flat tire YAMAHA YZ450F 2010 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: YZ450F, Model: YAMAHA YZ450F 2010Pages: 230, PDF Size: 14.09 MB

Page 77 of 230

3-21

CHASSIS

CHECKING THE TIRE PRESSURE

1. Measure:

• Tire pressure

Out of specification→Adjust.

• Check the tire while it is cold.

• Loose bead stoppers allow the tire

to slip off its position on the rim

when the tire pressure is low.

• A tilted tire valve stem indicates that

the tire slips off its position on the

rim.

• If the tire valve stem is found tilted,

the tire is considered to be slipping

off its position. Correct the tire posi-

tion.

CHECKING AND TIGHTENING THE

SPOKES

The following procedure applies to all

of the spokes.

1. Check:

• Spokes

Bend/damage→Replace.

Loose spoke→Retighten.

Tap the spokes with a screw-

driver.

A tight spoke will emit a clear, ringing

tone; a loose spoke will sound flat.

2. Tighten:

• Spokes

(with a spoke nipple wrench "1")

Be sure to retighten these spokes be-

fore and after break-in.

CHECKING THE WHEELS

1. Inspect:

• Wheel runout

Elevate the wheel and turn it.

Abnormal runout→ Replace.

2. Inspect:

• Bearing free play

Exist play→Replace.

CHECKING AND ADJUSTING THE

STEERING HEAD

1. Place a stand under the engine to

raise the front wheel off the

ground. WARNING! Securely

support the vehicle so that

there is no danger of it falling

over.

2. Check:

• Steering stem

Grasp the bottom of the forks and

gently rock the fork assembly

back and forth.

Free play→Adjust steering head.3. Check:

• Steering smooth action

Turn the handlebar lock to lock.

Unsmooth action→Adjust steer-

ing ring nut.

4. Adjust:

• Steering ring nut

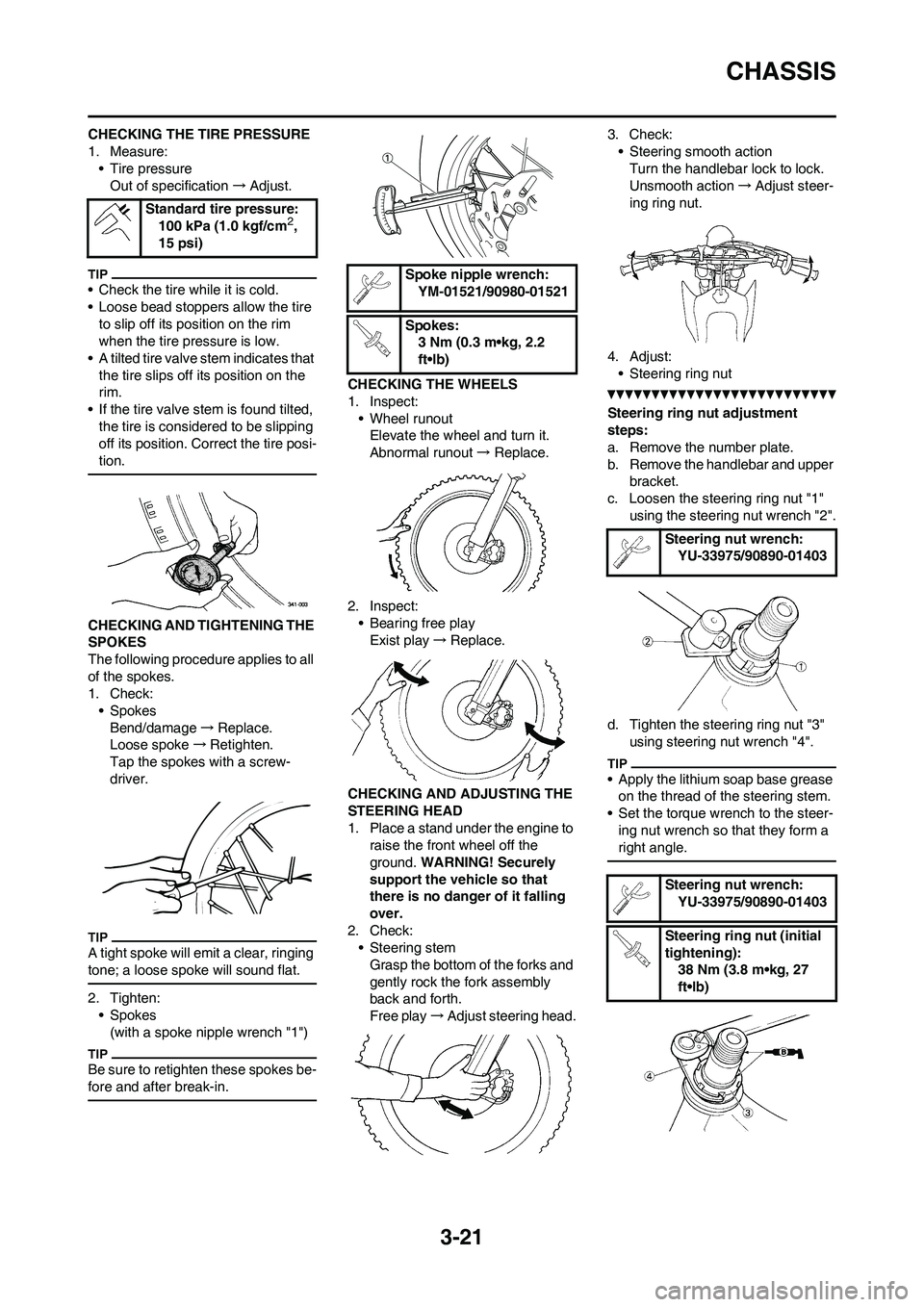

Steering ring nut adjustment

steps:

a. Remove the number plate.

b. Remove the handlebar and upper

bracket.

c. Loosen the steering ring nut "1"

using the steering nut wrench "2".

d. Tighten the steering ring nut "3"

using steering nut wrench "4".

• Apply the lithium soap base grease

on the thread of the steering stem.

• Set the torque wrench to the steer-

ing nut wrench so that they form a

right angle.

Standard tire pressure:

100 kPa (1.0 kgf/cm2,

15 psi)

Spoke nipple wrench:

YM-01521/90980-01521

Spokes:

3 Nm (0.3 m•kg, 2.2

ft•lb)

Steering nut wrench:

YU-33975/90890-01403

Steering nut wrench:

YU-33975/90890-01403

Steering ring nut (initial

tightening):

38 Nm (3.8 m•kg, 27

ft•lb)

Page 224 of 230

8-1

CHASSIS

TUNING

CHASSIS

SELECTION OF THE SECONDARY

REDUCTION RATIO (SPROCKET)

• It is generally said that the second-ary gear ratio should be reduced for

a longer straight portion of a speed

course and should be increased for

a course with many corners. Actual-

ly, however, as the speed depends

on the ground condition of the day

of the race, be sure to run through

the circuit to set the machine suit-

able for the entire course.

• In actuality, it is very difficult to achieve settings suitable for the en-

tire course and some settings may

be sacrificed. Thus, the settings

should be matched to the portion of

the course that has the greatest ef-

fect on the race result. In such a

case, run through the entire course

while making notes of lap times to

find the best balance; then, deter-

mine the secondary reduction ratio.

• If a course has a long straight por- tion where a machine can run at

maximum speed, the machine is

generally set such that it can devel-

op its maximum revolutions toward

the end of the straight line, with care

taken to avoid the engine over-rev-

ving.

Riding technique varies from rider to

rider and the performance of a ma-

chine also vary fr om machine to ma-

chine. Therefore, do not imitate other

rider's settings from the beginning but

choose your own setting according to

the level of your riding technique.

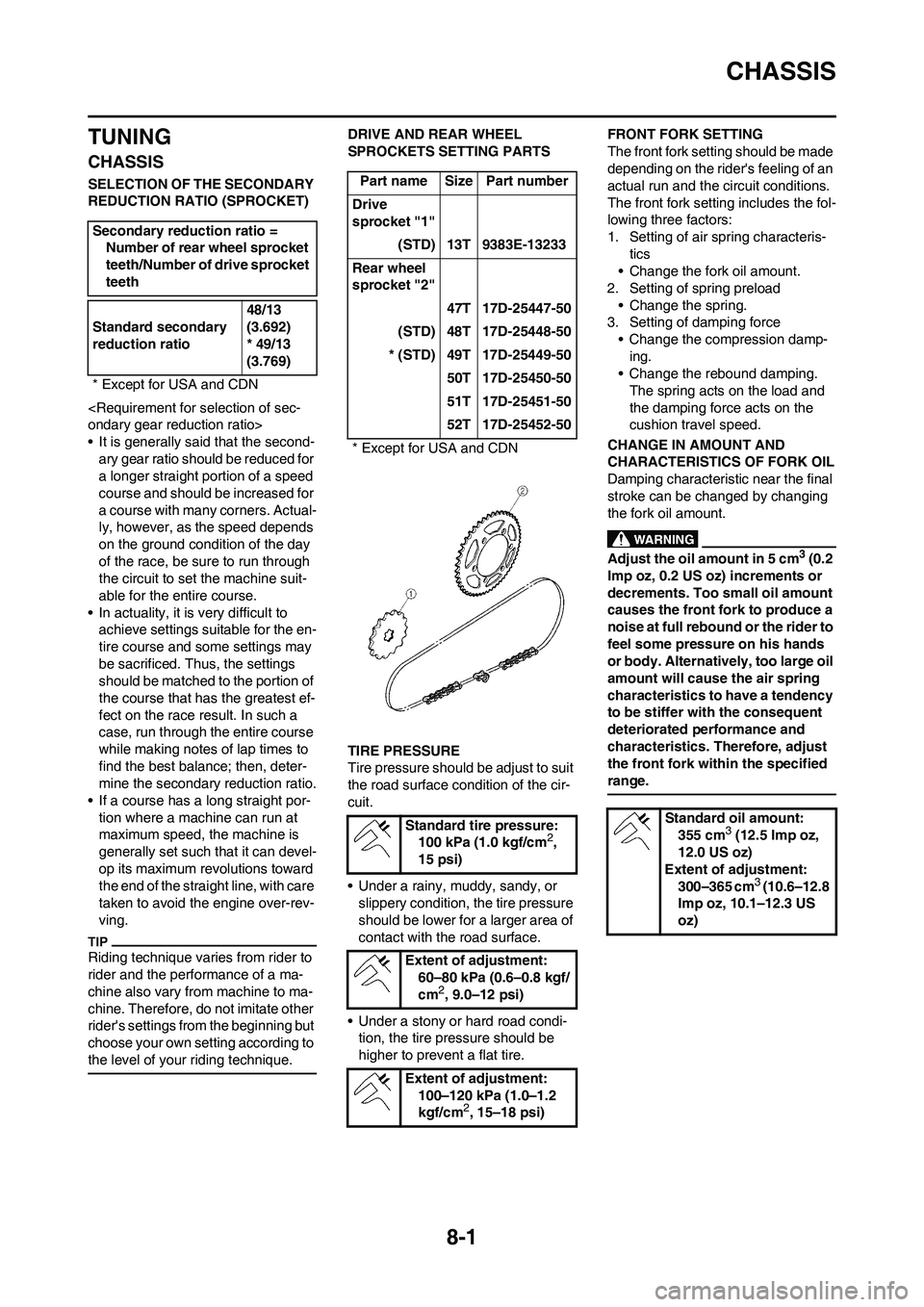

DRIVE AND REAR WHEEL

SPROCKETS SETTING PARTS

TIRE PRESSURE

Tire pressure should be adjust to suit

the road surface condition of the cir-

cuit.

• Under a rainy, muddy, sandy, or slippery condition, the tire pressure

should be lower for a larger area of

contact with the road surface.

• Under a stony or hard road condi- tion, the tire pressure should be

higher to prevent a flat tire. FRONT FORK SETTING

The front fork setting should be made

depending on the rider's feeling of an

actual run and the circuit conditions.

The front fork setting includes the fol-

lowing three factors:

1. Setting of air spring characteris-

tics

• Change the fork oil amount.

2. Setting of spring preload

• Change the spring.

3. Setting of damping force • Change the compression damp-

ing.

• Change the rebound damping. The spring acts on the load and

the damping force acts on the

cushion travel speed.

CHANGE IN AMOUNT AND

CHARACTERISTICS OF FORK OIL

Damping characteristic near the final

stroke can be changed by changing

the fork oil amount.

Adjust the oil amount in 5 cm3 (0.2

Imp oz, 0.2 US oz) increments or

decrements. Too small oil amount

causes the front fork to produce a

noise at full rebound or the rider to

feel some pressure on his hands

or body. Alternatively, too large oil

amount will cause the air spring

characteristics to have a tendency

to be stiffer with the consequent

deteriorated performance and

characteristics. Therefore, adjust

the front fork within the specified

range.

Secondary reduction ratio = Number of rear wheel sprocket

teeth/Number of drive sprocket

teeth

Standard secondary

reduction ratio 48/13

(3.692)

* 49/13

(3.769)

* Except for USA and CDN

Part name Size Part number

Drive

sprocket "1" (STD) 13T 9383E-13233

Rear wheel

sprocket "2" 47T 17D-25447-50

(STD) 48T 17D-25448-50

* (STD) 49T 17D-25449-50 50T 17D-25450-50

51T 17D-25451-50

52T 17D-25452-50

* Except for USA and CDN

Standard tire pressure:100 kPa (1.0 kgf/cm

2,

15 psi)

Extent of adjustment: 60–80 kPa (0.6–0.8 kgf/

cm

2, 9.0–12 psi)

Extent of adjustment: 100–120 kPa (1.0–1.2

kgf/cm

2, 15–18 psi)

Standard oil amount:

355 cm3 (12.5 Imp oz,

12.0 US oz)

Extent of adjustment:

300–365 cm

3 (10.6–12.8

Imp oz, 10.1–12.3 US

oz)