torque YAMAHA YZ450F 2006 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: YZ450F, Model: YAMAHA YZ450F 2006Pages: 650, PDF Size: 20.71 MB

Page 296 of 650

4 - 28

ENGCAMSHAFTS

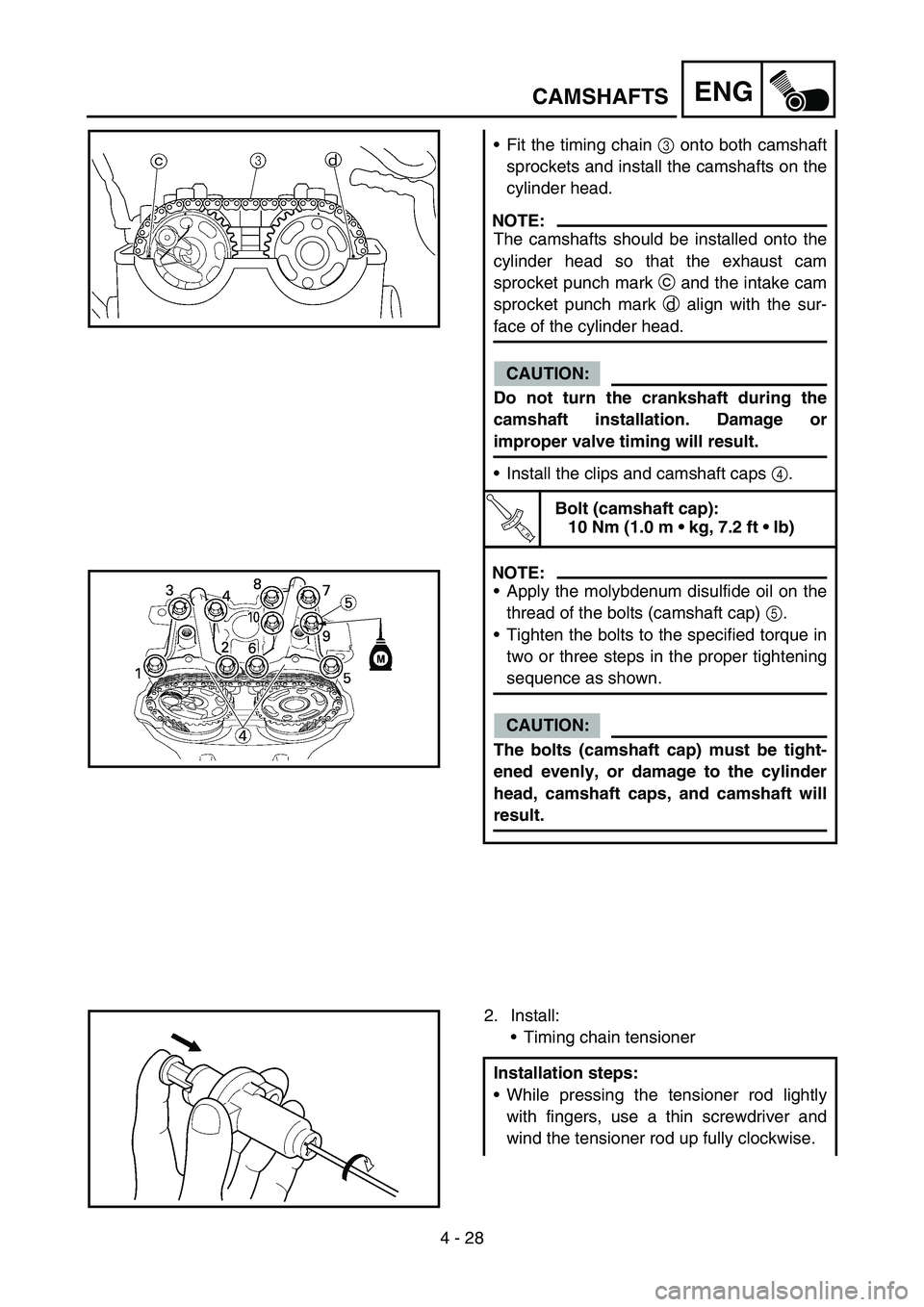

Fit the timing chain 3 onto both camshaft

sprockets and install the camshafts on the

cylinder head.

NOTE:

The camshafts should be installed onto the

cylinder head so that the exhaust cam

sprocket punch mark c and the intake cam

sprocket punch mark d align with the sur-

face of the cylinder head.

CAUTION:

Do not turn the crankshaft during the

camshaft installation. Damage or

improper valve timing will result.

Install the clips and camshaft caps 4.

T R..

Bolt (camshaft cap):

10 Nm (1.0 m kg, 7.2 ft lb)

NOTE:

Apply the molybdenum disulfide oil on the

thread of the bolts (camshaft cap) 5.

Tighten the bolts to the specified torque in

two or three steps in the proper tightening

sequence as shown.

CAUTION:

The bolts (camshaft cap) must be tight-

ened evenly, or damage to the cylinder

head, camshaft caps, and camshaft will

result.

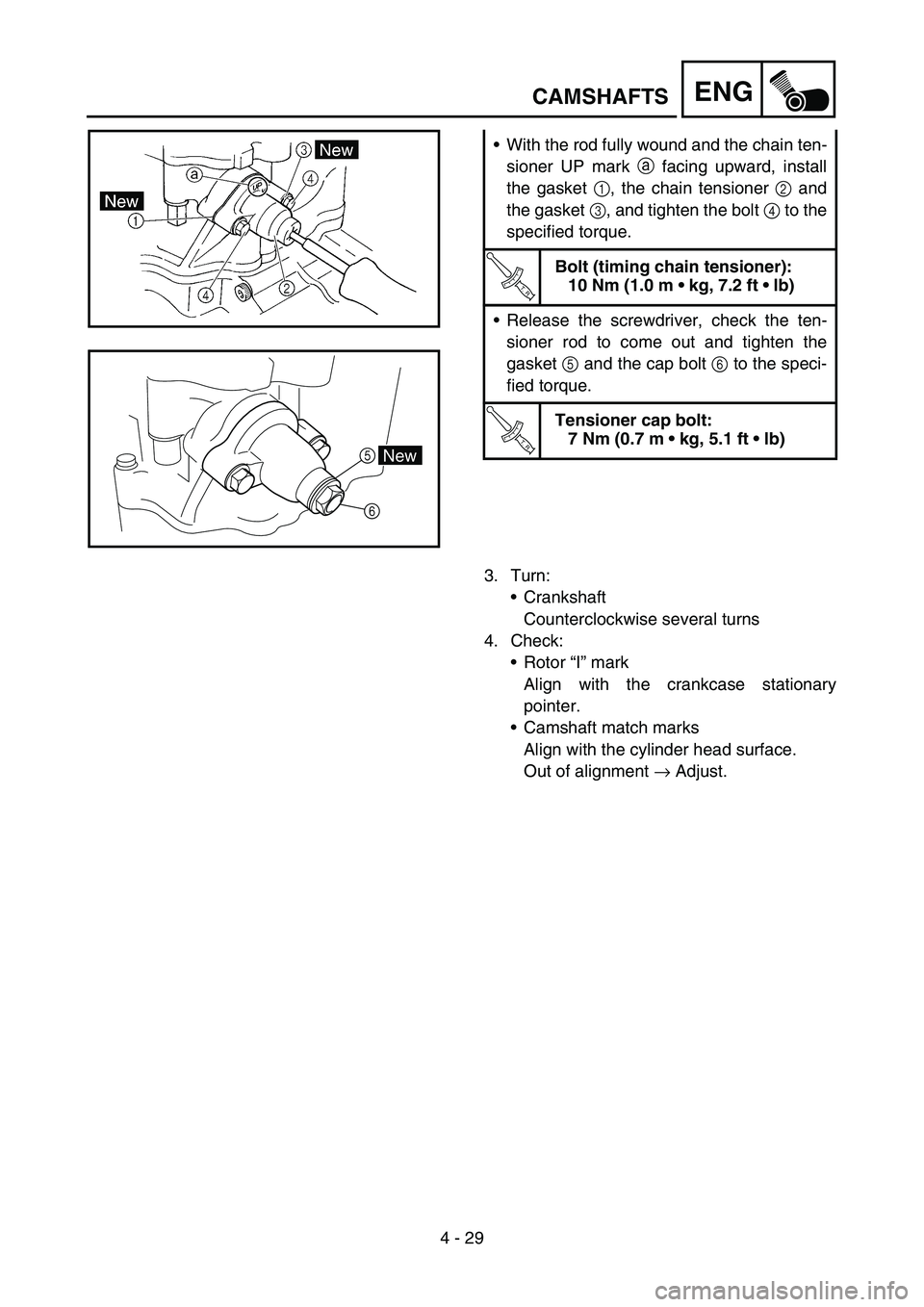

2. Install:

Timing chain tensioner

Installation steps:

While pressing the tensioner rod lightly

with fingers, use a thin screwdriver and

wind the tensioner rod up fully clockwise.

Page 298 of 650

4 - 29

ENG

With the rod fully wound and the chain ten-

sioner UP mark a facing upward, install

the gasket 1, the chain tensioner 2 and

the gasket 3, and tighten the bolt 4 to the

specified torque.

T R..

Bolt (timing chain tensioner):

10 Nm (1.0 m kg, 7.2 ft lb)

Release the screwdriver, check the ten-

sioner rod to come out and tighten the

gasket 5 and the cap bolt 6 to the speci-

fied torque.

T R..

Tensioner cap bolt:

7 Nm (0.7 m kg, 5.1 ft lb)

6

5New

3. Turn:

Crankshaft

Counterclockwise several turns

4. Check:

Rotor “I” mark

Align with the crankcase stationary

pointer.

Camshaft match marks

Align with the cylinder head surface.

Out of alignment → Adjust.

CAMSHAFTS

Page 304 of 650

4 - 32

ENGCYLINDER HEAD

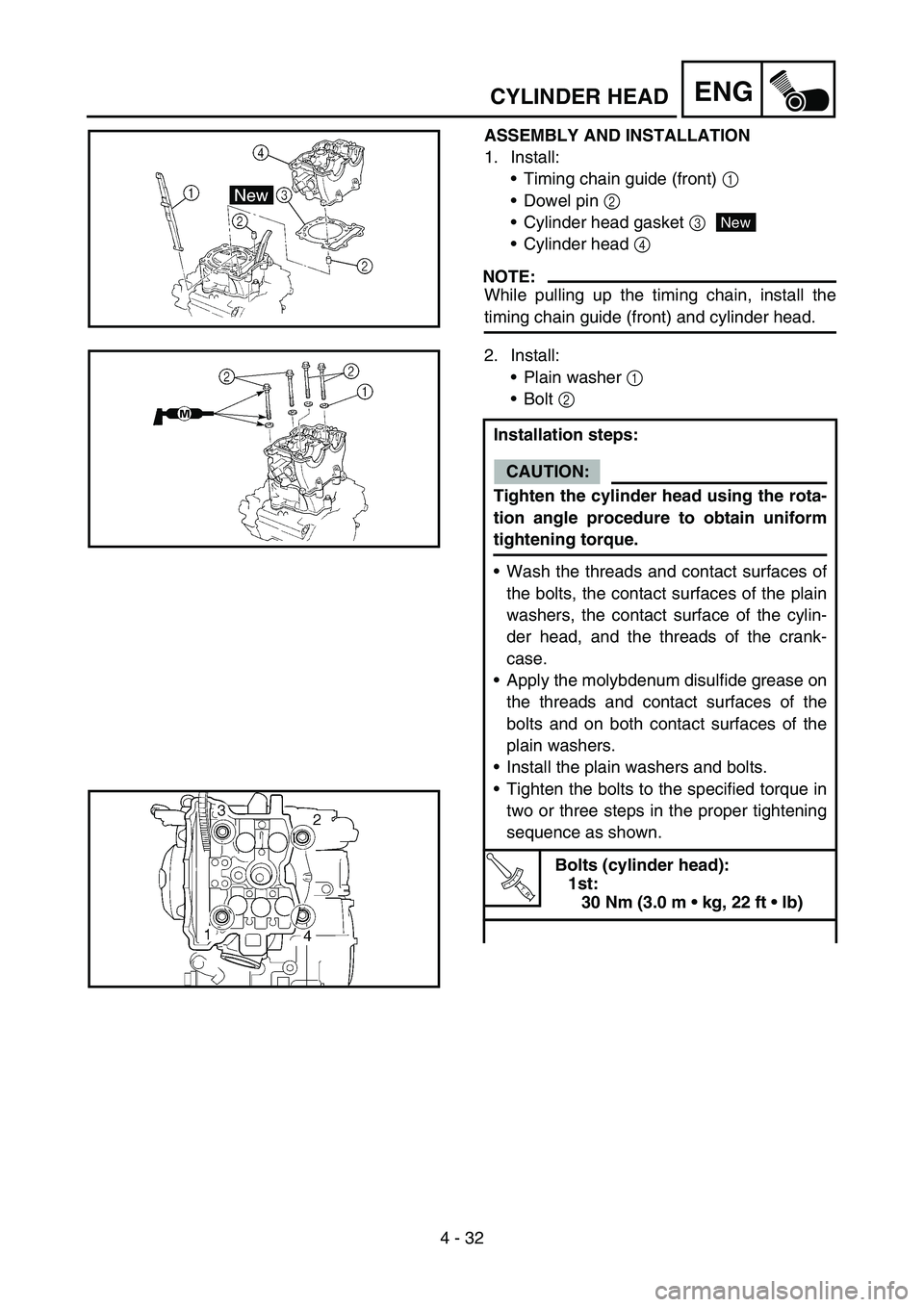

ASSEMBLY AND INSTALLATION

1. Install:

Timing chain guide (front) 1

Dowel pin 2

Cylinder head gasket 3

Cylinder head 4

NOTE:

While pulling up the timing chain, install the

timing chain guide (front) and cylinder head.

New

2. Install:

Plain washer 1

Bolt 2

Installation steps:

CAUTION:

Tighten the cylinder head using the rota-

tion angle procedure to obtain uniform

tightening torque.

Wash the threads and contact surfaces of

the bolts, the contact surfaces of the plain

washers, the contact surface of the cylin-

der head, and the threads of the crank-

case.

Apply the molybdenum disulfide grease on

the threads and contact surfaces of the

bolts and on both contact surfaces of the

plain washers.

Install the plain washers and bolts.

Tighten the bolts to the specified torque in

two or three steps in the proper tightening

sequence as shown.

T R..

Bolts (cylinder head):

1st:

30 Nm (3.0 m kg, 22 ft lb)

Page 306 of 650

4 - 33

ENG

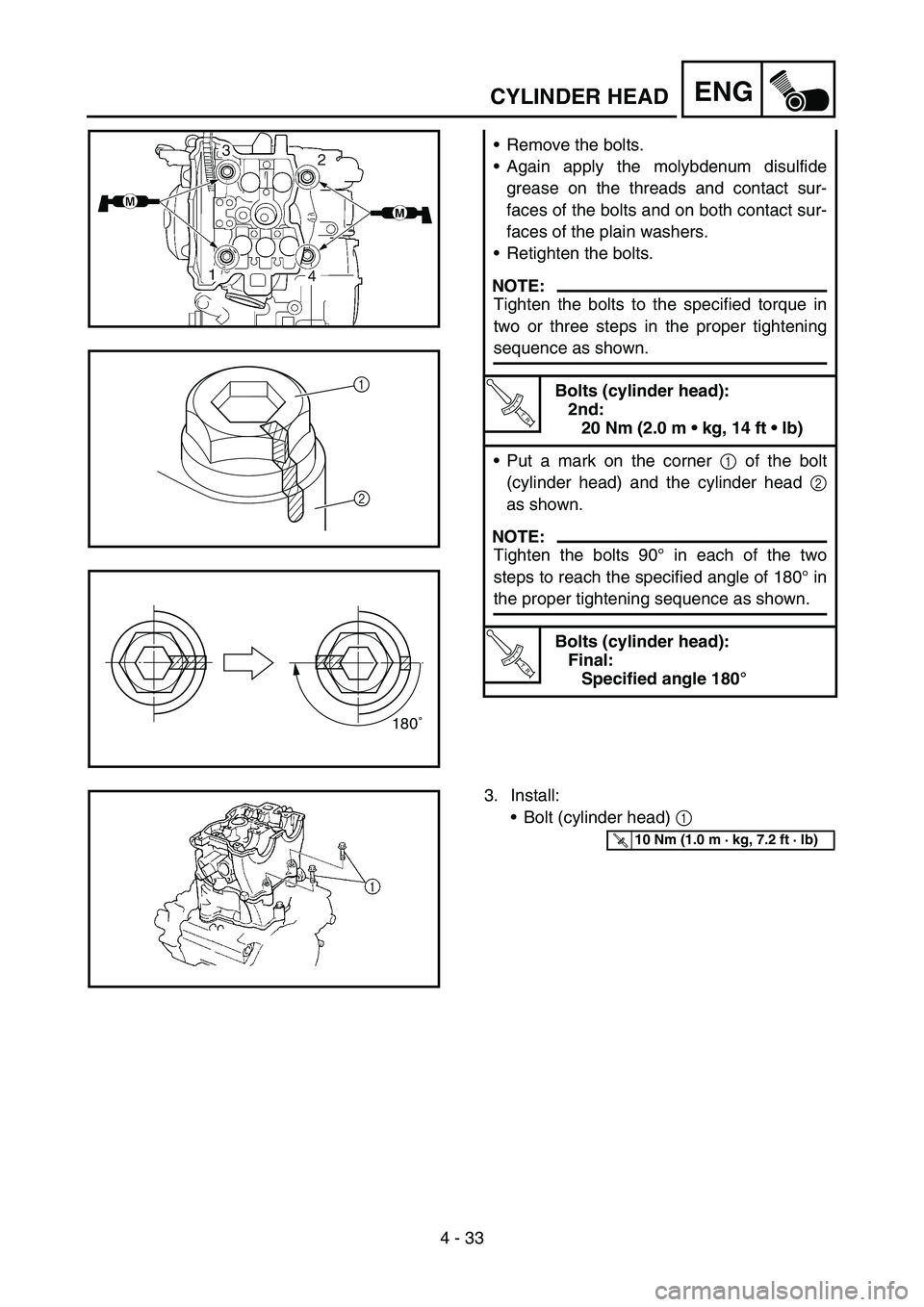

Remove the bolts.

Again apply the molybdenum disulfide

grease on the threads and contact sur-

faces of the bolts and on both contact sur-

faces of the plain washers.

Retighten the bolts.

NOTE:

Tighten the bolts to the specified torque in

two or three steps in the proper tightening

sequence as shown.

T R..

Bolts (cylinder head):

2nd:

20 Nm (2.0 m kg, 14 ft lb)

Put a mark on the corner 1 of the bolt

(cylinder head) and the cylinder head 2

as shown.

NOTE:

Tighten the bolts 90° in each of the two

steps to reach the specified angle of 180° in

the proper tightening sequence as shown.

T R..

Bolts (cylinder head):

Final:

Specified angle 180°

1

2

180˚

3. Install:

Bolt (cylinder head) 1

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

CYLINDER HEAD

Page 508 of 650

5 - 35

CHASFRONT FORK

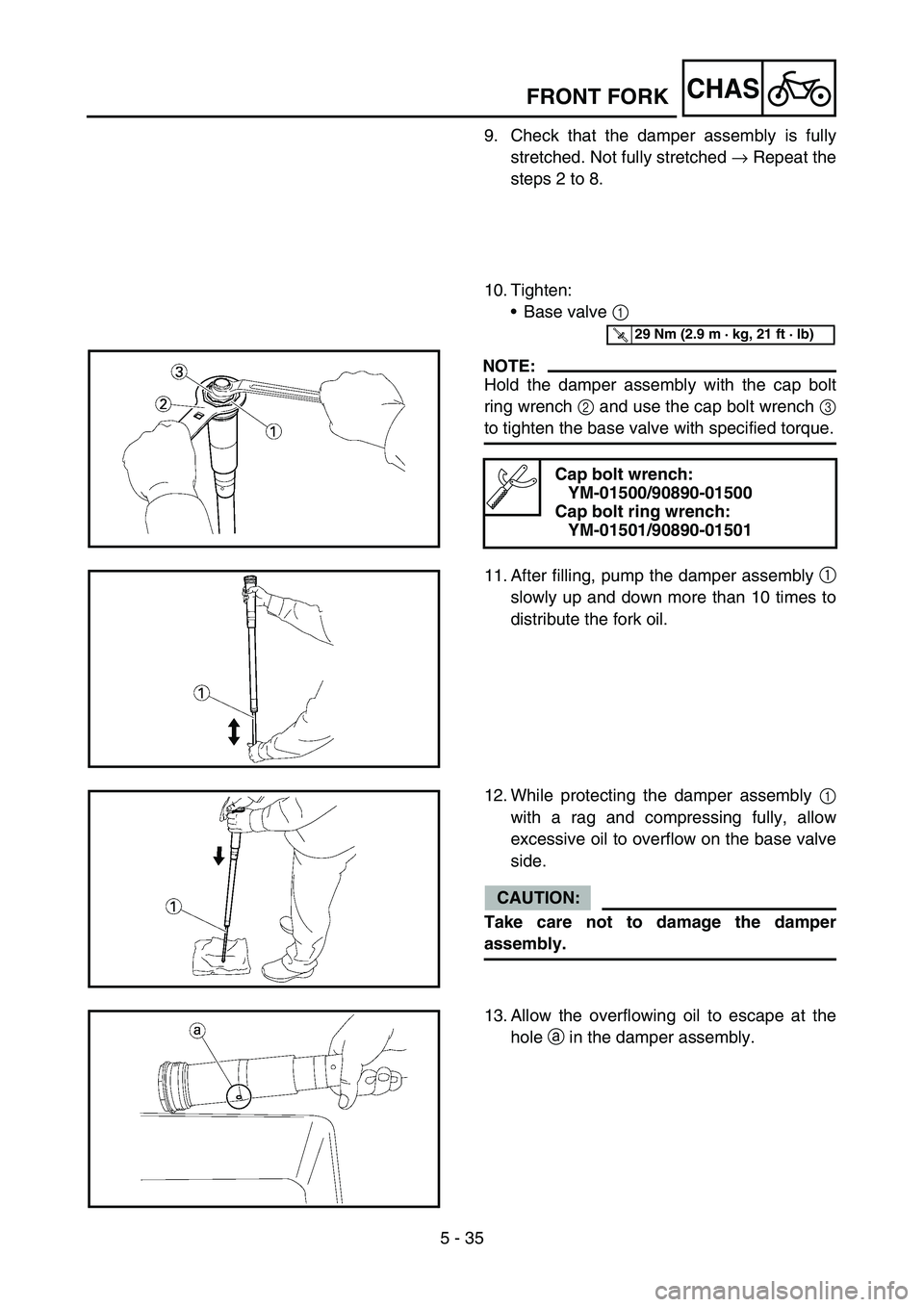

9. Check that the damper assembly is fully

stretched. Not fully stretched → Repeat the

steps 2 to 8.

10. Tighten:

Base valve 1

NOTE:

Hold the damper assembly with the cap bolt

ring wrench 2 and use the cap bolt wrench 3

to tighten the base valve with specified torque.

Cap bolt wrench:

YM-01500/90890-01500

Cap bolt ring wrench:

YM-01501/90890-01501

T R..29 Nm (2.9 m · kg, 21 ft · lb)

11. After filling, pump the damper assembly 1

slowly up and down more than 10 times to

distribute the fork oil.

12. While protecting the damper assembly 1

with a rag and compressing fully, allow

excessive oil to overflow on the base valve

side.

CAUTION:

Take care not to damage the damper

assembly.

13. Allow the overflowing oil to escape at the

hole a in the damper assembly.

Page 516 of 650

5 - 39

CHASFRONT FORK

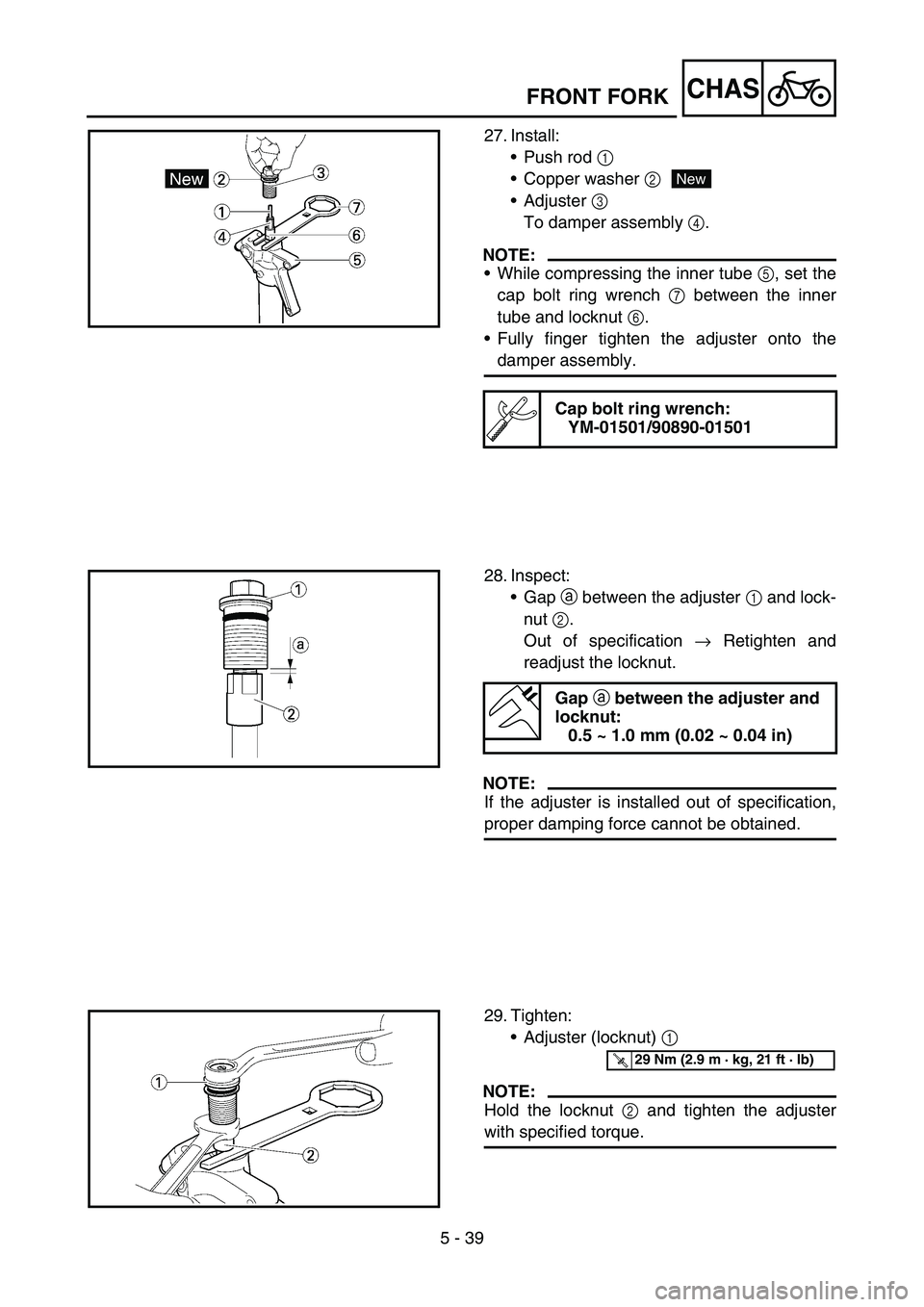

27. Install:

Push rod 1

Copper washer 2

Adjuster 3

To damper assembly 4.

NOTE:

While compressing the inner tube 5, set the

cap bolt ring wrench 7 between the inner

tube and locknut 6.

Fully finger tighten the adjuster onto the

damper assembly.

Cap bolt ring wrench:

YM-01501/90890-01501

New

28. Inspect:

Gap a between the adjuster 1 and lock-

nut 2.

Out of specification → Retighten and

readjust the locknut.

NOTE:

If the adjuster is installed out of specification,

proper damping force cannot be obtained.

Gap

a between the adjuster and

locknut:

0.5 ~ 1.0 mm (0.02 ~ 0.04 in)

29. Tighten:

Adjuster (locknut) 1

NOTE:

Hold the locknut 2 and tighten the adjuster

with specified torque.

T R..29 Nm (2.9 m · kg, 21 ft · lb)

Page 520 of 650

5 - 41

CHAS

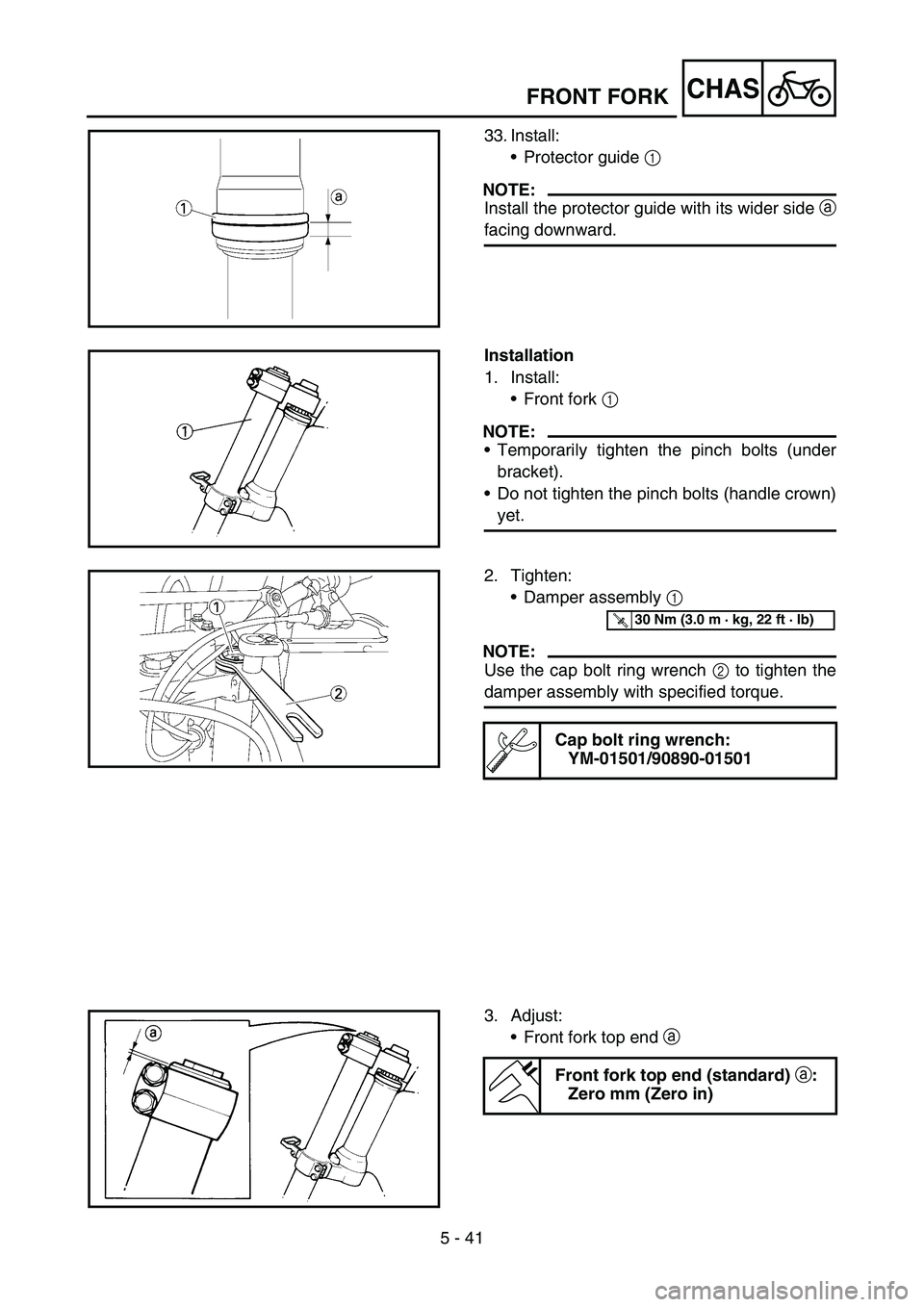

33. Install:

Protector guide 1

NOTE:

Install the protector guide with its wider side a

facing downward.

Installation

1. Install:

Front fork 1

NOTE:

Temporarily tighten the pinch bolts (under

bracket).

Do not tighten the pinch bolts (handle crown)

yet.

2. Tighten:

Damper assembly 1

NOTE:

Use the cap bolt ring wrench 2 to tighten the

damper assembly with specified torque.

Cap bolt ring wrench:

YM-01501/90890-01501

T R..30 Nm (3.0 m · kg, 22 ft · lb)

3. Adjust:

Front fork top end a

Front fork top end (standard) a:

Zero mm (Zero in)

FRONT FORK

Page 522 of 650

5 - 42

CHAS

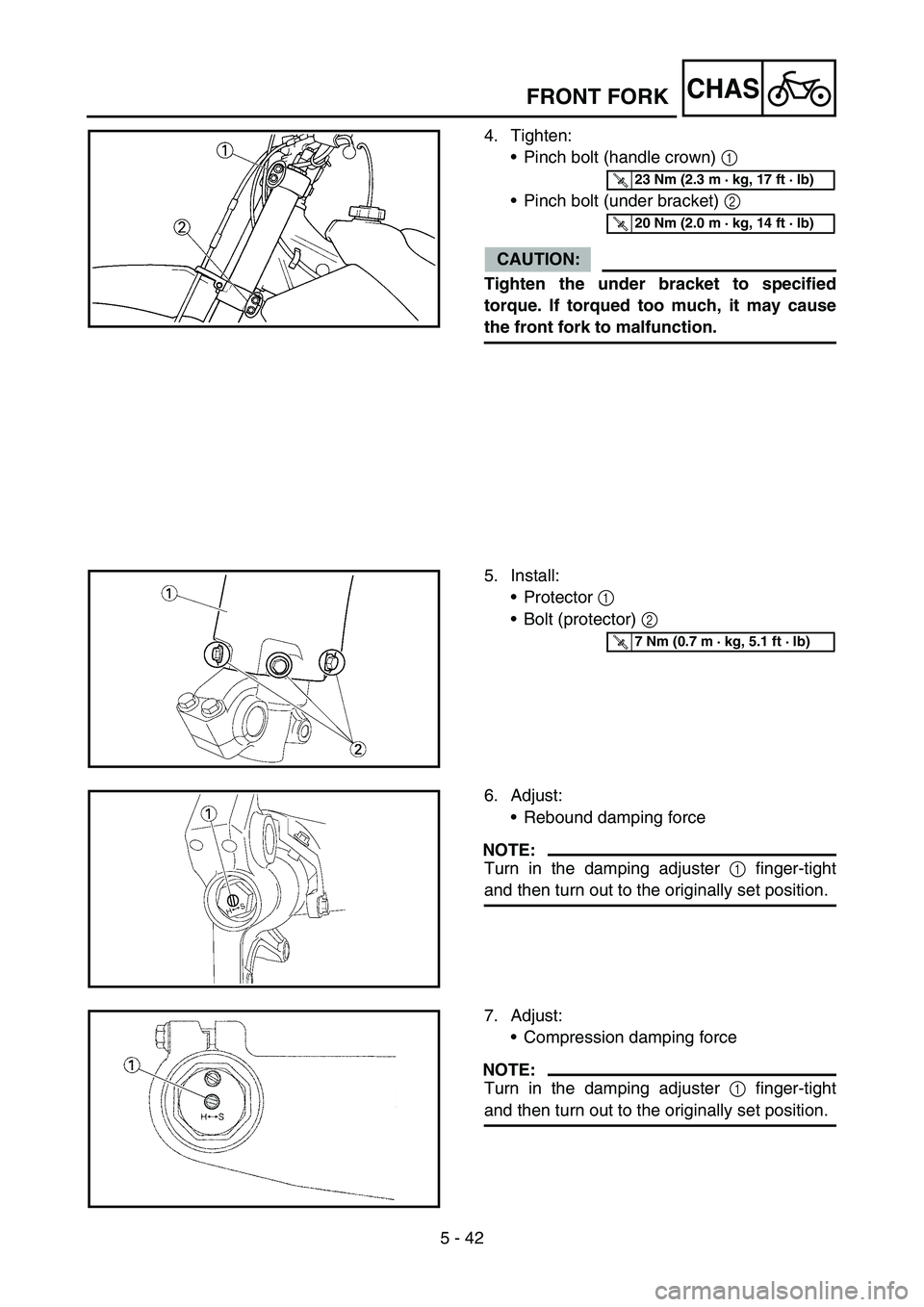

4. Tighten:

Pinch bolt (handle crown) 1

Pinch bolt (under bracket) 2

CAUTION:

Tighten the under bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction.

T R..23 Nm (2.3 m · kg, 17 ft · lb)

T R..20 Nm (2.0 m · kg, 14 ft · lb)

5. Install:

Protector 1

Bolt (protector) 2

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

6. Adjust:

Rebound damping force

NOTE:

Turn in the damping adjuster 1 finger-tight

and then turn out to the originally set position.

7. Adjust:

Compression damping force

NOTE:

Turn in the damping adjuster 1 finger-tight

and then turn out to the originally set position.

FRONT FORK

Page 544 of 650

5 - 53

CHASSTEERING

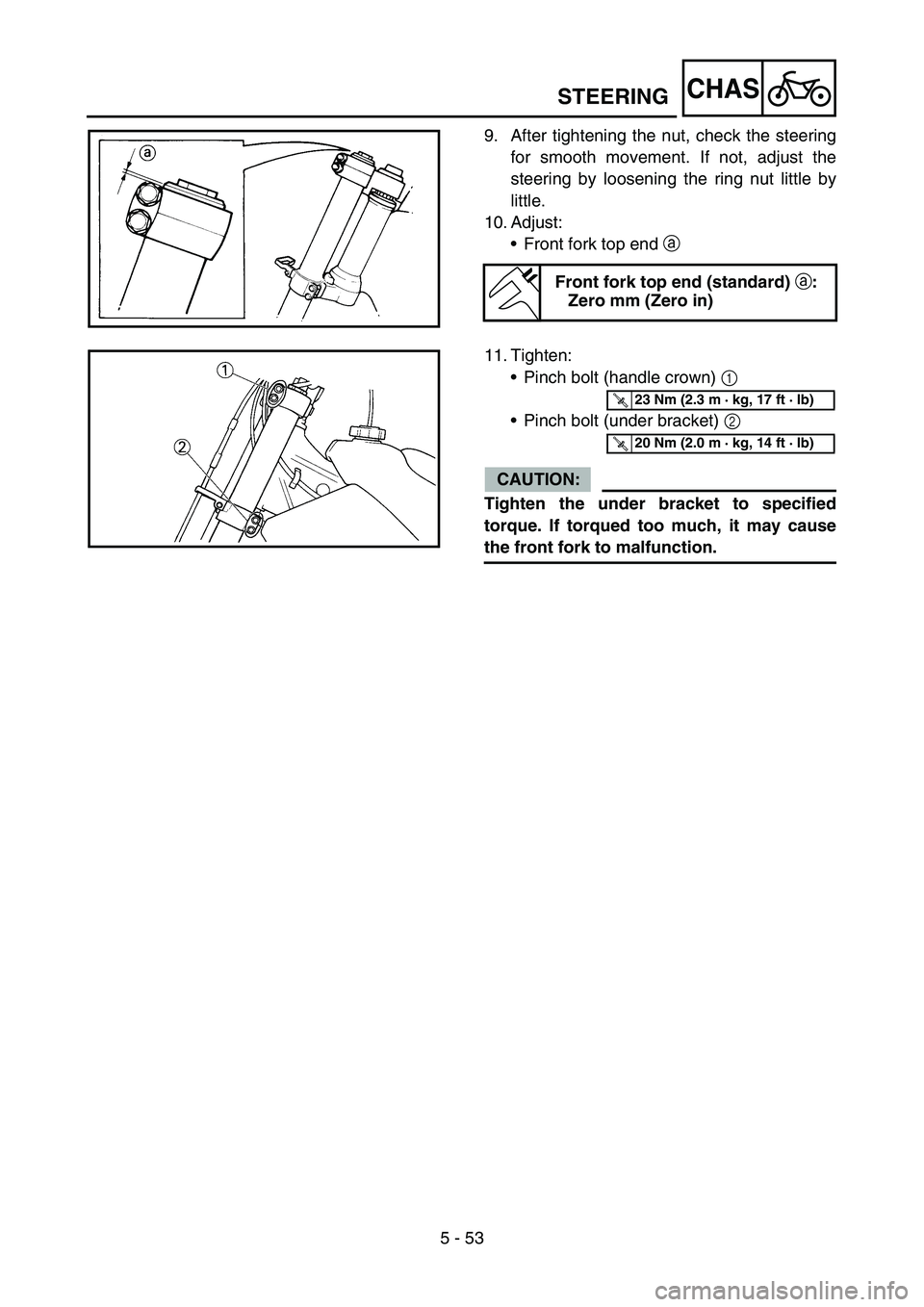

9. After tightening the nut, check the steering

for smooth movement. If not, adjust the

steering by loosening the ring nut little by

little.

10. Adjust:

•Front fork top end a

Front fork top end (standard)

a:

Zero mm (Zero in)

11. Tighten:

•Pinch bolt (handle crown) 1

•Pinch bolt (under bracket) 2

CAUTION:

Tighten the under bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction.

T R..23 Nm (2.3 m · kg, 17 ft · lb)

T R..20 Nm (2.0 m · kg, 14 ft · lb)

Page 642 of 650

7 - 20

TUNSETTING

EC72H002

Suspension setting

•Front fork

NOTE:

•If any of the following symptoms is experienced with the standard position as the base, make

resetting by reference to the adjustment procedure given in the same chart.

•Before any change, set the rear shock absorber sunken length to the standard figure 90 ~ 100 mm

(3.5 ~ 3.9 in).

SymptomSection

Check Adjust

JumpLarge

gapMedium

gapSmall

gap

Stiff over entire rangeCompression damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Oil amount Decrease oil amount by about 5 ~ 10 cm

3 (0.2 ~

0.4 Imp oz, 0.2 ~ 0.3 US oz).

Spring Replace with soft spring.

Unsmooth movement

over entire rangeOuter tube Check for any bends, dents, and other noticeable

scars, etc. If any, replace affected parts.

Inner tube

Slide metal Replace with a new one for extended use.

Piston metal Replace with a new one for extended use.

Under bracket tightening

torqueRetighten to specified torque.

Poor initial

movementRebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Oil seal Apply grease in oil seal wall.

Soft over entire

range, bottoming outCompression damping Turn adjuster clockwise (about 2 clicks) to increase

damping.

Oil amount Increase oil amount by about 5 ~ 10 cm

3 (0.2 ~

0.4 Imp oz, 0.2 ~ 0.3 US oz).

Spring Replace with stiff spring.

Stiff toward stroke

endOil amountDecrease oil amount by about 5 cm

3 (0.2 Imp oz,

0.2 US oz).

Soft toward stroke

end, bottoming outOil amountIncrease oil amount by about 5 cm

3 (0.2 Imp oz,

0.2 US oz).

Stiff initial movement Compression dampingTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Low front, tending to

lower front postureCompression damping Turn adjuster clockwise (about 2 clicks) to increase

damping.

Rebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Balance with rear end Set sunken length for 95 ~ 100 mm (3.7 ~ 3.9 in) when

one passenger is astride seat (lower rear posture).

Oil amount Increase oil amount by about 5 cm

3 (0.2 Imp oz,

0.2 US oz).

“Obtrusive” front,

tending to upper front

postureCompression damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Balance with rear end Set sunken length for 90 ~ 95 mm (3.5 ~ 3.7 in)

when one passenger is astride seat (upper rear pos-

ture).

Spring Replace with soft spring.

Oil amount Decrease oil amount by about 5 ~ 10 cm

3 (0.2 ~

0.4 Imp oz, 0.2 ~ 0.3 US oz).