light YAMAHA YZ450F 2005 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: YZ450F, Model: YAMAHA YZ450F 2005Pages: 646, PDF Size: 16.06 MB

Page 430 of 646

4 - 95

ENGTRANSMISSION, SHIFT CAM AND SHIFT FORK

EC4H3000

REMOVAL POINTS

Shift fork, shaft cam and transmission

1. Remove:

Shift forks

Shift cam

Main axle

Drive axle

NOTE:

Tap lightly on the transmission drive axle and

shift cam with a soft hammer to remove.

Remove assembly carefully. Note the posi-

tion of each part. Pay particular attention to

the location and direction of shift forks.

EC4H4000

INSPECTION

EC4H4200

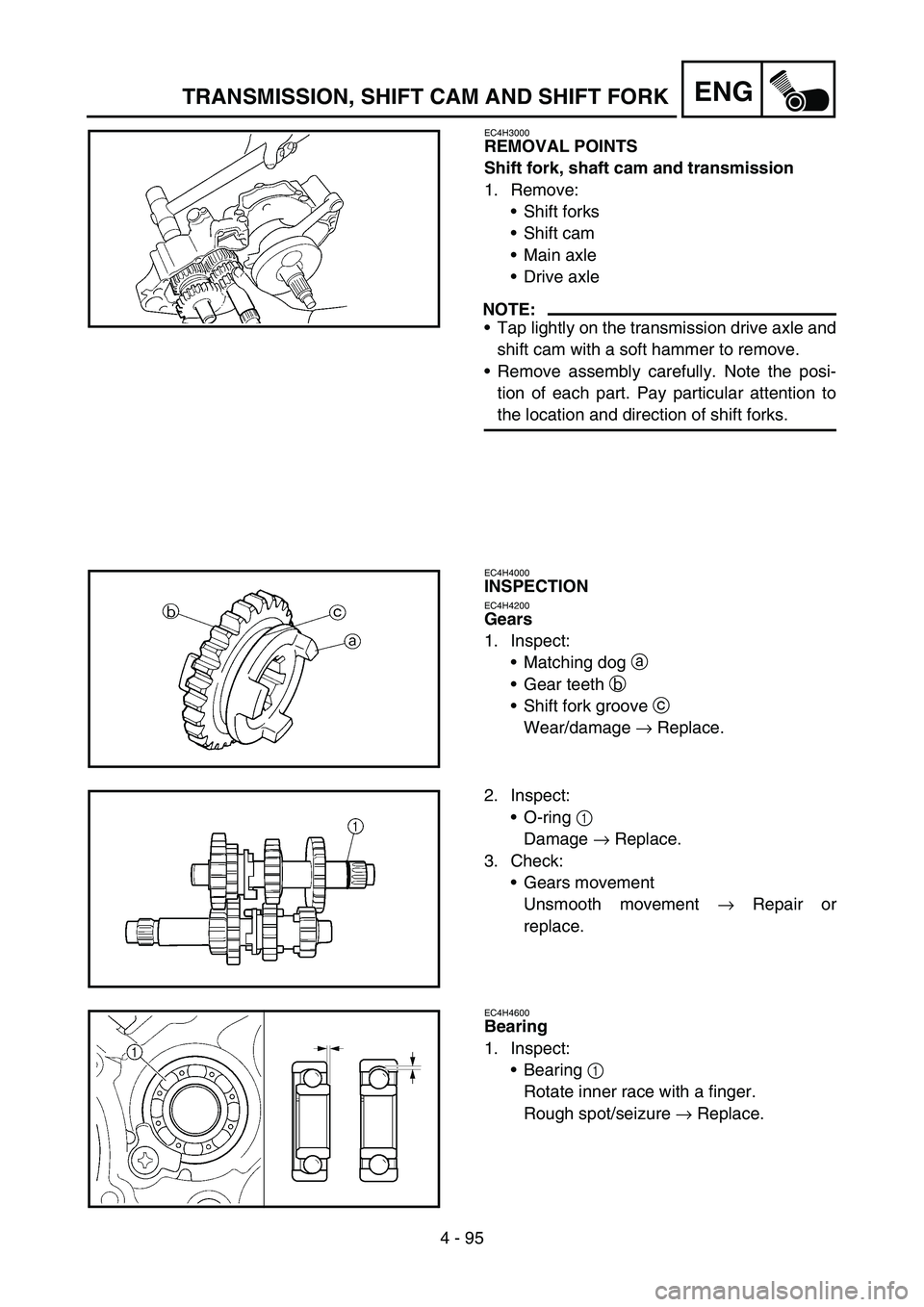

Gears

1. Inspect:

Matching dog a

Gear teeth b

Shift fork groove c

Wear/damage → Replace.

2. Inspect:

O-ring 1

Damage → Replace.

3. Check:

Gears movement

Unsmooth movement → Repair or

replace.

EC4H4600

Bearing

1. Inspect:

Bearing 1

Rotate inner race with a finger.

Rough spot/seizure → Replace.

Page 478 of 646

5 - 21

CHASFRONT BRAKE AND REAR BRAKE

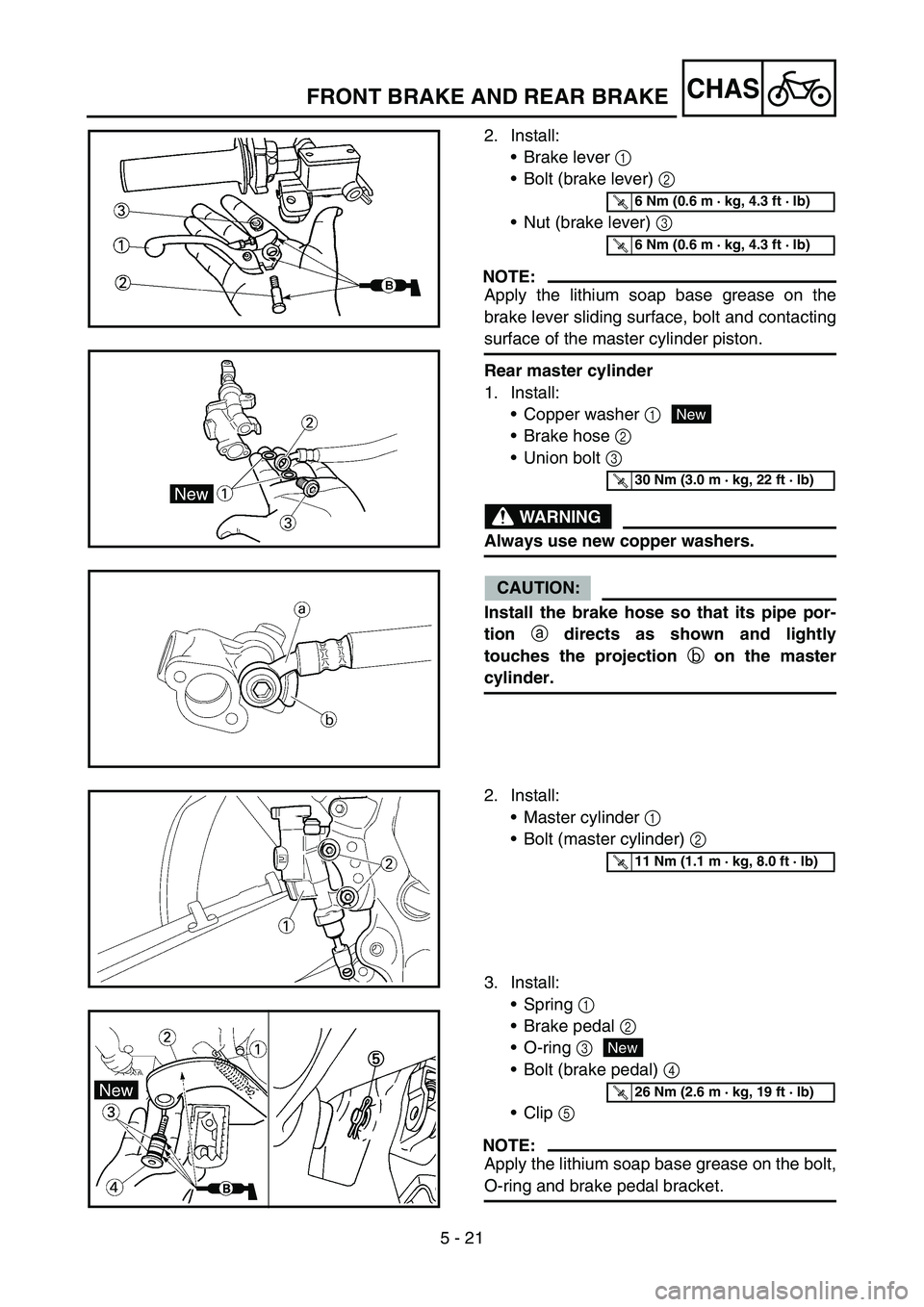

2. Install:

Brake lever 1

Bolt (brake lever) 2

Nut (brake lever) 3

NOTE:

Apply the lithium soap base grease on the

brake lever sliding surface, bolt and contacting

surface of the master cylinder piston.

Rear master cylinder

1. Install:

Copper washer 1

Brake hose 2

Union bolt 3

WARNING

Always use new copper washers.

CAUTION:

Install the brake hose so that its pipe por-

tion

a directs as shown and lightly

touches the projection

b on the master

cylinder.

T R..6 Nm (0.6 m · kg, 4.3 ft · lb)

T R..6 Nm (0.6 m · kg, 4.3 ft · lb)

New

T R..30 Nm (3.0 m · kg, 22 ft · lb)

2. Install:

Master cylinder 1

Bolt (master cylinder) 2

3. Install:

Spring 1

Brake pedal 2

O-ring 3

Bolt (brake pedal) 4

Clip 5

NOTE:

Apply the lithium soap base grease on the bolt,

O-ring and brake pedal bracket.

T R..11 Nm (1.1 m · kg, 8.0 ft · lb)

New

T R..26 Nm (2.6 m · kg, 19 ft · lb)

Page 480 of 646

5 - 22

CHASFRONT BRAKE AND REAR BRAKE

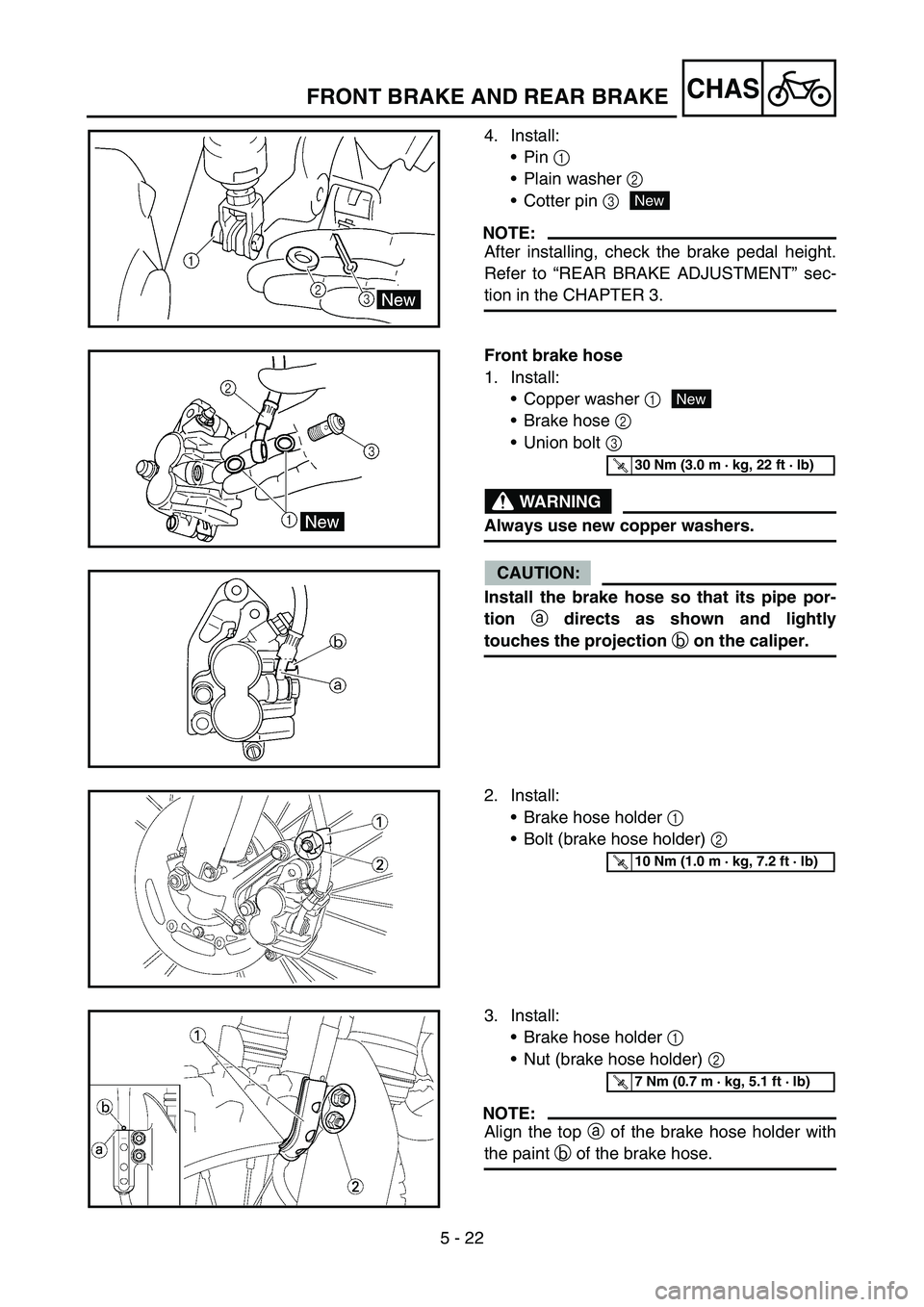

4. Install:

Pin 1

Plain washer 2

Cotter pin 3

NOTE:

After installing, check the brake pedal height.

Refer to “REAR BRAKE ADJUSTMENT” sec-

tion in the CHAPTER 3.

New

Front brake hose

1. Install:

Copper washer 1

Brake hose 2

Union bolt 3

WARNING

Always use new copper washers.

CAUTION:

Install the brake hose so that its pipe por-

tion

a directs as shown and lightly

touches the projection

b on the caliper.

New

T R..30 Nm (3.0 m · kg, 22 ft · lb)

2. Install:

Brake hose holder 1

Bolt (brake hose holder) 2

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

3. Install:

Brake hose holder 1

Nut (brake hose holder) 2

NOTE:

Align the top a of the brake hose holder with

the paint b of the brake hose.

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

Page 482 of 646

5 - 23

CHASFRONT BRAKE AND REAR BRAKE

4. Pass the brake hose through the cable

guide 1.

5. Install:

Copper washer 1

Brake hose 2

Union bolt 3

WARNING

Always use new copper washers.

CAUTION:

Install the brake hose so that its pipe por-

tion

a directs as shown and lightly

touches the projection

b on the master

cylinder.

New

T R..30 Nm (3.0 m · kg, 22 ft · lb)

Rear brake hose

1. Install:

Copper washer 1

Brake hose 2

Union bolt 3

WARNING

Always use new copper washers.

CAUTION:

Install the brake hose so that its pipe por-

tion

a directs as shown and lightly

touches the projection

b on the caliper.

New

T R..30 Nm (3.0 m · kg, 22 ft · lb)

Page 600 of 646

7 - 2

TUN

CAUTION:

The carburetor is extremely sensitive to

foreign matter (dirt, sand, water, etc.).

During installation, do not allow foreign

matter to get into the carburetor.

Always handle the carburetor and its

components carefully. Even slight

scratches, bends or damage to carburetor

parts may prevent the carburetor from

functioning correctly. Carefully perform

all servicing with the appropriate tools

and without applying excessive force.

When the engine is stopped or when

riding at no load, do not open and close

the throttle unnecessarily. Otherwise, too

much fuel may be discharged, starting

may become difficult or the engine may

not run well.

After installing the carburetor, check that

the throttle operates correctly and opens

and closes smoothly.

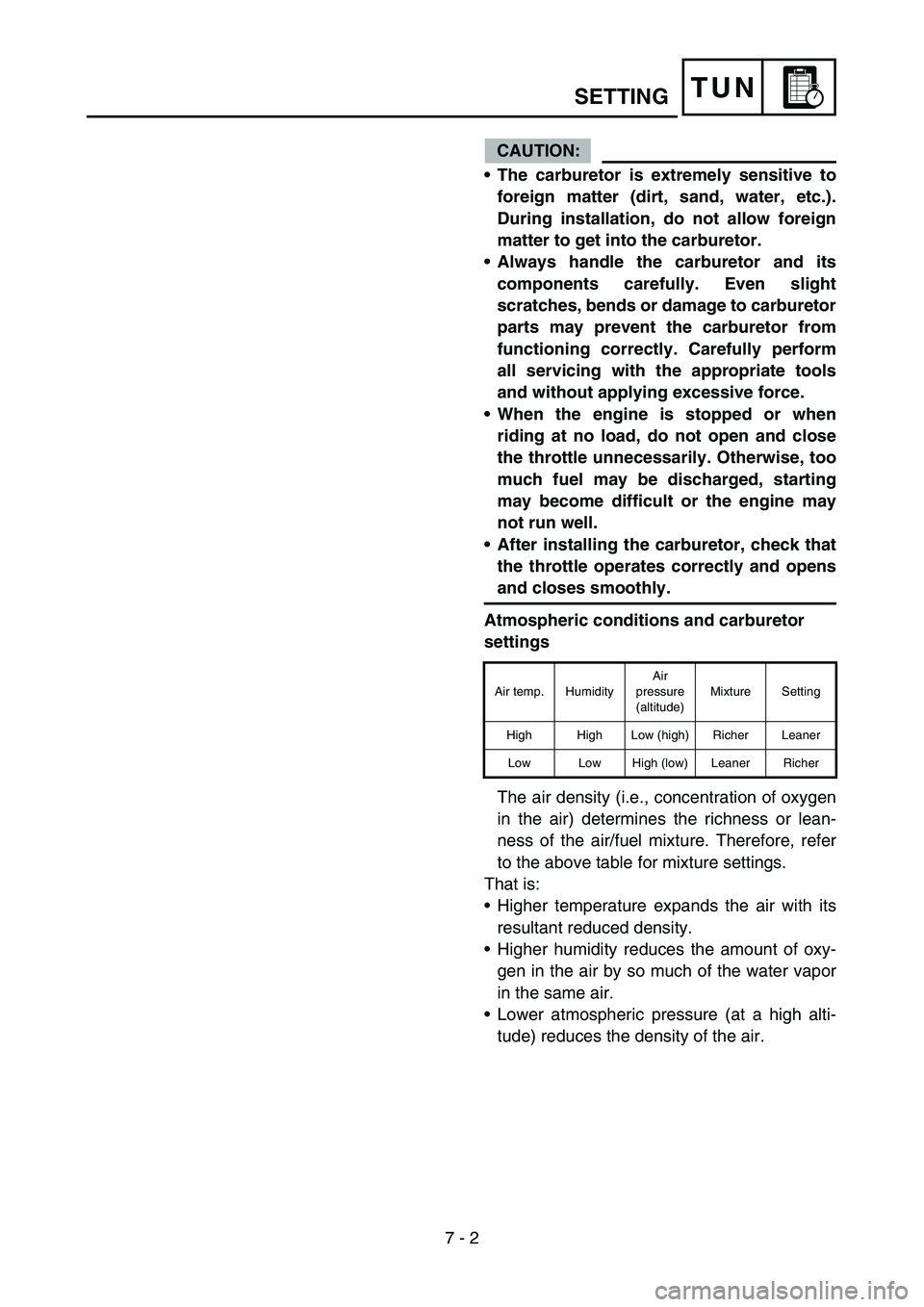

Atmospheric conditions and carburetor

settings

The air density (i.e., concentration of oxygen

in the air) determines the richness or lean-

ness of the air/fuel mixture. Therefore, refer

to the above table for mixture settings.

That is:

Higher temperature expands the air with its

resultant reduced density.

Higher humidity reduces the amount of oxy-

gen in the air by so much of the water vapor

in the same air.

Lower atmospheric pressure (at a high alti-

tude) reduces the density of the air.

Air temp. HumidityAir

pressure

(altitude)Mixture Setting

High High Low (high) Richer Leaner

Low Low High (low) Leaner Richer

SETTING