radiator YAMAHA YZ426F 2001 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ426F, Model: YAMAHA YZ426F 2001Pages: 626, PDF Size: 47.57 MB

Page 22 of 626

CHAPTER 4

ENGINE

SEAT, FUEL TANK AND

SIDE COVERS

.......................................... 4-1

EXHAUST PIPE AND SILENCER

............ 4-2

RADIATOR

............................................... 4-4

CARBURETOR

......................................... 4-7

CAMSHAFTS

.......................................... 4-19

CYLINDER HEAD

................................... 4-26

VALVES AND VALVE SPRINGS

........... 4-30

CYLINDER AND PISTON

....................... 4-39

CLUTCH

.................................................. 4-45

OIL FILTER, WATER PUMP AND

CRANKCASE COVER (RIGHT)

............. 4-52

BALANCER

............................................ 4-59

OIL PUMP

............................................... 4-62

KICK AXLE AND SHIFT SHAFT

............ 4-66

CDI MAGNETO

....................................... 4-73

ENGINE REMOVAL

................................ 4-77

CRANKCASE AND CRANKSHAFT

....... 4-82

TRANSMISSION, SHIFT CAM AND

SHIFT FORK

........................................... 4-91

CHAPTER 5

CHASSIS

FRONT WHEEL AND REAR WHEEL

...... 5-1

FRONT BRAKE AND REAR BRAKE

.... 5-10

FRONT FORK

......................................... 5-27

HANDLEBAR

.......................................... 5-40

STEERING

.............................................. 5-45

SWINGARM

............................................ 5-50

REAR SHOCK ABSORBER

................... 5-57

Page 26 of 626

GEN

INFO

1 - 1

DESCRIPTION

EC100000

GENERAL INFORMATION

EC110000

DESCRIPTION

1

Clutch lever

2

Decompression lever

3

Front brake lever

4

Throttle grip

5

Radiator cap

6

Fuel tank cap

7

Oil filler plug/dipstick

8

“ENGINE STOP” button

9

Kick starter

0

Fuel tank

A

Radiator

B

Coolant drain bolt

C

Rear brake pedal

D

Valve joint

E

Fuel cock

F

Cold starter knob

G

Hot starter knob (red)

H

Drive chain

I

Air cleaner

J

Shift pedal

K

Front fork

NOTE:

l

The machine you have purchased may differ

slightly from those shown in the following.

l

Designs and specifications are subject to

change without notice.

1

Page 38 of 626

GEN

INFO

1 - 7

SPECIAL TOOLS

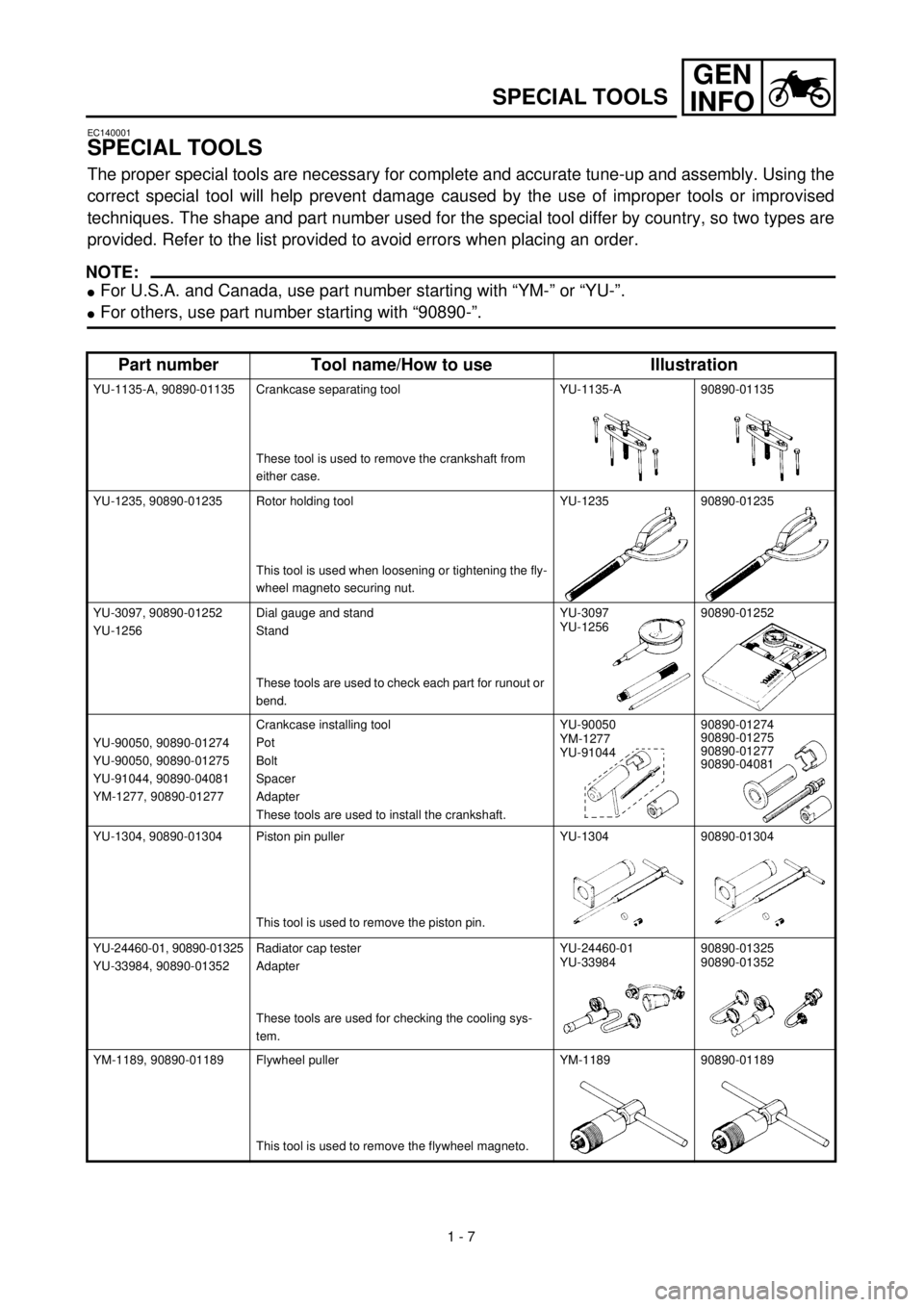

EC140001

SPECIAL TOOLS

The proper special tools are necessary for complete and accurate tune-up and assembly. Using the

correct special tool will help prevent damage caused by the use of improper tools or improvised

techniques. The shape and part number used for the special tool differ by country, so two types are

provided. Refer to the list provided to avoid errors when placing an order.

NOTE:

lFor U.S.A. and Canada, use part number starting with “YM-” or “YU-”.

lFor others, use part number starting with “90890-”.

Part number Tool name/How to use Illustration

YU-1135-A, 90890-01135 Crankcase separating tool

These tool is used to remove the crankshaft from

either case.YU-1135-A 90890-01135

YU-1235, 90890-01235 Rotor holding tool

This tool is used when loosening or tightening the fly-

wheel magneto securing nut.YU-1235 90890-01235

YU-3097, 90890-01252

YU-1256Dial gauge and stand

Stand

These tools are used to check each part for runout or

bend.YU-3097

YU-125690890-01252

YU-90050, 90890-01274

YU-90050, 90890-01275

YU-91044, 90890-04081

YM-1277, 90890-01277Crankcase installing tool

Pot

Bolt

Spacer

Adapter

These tools are used to install the crankshaft.YU-90050

YM-1277

YU-9104490890-01274

90890-01275

90890-01277

90890-04081

YU-1304, 90890-01304 Piston pin puller

This tool is used to remove the piston pin.YU-1304 90890-01304

YU-24460-01, 90890-01325

YU-33984, 90890-01352Radiator cap tester

Adapter

These tools are used for checking the cooling sys-

tem.YU-24460-01

YU-3398490890-01325

90890-01352

YM-1189, 90890-01189 Flywheel puller

This tool is used to remove the flywheel magneto.YM-1189 90890-01189

Page 80 of 626

SPEC

2 - 9

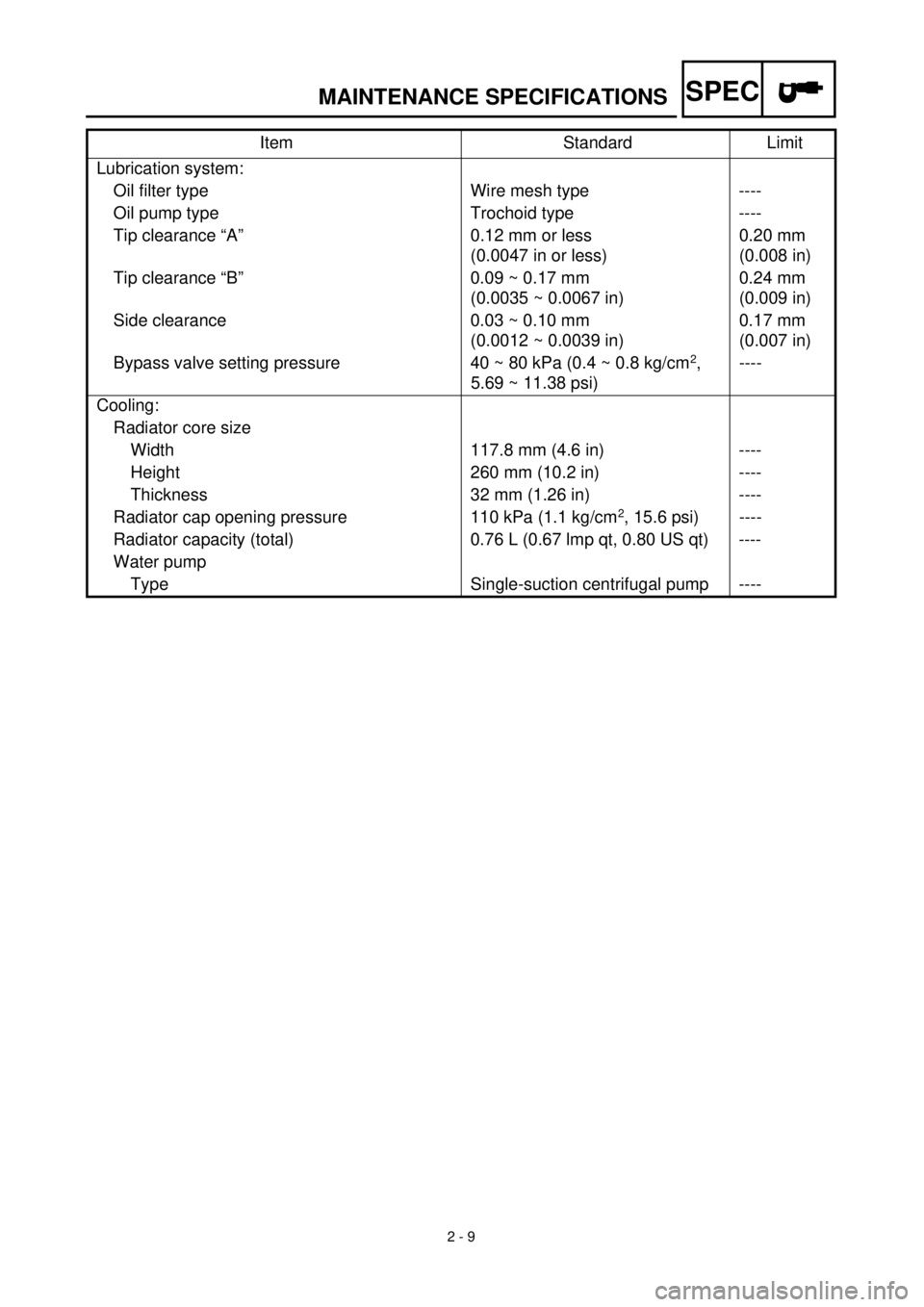

MAINTENANCE SPECIFICATIONS

Lubrication system:

Oil filter type Wire mesh type ----

Oil pump type Trochoid type ----

Tip clearance “A” 0.12 mm or less

(0.0047 in or less)0.20 mm

(0.008 in)

Tip clearance “B” 0.09 ~ 0.17 mm

(0.0035 ~ 0.0067 in)0.24 mm

(0.009 in)

Side clearance 0.03 ~ 0.10 mm

(0.0012 ~ 0.0039 in)0.17 mm

(0.007 in)

Bypass valve setting pressure 40 ~ 80 kPa (0.4 ~ 0.8 kg/cm

2

,

5.69 ~ 11.38 psi)----

Cooling:

Radiator core size

Width 117.8 mm (4.6 in) ----

Height 260 mm (10.2 in) ----

Thickness 32 mm (1.26 in) ----

Radiator cap opening pressure 110 kPa (1.1 kg/cm

2

, 15.6 psi) ----

Radiator capacity (total) 0.76 L (0.67 lmp qt, 0.80 US qt) ----

Water pump

Type Single-suction centrifugal pump ----Item Standard Limit

Page 82 of 626

SPEC

2 - 11

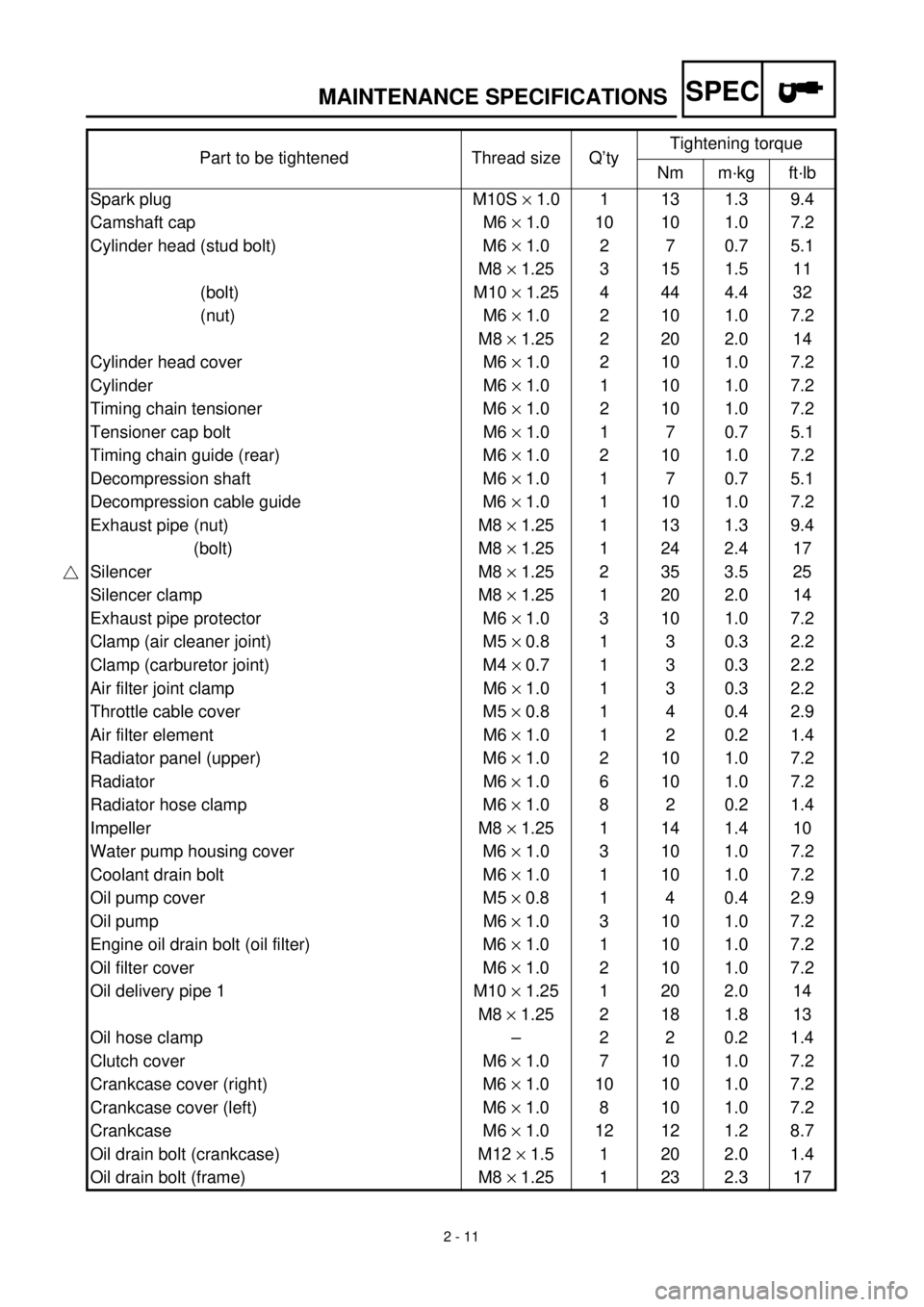

MAINTENANCE SPECIFICATIONS

Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Spark plug M10S

´

1.0 1 13 1.3 9.4

Camshaft cap M6

´

1.0 10 10 1.0 7.2

Cylinder head (stud bolt) M6

´

1.0 2 7 0.7 5.1

M8

´

1.25 3 15 1.5 11

(bolt) M10

´

1.25 4 44 4.4 32

(nut) M6

´

1.0 2 10 1.0 7.2

M8

´

1.25 2 20 2.0 14

Cylinder head cover M6

´

1.0 2 10 1.0 7.2

Cylinder M6

´

1.0 1 10 1.0 7.2

Timing chain tensioner M6

´

1.0 2 10 1.0 7.2

Tensioner cap bolt M6

´

1.0 1 7 0.7 5.1

Timing chain guide (rear) M6

´

1.0 2 10 1.0 7.2

Decompression shaft M6

´

1.0 1 7 0.7 5.1

Decompression cable guide M6

´

1.0 1 10 1.0 7.2

Exhaust pipe (nut) M8

´

1.25 1 13 1.3 9.4

(bolt) M8

´

1.25 1 24 2.4 17

Silencer M8

´

1.25 2 35 3.5 25

Silencer clamp M8

´

1.25 1 20 2.0 14

Exhaust pipe protector M6

´

1.0 3 10 1.0 7.2

Clamp (air cleaner joint) M5

´

0.8 1 3 0.3 2.2

Clamp (carburetor joint) M4

´

0.7 1 3 0.3 2.2

Air filter joint clamp M6

´

1.0 1 3 0.3 2.2

Throttle cable cover M5

´

0.8 1 4 0.4 2.9

Air filter element M6

´

1.0 1 2 0.2 1.4

Radiator panel (upper) M6

´

1.0 2 10 1.0 7.2

Radiator M6

´

1.0 6 10 1.0 7.2

Radiator hose clamp M6

´

1.0 8 2 0.2 1.4

Impeller M8

´

1.25 1 14 1.4 10

Water pump housing cover M6

´

1.0 3 10 1.0 7.2

Coolant drain bolt M6

´

1.0 1 10 1.0 7.2

Oil pump cover M5

´

0.8 1 4 0.4 2.9

Oil pump M6

´

1.0 3 10 1.0 7.2

Engine oil drain bolt (oil filter) M6

´

1.0 1 10 1.0 7.2

Oil filter cover M6

´

1.0 2 10 1.0 7.2

Oil delivery pipe 1 M10

´

1.25 1 20 2.0 14

M8

´ 1.25 2 18 1.8 13

Oil hose clamp – 2 2 0.2 1.4

Clutch cover M6 ´ 1.0 7 10 1.0 7.2

Crankcase cover (right) M6 ´ 1.0 10 10 1.0 7.2

Crankcase cover (left) M6 ´ 1.0 8 10 1.0 7.2

Crankcase M6 ´ 1.0 12 12 1.2 8.7

Oil drain bolt (crankcase) M12 ´ 1.5 1 20 2.0 1.4

Oil drain bolt (frame) M8 ´ 1.25 1 23 2.3 17

Page 87 of 626

SPEC

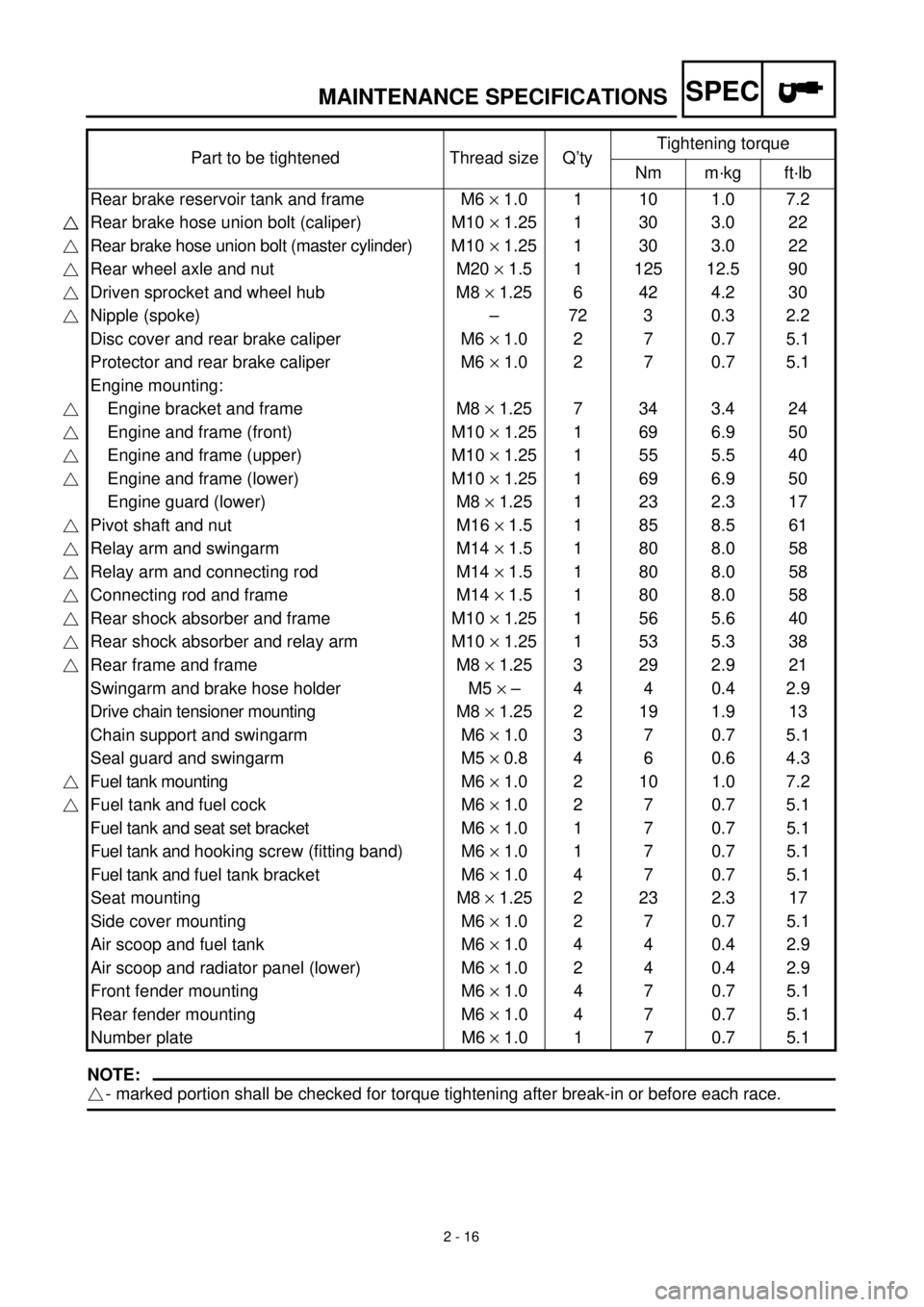

2 - 16

MAINTENANCE SPECIFICATIONS

NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race.Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Rear brake reservoir tank and frame M6 ´ 1.0 1 10 1.0 7.2

Rear brake hose union bolt (caliper) M10 ´ 1.25 1 30 3.0 22

Rear brake hose union bolt (master cylinder)M10 ´ 1.25 1 30 3.0 22

Rear wheel axle and nut M20 ´ 1.5 1 125 12.5 90

Driven sprocket and wheel hub M8 ´ 1.25 6 42 4.2 30

Nipple (spoke) – 72 3 0.3 2.2

Disc cover and rear brake caliper M6 ´ 1.0 2 7 0.7 5.1

Protector and rear brake caliper M6 ´ 1.0 2 7 0.7 5.1

Engine mounting:

Engine bracket and frame M8 ´ 1.25 7 34 3.4 24

Engine and frame (front) M10 ´ 1.25 1 69 6.9 50

Engine and frame (upper) M10 ´ 1.25 1 55 5.5 40

Engine and frame (lower) M10 ´ 1.25 1 69 6.9 50

Engine guard (lower) M8 ´ 1.25 1 23 2.3 17

Pivot shaft and nut M16 ´ 1.5 1 85 8.5 61

Relay arm and swingarm M14 ´ 1.5 1 80 8.0 58

Relay arm and connecting rod M14 ´ 1.5 1 80 8.0 58

Connecting rod and frame M14 ´ 1.5 1 80 8.0 58

Rear shock absorber and frame M10 ´ 1.25 1 56 5.6 40

Rear shock absorber and relay arm M10 ´ 1.25 1 53 5.3 38

Rear frame and frame M8 ´ 1.25 3 29 2.9 21

Swingarm and brake hose holder M5 ´ – 4 4 0.4 2.9

Drive chain tensioner mounting M8 ´ 1.25 2 19 1.9 13

Chain support and swingarm M6 ´ 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 ´ 0.8 4 6 0.6 4.3

Fuel tank mounting M6 ´ 1.0 2 10 1.0 7.2

Fuel tank and fuel cock M6 ´ 1.0 2 7 0.7 5.1

Fuel tank and seat set bracket M6 ´ 1.0 1 7 0.7 5.1

Fuel tank and hooking screw (fitting band) M6 ´ 1.0 1 7 0.7 5.1

Fuel tank and fuel tank bracket M6 ´ 1.0 4 7 0.7 5.1

Seat mounting M8 ´ 1.25 2 23 2.3 17

Side cover mounting M6 ´ 1.0 2 7 0.7 5.1

Air scoop and fuel tank M6 ´ 1.0 4 4 0.4 2.9

Air scoop and radiator panel (lower) M6 ´ 1.0 2 4 0.4 2.9

Front fender mounting M6 ´ 1.0 4 7 0.7 5.1

Rear fender mounting M6 ´ 1.0 4 7 0.7 5.1

Number plate M6 ´ 1.0 1 7 0.7 5.1

Page 132 of 626

2 - 22

SPEC

CABLE ROUTING DIAGRAM

ï

Fasten the TPS lead (in the

sub wire harness) under the

frame so that it does not con-

tact the carburetor.

ð

Fasten the TPS lead under the

coupler to the frame with a

plastic locking tie.

ñ

Pass the carburetor breather

hose and overflow hose

between the connecting rod

and cross tube (frame).

÷

Fasten the neutral switch lead

and oil hose together with a

plastic locking tie and cut off

the tie end.

ö

Fasten the cylinder head

breather hose and neutral

switch lead to the frame with a

plastic locking tie.

¯

Fasten the neutral switch lead

to the frame with a plastic

band.

¸

Fasten the cylinder head

breather hose with the hose

holder.

Î

Pass the clutch cable through

the cable guide.

å

Fasten the neutral switch lead

and CDI magneto lead together

with a plastic band.

ê

Pass the clutch cable on the

inside the cylinder head

breather hose.

æ

Pass the cylinder head

breather hose along the inner

side of the radiator pipe.

è

Pass the radiator breather

hose from the right side of the

frame to the left side, over radi-

ator pipe 1, along the inner side

of radiator hose 4 and the radi-

ator, and between the lower

engine bracket, crankcase, oil

hose and the frame.

×Pass the clutch cable between

the frame and radiator and

over the lower boss on the radi-

ator.

Page 134 of 626

2 - 23

SPEC

ãPass the neutral switch lead and

CDI magneto lead over the middle

radiator mounting boss. Then, pass

the decompression cable under the

middle radiator mounting boss and

along the left side of the neutral

switch lead and CDI magneto lead.

ôFit the brake hose into the guide on

the protector.

çFasten the ignition coil lead (in the

sub wire harness) on the upper

inside of the frame and cut off the

tie end.

óPass the ignition coil lead (in the

sub wire harness) under the cush-

ion bracket (frame).Fasten the ignition coil lead (in the

sub wire harness) to the frame

and cut off the tie end.

Pass the carburetor breather

hoses and overflow hose so that

all there hoses do not contact the

rear shock absorber.

CABLE ROUTING DIAGRAM

Page 136 of 626

2 - 24

SPECCABLE ROUTING DIAGRAM

1Clamp

2Ignition coil

3High tension cord

4CDI unit

5CDI unit band

6Throttle cable (pull)

7Throttle cable (return)

8Radiator (left)

9Radiator breather hose

0Radiator (right)

ACDI unit stay (frame)Fasten the ignition coil lead to the

frame with a plastic band.

õFasten the ignition coil and ground

lead to the frame with the bolt.

‚Pass the ignition coil lead (in the

sub wire harness) so that it does

not contact the carburetor and

rear shock absorber and connect

it with the lead from the ignition

coil on the inside of the frame.

ëPass the throttle cables over the

high tension cord.

äPass the throttle cables along the

outer side of the CDI unit leads.

ìUsing a plastic locking tie, clamp

to the frame the CDI unit leads at

their protecting tubes.íPass the throttle cables between

the top radiator mounting boss

and middle radiator mounting

boss.

îPass the CDI unit leads over the

top radiator mounting boss.

éCross the pull and return throttle

cables before the radiator.

ïPass the throttle cables through

the cable guide.

ðPass the radiator breather hose

between the frame and the radia-

tor without pinching it.

ñPass the radiator breather hose

behind the decompression cable.

÷Insert the CDI unit band over the

CDI unit stay (frame) as far as

possible.

Page 141 of 626

3 - 2

INSP

ADJ

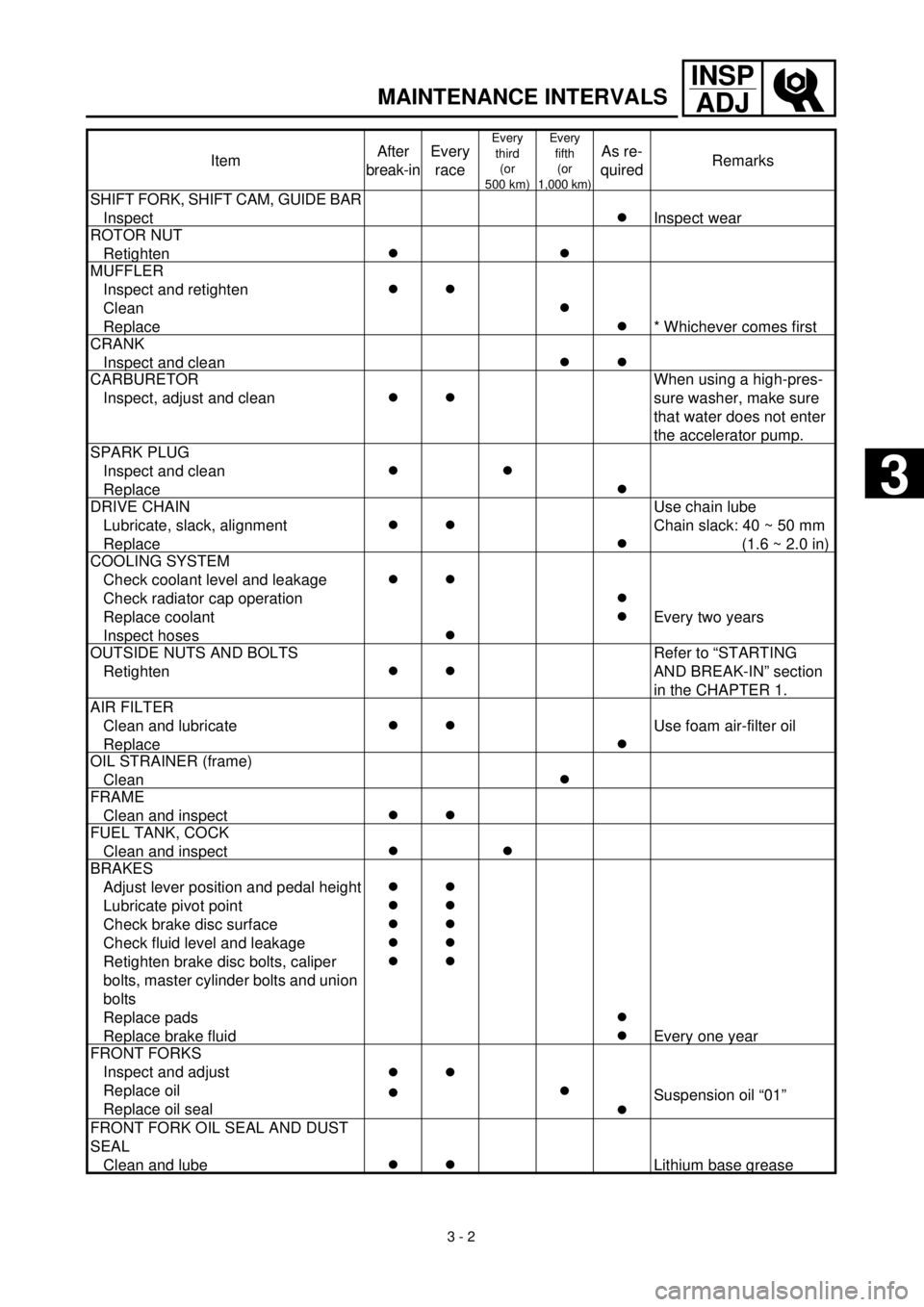

MAINTENANCE INTERVALS

SHIFT FORK, SHIFT CAM, GUIDE BAR

Inspect

c

Inspect wear

ROTOR NUT

Retighten

c

c

MUFFLER

Inspect and retighten

Clean

Replace

c

c

c

c

* Whichever comes first

CRANK

Inspect and clean

c

c

CARBURETOR

Inspect, adjust and clean

c

c

When using a high-pres-

sure washer, make sure

that water does not enter

the accelerator pump.

SPARK PLUG

Inspect and clean

Replace

c

c

c

DRIVE CHAIN

Lubricate, slack, alignment

Replace

c

c

c

Use chain lube

Chain slack: 40 ~ 50 mm

(1.6 ~ 2.0 in)

COOLING SYSTEM

Check coolant level and leakage

Check radiator cap operation

Replace coolant

Inspect hoses

c

c

c

c

c

Every two years

OUTSIDE NUTS AND BOLTS

Retighten

c

c

Refer to “STARTING

AND BREAK-IN” section

in the CHAPTER 1.

AIR FILTER

Clean and lubricate

Replace

c

c

c

Use foam air-filter oil

OIL STRAINER (frame)

Clean

c

FRAME

Clean and inspect

c

c

FUEL TANK, COCK

Clean and inspect

c

c

BRAKES

Adjust lever position and pedal height

Lubricate pivot point

Check brake disc surface

Check fluid level and leakage

Retighten brake disc bolts, caliper

bolts, master cylinder bolts and union

bolts

Replace pads

Replace brake fluid

c

c

c

c

c

c

c

c

c

c

c

c

Every one year

FRONT FORKS

Inspect and adjust

Replace oil

Replace oil seal

c

c

c

c

c

Suspension oil “01”

FRONT FORK OIL SEAL AND DUST

SEAL

Clean and lube

c

c

Lithium base grease ItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)

As re-

quiredRemarks

3