seat adjustment YAMAHA YZ426F 2001 Betriebsanleitungen (in German)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ426F, Model: YAMAHA YZ426F 2001Pages: 626, PDF-Größe: 47.57 MB

Page 76 of 626

SPEC

2 - 5

MAINTENANCE SPECIFICATIONS

Cam chain:

Cam chain type/No. of links 92RH2010-120MPX/120 ----

Cam chain adjustment method Automatic ----

Valve, valve seat, valve guide:

Valve clearance (cold) IN 0.10 ~ 0.15 mm

(0.0039 ~ 0.0059 in)----

EX 0.20 ~ 0.25 mm

(0.0079 ~ 0.0098 in)----

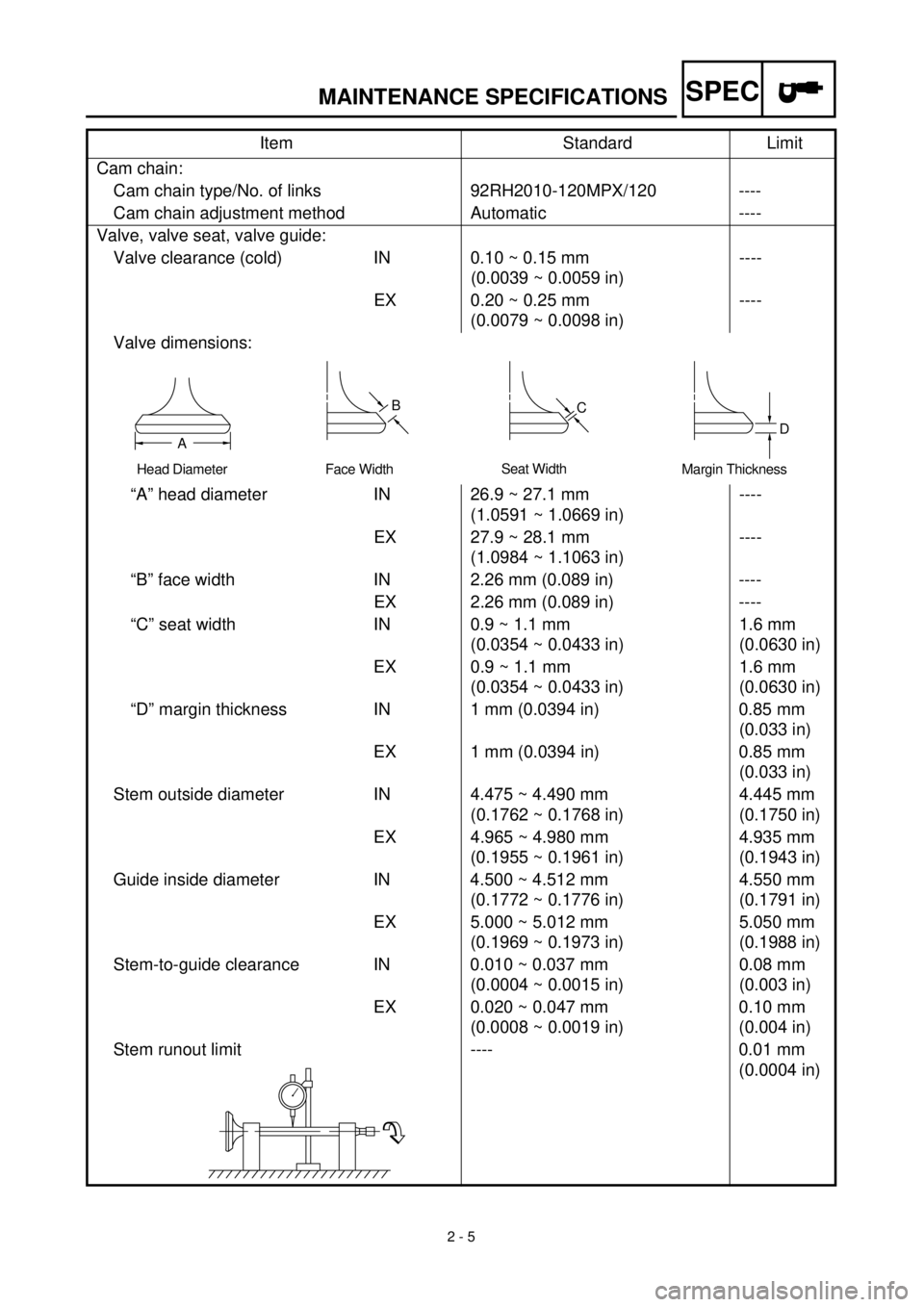

Valve dimensions:

“A” head diameter IN 26.9 ~ 27.1 mm

(1.0591 ~ 1.0669 in)----

EX 27.9 ~ 28.1 mm

(1.0984 ~ 1.1063 in)----

“B” face width IN 2.26 mm (0.089 in) ----

EX 2.26 mm (0.089 in) ----

“C” seat width IN 0.9 ~ 1.1 mm

(0.0354 ~ 0.0433 in)1.6 mm

(0.0630 in)

EX 0.9 ~ 1.1 mm

(0.0354 ~ 0.0433 in)1.6 mm

(0.0630 in)

“D” margin thickness IN 1 mm (0.0394 in) 0.85 mm

(0.033 in)

EX 1 mm (0.0394 in) 0.85 mm

(0.033 in)

Stem outside diameter IN 4.475 ~ 4.490 mm

(0.1762 ~ 0.1768 in)4.445 mm

(0.1750 in)

EX 4.965 ~ 4.980 mm

(0.1955 ~ 0.1961 in)4.935 mm

(0.1943 in)

Guide inside diameter IN 4.500 ~ 4.512 mm

(0.1772 ~ 0.1776 in)4.550 mm

(0.1791 in)

EX 5.000 ~ 5.012 mm

(0.1969 ~ 0.1973 in)5.050 mm

(0.1988 in)

Stem-to-guide clearance IN 0.010 ~ 0.037 mm

(0.0004 ~ 0.0015 in)0.08 mm

(0.003 in)

EX 0.020 ~ 0.047 mm

(0.0008 ~ 0.0019 in)0.10 mm

(0.004 in)

Stem runout limit ---- 0.01 mm

(0.0004 in) Item Standard Limit

Head Diameter

B

Face WidthC

Seat Width

D

Margin ThicknessA

Page 140 of 626

3 - 1

INSP

ADJ

MAINTENANCE INTERVALS

EC300000

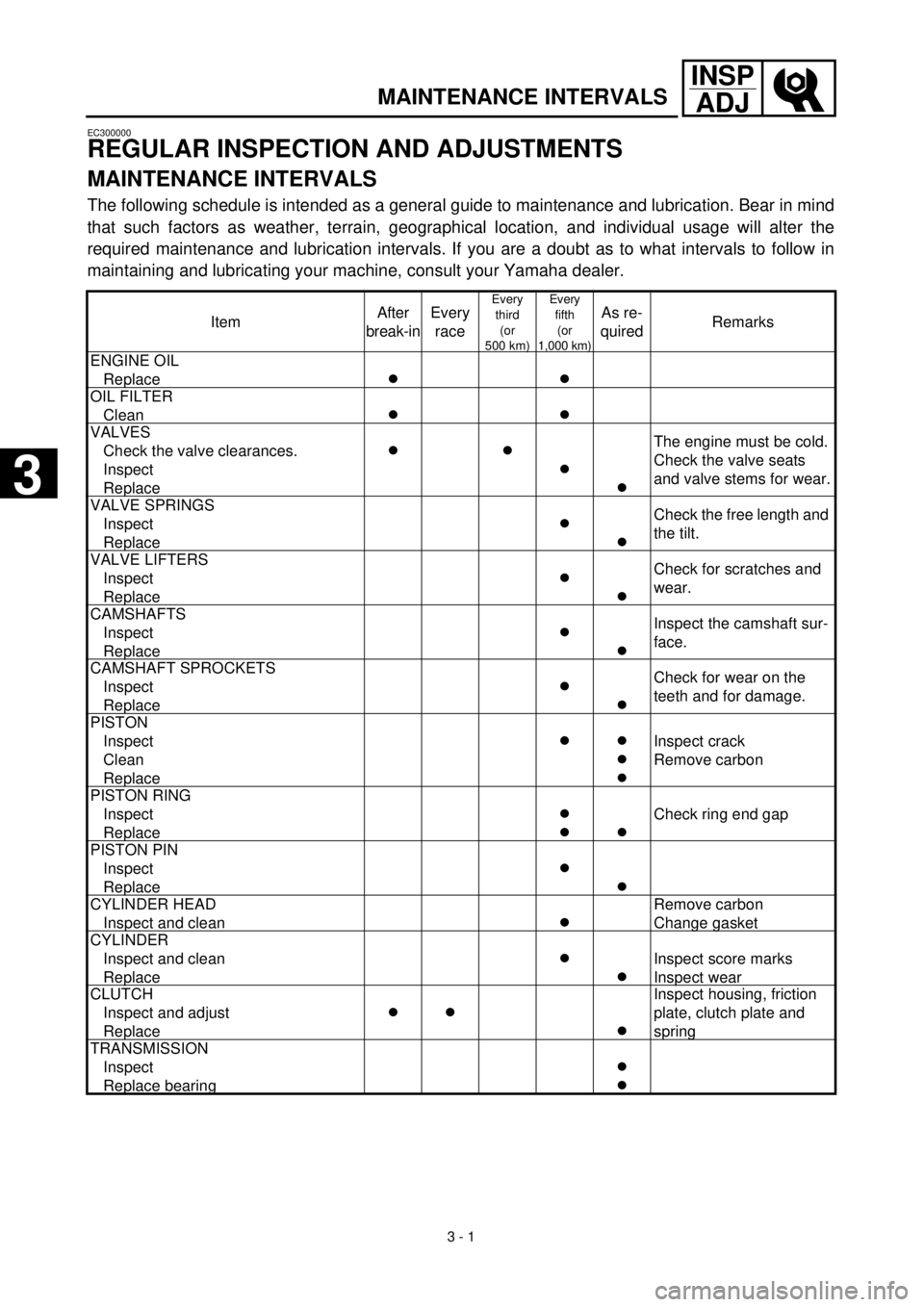

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind

that such factors as weather, terrain, geographical location, and individual usage will alter the

required maintenance and lubrication intervals. If you are a doubt as to what intervals to follow in

maintaining and lubricating your machine, consult your Yamaha dealer.

ItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)

As re-

quiredRemarks

ENGINE OIL

Replace

c

c

OIL FILTER

Clean

cc

VALVES

Check the valve clearances.

Inspect

Replace

c

c

c

c

The engine must be cold.

Check the valve seats

and valve stems for wear.

VALVE SPRINGS

Inspect

Replace

c

c

Check the free length and

the tilt.

VALVE LIFTERS

Inspect

Replace

c

c

Check for scratches and

wear.

CAMSHAFTS

Inspect

Replace

c

c

Inspect the camshaft sur-

face.

CAMSHAFT SPROCKETS

Inspect

Replace

c

c

Check for wear on the

teeth and for damage.

PISTON

Inspect

Clean

Replace

c

c

c

c

Inspect crack

Remove carbon

PISTON RING

Inspect

Replace

c

c

c

Check ring end gap

PISTON PIN

Inspect

Replace

c

c

CYLINDER HEAD

Inspect and clean

c

Remove carbon

Change gasket

CYLINDER

Inspect and clean

Replace

c

c

Inspect score marks

Inspect wear

CLUTCH

Inspect and adjust

Replace

c

c

c

Inspect housing, friction

plate, clutch plate and

spring

TRANSMISSION

Inspect

Replace bearing

c

c

3

Page 176 of 626

3 - 17

INSP

ADJ

PILOT SCREW ADJUSTMENT

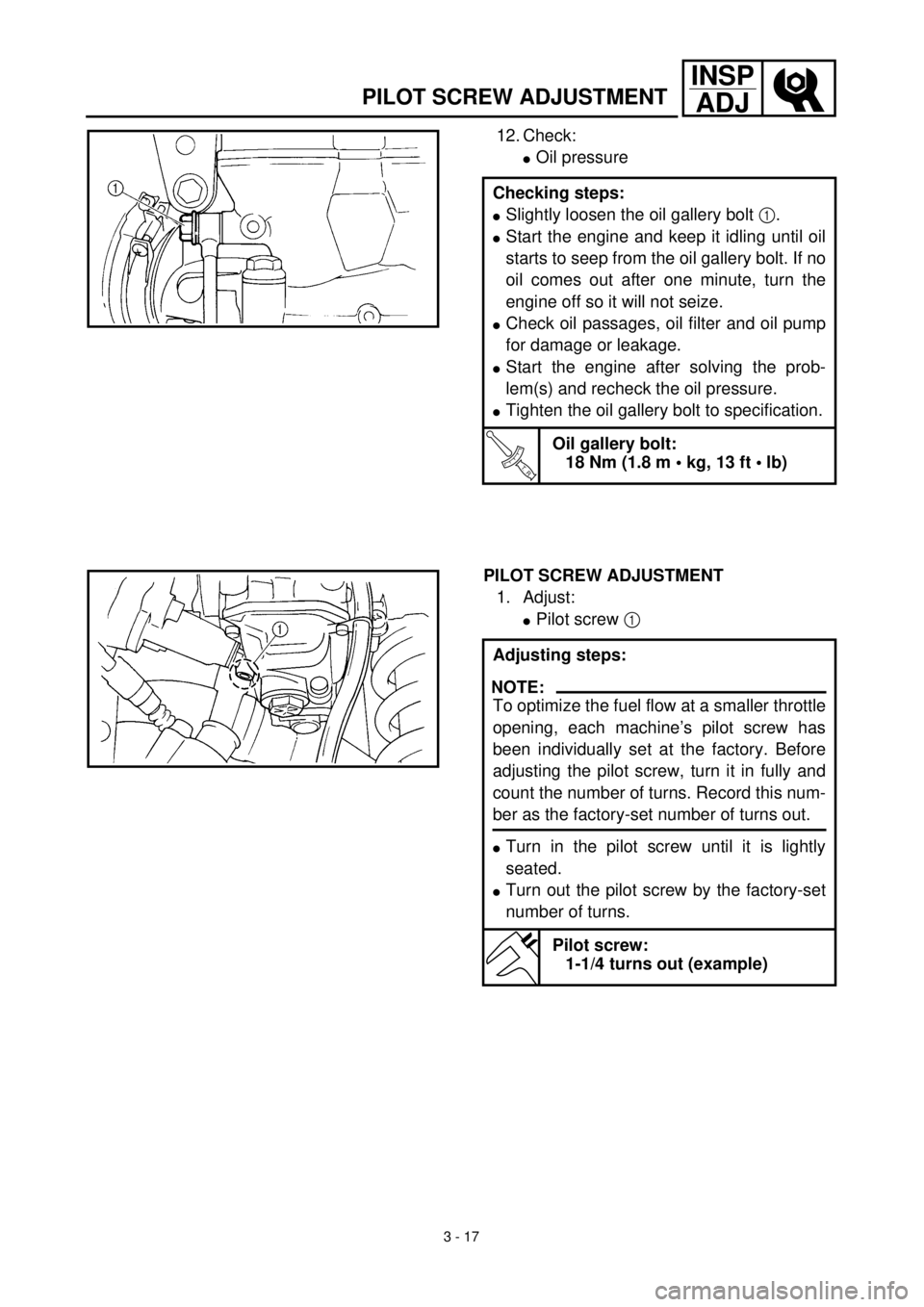

12. Check:

lOil pressure

Checking steps:

lSlightly loosen the oil gallery bolt 1.

lStart the engine and keep it idling until oil

starts to seep from the oil gallery bolt. If no

oil comes out after one minute, turn the

engine off so it will not seize.

lCheck oil passages, oil filter and oil pump

for damage or leakage.

lStart the engine after solving the prob-

lem(s) and recheck the oil pressure.

lTighten the oil gallery bolt to specification.

T R..

Oil gallery bolt:

18 Nm (1.8 m • kg, 13 ft • lb)

PILOT SCREW ADJUSTMENT

1. Adjust:

lPilot screw 1

Adjusting steps:

NOTE:

To optimize the fuel flow at a smaller throttle

opening, each machine’s pilot screw has

been individually set at the factory. Before

adjusting the pilot screw, turn it in fully and

count the number of turns. Record this num-

ber as the factory-set number of turns out.

lTurn in the pilot screw until it is lightly

seated.

lTurn out the pilot screw by the factory-set

number of turns.

Pilot screw:

1-1/4 turns out (example)

Page 178 of 626

3 - 18

INSP

ADJIDLE SPEED ADJUSTMENT/

VALVE CLEARANCE ADJUSTMENT

EC35M021

IDLE SPEED ADJUSTMENT

1. Start the engine and thoroughly warm it

up.

2. Adjust:

lIdle speed

Adjustment steps:

lAdjust the pilot screw.

Refer to “PILOT SCREW ADJUSTMENT”

section.

lTurn the throttle stop screw 1 until the

engine runs at the lowest possible speed.

To increase idle speed ®

Turn the throttle stop screw 1 in a.

To decrease idle speed ®

Turn the throttle stop screw 1 out b.

Engine idling speed:

1,700 ~ 1,900 r/min

VALVE CLEARANCE ADJUSTMENT

NOTE:

lThe valve clearance should be adjusted

when the engine is cool to the touch.

lThe piston must be at Top Dead Center

(T.D.C.) on compression stroke to check or

adjust the valve clearance.

1. Remove:

lSeat

lFuel tank

Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section in the CHAPTER 4.

2. Remove:

lCarburetor

Refer to “CARBURETOR” section in

the CHAPTER 4.

lSpark plug cap

lEngine stay (upper)

lCylinder head cover

Refer to “CAMSHAFTS” section in the

CHAPTER 4.

3. Remove:

lTiming plug 1

lStraight plug 2

lO-ring

Page 260 of 626

4 - 12

ENGCARBURETOR

EC464511

Float height

1. Measure:

lFloat height a

Out of specification ® Adjust.

Float height:

8.0 mm (0.31 in)

Measurement and adjustment steps:

lHold the carburetor in an upside down

position.

NOTE:

lSlowly tilt the carburetor in the opposite

direction, then take the measurement

when the needle valve aligns with the float

arm.

lIf the carburetor is level, the weight of the

float will push in the needle valve, result-

ing in an incorrect measurement.

lMeasure the distance between the mating

surface of the float chamber and top of the

float using a vernier calipers.

NOTE:

The float arm should be resting on the nee-

dle valve, but not compressing the needle

valve.

lIf the float height is not within specifica-

tion, inspect the valve seat and needle

valve.

lIf either is worn, replace them both.

lIf both are fine, adjust the float height by

bending the float tab b on the float.

lRecheck the float height.

EC464600

Float

1. Inspect:

lFloat 1

Damage ® Replace.

Page 618 of 626

7 - 20

TUN

SETTING

EC72H002

Suspension setting

l

Front fork

NOTE:

l

If any of the following symptoms is experienced with the standard position as the base, make

resetting by reference to the adjustment procedure given in the same chart.

l

Before any change, set the rear shock absorber sunken length to the standard figure 90 ~

100 mm (3.5 ~ 3.9 in).

SymptomSection

Check Adjust

JumpLarge

gap

Medium

gap

Small

gap

Stiff over entire range

CCC

Compression damping

Oil level (oil amount)

SpringTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Decrease oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).

Replace with soft spring.

Unsmooth movement

over entire range

CCCC

Outer tube

Inner tube

Under bracket tightening

torqueCheck for any bends, dents, and other noticeable

scars, etc. If any, replace affected parts.

Retighten to specified torque.

Poor initial

movement

C

Rebound damping

Oil sealTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Apply grease in oil seal wall.

Soft over entire range,

bottoming out

CC

Compression damping

Oil level (oil amount)

SpringTurn adjuster clockwise (about 2 clicks) to increase

damping.

Increase oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).

Replace with stiff spring.

Stiff toward stroke end

C

Oil level (oil amount) Decrease oil level by about 5 mm (0.2 in).

Soft toward stroke end,

bottoming out

C

Oil level (oil amount) Increase oil level by about 5 mm (0.2 in).

Stiff initial movement

CCCC

Compression dampingTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Low front, tending to

lower front posture

CC

Compression damping

Rebound damping

Balance with rear end

Oil level (oil amount)Turn adjuster clockwise (about 2 clicks) to increase

damping.

Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Set sunken length for 95 ~ 100 mm (3.7 ~ 3.9 in) when

one passenger is astride seat (lower rear posture).

Increase oil level by about 5 mm (0.2 in).

“Obtrusive” front, tend-

ing to upper front pos-

ture

CC

Compression damping

Balance with rear end

Spring

Oil lever (oil amount)Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Set sunken length for 90 ~ 95 mm (3.5 ~ 3.7 in) when

one passenger is astride seat (upper rear posture).

Replace with soft spring.

Decrease oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).

Page 619 of 626

7 - 21

TUN

SETTING

l

Rear shock absorber

NOTE:

l

If any of the following symptoms is experienced with the standard position as the base, make

resetting by reference to the adjustment procedure given in the same chart.

l

Adjust the rebound damping in 2-click increments or decrements.

l

Adjust the low compression damping in 1-click increments or decrements.

l

Adjust the high compression damping in 1/6 turn increments or decrements.

SymptomSection

Check Adjust

JumpLarge

gap

Medium

gap

Small

gap

Stiff, tending to sink

CC

Rebound damping

Spring set lengthTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Set sunken length for 90 ~ 100 mm (3.5 ~ 3.9 in) when

one passenger is astride seat.

Spongy and unstable

CC

Rebound damping

Low compression damping

SpringTurn adjuster clockwise (about 2 clicks) to increase

damping.

Turn adjuster clockwise (about 1 click) to increase

damping.

Replace with stiff spring.

Heavy and dragging

CC

Rebound damping

SpringTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Replace with soft spring.

Poor road gripping

C

Rebound damping

Low compression damping

High compression damp-

ing

Spring set length

SpringTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Turn adjuster clockwise (about 1 clicks) to increase

damping.

Turn adjuster clockwise (about 1/6 clicks) to increase

damping.

Set sunken length for 90 ~ 100 mm (3.5 ~ 3.9 in) when

one passenger is astride seat.

Replace with soft spring.

Bottoming out

CC

High compression damp-

ing

Spring set length

SpringTurn adjuster clockwise (about 1/6 turn) to increase

damping.

Set sunken length for 90 ~ 100 mm (3.5 ~ 3.9 in) when

one passenger in astride seat.

Replace with stiff spring.

Bouncing

CC

Rebound damping

SpringTurn adjuster clockwise (about 2 clicks) to increase

damping.

Replace with soft spring.

Stiff travel

CC

High compression damp-

ing

Spring set length

SpringTurn adjuster counterclockwise (about 1/6 turn) to

decrease damping.

Set sunken length for 95 ~ 100 mm (3.7 ~ 3.9 in) when

one passenger is astride seat.

Replace with soft spring.