light YAMAHA YZ450F 2009 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2009, Model line: YZ450F, Model: YAMAHA YZ450F 2009Pages: 190, PDF Size: 12.39 MB

Page 130 of 190

4-60

TRANSMISSION, SHIFT CAM AND SHIFT FORK

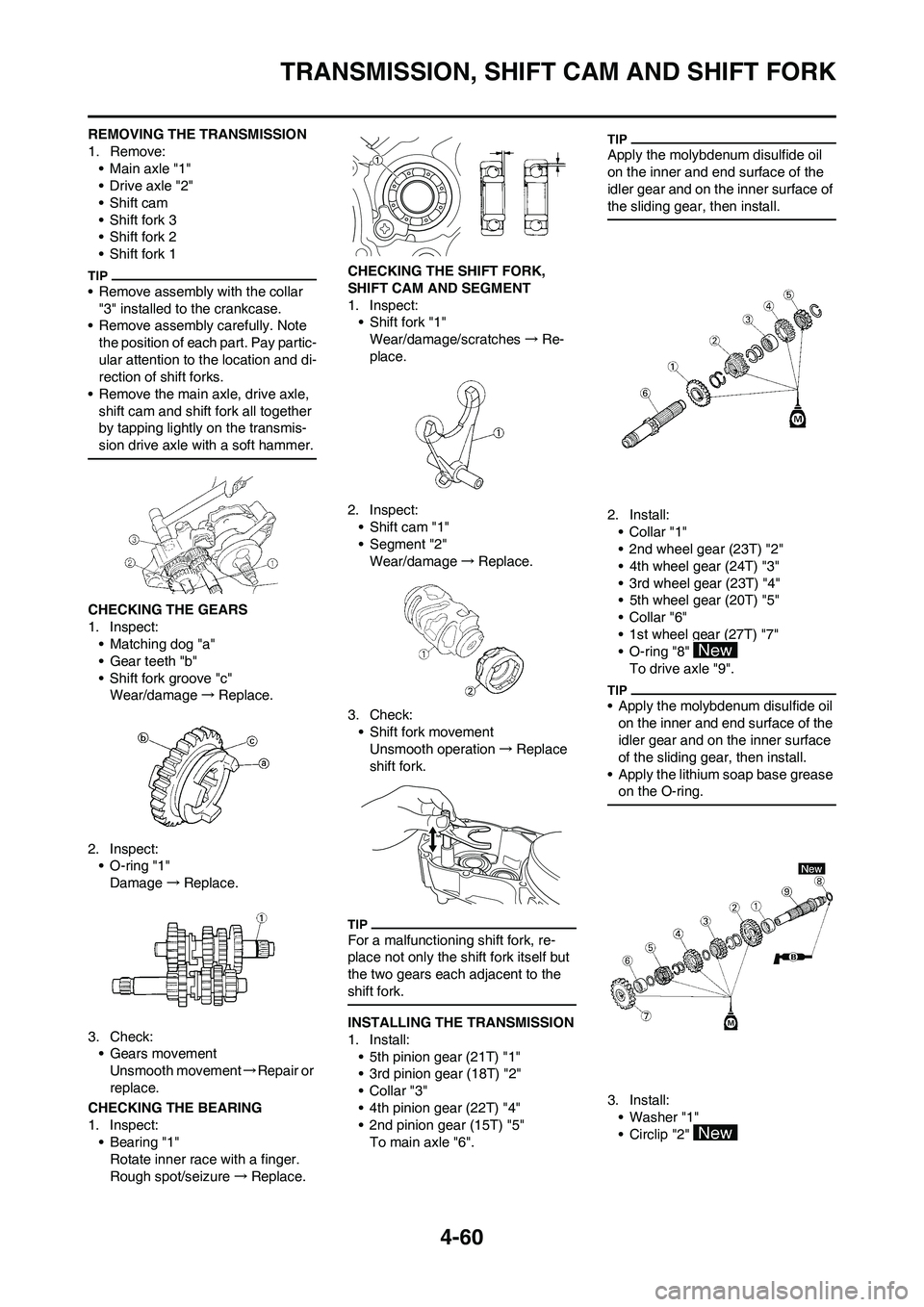

REMOVING THE TRANSMISSION

1. Remove:

• Main axle "1"

•Drive axle "2"

•Shift cam

• Shift fork 3

• Shift fork 2

• Shift fork 1

• Remove assembly with the collar

"3" installed to the crankcase.

• Remove assembly carefully. Note

the position of each part. Pay partic-

ular attention to the location and di-

rection of shift forks.

• Remove the main axle, drive axle,

shift cam and shift fork all together

by tapping lightly on the transmis-

sion drive axle with a soft hammer.

CHECKING THE GEARS

1. Inspect:

• Matching dog "a"

• Gear teeth "b"

• Shift fork groove "c"

Wear/damage→Replace.

2. Inspect:

• O-ring "1"

Damage→Replace.

3. Check:

• Gears movement

Unsmooth movement→Repair or

replace.

CHECKING THE BEARING

1. Inspect:

• Bearing "1"

Rotate inner race with a finger.

Rough spot/seizure→Replace.CHECKING THE SHIFT FORK,

SHIFT CAM AND SEGMENT

1. Inspect:

• Shift fork "1"

Wear/damage/scratches→Re-

place.

2. Inspect:

• Shift cam "1"

• Segment "2"

Wear/damage→Replace.

3. Check:

• Shift fork movement

Unsmooth operation→Replace

shift fork.

For a malfunctioning shift fork, re-

place not only the shift fork itself but

the two gears each adjacent to the

shift fork.

INSTALLING THE TRANSMISSION

1. Install:

• 5th pinion gear (21T) "1"

• 3rd pinion gear (18T) "2"

•Collar "3"

• 4th pinion gear (22T) "4"

• 2nd pinion gear (15T) "5"

To main axle "6".

Apply the molybdenum disulfide oil

on the inner and end surface of the

idler gear and on the inner surface of

the sliding gear, then install.

2. Install:

•Collar "1"

• 2nd wheel gear (23T) "2"

• 4th wheel gear (24T) "3"

• 3rd wheel gear (23T) "4"

• 5th wheel gear (20T) "5"

•Collar "6"

• 1st wheel gear (27T) "7"

• O-ring "8"

To drive axle "9".

• Apply the molybdenum disulfide oil

on the inner and end surface of the

idler gear and on the inner surface

of the sliding gear, then install.

• Apply the lithium soap base grease

on the O-ring.

3. Install:

• Washer "1"

• Circlip "2"

Page 144 of 190

5-13

FRONT BRAKE AND REAR BRAKE

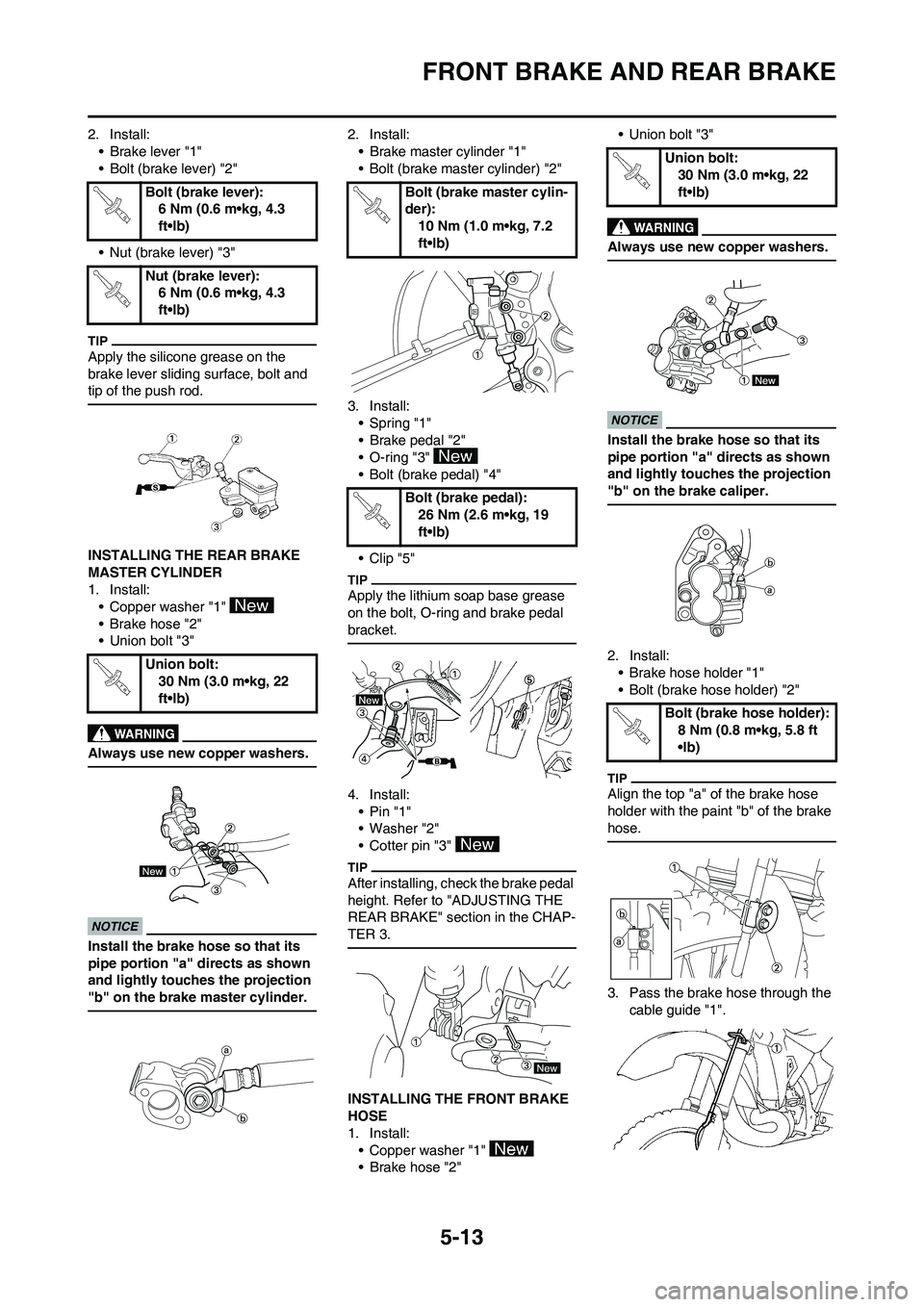

2. Install:

• Brake lever "1"

• Bolt (brake lever) "2"

• Nut (brake lever) "3"

Apply the silicone grease on the

brake lever sliding surface, bolt and

tip of the push rod.

INSTALLING THE REAR BRAKE

MASTER CYLINDER

1. Install:

• Copper washer "1"

•Brake hose "2"

• Union bolt "3"

Always use new copper washers.

Install the brake hose so that its

pipe portion "a" directs as shown

and lightly touches the projection

"b" on the brake master cylinder.

2. Install:

• Brake master cylinder "1"

• Bolt (brake master cylinder) "2"

3. Install:

• Spring "1"

• Brake pedal "2"

• O-ring "3"

• Bolt (brake pedal) "4"

•Clip "5"

Apply the lithium soap base grease

on the bolt, O-ring and brake pedal

bracket.

4. Install:

•Pin "1"

•Washer "2"

• Cotter pin "3"

After installing, check the brake pedal

height. Refer to "ADJUSTING THE

REAR BRAKE" section in the CHAP-

TER 3.

INSTALLING THE FRONT BRAKE

HOSE

1. Install:

• Copper washer "1"

• Brake hose "2"• Union bolt "3"

Always use new copper washers.

Install the brake hose so that its

pipe portion "a" directs as shown

and lightly touches the projection

"b" on the brake caliper.

2. Install:

• Brake hose holder "1"

• Bolt (brake hose holder) "2"

Align the top "a" of the brake hose

holder with the paint "b" of the brake

hose.

3. Pass the brake hose through the

cable guide "1". Bolt (brake lever):

6 Nm (0.6 m•kg, 4.3

ft•lb)

Nut (brake lever):

6 Nm (0.6 m•kg, 4.3

ft•lb)

Union bolt:

30 Nm (3.0 m•kg, 22

ft•lb)

Bolt (brake master cylin-

der):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (brake pedal):

26 Nm (2.6 m•kg, 19

ft•lb)

Union bolt:

30 Nm (3.0 m•kg, 22

ft•lb)

Bolt (brake hose holder):

8 Nm (0.8 m•kg, 5.8 ft

•lb)

Page 145 of 190

5-14

FRONT BRAKE AND REAR BRAKE

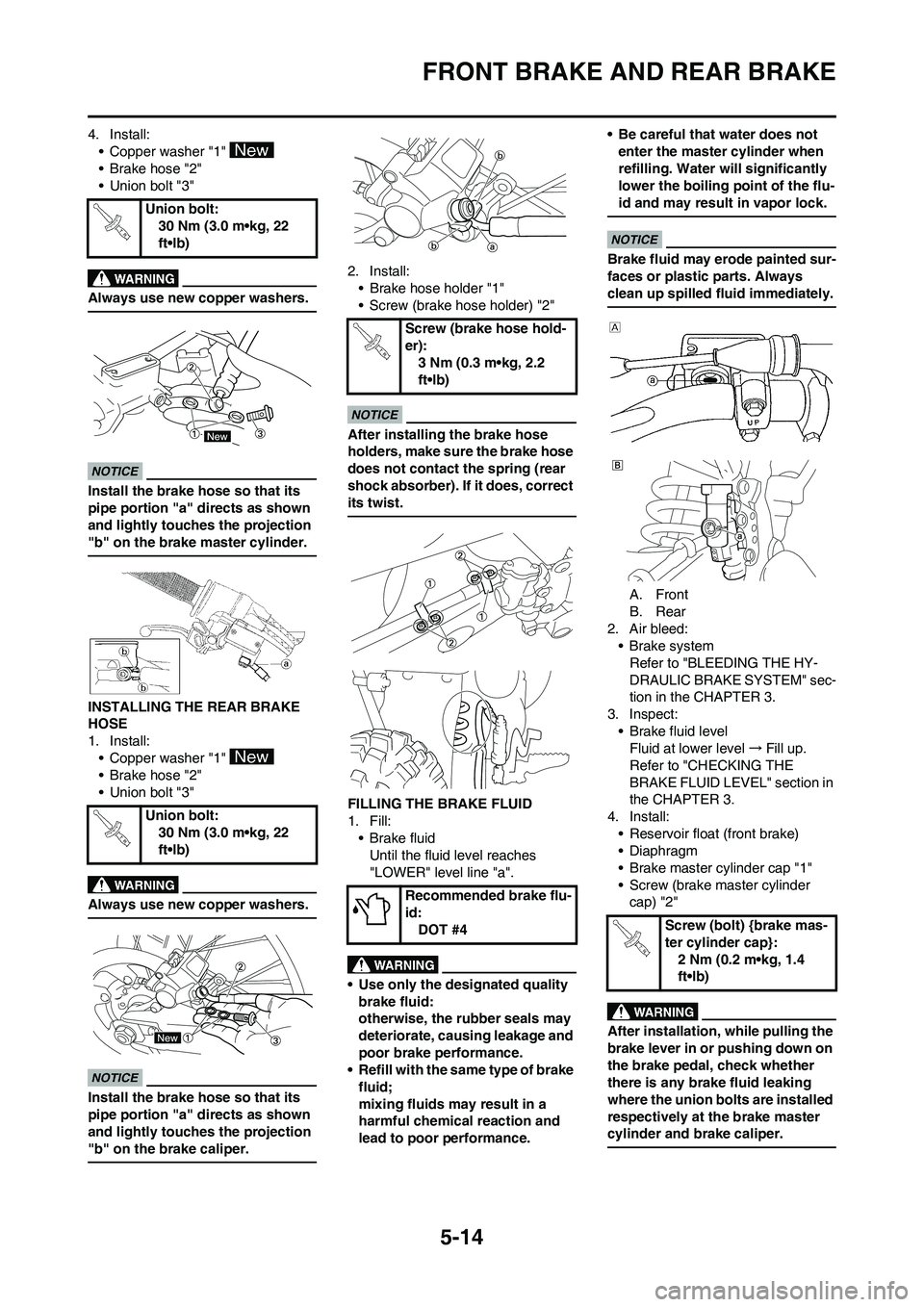

4. Install:

• Copper washer "1"

•Brake hose "2"

• Union bolt "3"

Always use new copper washers.

Install the brake hose so that its

pipe portion "a" directs as shown

and lightly touches the projection

"b" on the brake master cylinder.

INSTALLING THE REAR BRAKE

HOSE

1. Install:

• Copper washer "1"

•Brake hose "2"

• Union bolt "3"

Always use new copper washers.

Install the brake hose so that its

pipe portion "a" directs as shown

and lightly touches the projection

"b" on the brake caliper.

2. Install:

• Brake hose holder "1"

• Screw (brake hose holder) "2"

After installing the brake hose

holders, make sure the brake hose

does not contact the spring (rear

shock absorber). If it does, correct

its twist.

FILLING THE BRAKE FLUID

1. Fill:

•Brake fluid

Until the fluid level reaches

"LOWER" level line "a".

• Use only the designated quality

brake fluid:

otherwise, the rubber seals may

deteriorate, causing leakage and

poor brake performance.

• Refill with the same type of brake

fluid;

mixing fluids may result in a

harmful chemical reaction and

lead to poor performance.• Be careful that water does not

enter the master cylinder when

refilling. Water will significantly

lower the boiling point of the flu-

id and may result in vapor lock.

Brake fluid may erode painted sur-

faces or plastic parts. Always

clean up spilled fluid immediately.

A. Front

B. Rear

2. Air bleed:

• Brake system

Refer to "BLEEDING THE HY-

DRAULIC BRAKE SYSTEM" sec-

tion in the CHAPTER 3.

3. Inspect:

• Brake fluid level

Fluid at lower level→Fill up.

Refer to "CHECKING THE

BRAKE FLUID LEVEL" section in

the CHAPTER 3.

4. Install:

• Reservoir float (front brake)

• Diaphragm

• Brake master cylinder cap "1"

• Screw (brake master cylinder

cap) "2"

After installation, while pulling the

brake lever in or pushing down on

the brake pedal, check whether

there is any brake fluid leaking

where the union bolts are installed

respectively at the brake master

cylinder and brake caliper.

Union bolt:

30 Nm (3.0 m•kg, 22

ft•lb)

Union bolt:

30 Nm (3.0 m•kg, 22

ft•lb)

Screw (brake hose hold-

er):

3 Nm (0.3 m•kg, 2.2

ft•lb)

Recommended brake flu-

id:

DOT #4

Screw (bolt) {brake mas-

ter cylinder cap}:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Page 179 of 190

7-1

ENGINE

TUNING

ENGINE

CARBURETOR SETTING

• The air/fuel mixture will vary de-

pending on atmospheric conditions.

Therefore, it is necessary to take

into consideration the air pressure,

ambient temperature, humidity,

etc., when adjusting the carburetor.

• Perform a test run to check for prop-

er engine performance (e.g., throt-

tle response) and spark plug(-s)

discoloration or fouling. Use these

readings to determine the best pos-

sible carburetor setting.

It is recommended to keep a record of

all carburetor settings and external

conditions (e.g., atmospheric condi-

tions, track/surface conditions, lap

times) to make future carburetor set-

ting easier.

• The carburetor is a part of the

fuel line. Therefore, be sure to in-

stall it in a wellventilated area,

away from flammable objects

and any sources of fire.

• Never look into the carburetor in-

take. Flames may shoot out from

the pipe if the engine backfires

while it is being started. Gasoline

may be discharged from the ac-

celerator pump nozzle when the

carburetor has been removed.

• The carburetor is extremely sen-

sitive to foreign matter (dirt,

sand, water, etc.). During instal-

lation, do not allow foreign mat-

ter to get into the carburetor.

• Always handle the carburetor

and its components carefully.

Even slight scratches, bends or

damage to carburetor parts may

prevent the carburetor from

functioning correctly. Carefully

perform all servicing with the ap-

propriate tools and without ap-

plying excessive force.

• When the engine is stopped or

when riding at no load, do not

open and close the throttle un-

necessarily. Otherwise, too

much fuel may be discharged,

starting may become difficult or

the engine may not run well.• After installing the carburetor,

check that the throttle operates

correctly and opens and closes

smoothly.

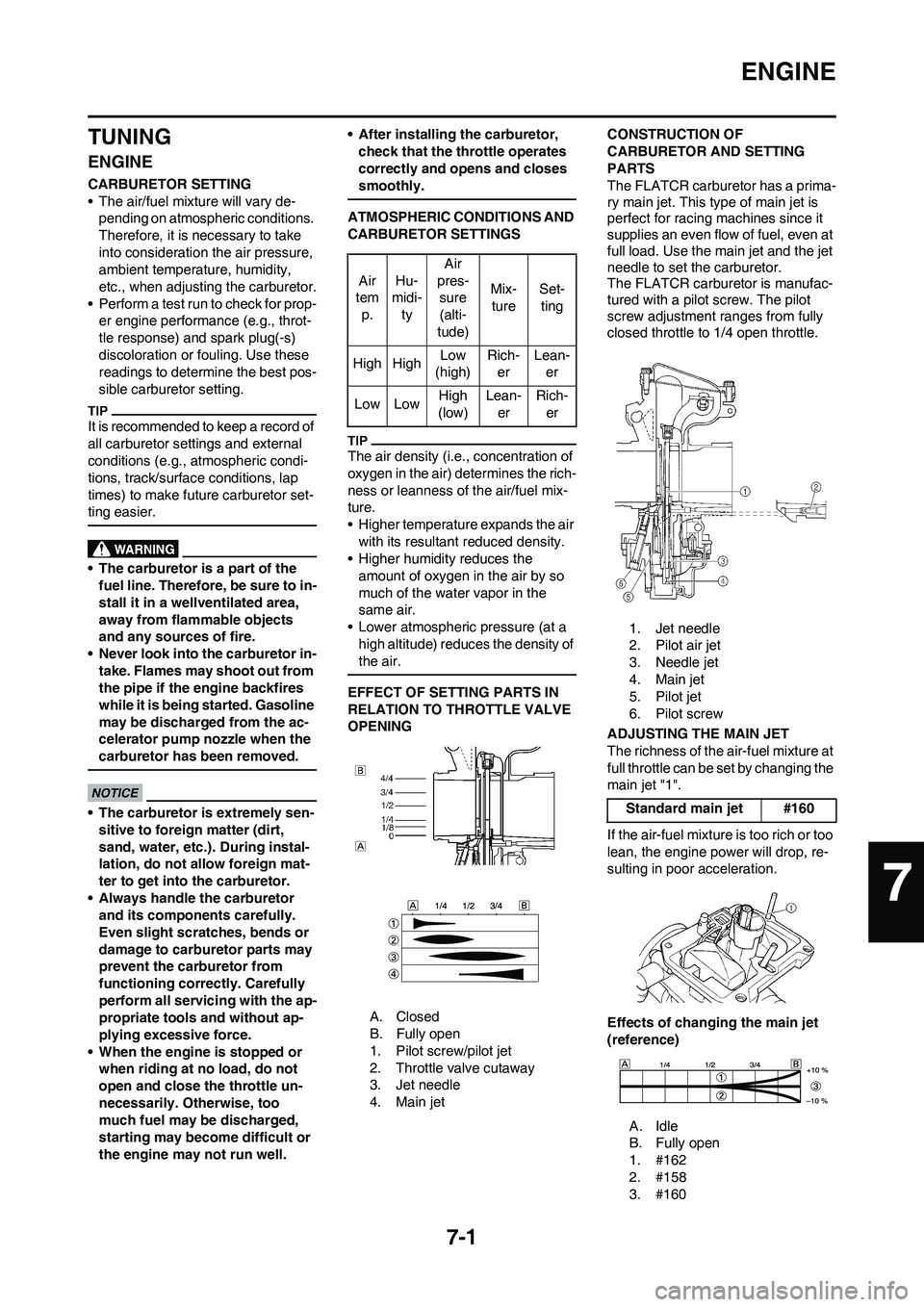

ATMOSPHERIC CONDITIONS AND

CARBURETOR SETTINGS

The air density (i.e., concentration of

oxygen in the air) determines the rich-

ness or leanness of the air/fuel mix-

ture.

• Higher temperature expands the air

with its resultant reduced density.

• Higher humidity reduces the

amount of oxygen in the air by so

much of the water vapor in the

same air.

• Lower atmospheric pressure (at a

high altitude) reduces the density of

the air.

EFFECT OF SETTING PARTS IN

RELATION TO THROTTLE VALVE

OPENING

A. Closed

B. Fully open

1. Pilot screw/pilot jet

2. Throttle valve cutaway

3. Jet needle

4. Main jetCONSTRUCTION OF

CARBURETOR AND SETTING

PARTS

The FLATCR carburetor has a prima-

ry main jet. This type of main jet is

perfect for racing machines since it

supplies an even flow of fuel, even at

full load. Use the main jet and the jet

needle to set the carburetor.

The FLATCR carburetor is manufac-

tured with a pilot screw. The pilot

screw adjustment ranges from fully

closed throttle to 1/4 open throttle.

1. Jet needle

2. Pilot air jet

3. Needle jet

4. Main jet

5. Pilot jet

6. Pilot screw

ADJUSTING THE MAIN JET

The richness of the air-fuel mixture at

full throttle can be set by changing the

main jet "1".

If the air-fuel mixture is too rich or too

lean, the engine power will drop, re-

sulting in poor acceleration.

Effects of changing the main jet

(reference)

A. Idle

B. Fully open

1. #162

2. #158

3. #160 Air

tem

p.Hu-

midi-

tyAir

pres-

sure

(alti-

tude)Mix-

tureSet-

ting

High HighLow

(high)Rich-

erLean-

er

Low LowHigh

(low)Lean-

erRich-

er

Standard main jet #160

7