engine YAMAHA YZ250LC 2007 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: YZ250LC, Model: YAMAHA YZ250LC 2007Pages: 596, PDF Size: 14.47 MB

Page 58 of 596

1-15

STARTING AND BREAK-IN

GEN

INFO

cC

9After the break-in or before each race, you

must check the entire machine for loose fit-

tings and fasteners as per “TORQUE-

CHECK POINTS”.

Tighten all such fasteners as required.

9When any of the following parts have been

replaced, they must be broken in.

CYLINDER AND CRANKSHAFT:

About one hour of break-in operation is

necessary.

PISTON, RING AND GEARS:

These parts require about 30 minutes of

break-in operation at half-throttle or less.

Observe the condition of the engine careful-

ly during operation.

1P8-9-32-1 4/12/06 11:43 AM Page 34

Page 60 of 596

1-16

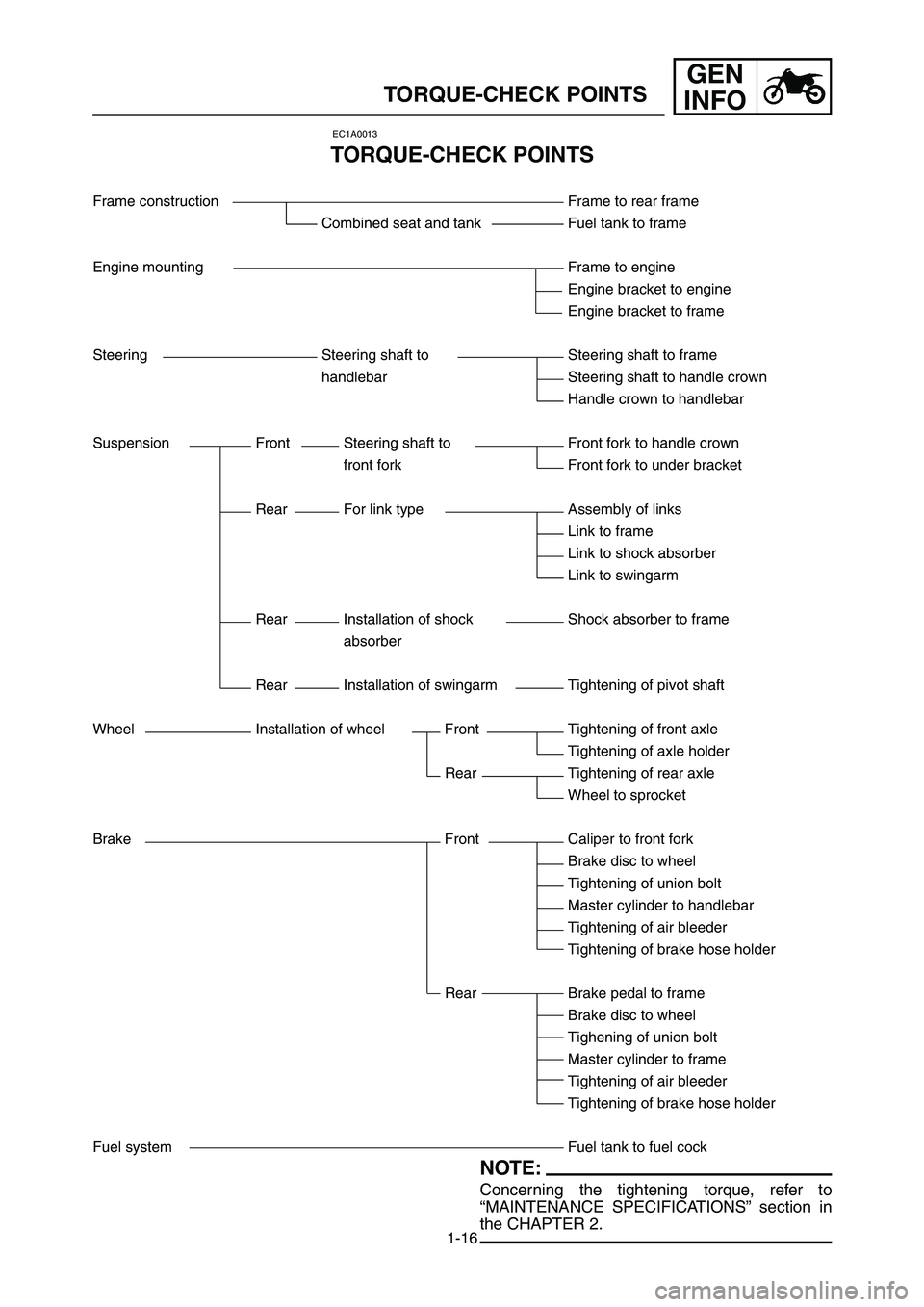

TORQUE-CHECK POINTS

GEN

INFO

EC1A0013

TORQUE-CHECK POINTS

Frame construction Frame to rear frame

Combined seat and tank Fuel tank to frame

Engine mounting Frame to engine

Engine bracket to engine

Engine bracket to frame

Steering Steering shaft to Steering shaft to frame

handlebar Steering shaft to handle crown

Handle crown to handlebar

Suspension Front Steering shaft to Front fork to handle crown

front fork Front fork to under bracket

Rear For link type Assembly of links

Link to frame

Link to shock absorber

Link to swingarm

Rear Installation of shock Shock absorber to frame

absorber

Rear Installation of swingarm Tightening of pivot shaft

Wheel Installation of wheel Front Tightening of front axle

Tightening of axle holder

Rear Tightening of rear axle

Wheel to sprocket

Brake Front Caliper to front fork

Brake disc to wheel

Tightening of union bolt

Master cylinder to handlebar

Tightening of air bleeder

Tightening of brake hose holder

Rear Brake pedal to frame

Brake disc to wheel

Tighening of union bolt

Master cylinder to frame

Tightening of air bleeder

Tightening of brake hose holder

Fuel system Fuel tank to fuel cock

NOTE:

Concerning the tightening torque, refer to

“MAINTENANCE SPECIFICATIONS” section in

the CHAPTER 2.

1P8-9-32-1 4/12/06 11:43 AM Page 36

Page 64 of 596

1-17

CLEANING AND STORAGE

GEN

INFO

EC1B0000

CLEANING AND STORAGE

EC1B1000

CLEANING

Frequent cleaning of your machine will enhance

its appearance, maintain good overall perfor-

mance, and extend the life of many components.

1. Before washing the machine, block off the

end of the exhaust pipe to prevent water

from entering. A plastic bag secured with a

rubber band may be used for this purpose.

2. If the engine is excessively greasy, apply

some degreaser to it with a paint brush. Do

not apply degreaser to the chain, sprockets,

or wheel axles.

3. Rinse the dirt and degreaser off with a gar-

den hose; use only enough pressure to do

the job.

cC

Excessive hose pressure may cause water

seepage and contamination of wheel bear-

ings, front forks, brakes and transmission

seals. Many expensive repair bills have

resulted from improper high pressure

detergent applications such as those avail-

able in coin-operated car washers.

4. After the majority of the dirt has been hosed

off, wash all surfaces with warm water and a

mild detergent. Use an old toothbrush to

clean hard-to-reach places.

5. Rinse the machine off immediately with

clean water, and dry all surfaces with a soft

towel or cloth.

6. Immediately after washing, remove excess

water from the chain with a paper towel and

lubricate the chain to prevent rust.

7. Clean the seat with a vinyl upholstery clean-

er to keep the cover pliable and glossy.

8. Automotive wax may be applied to all paint-

ed or chromed surfaces. Avoid combination

cleaner-waxes, as they may contain abra-

sives.

9. After completing the above, start the engine

and allow it to idle for several minutes.

1P8-9-32-1 4/12/06 11:43 AM Page 40

Page 66 of 596

1-18

CLEANING AND STORAGE

GEN

INFO

EC1B2001

STORAGE

If your machine is to be stored for 60 days or

more, some preventive measures must be taken

to avoid deterioration. After cleaning the

machine thoroughly, prepare it for storage as fol-

lows:

1. Drain the fuel tank, fuel lines, and the carbu-

retor float bowl.

2. Remove the spark plug, pour a tablespoon

of SAE 10W-30 motor oil in the spark plug

hole, and reinstall the plug. With the engine

stop switch pushed in, kick the engine over

several times to coat the cylinder walls with

oil.

3. Remove the drive chain, clean it thoroughly

with solvent, and lubricate it. Reinstall the

chain or store it in a plastic bag tied to the

frame.

4. Lubricate all control cables.

5. Block the frame up to raise the wheels off

the ground.

6. Tie a plastic bag over the exhaust pipe out-

let to prevent moisture from entering.

7. If the machine is to be stored in a humid or

salt-air environment, coat all exposed metal

surfaces with a film of light oil. Do not apply

oil to rubber parts or the seat cover.

NOTE:

Make any necessary repairs before the machine

is stored.

1P8-9-32-1 4/12/06 11:43 AM Page 42

Page 68 of 596

2-1

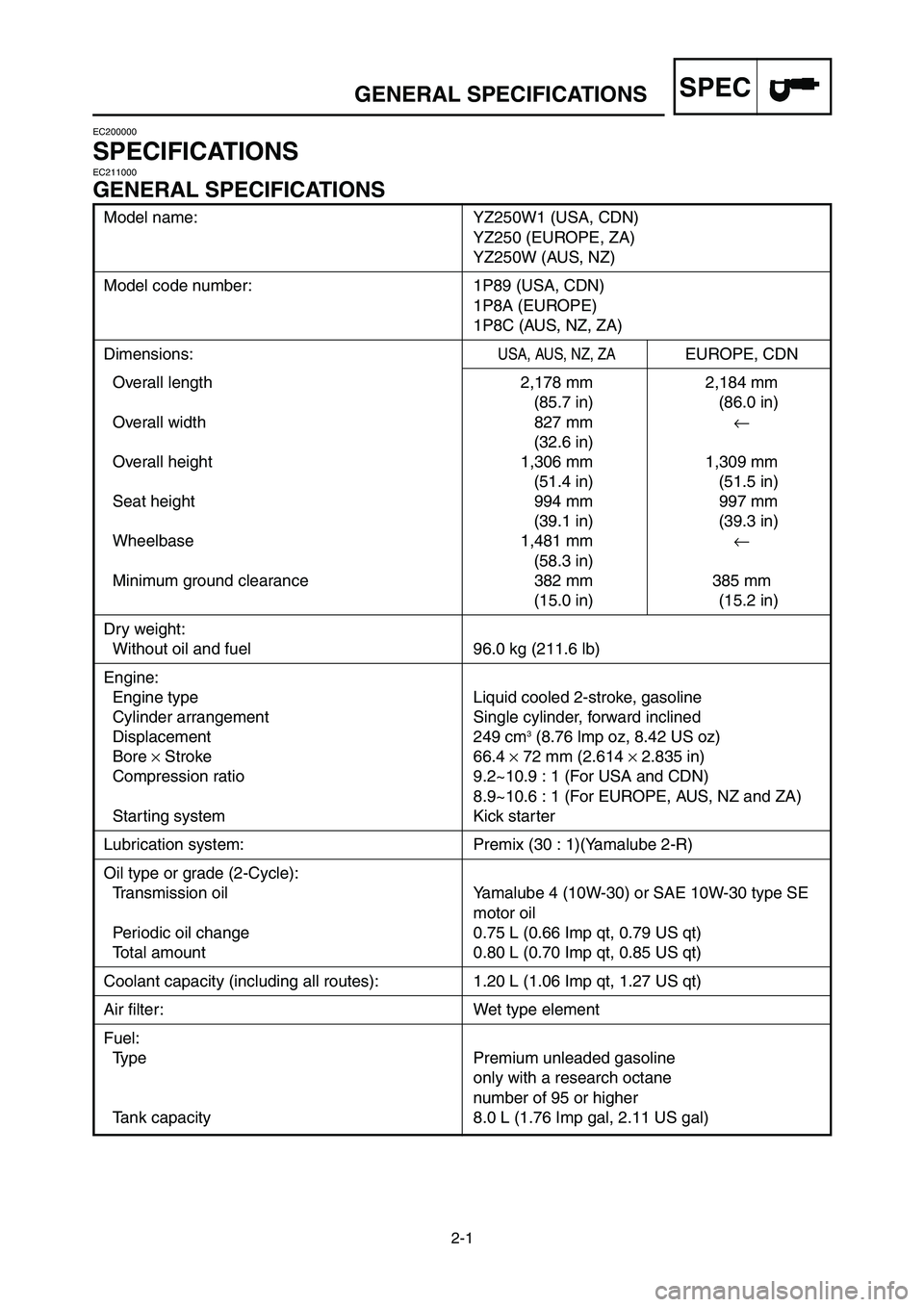

GENERAL SPECIFICATIONSSPEC

Model name: YZ250W1 (USA, CDN)

YZ250 (EUROPE, ZA)

YZ250W (AUS, NZ)

Model code number: 1P89 (USA, CDN)

1P8A (EUROPE)

1P8C (AUS, NZ, ZA)

Dimensions:USA, AUS, NZ, ZAEUROPE, CDN

Overall length 2,178 mm 2,184 mm

(85.7 in) (86.0 in)

Overall width 827 mm←

(32.6 in)

Overall height 1,306 mm 1,309 mm

(51.4 in) (51.5 in)

Seat height 994 mm 997 mm

(39.1 in) (39.3 in)

Wheelbase 1,481 mm←

(58.3 in)

Minimum ground clearance 382 mm 385 mm

(15.0 in) (15.2 in)

Dry weight:

Without oil and fuel 96.0 kg (211.6 lb)

Engine:

Engine type Liquid cooled 2-stroke, gasoline

Cylinder arrangement Single cylinder, forward inclined

Displacement 249 cm

3(8.76 lmp oz, 8.42 US oz)

Bore ×Stroke 66.4 ×72 mm (2.614 ×2.835 in)

Compression ratio 9.2~10.9 : 1 (For USA and CDN)

8.9~10.6 : 1 (For EUROPE, AUS, NZ and ZA)

Starting system Kick starter

Lubrication system: Premix (30 : 1)(Yamalube 2-R)

Oil type or grade (2-Cycle):

Transmission oil Yamalube 4 (10W-30) or SAE 10W-30 type SE

motor oil

Periodic oil change 0.75 L (0.66 Imp qt, 0.79 US qt)

Total amount 0.80 L (0.70 Imp qt, 0.85 US qt)

Coolant capacity (including all routes): 1.20 L (1.06 Imp qt, 1.27 US qt)

Air filter: Wet type element

Fuel:

Type Premium unleaded gasoline

only with a research octane

number of 95 or higher

Tank capacity 8.0 L (1.76 Imp gal, 2.11 US gal)

EC200000

SPECIFICATIONSEC211000

GENERAL SPECIFICATIONS

1P8-9-32-2 4/29/06 11:45 AM Page 2

Page 70 of 596

2-3

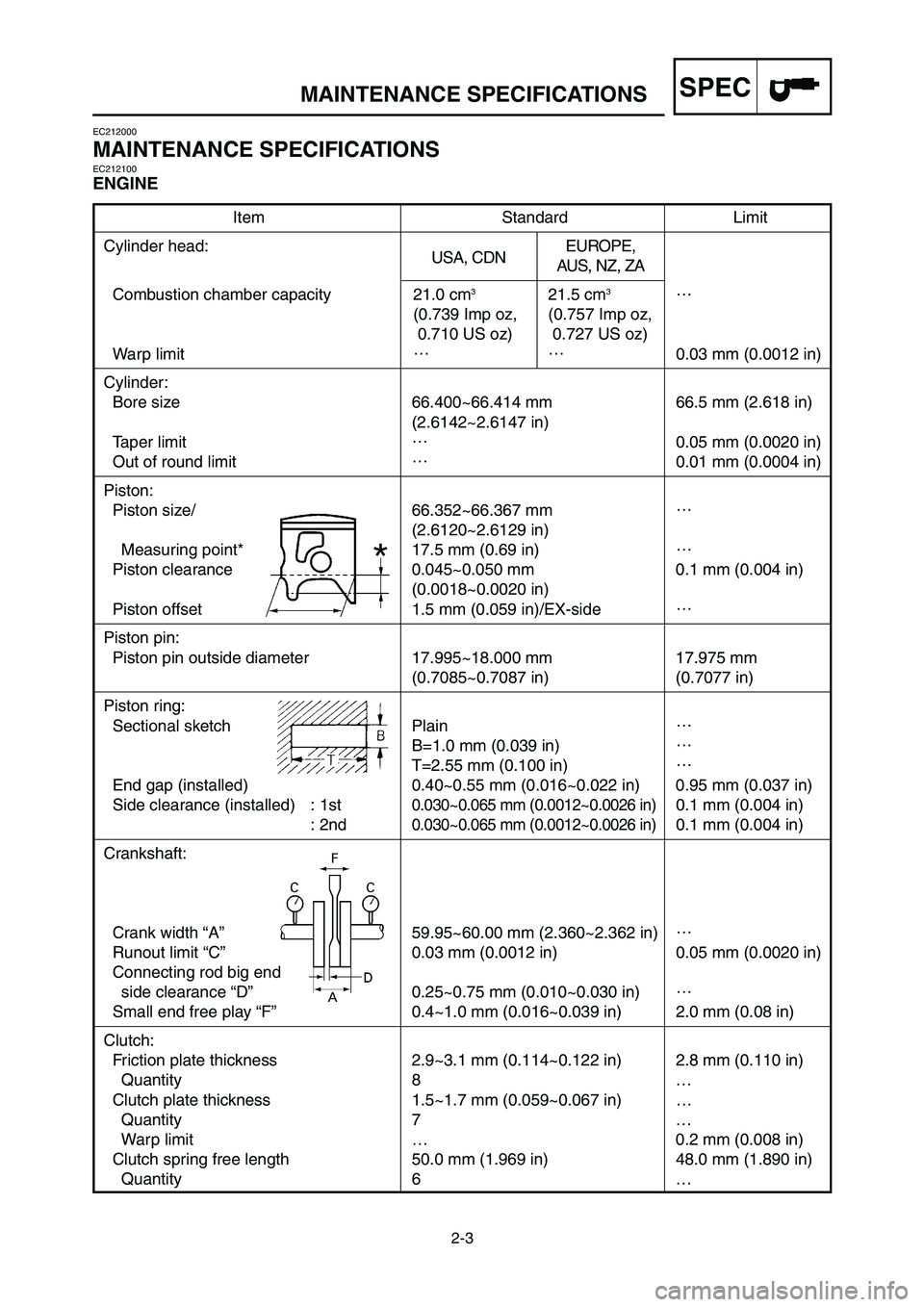

MAINTENANCE SPECIFICATIONSSPEC

Item Standard Limit

Cylinder head:

USA, CDNEUROPE,

AUS, NZ, ZA

Combustion chamber capacity 21.0 cm

321.5 cm3…

(0.739 Imp oz, (0.757 Imp oz,

0.710 US oz) 0.727 US oz)

Warp limit……

0.03 mm (0.0012 in)

Cylinder:

Bore size 66.400~66.414 mm 66.5 mm (2.618 in)

(2.6142~2.6147 in)

Taper limit…

0.05 mm (0.0020 in)

Out of round limit…

0.01 mm (0.0004 in)

Piston:

Piston size/ 66.352~66.367 mm…

(2.6120~2.6129 in)

Measuring point* 17.5 mm (0.69 in)…

Piston clearance 0.045~0.050 mm 0.1 mm (0.004 in)

(0.0018~0.0020 in)

Piston offset 1.5 mm (0.059 in)/EX-side…

Piston pin:

Piston pin outside diameter 17.995~18.000 mm 17.975 mm

(0.7085~0.7087 in) (0.7077 in)

Piston ring:

Sectional sketch Plain…

B=1.0 mm (0.039 in)…

T=2.55 mm (0.100 in)…

End gap (installed) 0.40~0.55 mm (0.016~0.022 in) 0.95 mm (0.037 in)

Side clearance (installed) : 1st

0.030~0.065 mm (0.0012~0.0026 in)0.1 mm (0.004 in)

: 2nd0.030~0.065 mm (0.0012~0.0026 in)0.1 mm (0.004 in)

Crankshaft:

Crank width “A” 59.95~60.00 mm (2.360~2.362 in)…

Runout limit “C” 0.03 mm (0.0012 in) 0.05 mm (0.0020 in)

Connecting rod big end

side clearance “D” 0.25~0.75 mm (0.010~0.030 in)…

Small end free play “F” 0.4~1.0 mm (0.016~0.039 in) 2.0 mm (0.08 in)

Clutch:

Friction plate thickness 2.9~3.1 mm (0.114~0.122 in) 2.8 mm (0.110 in)

Quantity 8 …

Clutch plate thickness 1.5~1.7 mm (0.059~0.067 in) …

Quantity 7 …

Warp limit … 0.2 mm (0.008 in)

Clutch spring free length 50.0 mm (1.969 in) 48.0 mm (1.890 in)

Quantity 6 …

EC212000

MAINTENANCE SPECIFICATIONSEC212100

ENGINE

1P8-9-32-2 4/29/06 11:45 AM Page 4

Page 77 of 596

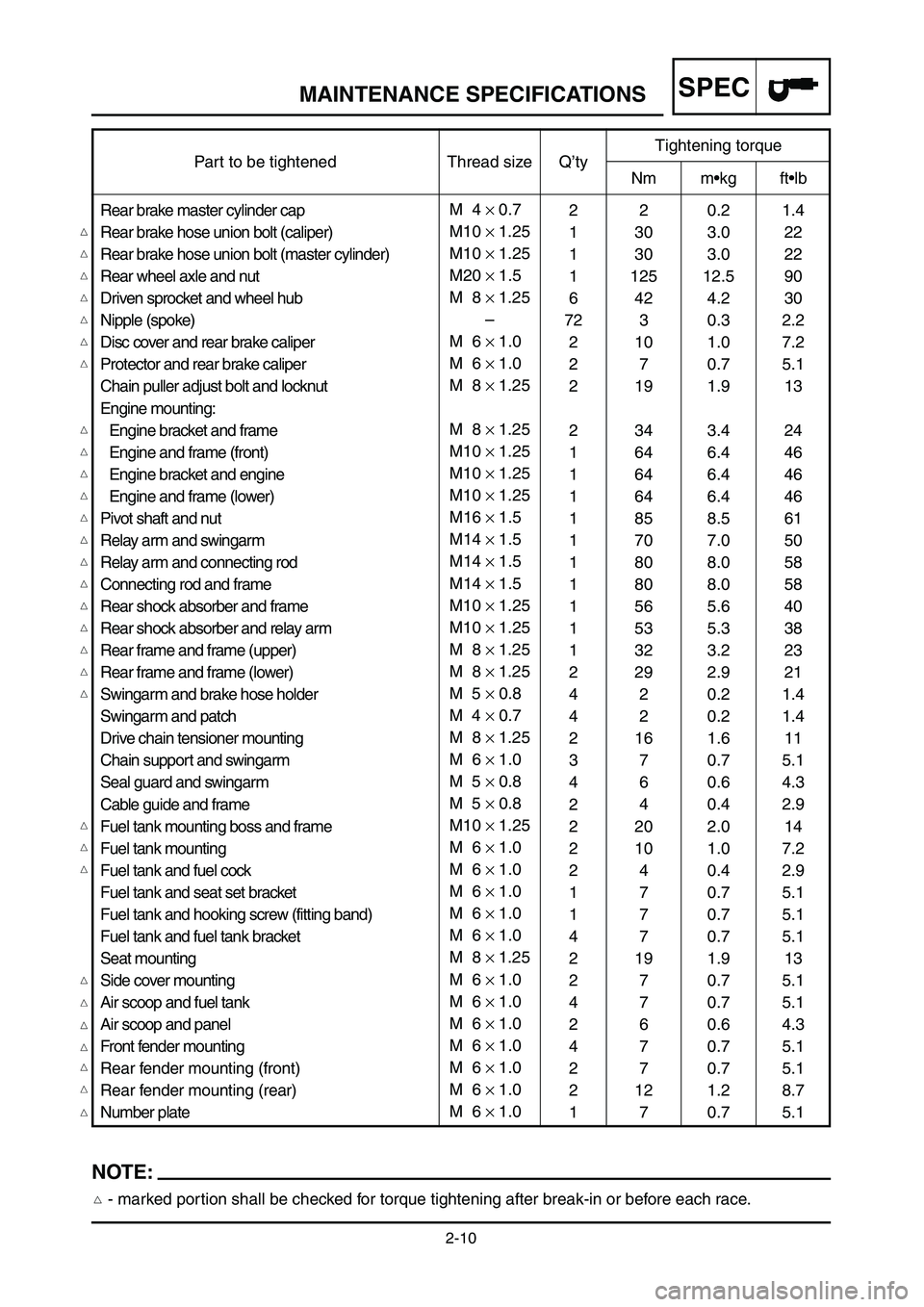

2-10

MAINTENANCE SPECIFICATIONSSPEC

M 4 × 0.7

M10 × 1.25

M10 × 1.25

M20 × 1.5

M 8 × 1.25

–

M 6 × 1.0

M 6 × 1.0

M 8 × 1.25

M 8 × 1.25

M10 × 1.25

M10 × 1.25

M10 × 1.25

M16 × 1.5

M14 × 1.5

M14 × 1.5

M14 × 1.5

M10 × 1.25

M10 × 1.25

M 8 × 1.25

M 8 × 1.25

M 5 ×0.8

M 4 ×0.7

M 8 × 1.25

M 6 × 1.0

M 5 ×0.8

M 5 ×0.8

M10 × 1.25

M 6 × 1.0

M 6 × 1.0

M 6 × 1.0

M 6 × 1.0

M 6 × 1.0

M 8 × 1.25

M 6 × 1.0

M 6 × 1.0

M 6 × 1.0

M 6 × 1.0

M 6 × 1.0

M 6 × 1.0

M 6 × 1.0 Rear brake master cylinder cap

Rear brake hose union bolt (caliper)

Rear brake hose union bolt (master cylinder)

Rear wheel axle and nut

Driven sprocket and wheel hub

Nipple (spoke)

Disc cover and rear brake caliper

Protector and rear brake caliper

Chain puller adjust bolt and locknut

Engine mounting:

Engine bracket and frame

Engine and frame (front)

Engine bracket and engine

Engine and frame (lower)

Pivot shaft and nut

Relay arm and swingarm

Relay arm and connecting rod

Connecting rod and frame

Rear shock absorber and frame

Rear shock absorber and relay arm

Rear frame and frame (upper)

Rear frame and frame (lower)

Swingarm and brake hose holder

Swingarm and patch

Drive chain tensioner mounting

Chain support and swingarm

Seal guard and swingarm

Cable guide and frame

Fuel tank mounting boss and frame

Fuel tank mounting

Fuel tank and fuel cock

Fuel tank and seat set bracket

Fuel tank and hooking screw (fitting band)

Fuel tank and fuel tank bracket

Seat mounting

Side cover mounting

Air scoop and fuel tank

Air scoop and panel

Front fender mounting

Rear fender mounting (front)

Rear fender mounting (rear)

Number platePart to be tightened Thread size Q’tyTightening torque

Nm m•kg ft•lb

2

1

1

1

6

72

2

2

2

2

1

1

1

1

1

1

1

1

1

1

2

4

4

2

3

4

2

2

2

2

1

1

4

2

2

4

2

4

2

2

12

30

30

125

42

3

10

7

19

34

64

64

64

85

70

80

80

56

53

32

29

2

2

16

7

6

4

20

10

4

7

7

7

19

7

7

6

7

7

12

70.2

3.0

3.0

12.5

4.2

0.3

1.0

0.7

1.9

3.4

6.4

6.4

6.4

8.5

7.0

8.0

8.0

5.6

5.3

3.2

2.9

0.2

0.2

1.6

0.7

0.6

0.4

2.0

1.0

0.4

0.7

0.7

0.7

1.9

0.7

0.7

0.6

0.7

0.7

1.2

0.71.4

22

22

90

30

2.2

7.2

5.1

13

24

46

46

46

61

50

58

58

40

38

23

21

1.4

1.4

11

5.1

4.3

2.9

14

7.2

2.9

5.1

5.1

5.1

13

5.1

5.1

4.3

5.1

5.1

8.7

5.1

NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race.

1P8-9-32-2 4/29/06 11:45 AM Page 11

Page 80 of 596

2-13

GENERAL TORQUE SPECIFICATIONS/

DEFINITION OF UNITS

SPEC

This chart specifies torque for standard faste-

ners with standard I.S.O. pitch threads. Torque

specifications for special components or assem-

blies are included in the applicable sections of

this book. To avoid warpage, tighten multi-faste-

ner assemblies in a crisscross fashion, in pro-

gressive stages, until full torque is reached.

Unless otherwise specified, torque specifications

call for clean, dry threads. Components should

be at room temperature.

A: Distance across flats

B: Outside thread diameter

EC230000

DEFINITION OF UNITS

EC220001

GENERAL TORQUE SPECIFICATIONS

ABTORQUE SPECIFICATION

(Nut) (Bolt)

Nm m•kg ft•lb

10 mm 6 mm 6 0.6 4.3

12 mm 8 mm 15 1.5 11

14 mm 10 mm 30 3.0 22

17 mm 12 mm 55 5.5 40

19 mm 14 mm 85 8.5 61

22 mm 16 mm 130 13 94

Unit Read Definition Measure

mm milimeter 10-

3meter Length

cm centimeter 10-2meter Length

kg kilogram 103gram Weight

N Newton 1 kg ×m/sec2Force

Nm Newton meter N ×m Torque

m•kg Meter kilogrma m ×kg Torque

Pa Pascal N/m2Pressure

N/mm Newton per millimeter N/mm Spring rate

L Liter — Volume or capacity

cm3Cubic centimeter — Volume or capacity

r/min Revolution per minute — Engine speed

1P8-9-32-2 4/29/06 11:45 AM Page 14

Page 120 of 596

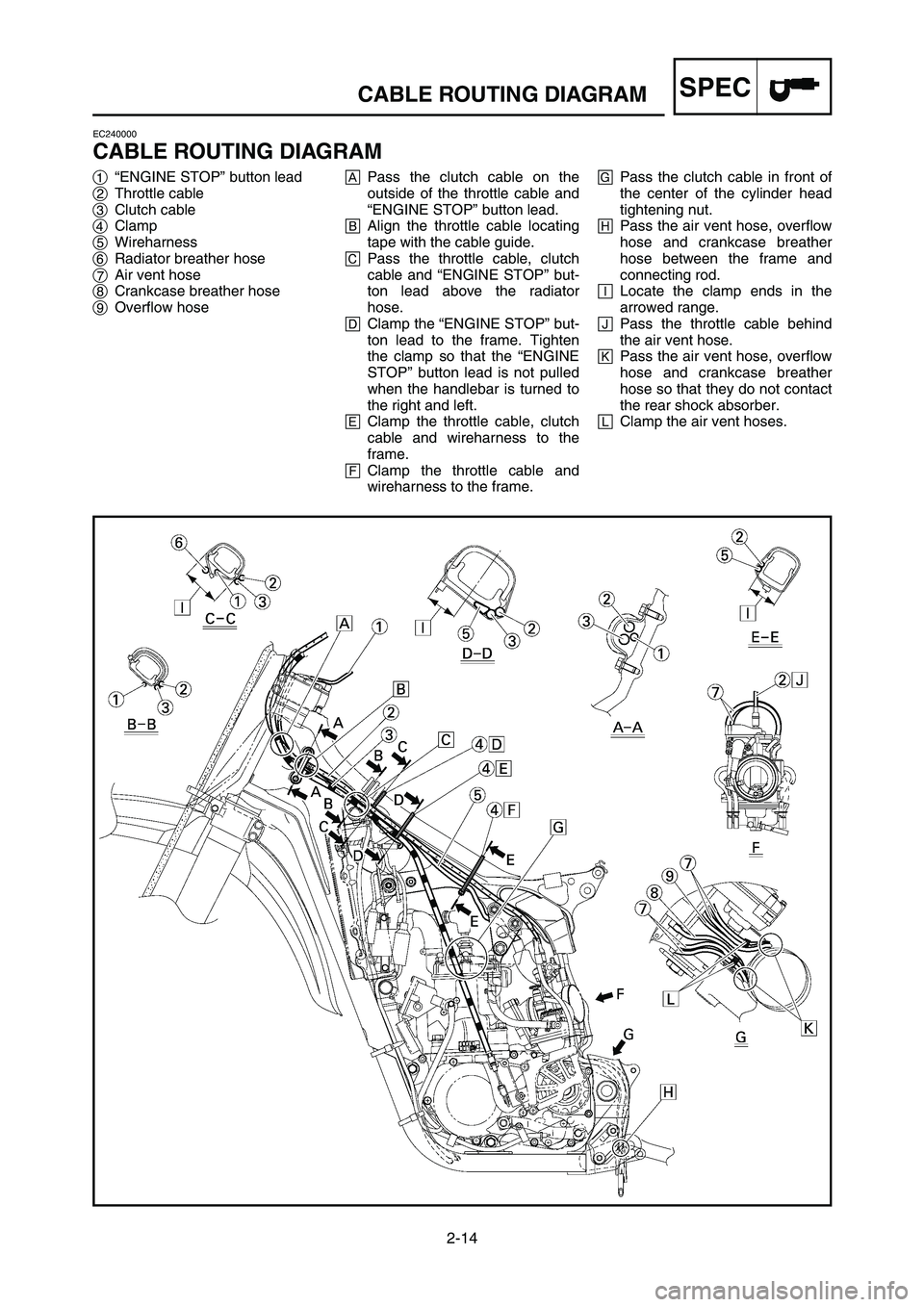

2-14

CABLE ROUTING DIAGRAMSPEC

EC240000

CABLE ROUTING DIAGRAM

1“ENGINE STOP” button lead

2Throttle cable

3Clutch cable

4Clamp

5Wireharness

6Radiator breather hose

7Air vent hose

8Crankcase breather hose

9Overflow hoseAPass the clutch cable on the

outside of the throttle cable and

“ENGINE STOP” button lead.

BAlign the throttle cable locating

tape with the cable guide.

CPass the throttle cable, clutch

cable and “ENGINE STOP” but-

ton lead above the radiator

hose.

DClamp the “ENGINE STOP” but-

ton lead to the frame. Tighten

the clamp so that the “ENGINE

STOP” button lead is not pulled

when the handlebar is turned to

the right and left.

EClamp the throttle cable, clutch

cable and wireharness to the

frame.

FClamp the throttle cable and

wireharness to the frame.GPass the clutch cable in front of

the center of the cylinder head

tightening nut.

HPass the air vent hose, overflow

hose and crankcase breather

hose between the frame and

connecting rod.

ILocate the clamp ends in the

arrowed range.

JPass the throttle cable behind

the air vent hose.

KPass the air vent hose, overflow

hose and crankcase breather

hose so that they do not contact

the rear shock absorber.

LClamp the air vent hoses.

1P8-9-32-2 4/29/06 11:46 AM Page 54

Page 121 of 596

2-14

SCHEMA DE CHEMINEMENT DES CABLES

KABELFÜHRUNGSÜBERSICHTPLAN

DIAGRAMMA DEL PASSAGGIO DEI CAVISPEC

KABELFÜHRUNGSÜBER-

SICHTPLAN

1ENGINE STOP“-Schalterkabel

2Gaszug

3Kupplungszug

4Klemme

5Kabelbaum

6Kühler-Entlüftungsschlauch

7Belüftungsschlauch

8Kurbelgehäuse-Entlüftungsschlauch

9Überlaufschlauch

ADen Kupplungszug außen am Gaszug

und am „ENGINE STOP“-Schalterkabel

entlangführen.

BDas Gaszug-Lokalisierungsband an der

Kabelführung ausrichten.

CDen Gaszug, den Kupplungszug und

das „ENGINE STOP“-Schalterkabel

über dem Kühlerschlauch entlang-

führen.

DDas „ENGINE STOP“-Schalterkabel am

Rahmen festklammern. Die Klemme

festziehen, damit nicht am „ENGINE

STOP“-Schalterkabel gezogen werden

kann, wenn der Lenker nach rechts

oder nach links bewegt wird.

EDen Gaszug, den Kupplungszug und

den Kabelbaum am Rahmen festklam-

mern.

FDen Gaszug und den Kabelbaum am

Rahmen festklammern.

GDen Kupplungszug vor der Mitte der

Zylinderkopf-Anzugsmutter entlang-

führen.

HDen Belüftungsschlauch, den Überlauf-

schlauch und den Kurbelgehäuse-Ent-

lüftungsschlauch zwischen dem Rah-

men und dem Pleuel entlangführen.

IDie Klemmenenden im zulässigen

Bereich anbringen.

JDen Gaszug hinter dem Belüftungs-

schlauch entlangführen.

KDen Belüftungsschlauch, den Überlauf-

schlauch und den Kurbelgehäuse-Ent-

lüftungsschlauch so entlangführen,

dass sie keinerlei Kontakt zum hinteren

Stoßdämpfer haben.

LDie Belüftungsschläuche festklammern.

SCHEMA DE

CHEMINEMENT DES

CABLES

1Fil du bouton “ENGINE STOP” 2Câble des gaz3Câble d’embrayage4Collier5Faisceau de fils6Durit de mise à l’air du radiateur7Durit de ventilation8Durit de mise à l’air du carter moteur9Durit de trop-plein

AFaire passer le câble d’embrayage à

l’extérieur du câble des gaz et du fil du

bouton “ENGINE STOP”.

BAligner la bande de positionnement du

câble des gaz sur le guide du câble.

CFaire passer le câble des gaz, le câble

d’embrayage et le fil du bouton “ENGI-

NE STOP” au-dessus de la durit de mise

à l’air du radiateur.

DBrider le fil du bouton “ENGINE STOP”

au cadre. Serrer le collier à pince de

façon à ce que le fil du bouton “ENGINE

STOP” ne soit pas tiré lorsque le guidon

tourne vers la gauche et vers la droite.

EBrider le câble des gaz, le câble

d’embrayage et le faisceau de fils au

cadre.

FBrider le câble des gaz et le faisceau de

fils au cadre.

GFaire passer le câble d’embrayage devant

le centre de l’écrou de serrage de la

culasse.

HFaire passer la durit de ventilation, la

durit de trop-plein et la durit de mise à

l’air du carter moteur entre le cadre et la

bielle.

IPlacer les extrémités du collier dans le

sens de la flèche.

JFaire passer le câble des gaz derrière la

durit de ventilation.

KFaire passer la durit de ventilation, la

durit de trop-plein et la durit de mise à

l’air du carter moteur de façon à ce

qu’elles ne soient pas en contact avec

l’amortisseur arrière.

LBrider les durits de ventilation.

IC240000

DIAGRAMMA DEL

PASSAGGIO DEI CAVI

1Conduttore del pulsante “ARRESTO

MOTORE”

2Cavo acceleratore3Cavo frizione4Morsetto5Cablaggio elettrico 6Flessibile di sfiato del radiatore7Flessibile di sfiato aria8Tubo di sfiato del carter9Flessibile di troppopieno carburante

AFar passare il cavo della frizione dal lato

esterno del cavo dell’acceleratore e del

conduttore del pulsante “ARRESTO

MOTORE”.

BAllineare il nastro di posizione del cavo

acceleratore con la guida per cavi.

CFar passare il cavo dell’acceleratore, il

cavo della frizione e il conduttore del

pulsante “ARRESTO MOTORE” sopra

il flessibile del radiatore.

DAgganciare al telaio il conduttore del

pulsante “ARRESTO MOTORE”. Serra-

re il morsetto in modo che il conduttore

del pulsante “ARRESTO MOTORE”

non venga trascinato quando il manubrio

ruota a sinistra e a destra.

EAgganciare al telaio il cavo acceleratore,

il cavo della frizione e il cablaggio elet-

trico.

FAgganciare al telaio il cavo acceleratore

e il cablaggio elettrico.

GPassare il cavo della frizione davanti al

centro del dado di serraggio della testata.

HFar passare il flessibile di sfiato aria, il

flessibile di troppopieno carburante e il

tubo di sfiato del carter tra il telaio e la

biella.

ICollocare le estremità del morsetto entro

la gamma indicata dalle frecce.

JPassare il cavo acceleratore dietro il fles-

sibile di sfiato aria.

KPassare il flessibile di sfiato aria, il fles-

sibile di troppopieno carburante e il fles-

sibile di sfiato del carter in modo tale da

non farli entrare in contatto con

l’ammortizzatore posteriore.

LFissare i tubi di sfiato.

1P8-9-32-2 4/29/06 11:46 AM Page 55