Valve YAMAHA YZ450F 2012 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2012, Model line: YZ450F, Model: YAMAHA YZ450F 2012Pages: 228, PDF Size: 11.42 MB

Page 161 of 228

5-22

FRONT FORK

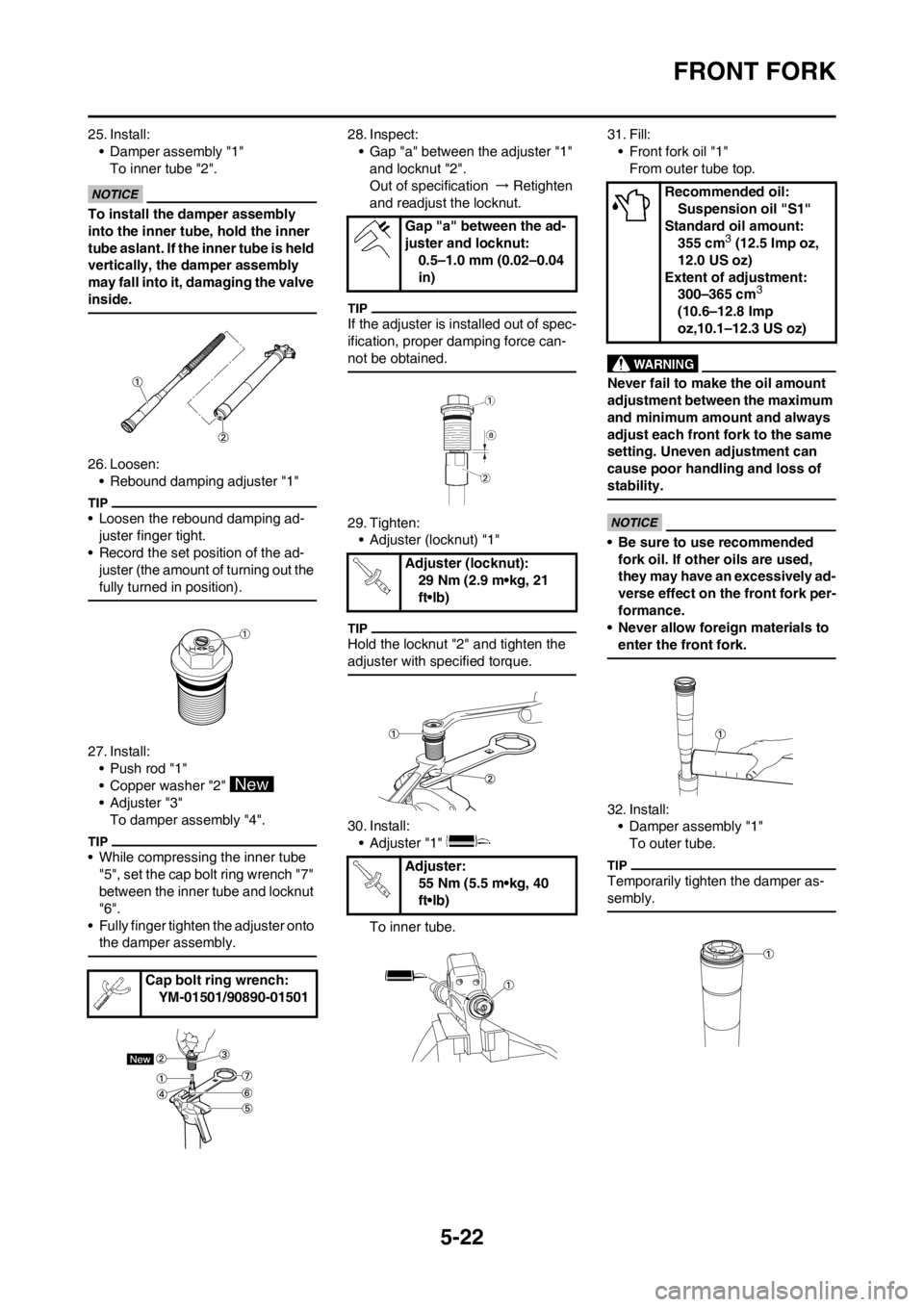

25. Install:

• Damper assembly "1"

To inner tube "2".

To install the damper assembly

into the inner tube, hold the inner

tube aslant. If the inner tube is held

vertically, the damper assembly

may fall into it, damaging the valve

inside.

26. Loosen:

• Rebound damping adjuster "1"

• Loosen the rebound damping ad-

juster finger tight.

• Record the set position of the ad-

juster (the amount of turning out the

fully turned in position).

27. Install:

• Push rod "1"

• Copper washer "2"

• Adjuster "3"

To damper assembly "4".

• While compressing the inner tube

"5", set the cap bolt ring wrench "7"

between the inner tube and locknut

"6".

• Fully finger tighten the adjuster onto

the damper assembly.

28. Inspect:

• Gap "a" between the adjuster "1"

and locknut "2".

Out of specification → Retighten

and readjust the locknut.

If the adjuster is installed out of spec-

ification, proper damping force can-

not be obtained.

29. Tighten:

• Adjuster (locknut) "1"

Hold the locknut "2" and tighten the

adjuster with specified torque.

30. Install:

• Adjuster "1"

To inner tube.31. Fill:

• Front fork oil "1"

From outer tube top.

Never fail to make the oil amount

adjustment between the maximum

and minimum amount and always

adjust each front fork to the same

setting. Uneven adjustment can

cause poor handling and loss of

stability.

• Be sure to use recommended

fork oil. If other oils are used,

they may have an excessively ad-

verse effect on the front fork per-

formance.

• Never allow foreign materials to

enter the front fork.

32. Install:

• Damper assembly "1"

To outer tube.

Temporarily tighten the damper as-

sembly.

Cap bolt ring wrench:

YM-01501/90890-01501

Gap "a" between the ad-

juster and locknut:

0.5–1.0 mm (0.02–0.04

in)

Adjuster (locknut):

29 Nm (2.9 m•kg, 21

ft•lb)

Adjuster:

55 Nm (5.5 m•kg, 40

ft•lb)

Recommended oil:

Suspension oil "S1"

Standard oil amount:

355 cm

3 (12.5 Imp oz,

12.0 US oz)

Extent of adjustment:

300–365 cm

3

(10.6–12.8 Imp

oz,10.1–12.3 US oz)

Page 177 of 228

5-38

REAR SHOCK ABSORBER

HANDLING NOTE

• Support the machine securely so

there is no danger of it falling

over.

• This rear shock absorber is pro-

vided with a separate type tank

filled with high-pressure nitro-

gen gas. To prevent the danger

of explosion, read and under-

stand the following information

before handling the shock ab-

sorber. The manufacturer can

not be held responsible for prop-

erty damage or personal injury

that may result from improper

handling.

• Never tamper or attempt to dis-

assemble the cylinder or the

tank.

• Never throw the rear shock ab-

sorber into an open flame or

other high heat. The rear shock

absorber may explode as a re-

sult of nitrogen gas expansion

and/ or damage to the hose.

• Be careful not to damage any

part of the gas tank. A damaged

gas tank will impair the damp-

ing performance or cause a

malfunction.

• Take care not to scratch the

contact surface of the piston

rod with the cylinder; or oil

could leak out.

• Never attempt to remove the

plug at the bottom of the nitro-

gen gas tank. It is very danger-

ous to remove the plug.

• When scrapping the rear shock

absorber, follow the instruc-

tions on disposal.

NOTES ON DISPOSAL (YAMAHA

DEALERS ONLY)

Before disposing the rear shock ab-

sorber, be sure to extract the nitrogen

gas from valve "1". Wear eye protec-

tion to prevent eye damage from es-

caping gas and/or metal chips.

To dispose of a damaged or worn-

out rear shock absorber, take the

unit to your Yamaha dealer for this

disposal procedure.

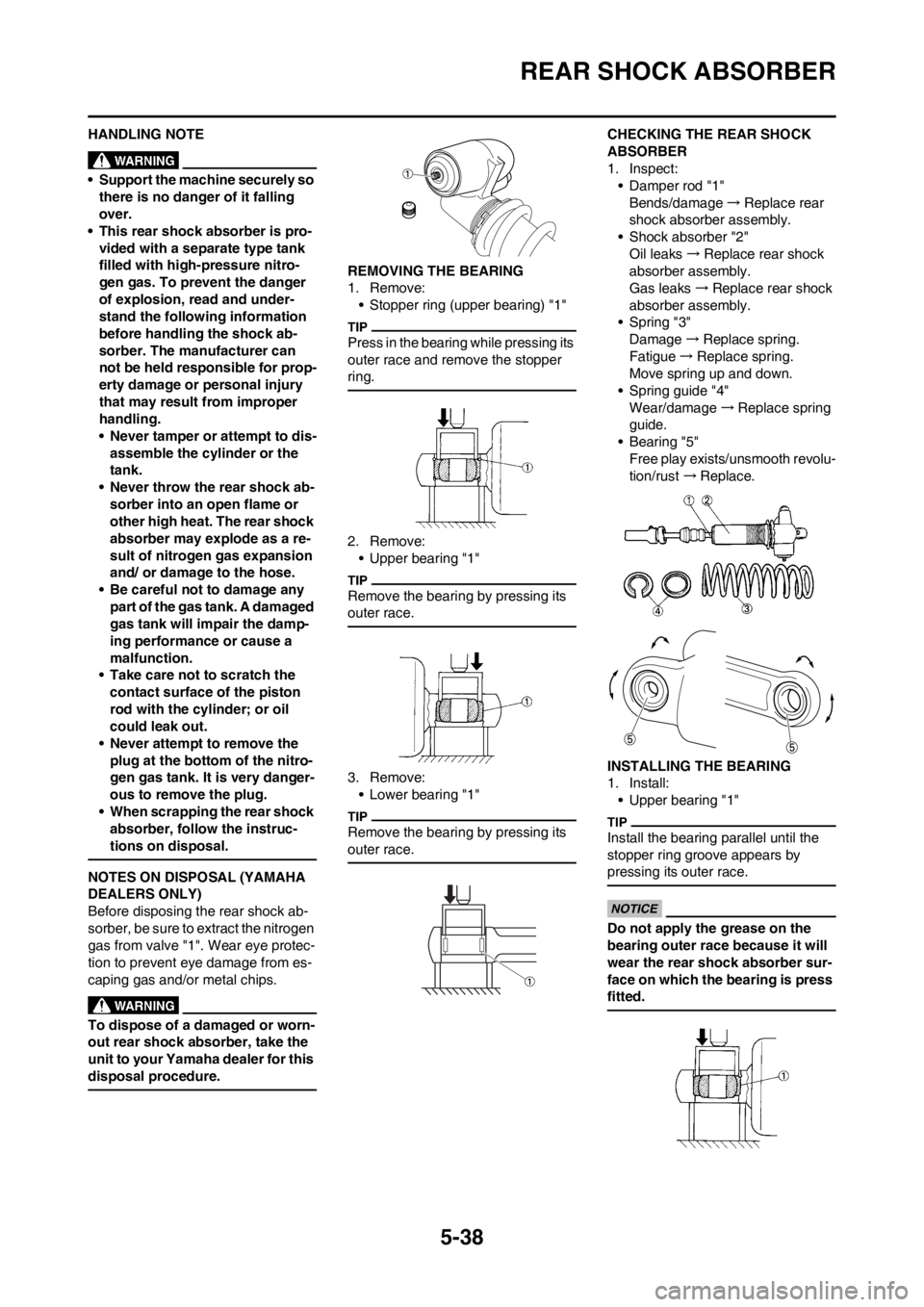

REMOVING THE BEARING

1. Remove:

• Stopper ring (upper bearing) "1"

Press in the bearing while pressing its

outer race and remove the stopper

ring.

2. Remove:

• Upper bearing "1"

Remove the bearing by pressing its

outer race.

3. Remove:

• Lower bearing "1"

Remove the bearing by pressing its

outer race.

CHECKING THE REAR SHOCK

ABSORBER

1. Inspect:

• Damper rod "1"

Bends/damage→Replace rear

shock absorber assembly.

• Shock absorber "2"

Oil leaks→Replace rear shock

absorber assembly.

Gas leaks→Replace rear shock

absorber assembly.

• Spring "3"

Damage→Replace spring.

Fatigue→Replace spring.

Move spring up and down.

• Spring guide "4"

Wear/damage→Replace spring

guide.

• Bearing "5"

Free play exists/unsmooth revolu-

tion/rust →Replace.

INSTALLING THE BEARING

1. Install:

• Upper bearing "1"

Install the bearing parallel until the

stopper ring groove appears by

pressing its outer race.

Do not apply the grease on the

bearing outer race because it will

wear the rear shock absorber sur-

face on which the bearing is press

fitted.

Page 184 of 228

6-6

THROTTLE BODY

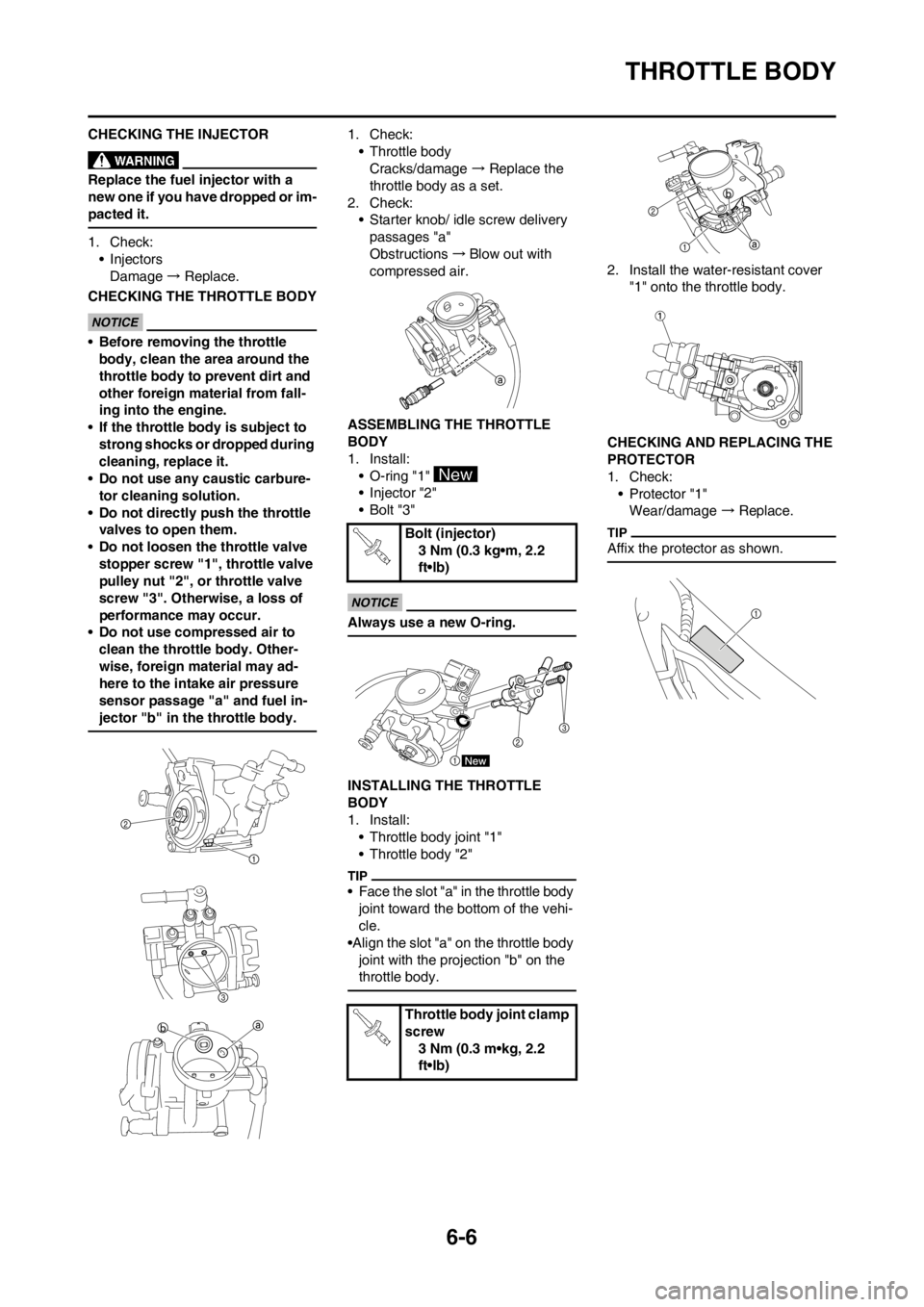

CHECKING THE INJECTOR

Replace the fuel injector with a

new one if you have dropped or im-

pacted it.

1. Check:

• Injectors

Damage → Replace.

CHECKING THE THROTTLE BODY

•Before removing the throttle

body, clean the area around the

throttle body to prevent dirt and

other foreign material from fall-

ing into the engine.

•If the throttle body is subject to

strong shocks or dropped during

cleaning, replace it.

•Do not use any caustic carbure-

tor cleaning solution.

•Do not directly push the throttle

valves to open them.

•Do not loosen the throttle valve

stopper screw "1", throttle valve

pulley nut "2", or throttle valve

screw "3". Otherwise, a loss of

performance may occur.

•Do not use compressed air to

clean the throttle body. Other-

wise, foreign material may ad-

here to the intake air pressure

sensor passage "a" and fuel in-

jector "b" in the throttle body.

1. Check:

• Throttle body

Cracks/damage → Replace the

throttle body as a set.

2. Check:

• Starter knob/ idle screw delivery

passages "a"

Obstructions →Blow out with

compressed air.

ASSEMBLING THE THROTTLE

BODY

1. Install:

• O-ring "1"

• Injector "2"

•Bolt "3"

Always use a new O-ring.

INSTALLING THE THROTTLE

BODY

1. Install:

• Throttle body joint "1"

• Throttle body "2"

• Face the slot "a" in the throttle body

joint toward the bottom of the vehi-

cle.

•Align the slot "a" on the throttle body

joint with the projection "b" on the

throttle body.

2. Install the water-resistant cover

"1" onto the throttle body.

CHECKING AND REPLACING THE

PROTECTOR

1. Check:

• Protector "1"

Wear/damage → Replace.

Affix the protector as shown.Bolt (injector)

3 Nm (0.3 kg•m, 2.2

ft•lb)

Throttle body joint clamp

screw

3 Nm (0.3 m•kg, 2.2

ft•lb)

Page 196 of 228

7-12

FUEL INJECTION SYSTEM

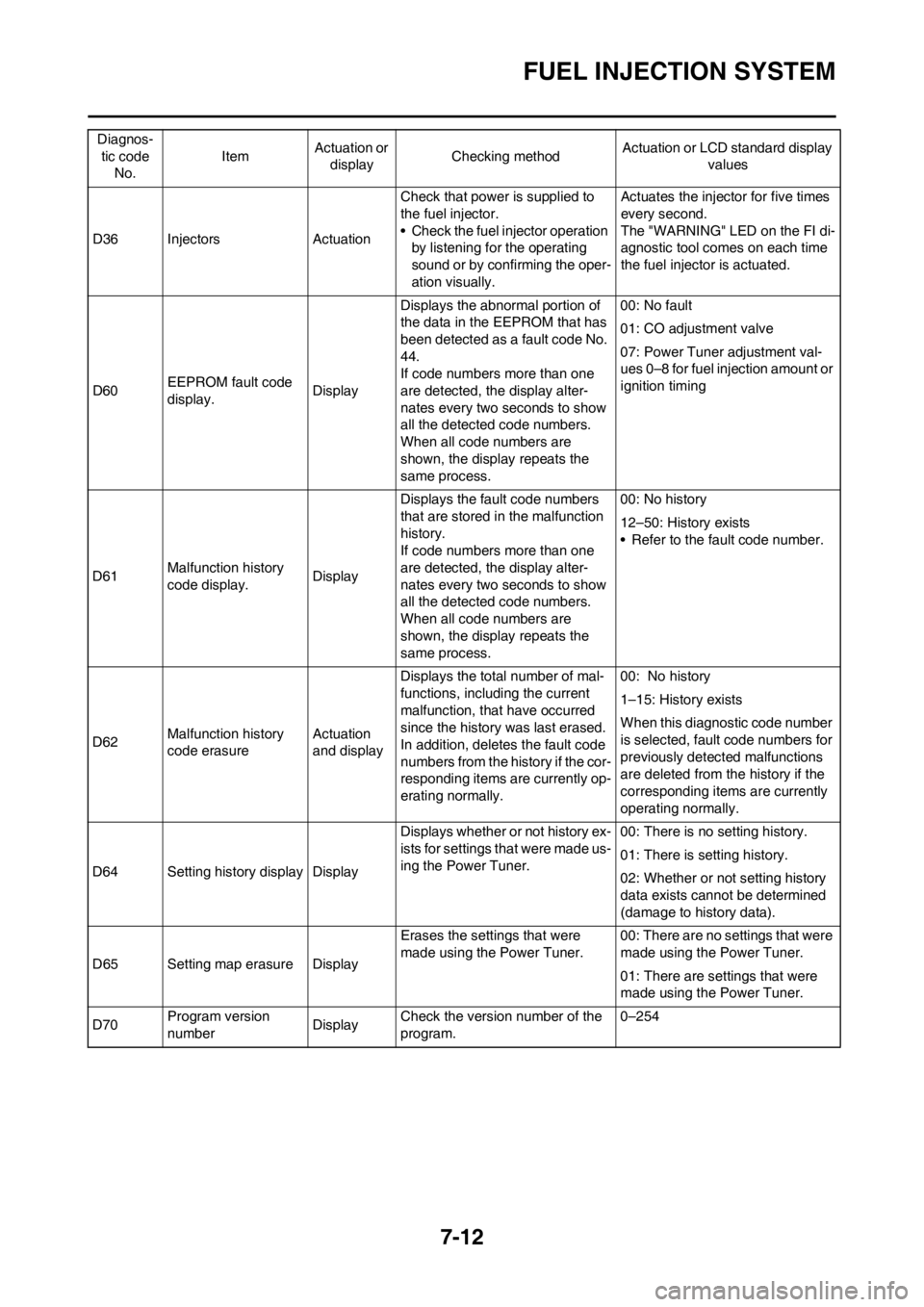

D36 Injectors ActuationCheck that power is supplied to

the fuel injector.

• Check the fuel injector operation

by listening for the operating

sound or by confirming the oper-

ation visually.Actuates the injector for five times

every second.

The "WARNING" LED on the FI di-

agnostic tool comes on each time

the fuel injector is actuated.

D60EEPROM fault code

display.DisplayDisplays the abnormal portion of

the data in the EEPROM that has

been detected as a fault code No.

44.

If code numbers more than one

are detected, the display alter-

nates every two seconds to show

all the detected code numbers.

When all code numbers are

shown, the display repeats the

same process.00: No fault

01: CO adjustment valve

07: Power Tuner adjustment val-

ues 0–8 for fuel injection amount or

ignition timing

D61Malfunction history

code display.DisplayDisplays the fault code numbers

that are stored in the malfunction

history.

If code numbers more than one

are detected, the display alter-

nates every two seconds to show

all the detected code numbers.

When all code numbers are

shown, the display repeats the

same process.00: No history

12–50: History exists

• Refer to the fault code number.

D62Malfunction history

code erasureActuation

and displayDisplays the total number of mal-

functions, including the current

malfunction, that have occurred

since the history was last erased.

In addition, deletes the fault code

numbers from the history if the cor-

responding items are currently op-

erating normally.00: No history

1–15: History exists

When this diagnostic code number

is selected, fault code numbers for

previously detected malfunctions

are deleted from the history if the

corresponding items are currently

operating normally.

D64 Setting history display DisplayDisplays whether or not history ex-

ists for settings that were made us-

ing the Power Tuner.00: There is no setting history.

01: There is setting history.

02: Whether or not setting history

data exists cannot be determined

(damage to history data).

D65 Setting map erasure DisplayErases the settings that were

made using the Power Tuner.00: There are no settings that were

made using the Power Tuner.

01: There are settings that were

made using the Power Tuner.

D70Program version

numberDisplayCheck the version number of the

program.0–254 Diagnos-

tic code

No.ItemActuation or

displayChecking methodActuation or LCD standard display

values

Page 201 of 228

7-17

FUEL INJECTION SYSTEM

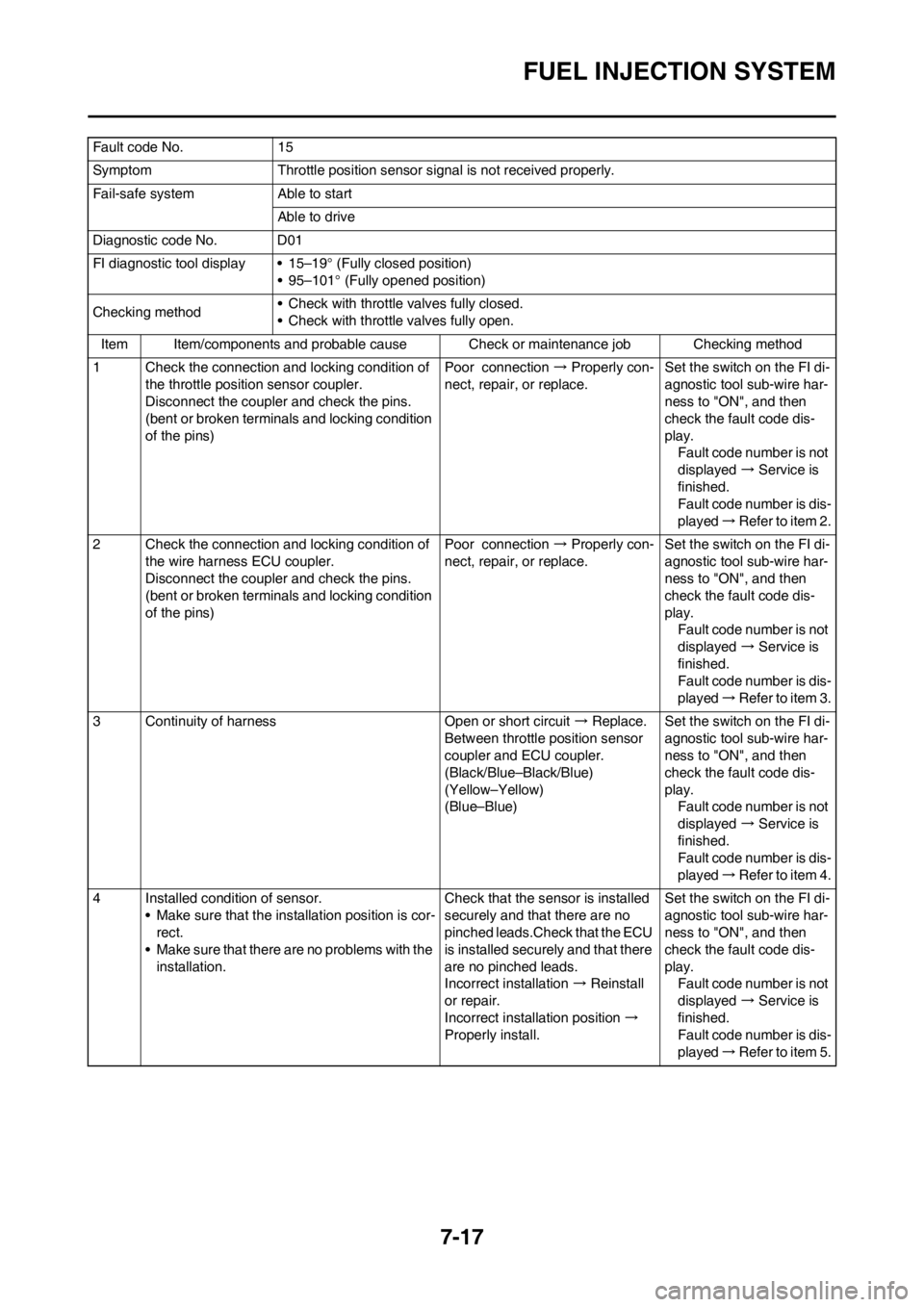

Fault code No. 15

Symptom Throttle position sensor signal is not received properly.

Fail-safe system Able to start

Able to drive

Diagnostic code No. D01

FI diagnostic tool display • 15–19° (Fully closed position)

• 95–101° (Fully opened position)

Checking method• Check with throttle valves fully closed.

• Check with throttle valves fully open.

Item Item/components and probable cause Check or maintenance job Checking method

1 Check the connection and locking condition of

the throttle position sensor coupler.

Disconnect the coupler and check the pins.

(bent or broken terminals and locking condition

of the pins)Poor connection → Properly con-

nect, repair, or replace.Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 2.

2 Check the connection and locking condition of

the wire harness ECU coupler.

Disconnect the coupler and check the pins.

(bent or broken terminals and locking condition

of the pins)Poor connection → Properly con-

nect, repair, or replace.Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 3.

3 Continuity of harness Open or short circuit → Replace.

Between throttle position sensor

coupler and ECU coupler.

(Black/Blue–Black/Blue)

(Yellow–Yellow)

(Blue–Blue)Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 4.

4 Installed condition of sensor.

• Make sure that the installation position is cor-

rect.

• Make sure that there are no problems with the

installation.Check that the sensor is installed

securely and that there are no

pinched leads.Check that the ECU

is installed securely and that there

are no pinched leads.

Incorrect installation → Reinstall

or repair.

Incorrect installation position →

Properly install.Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 5.

Page 202 of 228

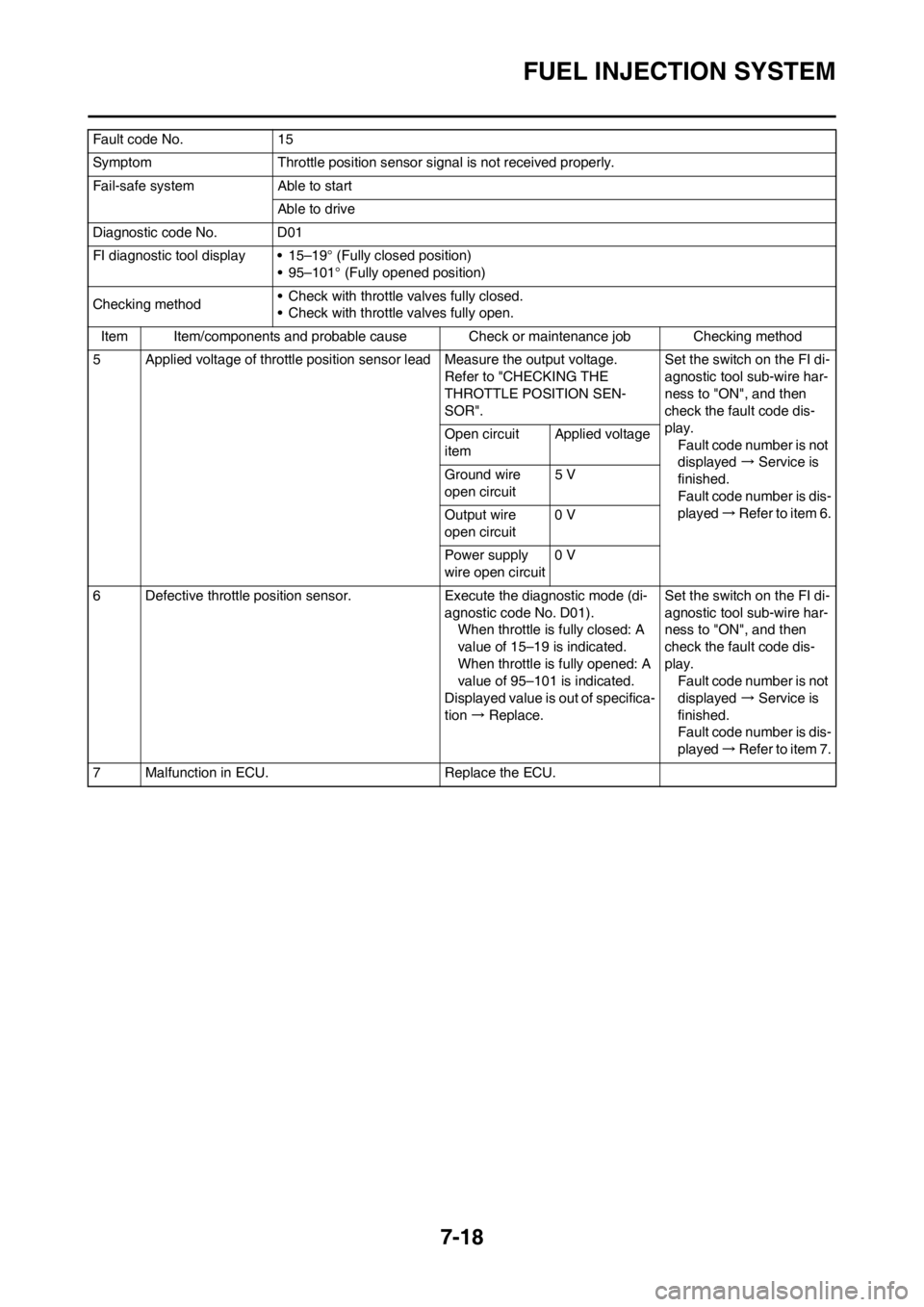

7-18

FUEL INJECTION SYSTEM

5 Applied voltage of throttle position sensor lead Measure the output voltage.

Refer to "CHECKING THE

THROTTLE POSITION SEN-

SOR".Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 6. Open circuit

itemApplied voltage

Ground wire

open circuit5 V

Output wire

open circuit0 V

Power supply

wire open circuit0 V

6 Defective throttle position sensor. Execute the diagnostic mode (di-

agnostic code No. D01).

When throttle is fully closed: A

value of 15–19 is indicated.

When throttle is fully opened: A

value of 95–101 is indicated.

Displayed value is out of specifica-

tion → Replace. Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 7.

7 Malfunction in ECU. Replace the ECU. Fault code No. 15

Symptom Throttle position sensor signal is not received properly.

Fail-safe system Able to start

Able to drive

Diagnostic code No. D01

FI diagnostic tool display • 15–19° (Fully closed position)

• 95–101° (Fully opened position)

Checking method• Check with throttle valves fully closed.

• Check with throttle valves fully open.

Item Item/components and probable cause Check or maintenance job Checking method

Page 203 of 228

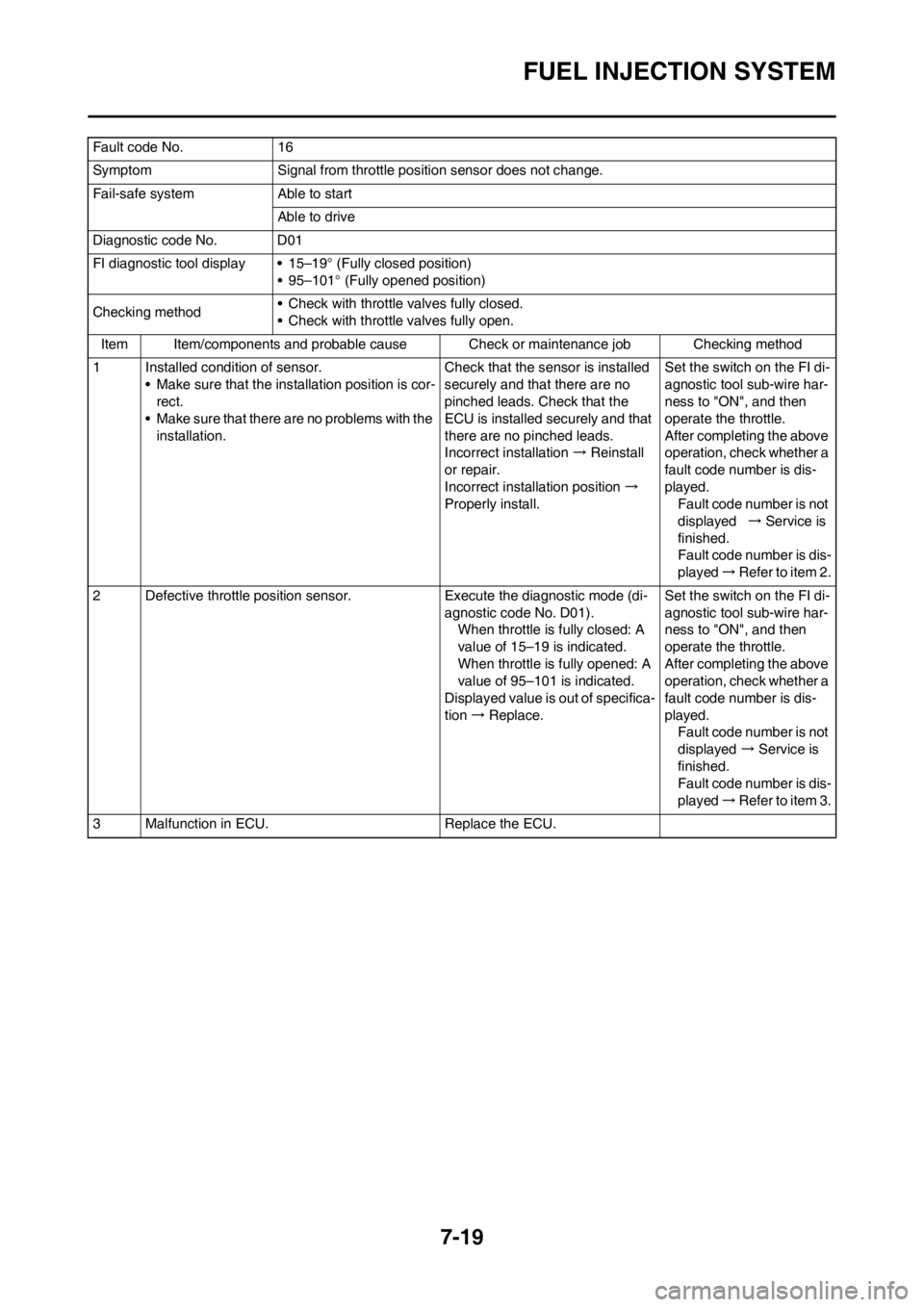

7-19

FUEL INJECTION SYSTEM

Fault code No. 16

Symptom Signal from throttle position sensor does not change.

Fail-safe system Able to start

Able to drive

Diagnostic code No. D01

FI diagnostic tool display • 15–19° (Fully closed position)

• 95–101° (Fully opened position)

Checking method• Check with throttle valves fully closed.

• Check with throttle valves fully open.

Item Item/components and probable cause Check or maintenance job Checking method

1 Installed condition of sensor.

• Make sure that the installation position is cor-

rect.

• Make sure that there are no problems with the

installation.Check that the sensor is installed

securely and that there are no

pinched leads. Check that the

ECU is installed securely and that

there are no pinched leads.

Incorrect installation → Reinstall

or repair.

Incorrect installation position →

Properly install.Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

operate the throttle.

After completing the above

operation, check whether a

fault code number is dis-

played.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 2.

2 Defective throttle position sensor. Execute the diagnostic mode (di-

agnostic code No. D01).

When throttle is fully closed: A

value of 15–19 is indicated.

When throttle is fully opened: A

value of 95–101 is indicated.

Displayed value is out of specifica-

tion → Replace.Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

operate the throttle.

After completing the above

operation, check whether a

fault code number is dis-

played.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 3.

3 Malfunction in ECU. Replace the ECU.

Page 214 of 228

7-30

FUEL INJECTION SYSTEM

Fault code No. 44

Symptom Error is detected while reading or writing on EEPROM.

Fail-safe system Able to start engine (depending on circumstances)

Able to drive vehicle (depending on circumstances)

Diagnostic code No. D60

FI diagnostic tool display 00: No fault

01: CO adjustment valve

07: Power Tuner adjustment values 0–8 for fuel injection amount or ignition timing

Checking method —

Item Item/components and probable cause Check or maintenance job Checking method

1 Determine the area of the problem Execute the diagnostic mode (di-

agnostic code No. D60).

00 is displayed: Refer to item 4.

01 is displayed: Refer to item 2.

07 is displayed: Refer to item 3.Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Repeat item 1.

If the fault code number

is still displayed, refer to

item 3.

2 EEPROM data error (CO adjustment value) Change the CO density and write

the changed setting on EEPROM.Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Repeat item 1.

If the fault code number

is still displayed, refer to

item 4.

3 EEPROM data error (Power Tuner adjustment

values for fuel injection amount or ignition tim-

ing)Erase the setting map in the diag-

nostic mode (diagnostic code No.

D65).Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 1.

4 Malfunction in ECU. Replace the ECU.