maintenance YAMAHA YZ450F 2011 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2011, Model line: YZ450F, Model: YAMAHA YZ450F 2011Pages: 230, PDF Size: 14.09 MB

Page 39 of 230

2-9

MAINTENANCE SPECIFICATIONS

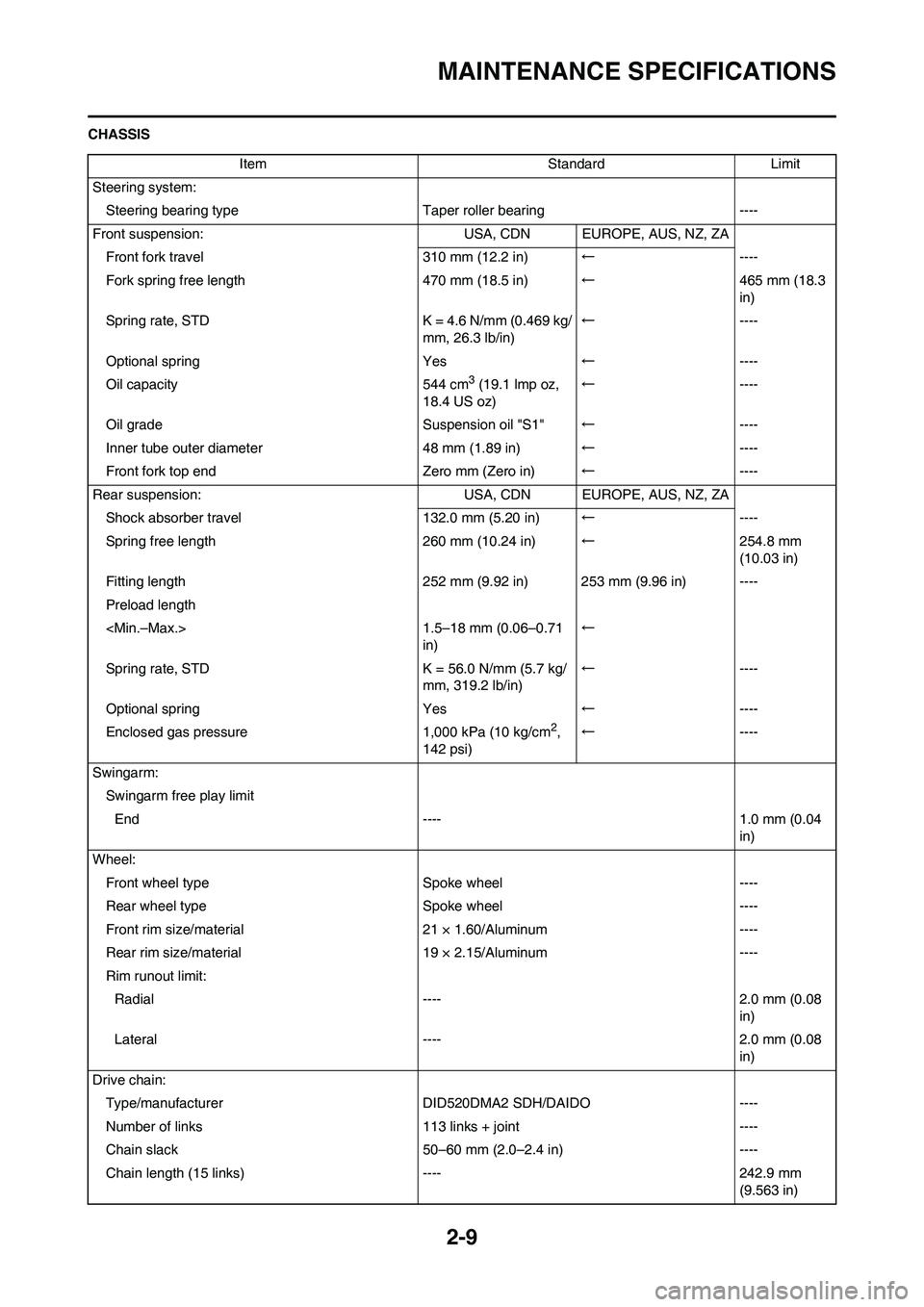

CHASSIS

Item Standard Limit

Steering system:

Steering bearing typeTaper roller bearing ----

Front suspension: USA, CDN EUROPE, AUS, NZ, ZA

Front fork travel 310 mm (12.2 in)←----

Fork spring free length 470 mm (18.5 in)←465 mm (18.3

in)

Spring rate, STD K = 4.6 N/mm (0.469 kg/

mm, 26.3 lb/in)←----

Optional spring Yes←----

Oil capacity 544 cm

3 (19.1 lmp oz,

18.4 US oz)←----

Oil grade Suspension oil "S1"←----

Inner tube outer diameter 48 mm (1.89 in)←----

Front fork top end Zero mm (Zero in)←----

Rear suspension: USA, CDN EUROPE, AUS, NZ, ZA

Shock absorber travel 132.0 mm (5.20 in)←----

Spring free length 260 mm (10.24 in)←254.8 mm

(10.03 in)

Fitting length 252 mm (9.92 in) 253 mm (9.96 in) ----

Preload length

in)←

Spring rate, STD K = 56.0 N/mm (5.7 kg/

mm, 319.2 lb/in)←----

Optional spring Yes←----

Enclosed gas pressure 1,000 kPa (10 kg/cm

2,

142 psi)←----

Swingarm:

Swingarm free play limit

End ---- 1.0 mm (0.04

in)

Wheel:

Front wheel type Spoke wheel ----

Rear wheel typeSpoke wheel ----

Front rim size/material 21 × 1.60/Aluminum ----

Rear rim size/material 19 × 2.15/Aluminum ----

Rim runout limit:

Radial ---- 2.0 mm (0.08

in)

Lateral ---- 2.0 mm (0.08

in)

Drive chain:

Type/manufacturer DID520DMA2 SDH/DAIDO ----

Number of links 113 links + joint ----

Chain slack 50–60 mm (2.0–2.4 in) ----

Chain length (15 links) ---- 242.9 mm

(9.563 in)

Page 40 of 230

2-10

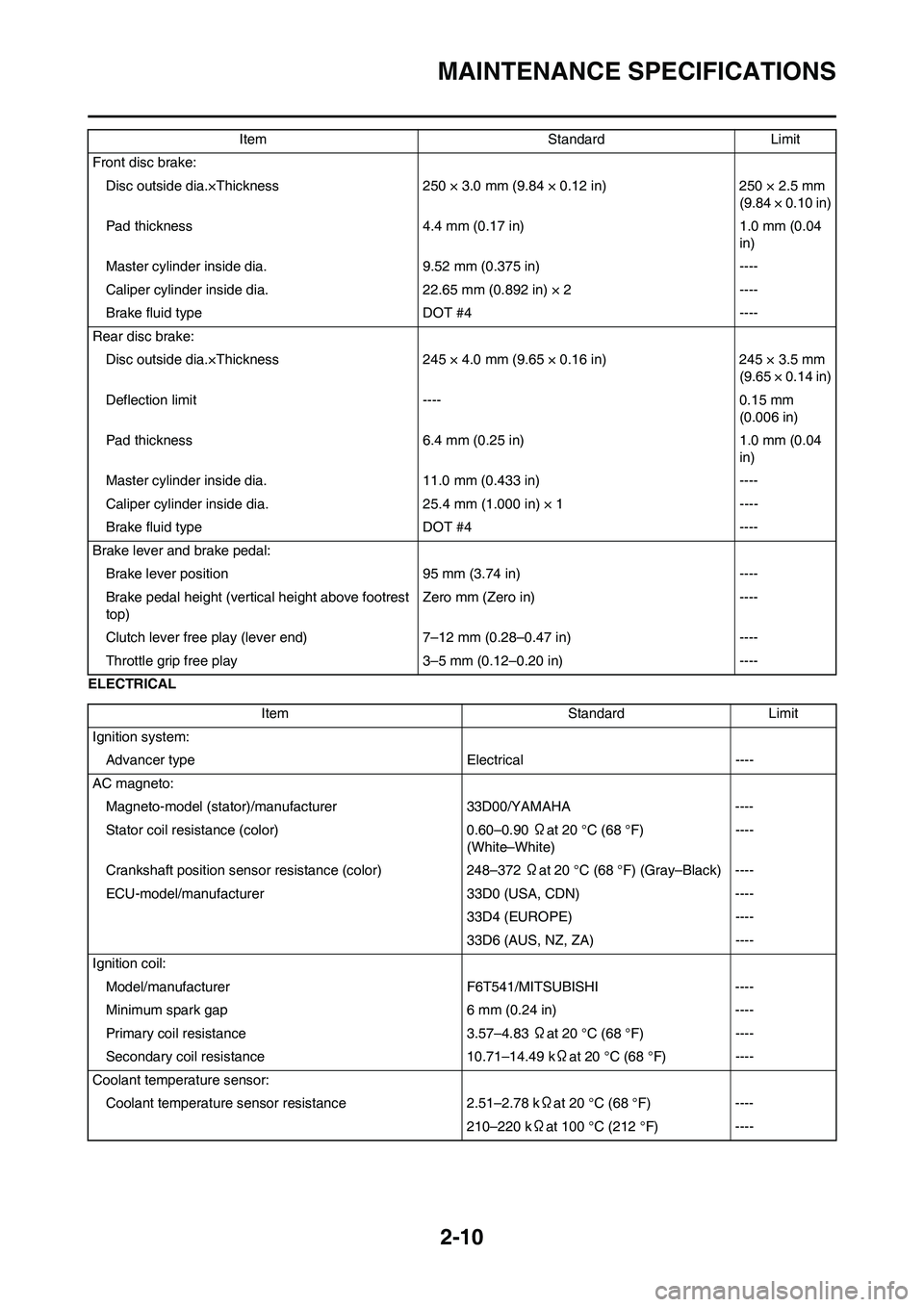

MAINTENANCE SPECIFICATIONS

ELECTRICALFront disc brake:

Disc outside dia.×Thickness 250 × 3.0 mm (9.84 × 0.12 in) 250 × 2.5 mm

(9.84 × 0.10 in)

Pad thickness 4.4 mm (0.17 in) 1.0 mm (0.04

in)

Master cylinder inside dia. 9.52 mm (0.375 in) ----

Caliper cylinder inside dia. 22.65 mm (0.892 in) × 2 ----

Brake fluid type DOT #4 ----

Rear disc brake:

Disc outside dia.×Thickness 245 × 4.0 mm (9.65 × 0.16 in) 245 × 3.5 mm

(9.65 × 0.14 in)

Deflection limit ---- 0.15 mm

(0.006 in)

Pad thickness 6.4 mm (0.25 in) 1.0 mm (0.04

in)

Master cylinder inside dia. 11.0 mm (0.433 in) ----

Caliper cylinder inside dia. 25.4 mm (1.000 in) × 1 ----

Brake fluid type DOT #4 ----

Brake lever and brake pedal:

Brake lever position 95 mm (3.74 in) ----

Brake pedal height (vertical height above footrest

top)Zero mm (Zero in) ----

Clutch lever free play (lever end) 7–12 mm (0.28–0.47 in) ----

Throttle grip free play3–5 mm (0.12–0.20 in) ---- Item Standard Limit

Item Standard Limit

Ignition system:

Advancer type Electrical ----

AC magneto:

Magneto-model (stator)/manufacturer 33D00/YAMAHA ----

Stator coil resistance (color) 0.60–0.90 Ωat 20 °C (68 °F)

(White–White)----

Crankshaft position sensor resistance (color) 248–372 Ωat 20 °C (68 °F) (Gray–Black) ----

ECU-model/manufacturer 33D0 (USA, CDN) ----

33D4 (EUROPE) ----

33D6 (AUS, NZ, ZA) ----

Ignition coil:

Model/manufacturer F6T541/MITSUBISHI ----

Minimum spark gap 6 mm (0.24 in) ----

Primary coil resistance 3.57–4.83 Ωat 20 °C (68 °F) ----

Secondary coil resistance 10.71–14.49 kΩat 20 °C (68 °F) ----

Coolant temperature sensor:

Coolant temperature sensor resistance 2.51–2.78 kΩat 20 °C (68 °F) ----

210–220 kΩat 100 °C (212 °F) ----

Page 57 of 230

3-1

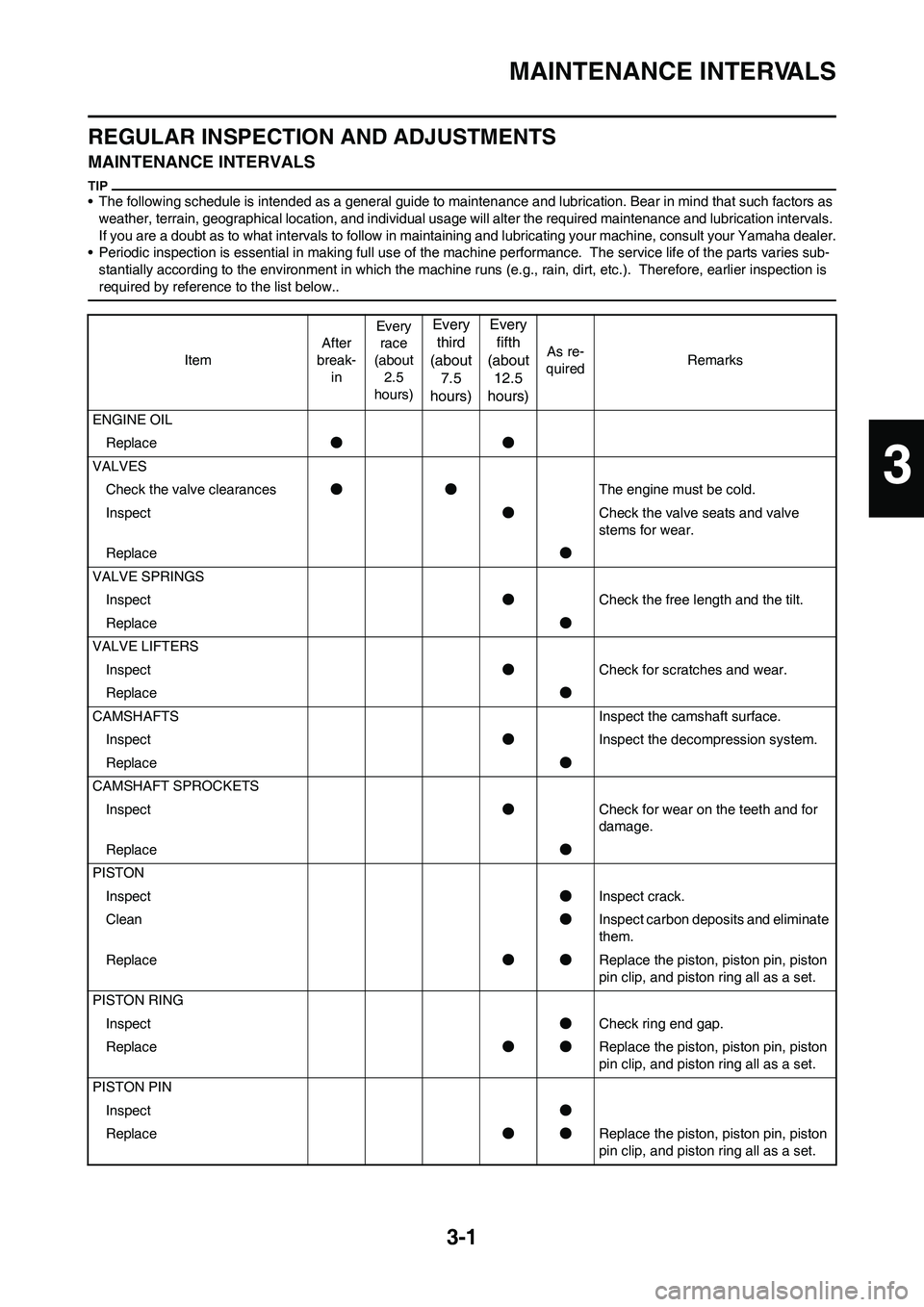

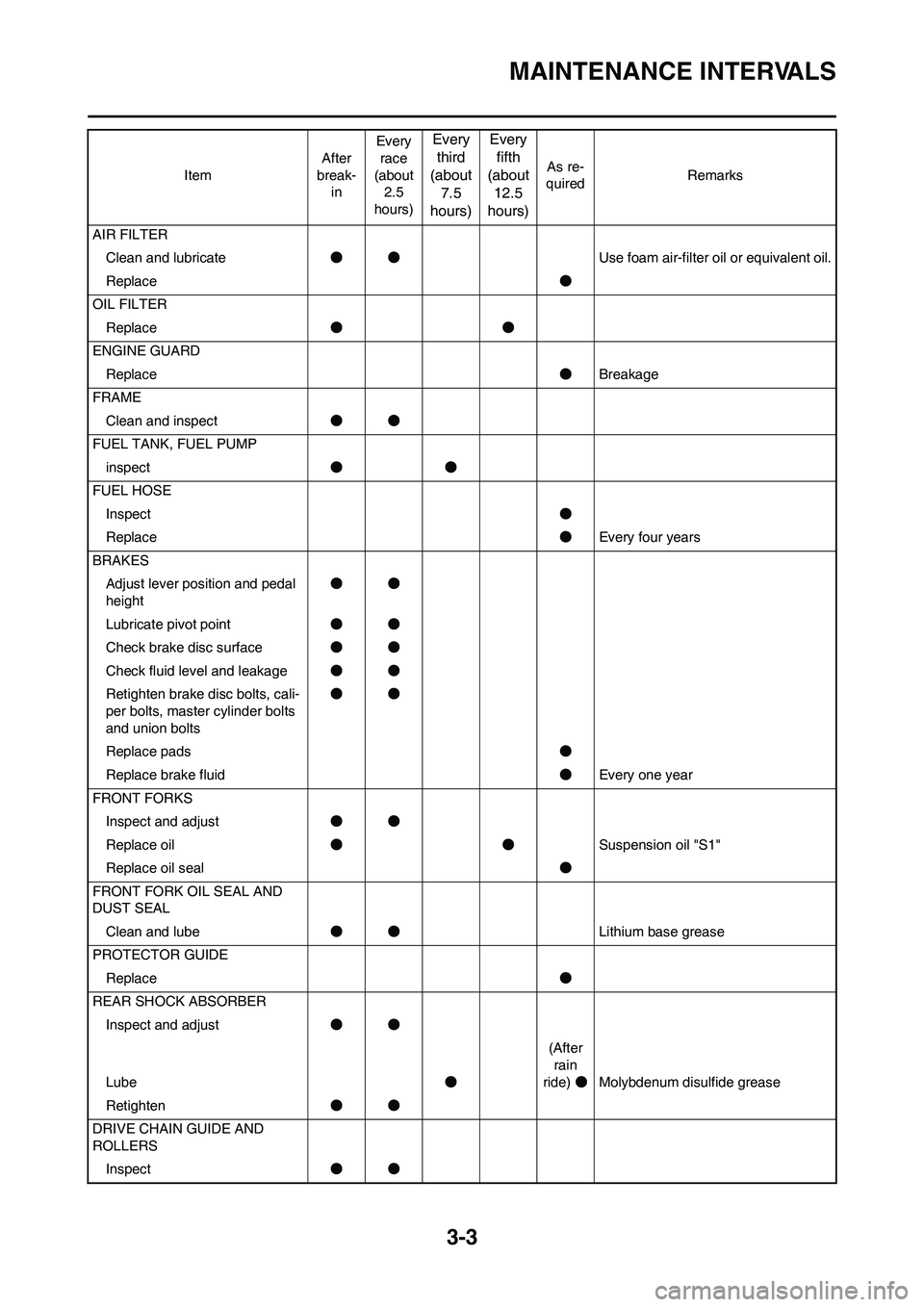

MAINTENANCE INTERVALS

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

• The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as

weather, terrain, geographical location, and individual usage will alter the required maintenance and lubrication intervals.

If you are a doubt as to what intervals to follow in maintaining and lubricating your machine, consult your Yamaha dealer.

• Periodic inspection is essential in making full use of the machine performance. The service life of the parts varies sub-

stantially according to the environment in which the machine runs (e.g., rain, dirt, etc.). Therefore, earlier inspection is

required by reference to the list below..

ItemAfter

break-

inEvery

race

(about

2.5

hours)

Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)

As re-

quiredRemarks

ENGINE OIL

Replace●●

VALVES

Check the valve clearances●●The engine must be cold.

Inspect●Check the valve seats and valve

stems for wear.

Replace●

VALVE SPRINGS

Inspect●Check the free length and the tilt.

Replace●

VALVE LIFTERS

Inspect●Check for scratches and wear.

Replace●

CAMSHAFTS Inspect the camshaft surface.

Inspect●Inspect the decompression system.

Replace●

CAMSHAFT SPROCKETS

Inspect●Check for wear on the teeth and for

damage.

Replace●

PISTON

Inspect●Inspect crack.

Clean●Inspect carbon deposits and eliminate

them.

Replace●●Replace the piston, piston pin, piston

pin clip, and piston ring all as a set.

PISTON RING

Inspect●Check ring end gap.

Replace●●Replace the piston, piston pin, piston

pin clip, and piston ring all as a set.

PISTON PIN

Inspect●

Replace●●Replace the piston, piston pin, piston

pin clip, and piston ring all as a set.

3

Page 58 of 230

3-2

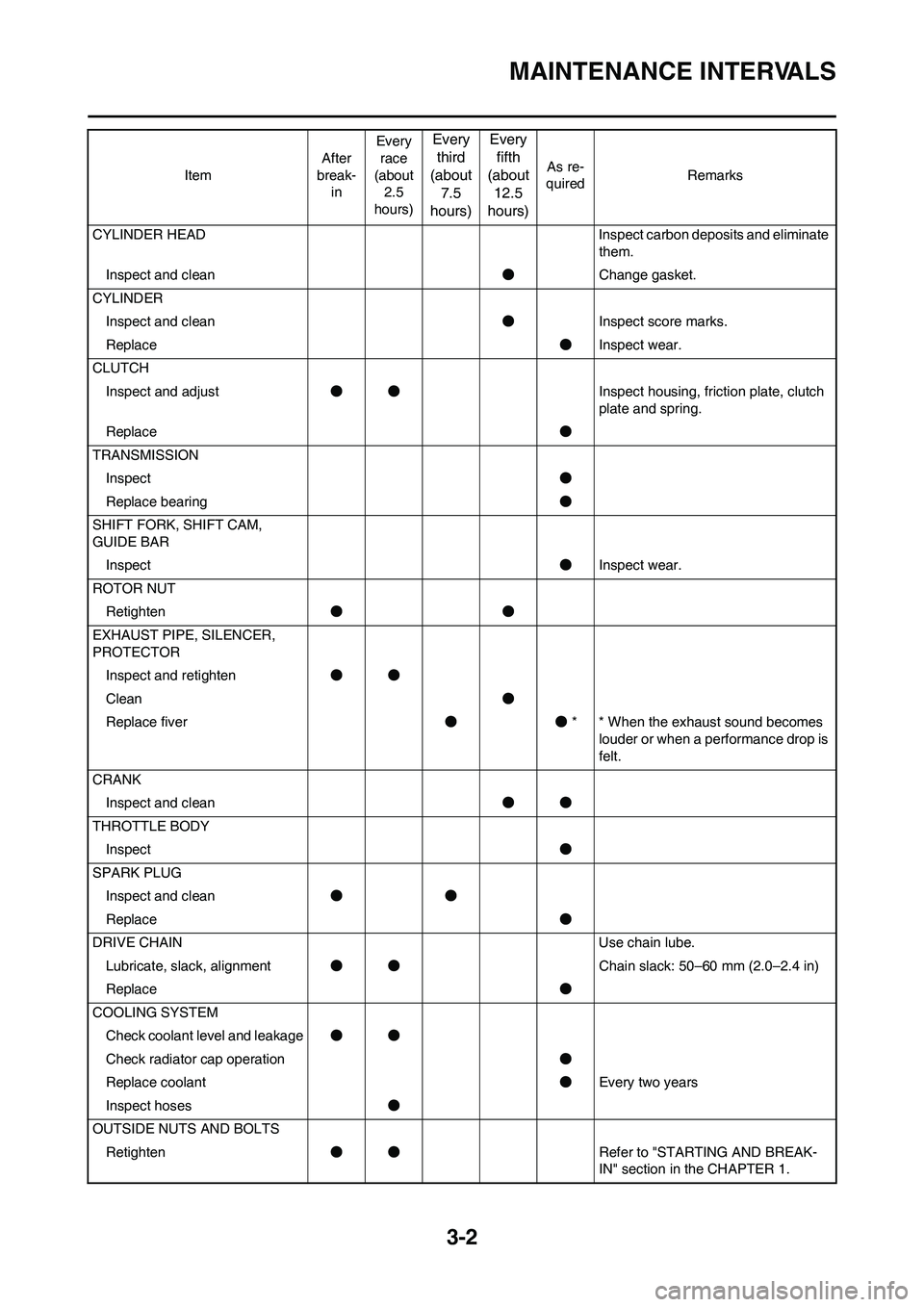

MAINTENANCE INTERVALS

CYLINDER HEAD Inspect carbon deposits and eliminate them.

Inspect and clean ●Change gasket.

CYLINDER Inspect and clean ●Inspect score marks.

Replace ●Inspect wear.

CLUTCH Inspect and adjust ●● Inspect housing, friction plate, clutch

plate and spring.

Replace ●

TRANSMISSION Inspect ●

Replace bearing ●

SHIFT FORK, SHIFT CAM,

GUIDE BAR Inspect ●Inspect wear.

ROTOR NUT Retighten ●●

EXHAUST PIPE, SILENCER,

PROTECTOR Inspect and retighten ●●

Clean ●

Replace fiver ●●* * When the exhaust sound becomes

louder or when a performance drop is

felt.

CRANK Inspect and clean ●●

THROTTLE BODY Inspect ●

SPARK PLUG Inspect and clean ●●

Replace ●

DRIVE CHAIN Use chain lube. Lubricate, slack, alignment ●● Chain slack: 50–60 mm (2.0–2.4 in)

Replace ●

COOLING SYSTEM Check coolant level and leakage ●●

Check radiator cap operation ●

Replace coolant ●Every two years

Inspect hoses ●

OUTSIDE NUTS AND BOLTS Retighten ●● Refer to "STARTING AND BREAK-

IN" section in the CHAPTER 1.

Item

After

break- in Every

race

(about 2.5

hours)

Every third

(about 7.5

hours) Every

fifth

(about 12.5

hours)

As re-

quired Remarks

Page 59 of 230

3-3

MAINTENANCE INTERVALS

AIR FILTER

Clean and lubricate●●Use foam air-filter oil or equivalent oil.

Replace●

OIL FILTER

Replace●●

ENGINE GUARD

Replace●Breakage

FRAME

Clean and inspect●●

FUEL TANK, FUEL PUMP

inspect●●

FUEL HOSE

Inspect●

Replace●Every four years

BRAKES

Adjust lever position and pedal

height●●

Lubricate pivot point●●

Check brake disc surface●●

Check fluid level and leakage●●

Retighten brake disc bolts, cali-

per bolts, master cylinder bolts

and union bolts●●

Replace pads●

Replace brake fluid●Every one year

FRONT FORKS

Inspect and adjust●●

Replace oil●●Suspension oil "S1"

Replace oil seal●

FRONT FORK OIL SEAL AND

DUST SEAL

Clean and lube●●Lithium base grease

PROTECTOR GUIDE

Replace●

REAR SHOCK ABSORBER

Inspect and adjust●●

Lube●(After

rain

ride)●Molybdenum disulfide grease

Retighten●●

DRIVE CHAIN GUIDE AND

ROLLERS

Inspect●● ItemAfter

break-

inEvery

race

(about

2.5

hours)

Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)

As re-

quiredRemarks

Page 60 of 230

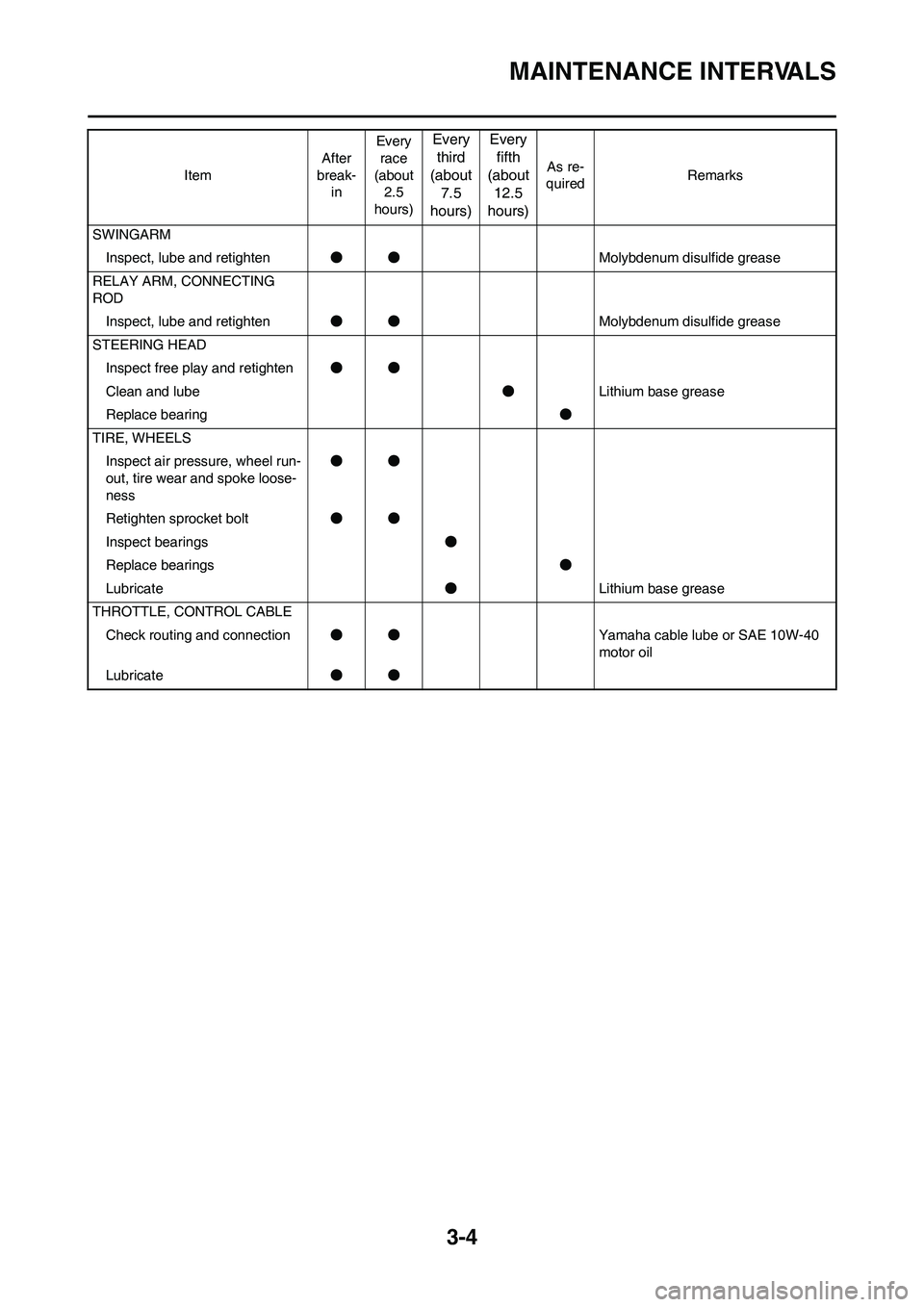

3-4

MAINTENANCE INTERVALS

SWINGARM

Inspect, lube and retighten●●Molybdenum disulfide grease

RELAY ARM, CONNECTING

ROD

Inspect, lube and retighten●●Molybdenum disulfide grease

STEERING HEAD

Inspect free play and retighten●●

Clean and lube●Lithium base grease

Replace bearing●

TIRE, WHEELS

Inspect air pressure, wheel run-

out, tire wear and spoke loose-

ness●●

Retighten sprocket bolt●●

Inspect bearings●

Replace bearings●

Lubricate●Lithium base grease

THROTTLE, CONTROL CABLE

Check routing and connection●●Yamaha cable lube or SAE 10W-40

motor oil

Lubricate●● ItemAfter

break-

inEvery

race

(about

2.5

hours)

Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)

As re-

quiredRemarks

Page 61 of 230

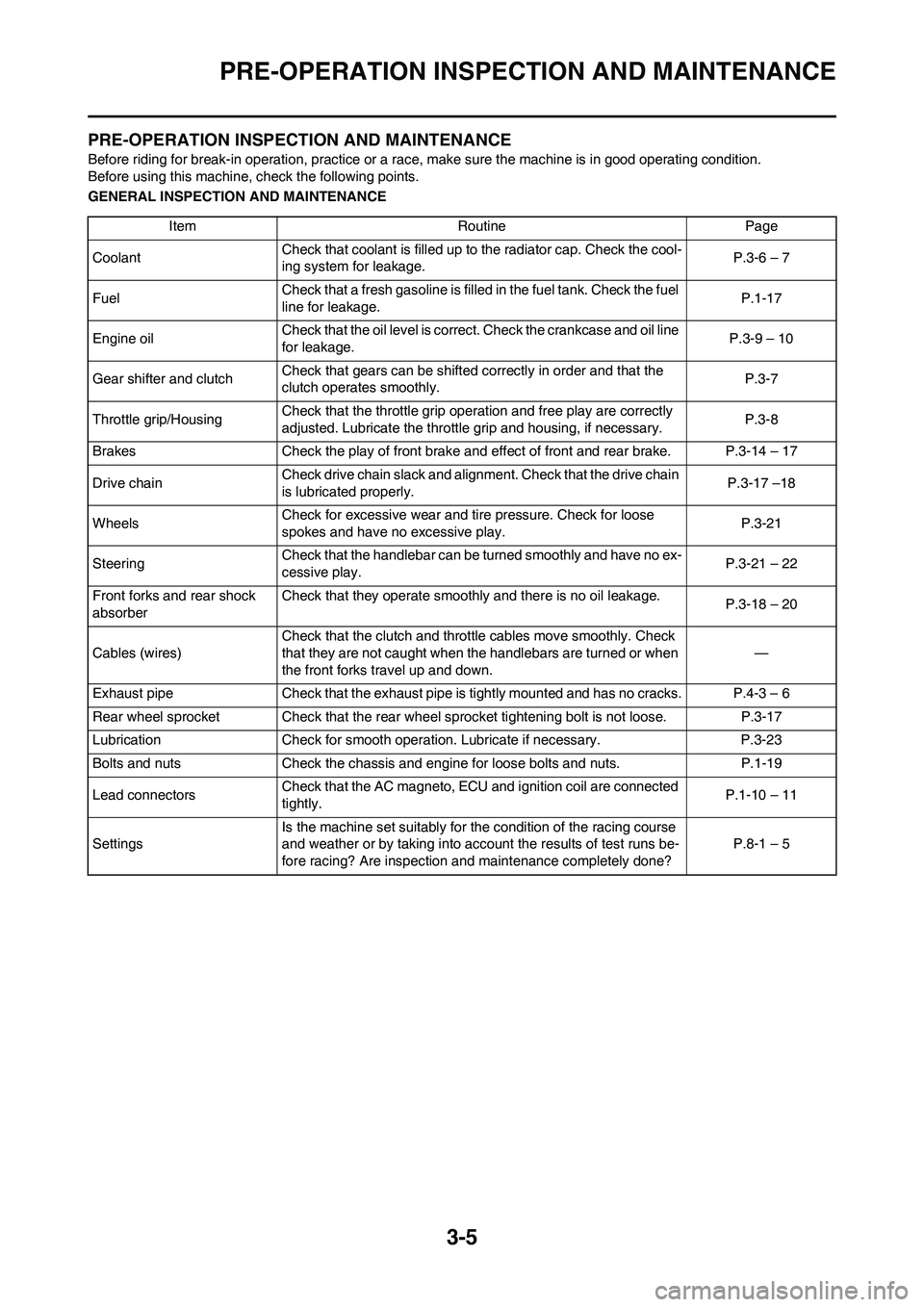

3-5

PRE-OPERATION INSPECTION AND MAINTENANCE

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap. Check the cool-

ing system for leakage.P.3-6 – 7

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the fuel

line for leakage.P.1-17

Engine oilCheck that the oil level is correct. Check the crankcase and oil line

for leakage.P.3-9 – 10

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-7

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-8

Brakes Check the play of front brake and effect of front and rear brake. P.3-14 – 17

Drive chainCheck drive chain slack and alignment. Check that the drive chain

is lubricated properly.P.3-17 –18

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-21

SteeringCheck that the handlebar can be turned smoothly and have no ex-

cessive play.P.3-21 – 22

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage.

P.3-18 – 20

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.—

Exhaust pipe Check that the exhaust pipe is tightly mounted and has no cracks. P.4-3 – 6

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-17

Lubrication Check for smooth operation. Lubricate if necessary. P.3-23

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-19

Lead connectorsCheck that the AC magneto, ECU and ignition coil are connected

tightly.P.1-10 – 11

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs be-

fore racing? Are inspection and maintenance completely done?P.8-1 – 5

Page 81 of 230

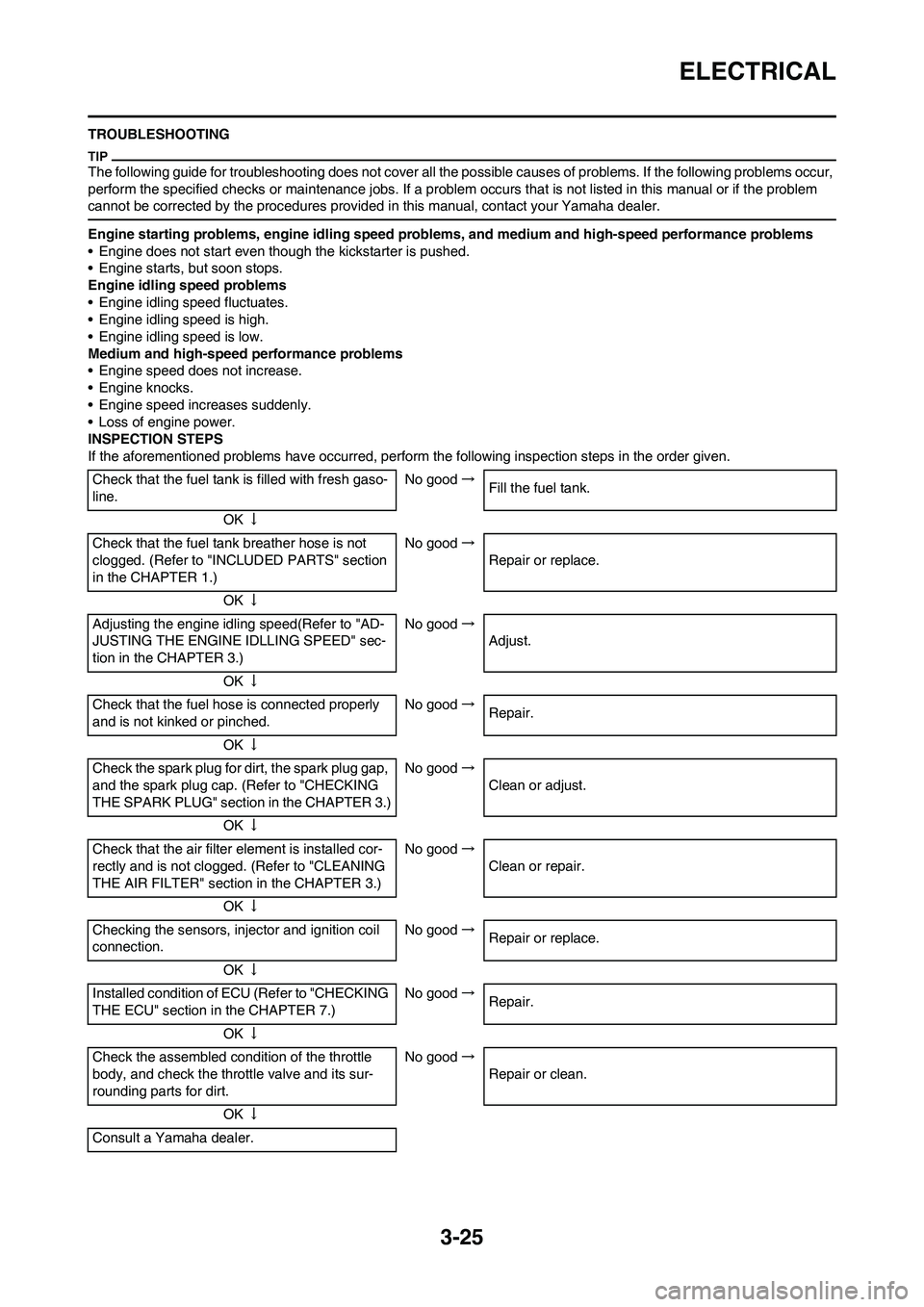

3-25

ELECTRICAL

TROUBLESHOOTING

The following guide for troubleshooting does not cover all the possible causes of problems. If the following problems occur,

perform the specified checks or maintenance jobs. If a problem occurs that is not listed in this manual or if the problem

cannot be corrected by the procedures provided in this manual, contact your Yamaha dealer.

Engine starting problems, engine idling speed problems, and medium and high-speed performance problems

• Engine does not start even though the kickstarter is pushed.

• Engine starts, but soon stops.

Engine idling speed problems

• Engine idling speed fluctuates.

• Engine idling speed is high.

• Engine idling speed is low.

Medium and high-speed performance problems

• Engine speed does not increase.

• Engine knocks.

• Engine speed increases suddenly.

• Loss of engine power.

INSPECTION STEPS

If the aforementioned problems have occurred, perform the following inspection steps in the order given.

Check that the fuel tank is filled with fresh gaso-

line.No good→

Fill the fuel tank.

OK↓

Check that the fuel tank breather hose is not

clogged. (Refer to "INCLUDED PARTS" section

in the CHAPTER 1.)No good→

Repair or replace.

OK↓

Adjusting the engine idling speed(Refer to "AD-

JUSTING THE ENGINE IDLLING SPEED" sec-

tion in the CHAPTER 3.)No good→

Adjust.

OK↓

Check that the fuel hose is connected properly

and is not kinked or pinched.No good→

Repair.

OK↓

Check the spark plug for dirt, the spark plug gap,

and the spark plug cap. (Refer to "CHECKING

THE SPARK PLUG" section in the CHAPTER 3.)No good→

Clean or adjust.

OK↓

Check that the air filter element is installed cor-

rectly and is not clogged. (Refer to "CLEANING

THE AIR FILTER" section in the CHAPTER 3.)No good→

Clean or repair.

OK↓

Checking the sensors, injector and ignition coil

connection.No good→

Repair or replace.

OK↓

Installed condition of ECU (Refer to "CHECKING

THE ECU" section in the CHAPTER 7.)No good→

Repair.

OK↓

Check the assembled condition of the throttle

body, and check the throttle valve and its sur-

rounding parts for dirt.No good→

Repair or clean.

OK↓

Consult a Yamaha dealer.

Page 199 of 230

7-13

FUEL INJECTION SYSTEM

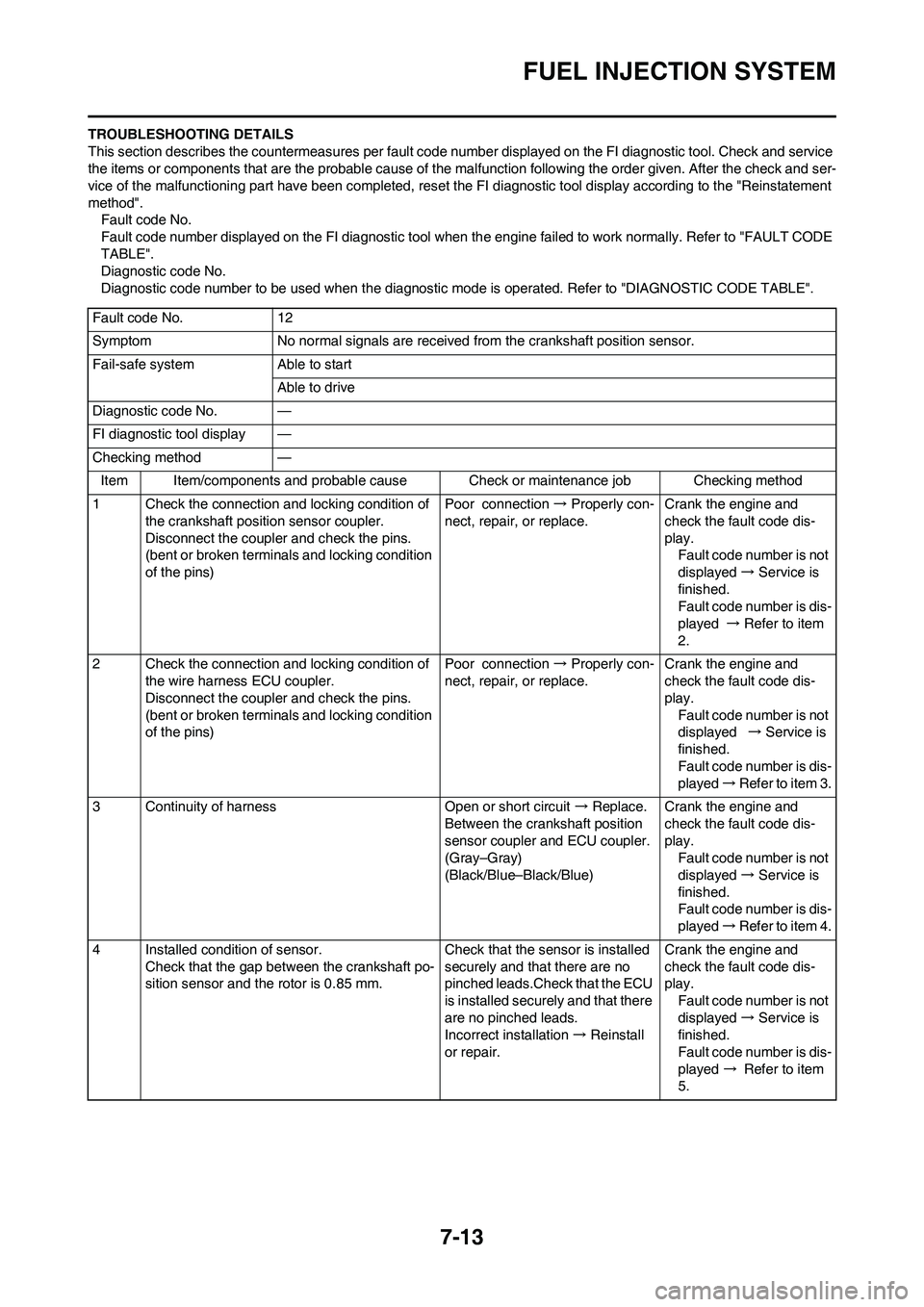

TROUBLESHOOTING DETAILS

This section describes the countermeasures per fault code number displayed on the FI diagnostic tool. Check and service

the items or components that are the probable cause of the malfunction following the order given. After the check and ser-

vice of the malfunctioning part have been completed, reset the FI diagnostic tool display according to the "Reinstatement

method".

Fault code No.

Fault code number displayed on the FI diagnostic tool when the engine failed to work normally. Refer to "FAULT CODE

TABLE".

Diagnostic code No.

Diagnostic code number to be used when the diagnostic mode is operated. Refer to "DIAGNOSTIC CODE TABLE".

Fault code No. 12

Symptom No normal signals are received from the crankshaft position sensor.

Fail-safe system Able to start

Able to drive

Diagnostic code No. —

FI diagnostic tool display —

Checking method —

Item Item/components and probable cause Check or maintenance job Checking method

1 Check the connection and locking condition of

the crankshaft position sensor coupler.

Disconnect the coupler and check the pins.

(bent or broken terminals and locking condition

of the pins)Poor connection → Properly con-

nect, repair, or replace.Crank the engine and

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item

2.

2 Check the connection and locking condition of

the wire harness ECU coupler.

Disconnect the coupler and check the pins.

(bent or broken terminals and locking condition

of the pins)Poor connection → Properly con-

nect, repair, or replace.Crank the engine and

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 3.

3 Continuity of harness Open or short circuit → Replace.

Between the crankshaft position

sensor coupler and ECU coupler.

(Gray–Gray)

(Black/Blue–Black/Blue)Crank the engine and

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 4.

4 Installed condition of sensor.

Check that the gap between the crankshaft po-

sition sensor and the rotor is 0.85 mm.Check that the sensor is installed

securely and that there are no

pinched leads.Check that the ECU

is installed securely and that there

are no pinched leads.

Incorrect installation → Reinstall

or repair.Crank the engine and

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item

5.

Page 200 of 230

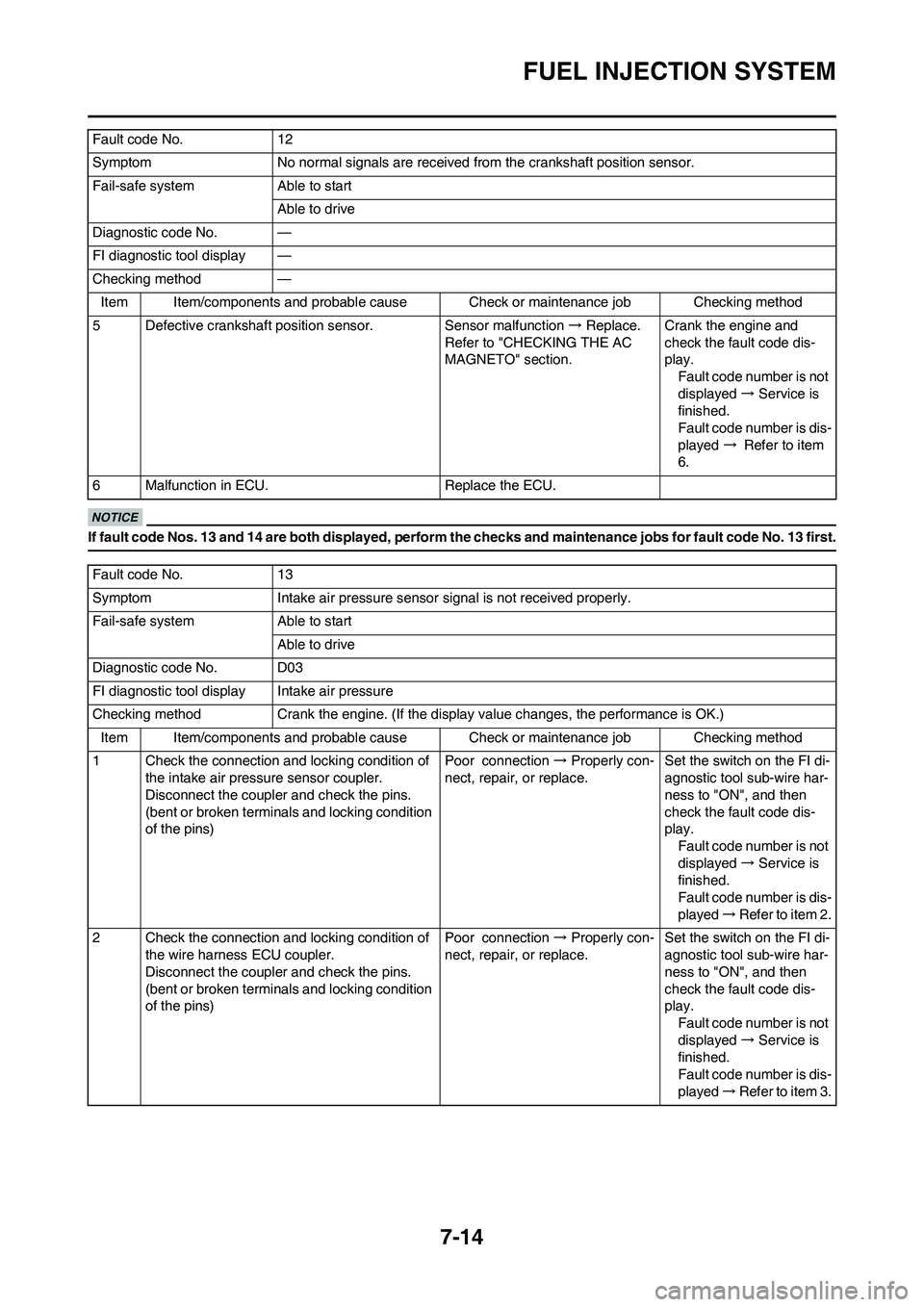

7-14

FUEL INJECTION SYSTEM

If fault code Nos. 13 and 14 are both displayed, perform the checks and maintenance jobs for fault code No. 13 first.

5 Defective crankshaft position sensor. Sensor malfunction → Replace.

Refer to "CHECKING THE AC

MAGNETO" section.Crank the engine and

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item

6.

6 Malfunction in ECU. Replace the ECU.

Fault code No. 13

Symptom Intake air pressure sensor signal is not received properly.

Fail-safe system Able to start

Able to drive

Diagnostic code No. D03

FI diagnostic tool display Intake air pressure

Checking method Crank the engine. (If the display value changes, the performance is OK.)

Item Item/components and probable cause Check or maintenance job Checking method

1 Check the connection and locking condition of

the intake air pressure sensor coupler.

Disconnect the coupler and check the pins.

(bent or broken terminals and locking condition

of the pins)Poor connection → Properly con-

nect, repair, or replace.Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 2.

2 Check the connection and locking condition of

the wire harness ECU coupler.

Disconnect the coupler and check the pins.

(bent or broken terminals and locking condition

of the pins)Poor connection → Properly con-

nect, repair, or replace.Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 3. Fault code No. 12

Symptom No normal signals are received from the crankshaft position sensor.

Fail-safe system Able to start

Able to drive

Diagnostic code No. —

FI diagnostic tool display —

Checking method —

Item Item/components and probable cause Check or maintenance job Checking method