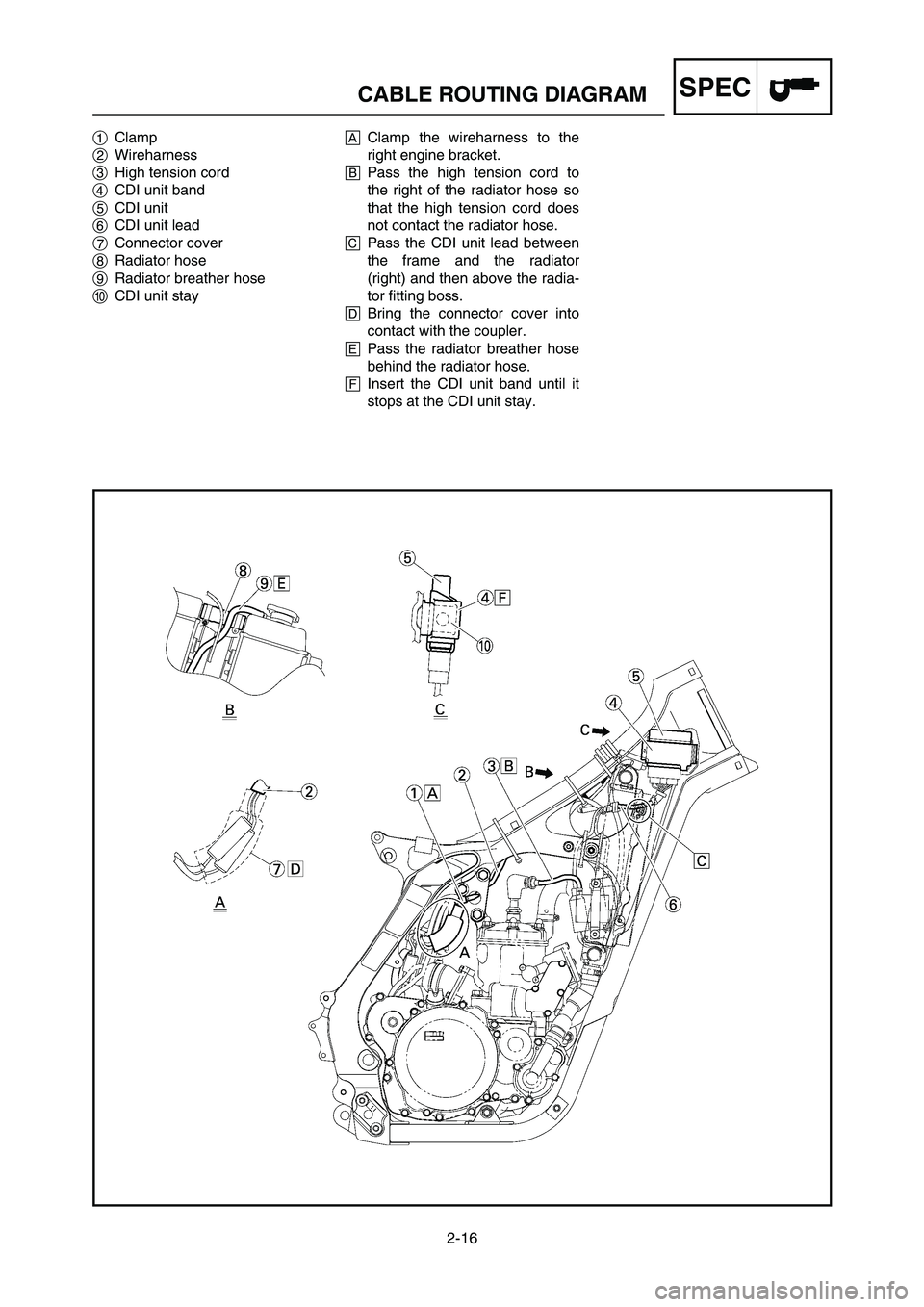

CABLE ROUTING DIAGRAMSPEC

1Clamp

2Wireharness

3High tension cord

4CDI unit band

5CDI unit

6CDI unit lead

7Connector cover

8Radiator hose

9Radiator breather hose

0CDI unit stayAClamp the wireharness to the

right engine bracket.

BPass the high tension cord to

the right of the radiator hose so

that the high tension cord does

not contact the radiator hose.

CPass the CDI unit lead between

the frame and the radiator

(right) and then above the radia-

tor fitting boss.

DBring the connector cover into

contact with the coupler.

EPass the radiator breather hose

behind the radiator hose.

FInsert the CDI unit band until it

stops at the CDI unit stay.

1P8-9-32-2 4/29/06 11:46 AM Page 58

Page 125 of 596

2-16

SCHEMA DE CHEMINEMENT DES CABLES

KABELFÜHRUNGSÜBERSICHTPLAN

DIAGRAMMA DEL PASSAGGIO DEI CAVISPEC

1Klemme

2Kabelbaum

3Hochspannungskabel

4CDI-Einheitsband

5CDI-Einheit

6CDI-Einheitskabel

7Steckverbinder-Abdeckung

8Kühlerschlauch

9Kühler-Entlüftungsschlauch

0CDI-Einheitshalterung

ADen Kabelbaum an der rechten Motor-

halterung festklammern.

BDas Hochspannungskabel rechts vom

Kühlerschlauch entlangführen, damit

das Hochspannungskabel nicht mit dem

Kühlerschlauch in Kontakt kommt.

CDas CDI-Einheitskabel zwischen dem

Rahmen und dem Kühler (rechts) ent-

langführen, und schließlich über die

Kühler-Einpassnabe führen.

DDie Steckverbinder-Abdeckung mit dem

Steckverbinder in Kontakt bringen.

EDen Kühler-Entlüftungsschlauch hinter

dem Kühlerschlauch entlangführen.

FDas CDI-Einheitsband einschieben, bis

es an der CDI-Einheitshalterung stoppt. 1Collier2Faisceau de fils3Fil haute tension4Bande du boîtier CDI 5Boîtier CDI6Fil du boîtier CDI 7Capuchon de connecteur 8Durit du radiateur9Durit de mise à l’air du radiateur0Support du boîtier CDI

ABrider le faisceau de fils au support droit

du moteur.

BFaire passer le fil haute tension à droite

de la durit du radiateur de façon à ce que

le fil haute tension ne soit pas en contact

avec la durit du radiateur.

CFaire passer le fil du boîtier CDI entre le

cadre et le radiateur (droite) et ensuite

au-dessus du bossage de montage du

radiateur.

DMettre le capuchon de connecteur en

contact avec le coupleur.

EFaire passer la durit de mise à l’air du

radiateur derrière la durit du radiateur.

FInsérer la bande adhésive de positionne-

ment du boîtier CDI jusqu’à ce qu’elle

s’arrête contre le support de l’unité CDI.

1Morsetto2Cablaggio elettrico3Cavo alta tensione4Nastro unità CDI5Unità CDI6Cavo unità CDI7Coperchio del connettore8Flessibile radiatore9Flessibile di sfiato aria del radiatore0Sostegno unità CDI

AAgganciare il cablaggio elettrico alla

staffa destra del motore.

BFar passare il cavo alta tensione a destra

del flessibile radiatore in modo che non

venga a contatto con il flessibile radiato-

re.

CPassare il conduttore dell’unità CDI tra il

telaio e il radiatore (a destra), quindi

sopra alla sporgenza del radiatore.

DPortare il coperchio del connettore a con-

tatto con l’accoppiatore.

EPassare il flessibile di sfiato del radiatore

dietro al flessibile del radiatore.

FInserire nel sostegno dell’unità CDI il

nastro dell’unità CDI, finché non si bloc-

ca.

1P8-9-32-2 4/29/06 11:46 AM Page 59

Page 126 of 596

2-17

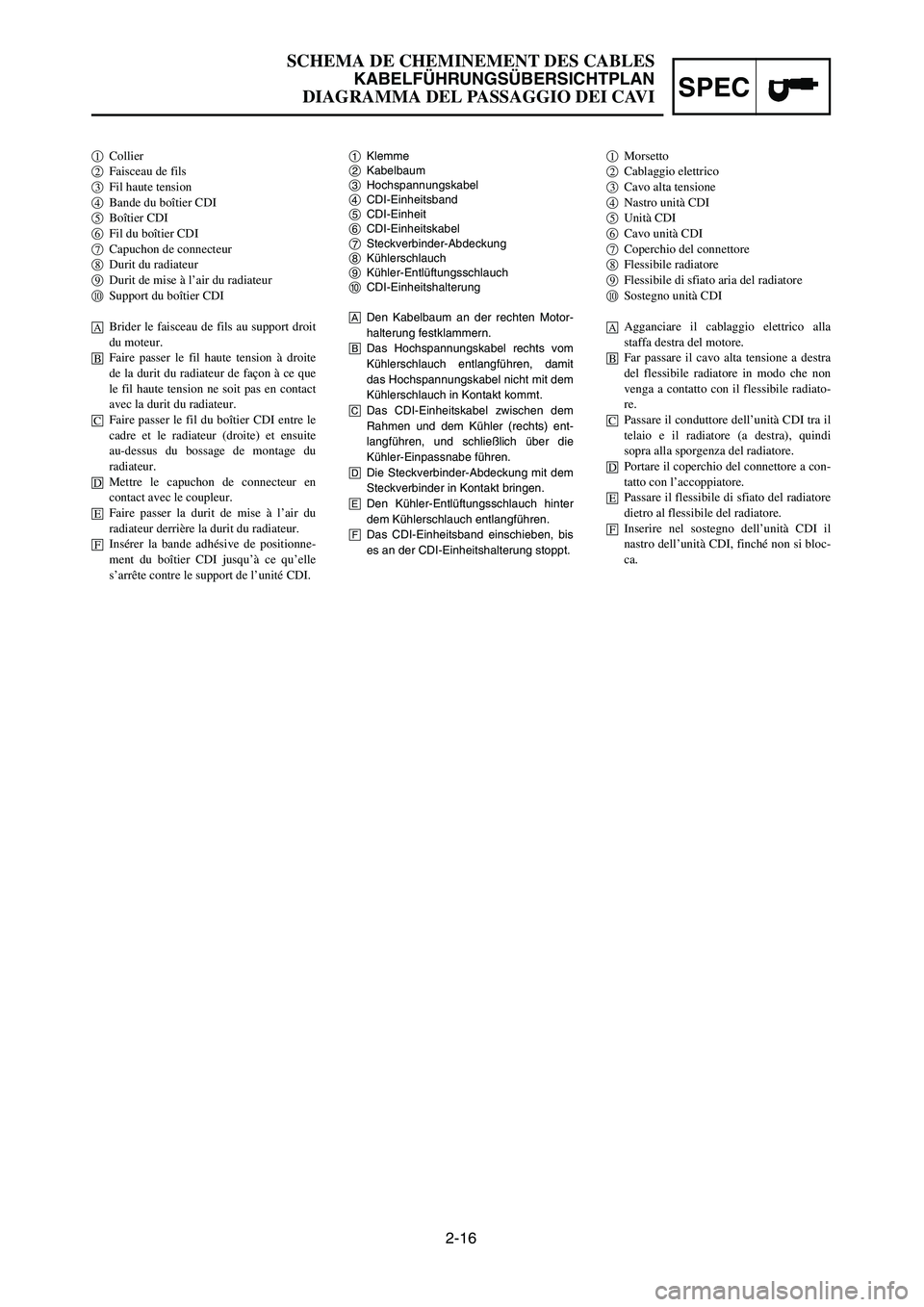

CABLE ROUTING DIAGRAMSPEC

1Master cylinder

2Brake hose holder

3Brake hoseAInstall the brake hose so that its pipe portion

directs as shown and lightly touches the projec-

tion on the caliper.

BPass the brake hose into the brake hose holders.

CIf the brake hose contacts the spring (rear shock

absorber), correct its twist.

DInstall the brake hose so that its pipe portion

directs as shown and lightly touches the projection

on the master cylinder.

1P8-9-32-2 4/29/06 11:46 AM Page 60

Page 127 of 596

2-17

SCHEMA DE CHEMINEMENT DES CABLES

KABELFÜHRUNGSÜBERSICHTPLAN

DIAGRAMMA DEL PASSAGGIO DEI CAVISPEC

1Hauptbremszylinder

2Bremsschlauchhalter

3Bremsschlauch

ABremsschlauch so einbauen, dass

seine Rohrstellung in die angegebene

Richtung zeigt und den Vorsprung an

der Felge leicht berührt.

BBremsschlauch in die Bremsschlauch-

halterungen einführen.

CFalls der Bresmsschlauch die Feder

(Hinterrad-Stoßdämpfer) berührt, seine

Verdrehung berichtigen.

DDen Bremsschlauch so einbauen, dass

sein Rohrteil gemäß Abbildung ange-

ordnet ist und den Überstand am

Hauptbremszylinder leicht berührt. 1Maître-cylindre2Support de tuyau de frein3Tuyau de frein

åInstallez le tuyau de frein de façon à ce

que la section conduite soit orientée

comme illustré et légèrement en contact

avec la saillie de l’étrier.

∫Faites ensuite passer le tuyau de frein

dans les supports du tuyau de frein.

çSi le tuyau de frein touche le ressort

(amortisseur arrière), ajuster le coude.

∂Installer le tuyau de frein de manière que

la partie avec le tuyau soit dirigée

comme indiqué et touche légèrement la

saillie sur le maître-cylindre.

1Cilindro principale2Supporto del tubo flessibile del freno3Tubo flessibile del freno

åInstallare il tubo flessibile del freno in

modo che la sua parte di tubo sia orienta-

ta come mostrato nell’illustrazione, leg-

germente a contatto con la sporgenza

sulla pinza.

∫Far passare il tubo flessibile del freno nei

supporti di tubo flessibile del freno.

çSe il tubo flessibile del freno tocca la

molla (ammortizzatore posteriore), cor-

reggerne la torsione.

∂Installare il tubo flessibile del freno in

maniera tale che la sua parte di tubo sia

rivolta come illustrato e tocchi legger-

mente la sporgenza sul cilindro principa-

le.

1P8-9-32-2 4/29/06 11:46 AM Page 61

Page 128 of 596

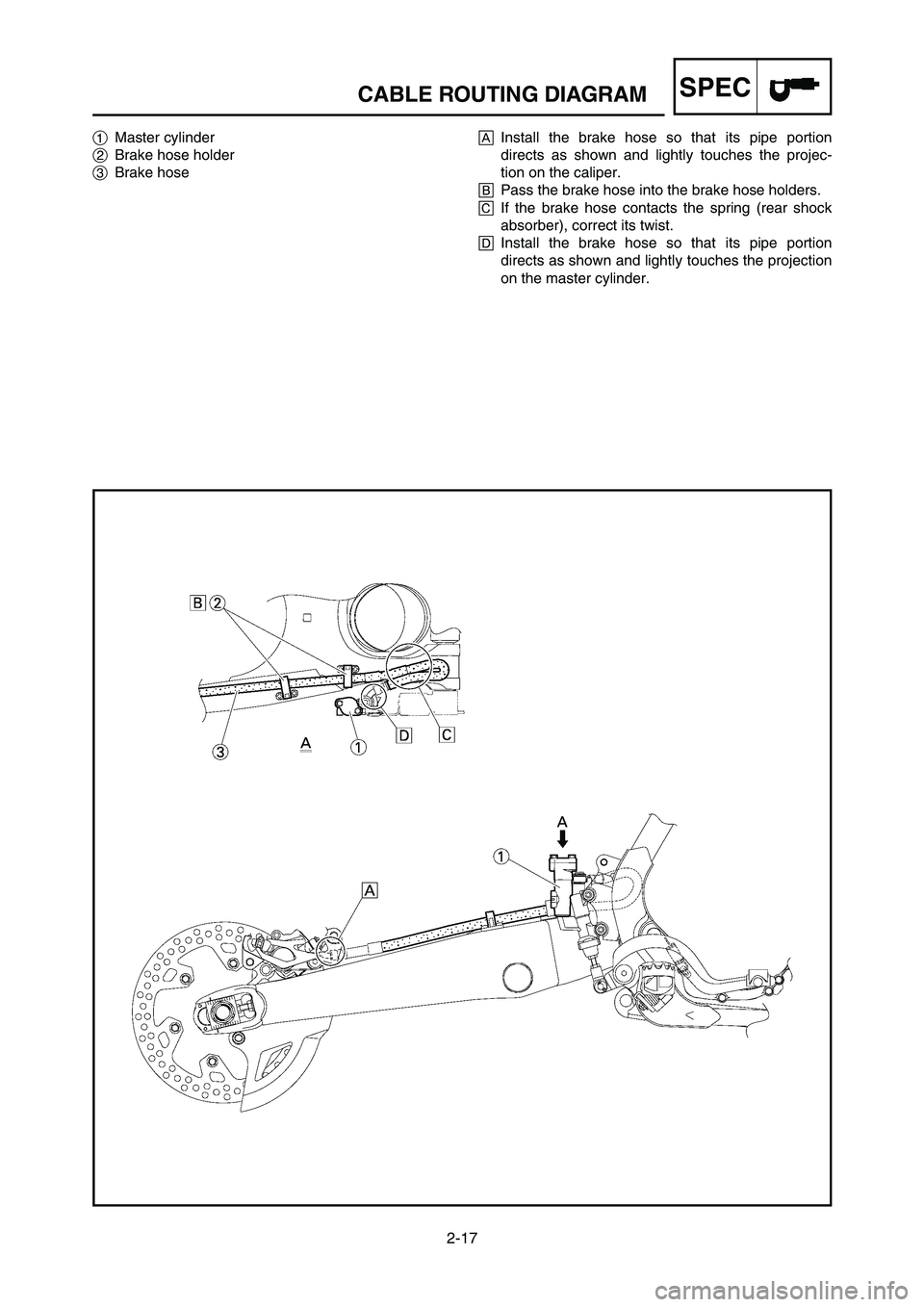

SPEC

2-18

CABLE ROUTING DIAGRAM

1Brake hose

2Master cylinder

3“ENGINE STOP” button lead

4“ENGINE STOP” button

5Throttle cable

6Clutch cable

7Clamp

8Cable guideAInstall the brake hose so that its pipe portion directs

as shown and lightly touches the projection on the

master cylinder.

BPass the “ENGINE STOP” button lead in the middle

of the clutch holder.

CClamp the “ENGINE STOP” button lead to the han-

dlebar.

DPass the brake hose in front of the number plate

and through the cable guide.

EPass the clutch cable through the cable guide on

the number plate.

1P8-9-32-2 4/29/06 11:46 AM Page 62

Page 129 of 596

SPEC

2-18

SCHEMA DE CHEMINEMENT DES CABLES

KABELFÜHRUNGSÜBERSICHTPLAN

DIAGRAMMA DEL PASSAGGIO DEI CAVI

1Bremsschlauch

2Hauptbremszylinder

3Leitungskabel des Motorstoppknopfes

„ENGINE STOP“

4Motorstoppknopf „ENGINE STOP“

5Gasseil

6Kupplungskabel

7Klemme

8Kabelführung

ADen Bremsschlauch so einbauen, dass

sein Rohrteil gemäß Abbildung ange-

ordnet ist und den Überstand am

Hauptbremszylinder leicht berührt.

BDas Leitungskabel des Motorstopp-

knopfes „ENGINE STOP“ in der Mitte

des Kupplungshalters durchführen.

CKabel des Motorausschaltknopfes am

Lenker festklemmen.

DDen Bremsschlauch vor dem Num-

mernschild und durch die Kabelführung

durchführen.

EDen Kupplungszug durch die Seilzug-

führung am Nummernschild hindurch-

führen. 1Tuyau de frein2Maître-cylindre3Fil de bouton d’arrêt du moteur “ENGI-

NE STOP”

4Bouton d’arrêt du moteur “ENGINE

STOP”

5Câble d’accélérateur6Câble d’embrayage7Bride8Guide de câble

åIstaller la tuyau de frein de manière que

la partie avec le tuyau soit dirigée

comme indipué et touche légèrement la

saillie sur le maîtrecylindre.

∫Faire passer le fil de bouton d’arrêt du

moteur “ENGINE STOP” au centre du

support d’embrayage.

çFixer le fil du bouton “ENGINE STOP”

sur le guidon.

∂Faire passer le tuyau de frein devant la

plaque d’immatriculation et à travers le

guide de câble.

´Faire passer le câble d’embrayage au tra-

vers du guide de câble sur la plaque

d’immatriculation.

1Tubo flessibile del freno2Cilindro principale3Conduttore del pulsante “ARRESTO

MOTORE”

4Pulsante “ARRESTO MOTORE”5Cavo dell’acceleratore6Cavo della frizione7Nastro8Guida per cavi

åInstallare il tubo flessibile del freno in

modo che la sua parte di tubo sia rivolta

come illustrato e tocchi leggermente la

sporgenza sul cilindro principale.

∫Far passare il conduttore del pulsante

“ARRESTO MOTORE” nel mezzo del

supporto della frizione.

çBloccare il conduttore del pulsante

“ARRESTO MOTORE” sul manubrio.

∂Far passare il tubo flessibile del freno

davanti alla targa e attraverso la guida

per cavi.

´Passare il cavo frizione attraverso la

guida per cavi sulla targa.

1P8-9-32-2 4/29/06 11:46 AM Page 63

Page 230 of 596

4-6

ENGRADIATOR

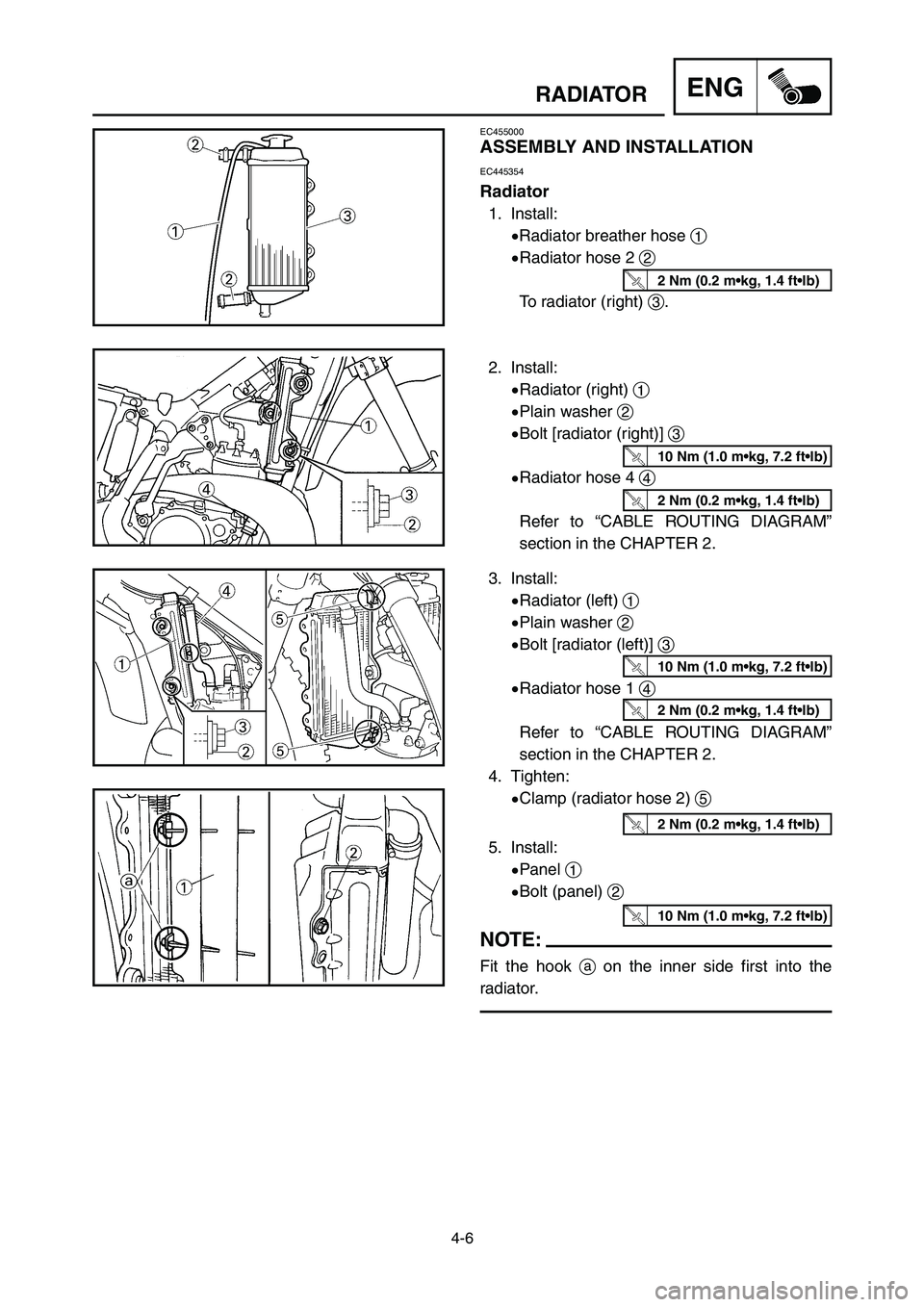

EC455000

ASSEMBLY AND INSTALLATION

EC445354

Radiator

1. Install:

9Radiator breather hose 1

9Radiator hose 2 2

To radiator (right) 3.

2. Install:

9Radiator (right) 1

9Plain washer 2

9Bolt [radiator (right)] 3

9Radiator hose 4 4

Refer to “CABLE ROUTING DIAGRAM”

section in the CHAPTER 2.

10 Nm (1.0 m•kg, 7.2 ft•lb)

2 Nm (0.2 m•kg, 1.4 ft•lb)

2 Nm (0.2 m•kg, 1.4 ft•lb)

3. Install:

9Radiator (left) 1

9Plain washer 2

9Bolt [radiator (left)] 3

9Radiator hose 1 4

Refer to “CABLE ROUTING DIAGRAM”

section in the CHAPTER 2.

4. Tighten:

9Clamp (radiator hose 2) 5

5. Install:

9Panel 1

9Bolt (panel) 2

NOTE:

Fit the hook aon the inner side first into the

radiator.

10 Nm (1.0 m•kg, 7.2 ft•lb)

2 Nm (0.2 m•kg, 1.4 ft•lb)

2 Nm (0.2 m•kg, 1.4 ft•lb)

10 Nm (1.0 m•kg, 7.2 ft•lb)

1P8-9-32-4a 4/10/06 1:53 PM Page 12

Page 248 of 596

![YAMAHA YZ250LC 2007 User Guide 4-15

ENGCARBURETOR AND REED VALVE

8. Install:

9Air vent hose [

/=580 mm (22.8 in)] 1

9Air vent hose [/=400mm (15.7 in)] 2

9Overflow hose [/=280mm (11.0 in)] 3

9Clamp 4

Refer to “CABLE ROUTING DIAGRA YAMAHA YZ250LC 2007 User Guide 4-15

ENGCARBURETOR AND REED VALVE

8. Install:

9Air vent hose [

/=580 mm (22.8 in)] 1

9Air vent hose [/=400mm (15.7 in)] 2

9Overflow hose [/=280mm (11.0 in)] 3

9Clamp 4

Refer to “CABLE ROUTING DIAGRA](/img/51/53963/w960_53963-247.png)

4-15

ENGCARBURETOR AND REED VALVE

8. Install:

9Air vent hose [

/=580 mm (22.8 in)] 1

9Air vent hose [/=400mm (15.7 in)] 2

9Overflow hose [/=280mm (11.0 in)] 3

9Clamp 4

Refer to “CABLE ROUTING DIAGRAM”

section in the CHAPTER 2.

NOTE:

Install the air vent hoses and overflow hose to

the carburetor with their ends not having the cuts

atoward the carburetor.

9. Install:

9Jet needle 1

9Collar 2

9Spring 3

9Needle holder 4

To throttle valve 5.

NOTE:

Install the spring with its smaller dia. afacing

the collar.

7. Install:

9Float chamber 1

9Plate 2

9Screw (float chamber) 3

1P8-9-32-4a 4/10/06 1:53 PM Page 30

Page 252 of 596

4-17

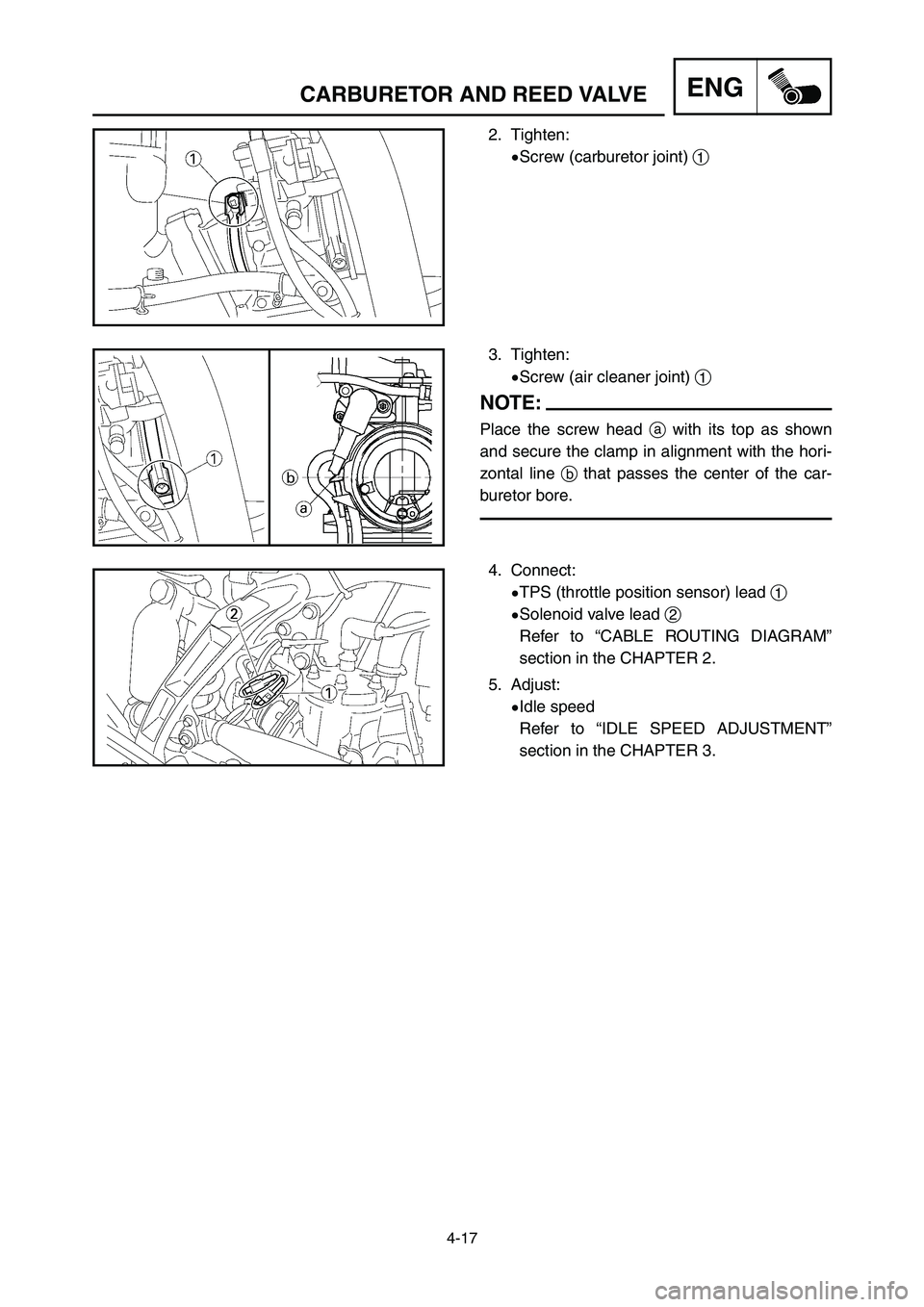

ENGCARBURETOR AND REED VALVE

2. Tighten:

9Screw (carburetor joint) 1

3. Tighten:

9Screw (air cleaner joint) 1

NOTE:

Place the screw head awith its top as shown

and secure the clamp in alignment with the hori-

zontal line bthat passes the center of the car-

buretor bore.

4. Connect:

9TPS (throttle position sensor) lead 1

9Solenoid valve lead 2

Refer to “CABLE ROUTING DIAGRAM”

section in the CHAPTER 2.

5. Adjust:

9Idle speed

Refer to “IDLE SPEED ADJUSTMENT”

section in the CHAPTER 3.

1P8-9-32-4a 4/10/06 1:53 PM Page 34

Page 336 of 596

![YAMAHA YZ250LC 2007 User Guide 4-59

CDI MAGNETOENG

7. Connect:

9CDI magneto lead 1

Refer to “CABLE ROUTING DIAGRAM”

section in the CHAPTER 2.

8. Install:

9Gasket [crankcase cover (left)]

9Crankcase cover (left) 1

9Screw [crankc YAMAHA YZ250LC 2007 User Guide 4-59

CDI MAGNETOENG

7. Connect:

9CDI magneto lead 1

Refer to “CABLE ROUTING DIAGRAM”

section in the CHAPTER 2.

8. Install:

9Gasket [crankcase cover (left)]

9Crankcase cover (left) 1

9Screw [crankc](/img/51/53963/w960_53963-335.png)

4-59

CDI MAGNETOENG

7. Connect:

9CDI magneto lead 1

Refer to “CABLE ROUTING DIAGRAM”

section in the CHAPTER 2.

8. Install:

9Gasket [crankcase cover (left)]

9Crankcase cover (left) 1

9Screw [crankcase cover (left)] 2

NOTE:

Tighten the screws in stage, using a crisscross

pattern.

5 Nm (0.5 m•kg, 3.6 ft•lb)

1P8-9-32-4c 5/1/06 10:46 AM Page 20