start stop button YAMAHA YZ450F 2006 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: YZ450F, Model: YAMAHA YZ450F 2006Pages: 650, PDF Size: 20.71 MB

Page 26 of 650

GEN

INFO

1 - 1

DESCRIPTION

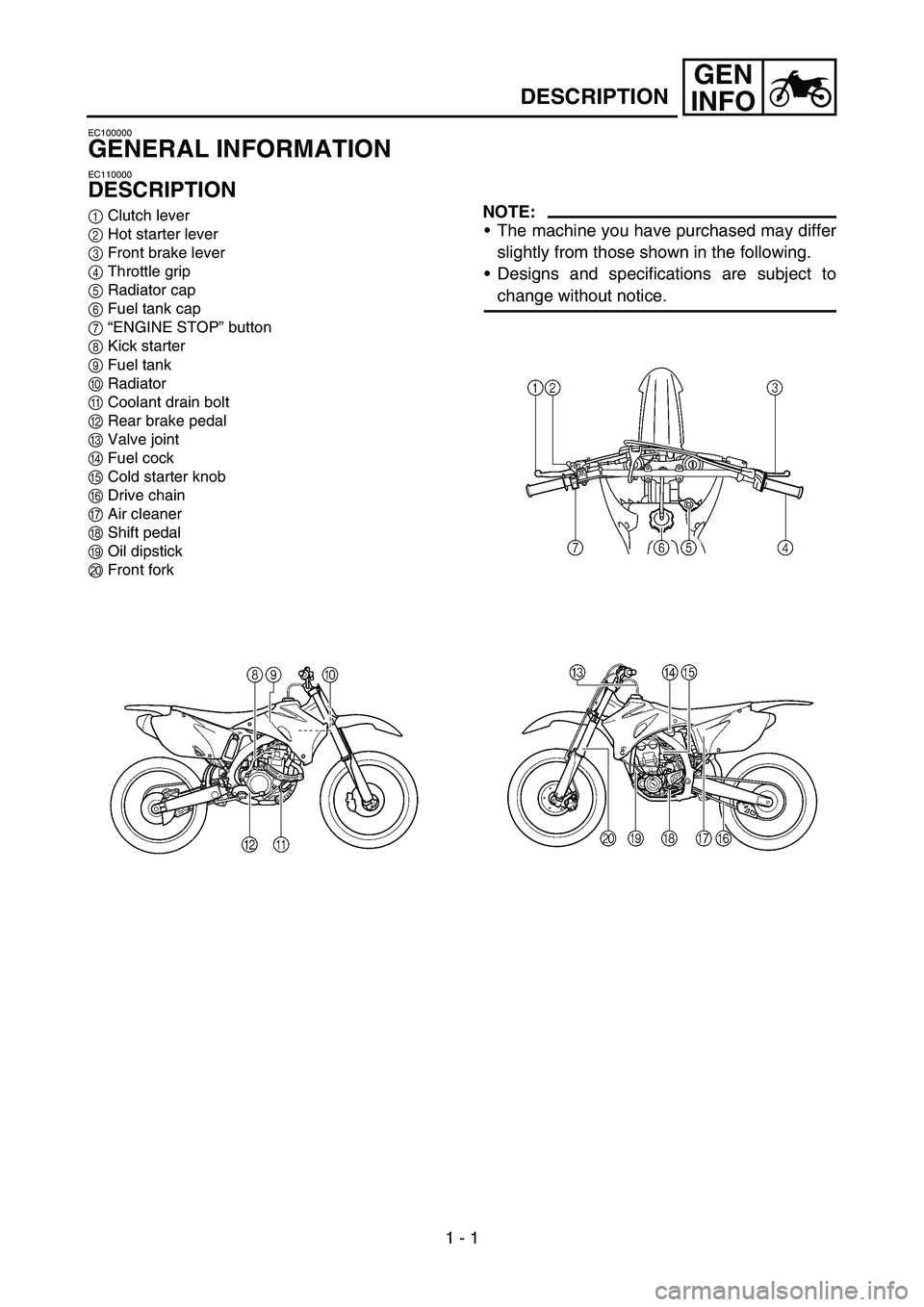

EC100000

GENERAL INFORMATION

EC110000

DESCRIPTION

1Clutch lever

2Hot starter lever

3Front brake lever

4Throttle grip

5Radiator cap

6Fuel tank cap

7“ENGINE STOP” button

8Kick starter

9Fuel tank

0Radiator

ACoolant drain bolt

BRear brake pedal

CValve joint

DFuel cock

ECold starter knob

FDrive chain

GAir cleaner

HShift pedal

IOil dipstick

JFront forkNOTE:

The machine you have purchased may differ

slightly from those shown in the following.

Designs and specifications are subject to

change without notice.

Page 48 of 650

1 - 10

GEN

INFO

CONTROL FUNCTIONS

EC150000

CONTROL FUNCTIONS

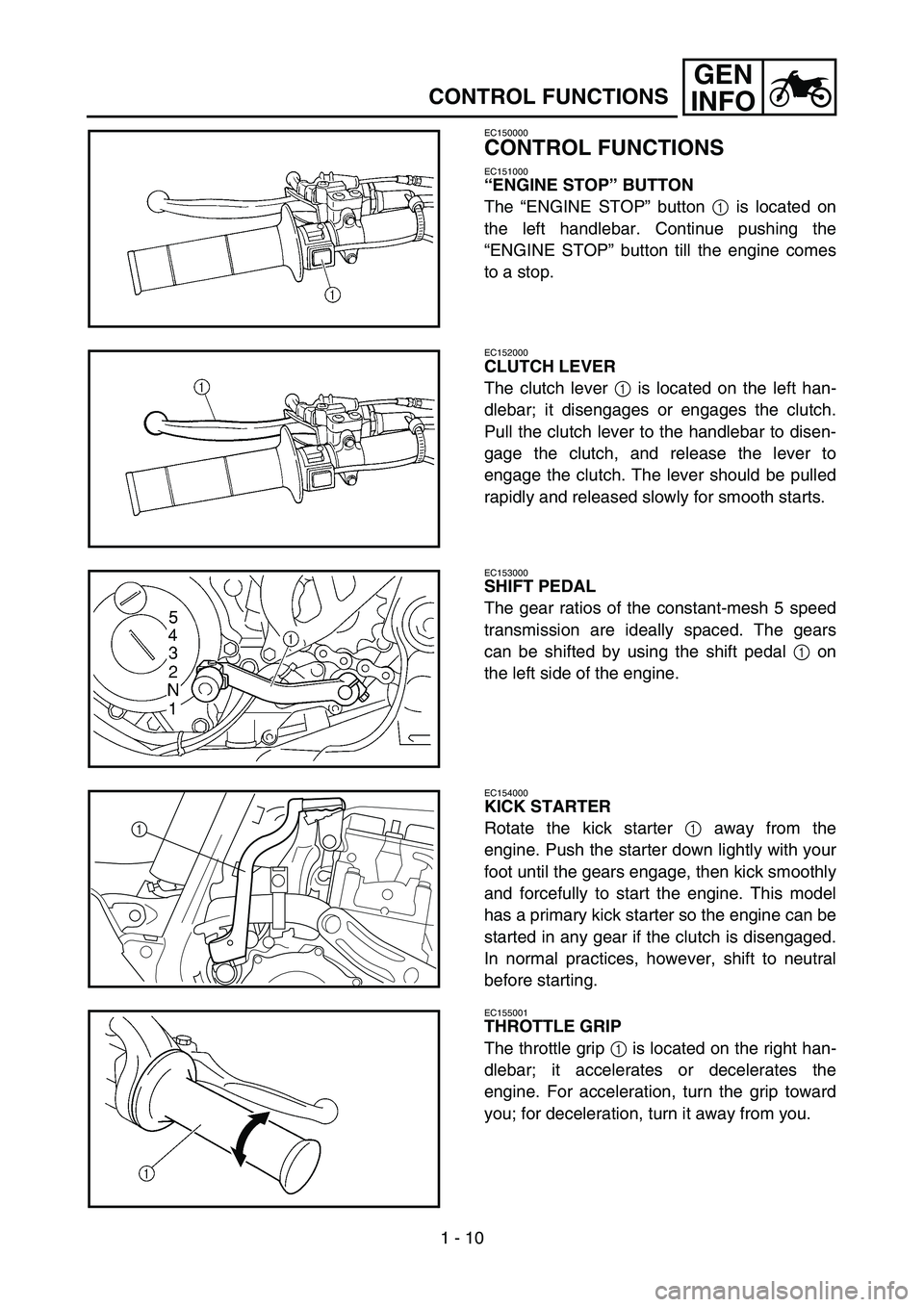

EC151000

“ENGINE STOP” BUTTON

The “ENGINE STOP” button 1 is located on

the left handlebar. Continue pushing the

“ENGINE STOP” button till the engine comes

to a stop.

EC152000

CLUTCH LEVER

The clutch lever 1 is located on the left han-

dlebar; it disengages or engages the clutch.

Pull the clutch lever to the handlebar to disen-

gage the clutch, and release the lever to

engage the clutch. The lever should be pulled

rapidly and released slowly for smooth starts.

EC153000

SHIFT PEDAL

The gear ratios of the constant-mesh 5 speed

transmission are ideally spaced. The gears

can be shifted by using the shift pedal 1 on

the left side of the engine.

EC154000

KICK STARTER

Rotate the kick starter 1 away from the

engine. Push the starter down lightly with your

foot until the gears engage, then kick smoothly

and forcefully to start the engine. This model

has a primary kick starter so the engine can be

started in any gear if the clutch is disengaged.

In normal practices, however, shift to neutral

before starting.

1

EC155001

THROTTLE GRIP

The throttle grip 1 is located on the right han-

dlebar; it accelerates or decelerates the

engine. For acceleration, turn the grip toward

you; for deceleration, turn it away from you.

Page 62 of 650

1 - 17

GEN

INFO

BREAK-IN PROCEDURES

1. Before starting the engine, fill the fuel tank

with the fuel.

2. Perform the pre-operation checks on the

machine.

3. Start and warm up the engine. Check the

idle speed, and check the operation of the

controls and the “ENGINE STOP” button.

Then, restart the engine and check its

operation within no more than 5 minutes

after it is restarted.

4. Operate the machine in the lower gears at

moderate throttle openings for five to eight

minutes.

5. Check how the engine runs when the

machine is ridden with the throttle 1/4 to 1/2

open (low to medium speed) for about one

hour.

6. Restart the engine and check the operation

of the machine throughout its entire operat-

ing range. Restart the machine and oper-

ate it for about 10 to 15 more minutes. The

machine will now be ready to race.

CAUTION:

After the break-in or before each race,

you must check the entire machine for

loose fittings and fasteners as per

“TORQUE-CHECK POINTS”.

Tighten all such fasteners as required.

When any of the following parts have

been replaced, they must be broken in.

CYLINDER AND CRANKSHAFT:

About one hour of break-in operation is

necessary.

PISTON, RING, VALVES, CAMSHAFTS

AND GEARS:

These parts require about 30 minutes of

break-in operation at half-throttle or less.

Observe the condition of the engine care-

fully during operation.

STARTING AND BREAK-IN

Page 132 of 650

2 - 22

SPECCABLE ROUTING DIAGRAM

1Hot starter cable

2Clamp

3TPS (throttle position sensor)

lead

4Hump (frame)

5Neutral switch lead

6Engine bracket

7Engine skid plate stay

8CDI magneto lead

9Clutch cable

0Radiator breather hose

ARadiator hose 2

B“ENGINE STOP” button leadCSub wire harness

DGround lead

ECDI unit bracket

FCDI unit

GCable guide

HIgnition coil lead

IThrottle cable

ÈFasten the hot starter cable and

throttle cables onto the frame.

Locate the clamp ends under

the hot starter cable.ÉFasten the hot starter cable,

throttle cables, TPS lead and

ignition coil lead to the frame.

ÊFasten the TPS lead to the

frame behind its hump.

ËPass the TPS lead over the hot

starter cable.

ÌPass the neutral switch lead on

the inside of the engine bracket.

ÍPass the neutral switch lead

over the engine skid plate stay.

C-C

G-G

E

2

Õ

4 58E

É

D GGA

AB

D

5

ÌÍ Í

Í Î

F

E

D

2

2

2

Ï Ð Ò

Ñ Ó

1

G

2

3

4 2

0

8

5

9

8Ë Ê

0

0 8 5

CC

B

È 2

9

FF

Ô

Ô

B-B

A-A

I

H

3

1

C

B

A

0

0

8

5

D-D

3 F-F

6

7

2 5 0

Page 140 of 650

2 - 26

SPECCABLE ROUTING DIAGRAM

1Throttle cable

2Clamp

3Hot starter cable

4Clutch cable

5“ENGINE STOP” button lead

6Cable guide

7Brake hose

8Hose guideÈFasten the “ENGINE STOP” button lead to the

handlebar.

ÉPass the clutch cable and hot starter cable

through the cable guide.

ÊPass the brake hose in front of the number plate.

ËPass the throttle cables through the cable guide.

ÌPass the clutch cable and hot starter cable

through the cable guide on the number plate.

A

B

C

A

B

C40˚± 10˚

40˚± 10˚

2

È3

2

5

4

2

3

5

6

Ë1

4

5

7

Ê

6

É

Ì

8

Page 524 of 650

5 - 43

CHAS

EC5B0000

HANDLEBAR

Extent of removal:

1 Handlebar removal

Extent of removal Order Part name Q’ty Remarks

HANDLEBAR REMOVAL

Preparation for removal Number plate Remove the band only.

1 Hot starter cable 1 Disconnect at the lever side.

2 Hot starter lever holder 1

3 Clutch cable 1 Disconnect at the lever side.

4 Clutch lever holder 1

5“ENGINE STOP” button 1

6 Master cylinder 1 Refer to “REMOVAL POINTS”.

7 Throttle cable cap 1

8 Throttle cable #1 (pulled) 1 Disconnect at the throttle side.

9 Throttle cable #2 (pushed) 1 Disconnect at the throttle side.

10 Grip (right) 1 Refer to “REMOVAL POINTS”.

11 Tube guide 1

12 Collar 1

13 Grip (left) 1 Refer to “REMOVAL POINTS”.

14 Handlebar holder (upper) 2

15 Handlebar 1

16 Handlebar holder (lower) 2

1

HANDLEBAR

Page 534 of 650

5 - 48

CHASHANDLEBAR

11. Install:

•“ENGINE STOP” button 1

•Clutch lever holder 2

•Bolt (clutch lever holder) 3

•Hot starter lever holder 4

•Bolt (hot starter lever holder) 5

•Clamp 6

NOTE:

•The “ENGINE STOP” button, clutch lever

holder and clamp should be installed accord-

ing to the dimensions shown.

•Pass the “ENGINE STOP” button lead in the

middle of the clutch lever holder.

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

12. Install:

•Clutch cable 1

•Hot starter cable 2

NOTE:

Apply the lithium soap base grease on the

clutch cable end and hot starter cable end.

13. Adjust:

•Clutch lever free play

Refer to “CLUTCH ADJUSTMENT” sec-

tion in the CHAPTER 3.

•Hot starter lever free play

Refer to “HOT STARTER LEVER

ADJUSTMENT” section in the CHAPTER

3.

Page 584 of 650

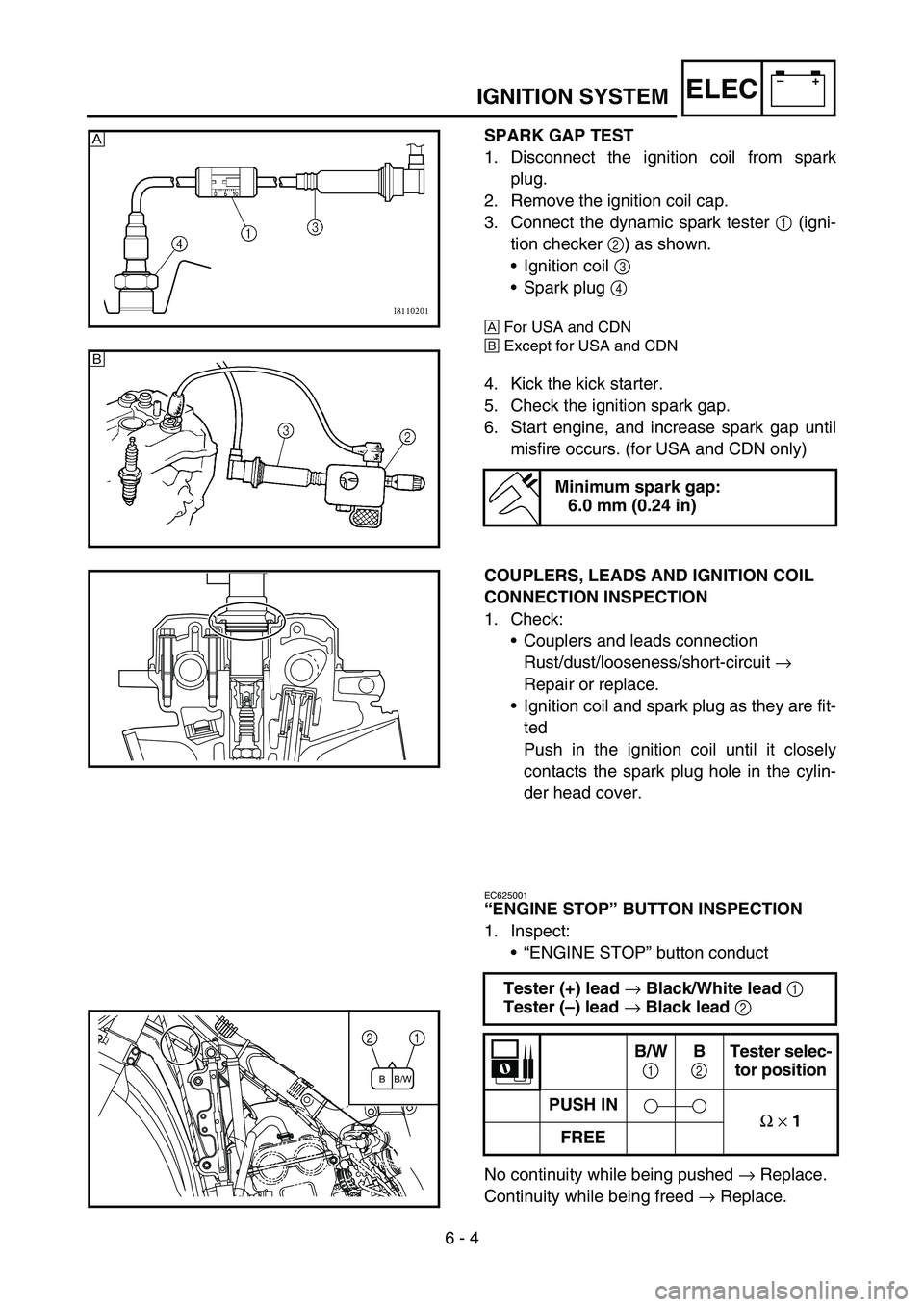

6 - 4

–+ELECIGNITION SYSTEM

SPARK GAP TEST

1. Disconnect the ignition coil from spark

plug.

2. Remove the ignition coil cap.

3. Connect the dynamic spark tester 1 (igni-

tion checker 2) as shown.

•Ignition coil 3

•Spark plug 4

ÈFor USA and CDN

ÉExcept for USA and CDN

4. Kick the kick starter.

5. Check the ignition spark gap.

6. Start engine, and increase spark gap until

misfire occurs. (for USA and CDN only)

Minimum spark gap:

6.0 mm (0.24 in)

È

É

COUPLERS, LEADS AND IGNITION COIL

CONNECTION INSPECTION

1. Check:

•Couplers and leads connection

Rust/dust/looseness/short-circuit →

Repair or replace.

•Ignition coil and spark plug as they are fit-

ted

Push in the ignition coil until it closely

contacts the spark plug hole in the cylin-

der head cover.

EC625001

“ENGINE STOP” BUTTON INSPECTION

1. Inspect:

•“ENGINE STOP” button conduct

No continuity while being pushed → Replace.

Continuity while being freed → Replace. Tester (+) lead

→ Black/White lead

1

Tester (–) lead

→ Black lead

2

B/W

1 B

2 Tester selec-

tor position

PUSH IN

Ω

× 1

FREE1 2

B/W B