air filter YAMAHA YZ450F 2012 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2012, Model line: YZ450F, Model: YAMAHA YZ450F 2012Pages: 228, PDF Size: 11.42 MB

Page 18 of 228

1-8

FEATURES

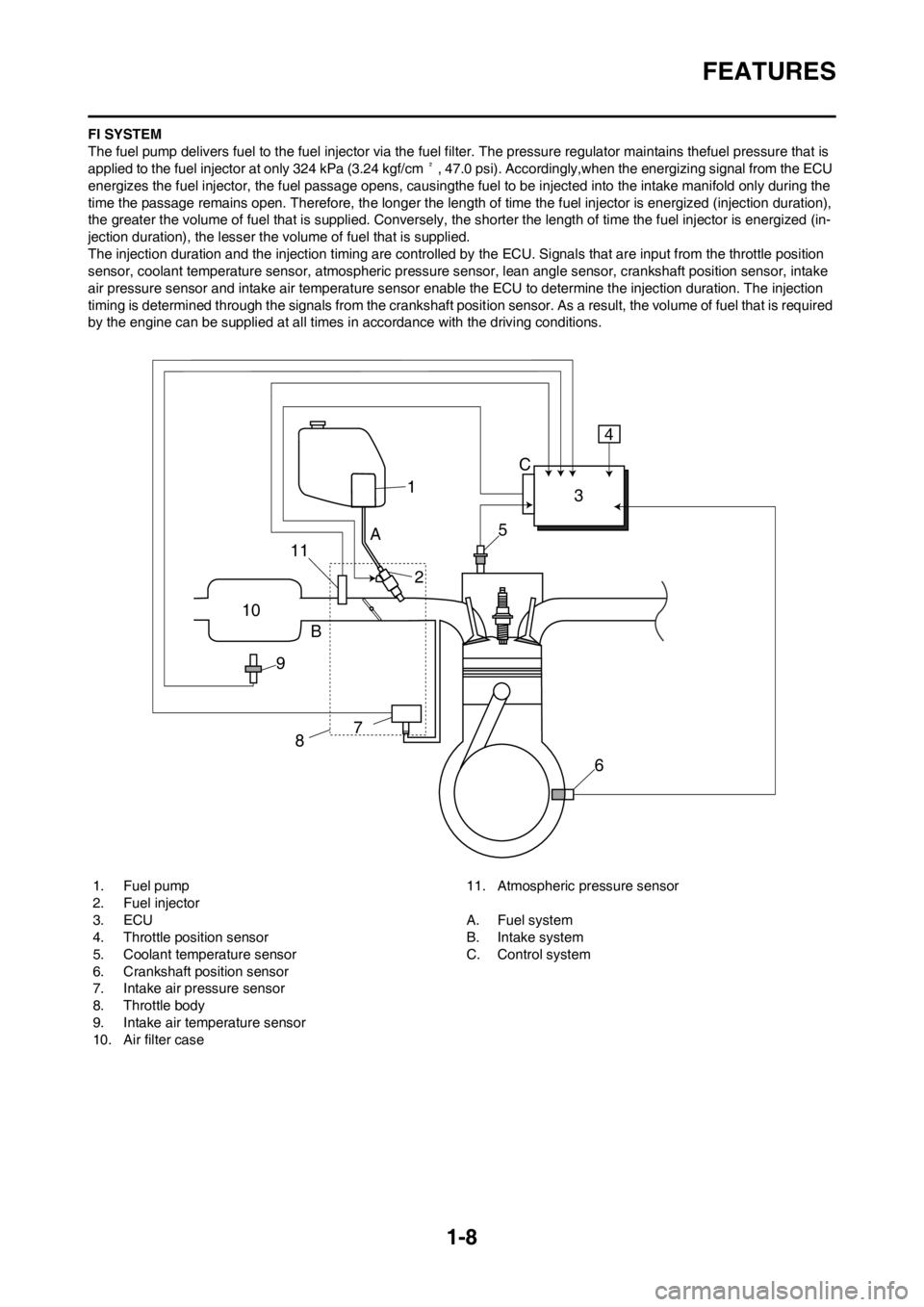

FI SYSTEM

The fuel pump delivers fuel to the fuel injector via the fuel filter. The pressure regulator maintains thefuel pressure that is

applied to the fuel injector at only 324 kPa (3.24 kgf/cm², 47.0 psi). Accordingly,when the energizing signal from the ECU

energizes the fuel injector, the fuel passage opens, causingthe fuel to be injected into the intake manifold only during the

time the passage remains open. Therefore, the longer the length of time the fuel injector is energized (injection duration),

the greater the volume of fuel that is supplied. Conversely, the shorter the length of time the fuel injector is energized (in-

jection duration), the lesser the volume of fuel that is supplied.

The injection duration and the injection timing are controlled by the ECU. Signals that are input from the throttle position

sensor, coolant temperature sensor, atmospheric pressure sensor, lean angle sensor, crankshaft position sensor, intake

air pressure sensor and intake air temperature sensor enable the ECU to determine the injection duration. The injection

timing is determined through the signals from the crankshaft position sensor. As a result, the volume of fuel that is required

by the engine can be supplied at all times in accordance with the driving conditions.

1. Fuel pump

2. Fuel injector

3. ECU

4. Throttle position sensor

5. Coolant temperature sensor

6. Crankshaft position sensor

7. Intake air pressure sensor

8. Throttle body

9. Intake air temperature sensor

10. Air filter case11. Atmospheric pressure sensor

A. Fuel system

B. Intake system

C. Control system

1

10

9B

87

6 5

A

23 C4

11

Page 28 of 228

1-18

STARTING AND BREAK-IN

• Unlike a two-stroke engine, this

engine cannot be kick started

when the throttle is open be-

cause the kickstarter may kick

back. Also, if the throttle is open

the air/fuel mixture may be too

lean for the engine to start.

• Before starting the machine, per-

form the checks in the pre-opera-

tion check list.

AIR FILTER MAINTENANCE

According to "CLEANING THE AIR

FILTER ELEMENT" section in the

CHAPTER 3, apply the foam-air-filter

oil or its equivalent to the element.

(Excess oil in the element may ad-

versely affect engine starting.)

STARTING A COLD ENGINE

1. Inspect the coolant level.

2. Shift the transmission into neutral.

3. Pull the starter knob/ idle screw

"1" to its full length.

Use the starter knob/ idle screw be-

low an air temperature of 15°C

(59°F).

4. Push the kickstarter down lightly

with your foot until resistance is

felt.

5. With the throttle fully closed, fold

out the kickstarter lever, move it

down lightly with your foot until the

gears engage, and then push it

down smoothly but forcefully.

Do not open the throttle while kick-

ing the kickstarter crank. Other-

wise, the kickstarter crank may

kick back.

If the engine fails to start, give the

kickstarter 10 to 20 slow kicks at full

throttle in order to clear the engine of

the rich air-fuel mixture retained in it.

6. When the engine starts running,

warm it up one or two minutes at

a steady speed (of 3,000 to 5,000

r/min), and then return the starter

knob/ idle screw to its original po-

sition.

7. Push the engine stop switch "1".

Do not warm up the engine for ex-

tended periods of time.

STARTING A WARM ENGINE

To start a warm engine, make sure

that the starter (choke) knob/idling

screw is pushed in and the throttle is

closed, and then start the engine by

pushing the kickstarter.

If the engine fails to start, give the

kickstarter 10 to 20 slow kicks at full

throttle in order to clear the engine of

the rich air-fuel mixture retained in it.

BREAK-IN PROCEDURES

1. Before starting the engine, fill the

fuel tank with the fuel.

2. Perform the pre-operation checks

on the machine.

3. Start and warm up the engine.

Check the idle speed, and check

the operation of the controls and

the engine stop switch. Then, re-

start the engine and check its op-

eration within no more than 5

minutes after it is restarted.

4. Operate the machine in the lower

gears at moderate throttle open-

ings for five to eight minutes.

5. Check how the engine runs when

the machine is ridden with the

throttle 1/4 to 1/2 open (low to me-

dium speed) for about one hour.6. Restart the engine and check the

operation of the machine through-

out its entire operating range. Re-

start the machine and operate it

for about 10 to 15 more minutes.

The machine will now be ready to

race.

• After the break-in or before each

race, you must check the entire

machine for loose fittings and

fasteners as per "TORQUE-

CHECK POINTS". Tighten all

such fasteners as required.

• When any of the following parts

have been replaced, they must

be broken in.

CYLINDER AND CRANKSHAFT:

About one hour of break-in oper-

ation is necessary.

PISTON, RING, VALVES, CAM-

SHAFTS AND GEARS:

These parts require about 30

minutes of break-in operation at

half-throttle or less. Observe the

condition of the engine carefully

during operation.

Page 31 of 228

2-1

GENERAL SPECIFICATIONS

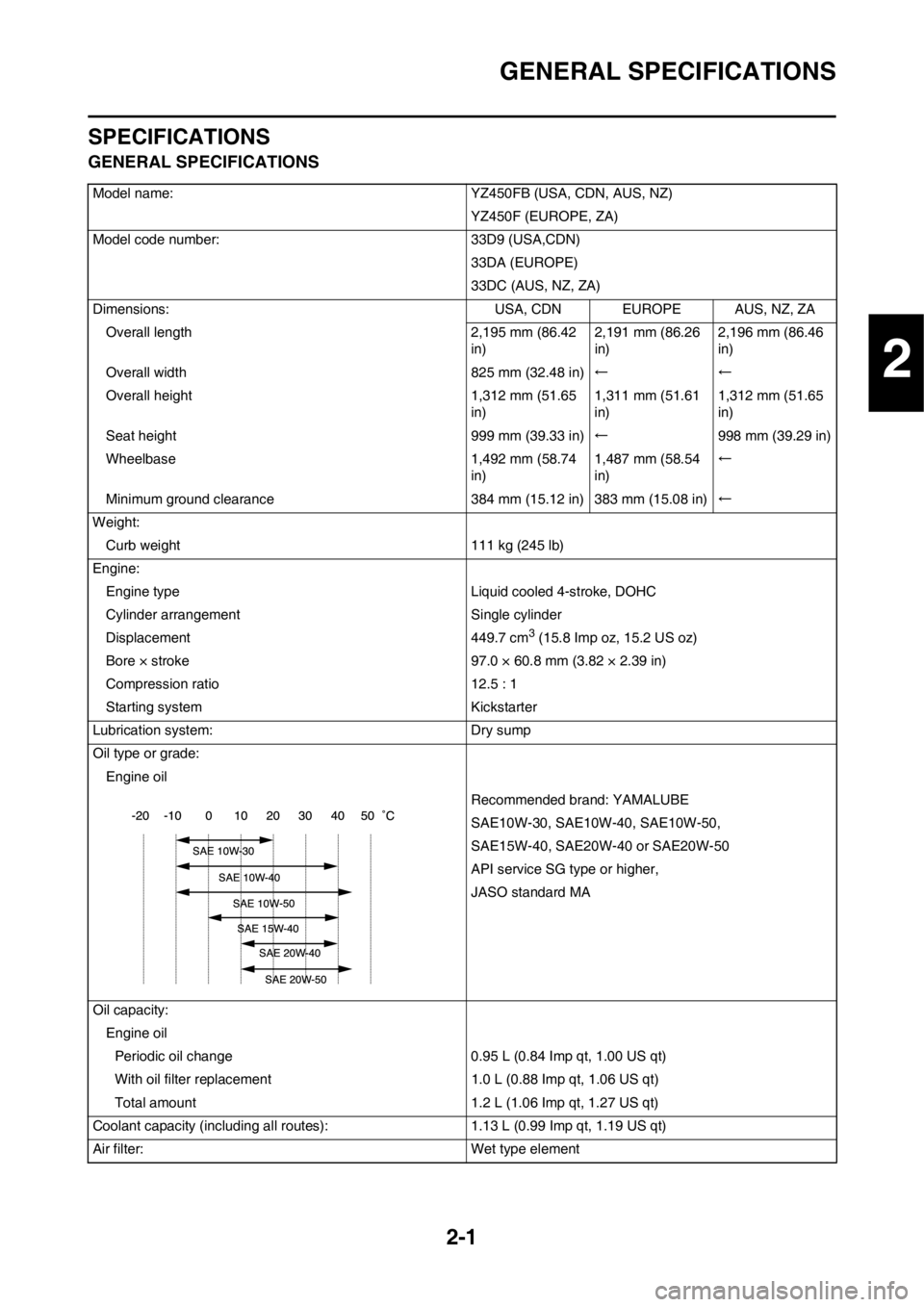

SPECIFICATIONS

GENERAL SPECIFICATIONS

Model name: YZ450FB (USA, CDN, AUS, NZ)

YZ450F (EUROPE, ZA)

Model code number: 33D9 (USA,CDN)

33DA (EUROPE)

33DC (AUS, NZ, ZA)

Dimensions: USA, CDN EUROPE AUS, NZ, ZA

Overall length 2,195 mm (86.42

in)2,191 mm (86.26

in)2,196 mm (86.46

in)

Overall width 825 mm (32.48 in)←←

Overall height 1,312 mm (51.65

in)1,311 mm (51.61

in)1,312 mm (51.65

in)

Seat height 999 mm (39.33 in)←998 mm (39.29 in)

Wheelbase 1,492 mm (58.74

in)1,487 mm (58.54

in)←

Minimum ground clearance 384 mm (15.12 in) 383 mm (15.08 in)←

Weight:

Curb weight 111 kg (245 lb)

Engine:

Engine type Liquid cooled 4-stroke, DOHC

Cylinder arrangement Single cylinder

Displacement 449.7 cm

3 (15.8 Imp oz, 15.2 US oz)

Bore × stroke 97.0 × 60.8 mm (3.82 × 2.39 in)

Compression ratio 12.5 : 1

Starting system Kickstarter

Lubrication system: Dry sump

Oil type or grade:

Engine oil

Recommended brand: YAMALUBE

SAE10W-30, SAE10W-40, SAE10W-50,

SAE15W-40, SAE20W-40 or SAE20W-50

API service SG type or higher,

JASO standard MA

Oil capacity:

Engine oil

Periodic oil change 0.95 L (0.84 Imp qt, 1.00 US qt)

With oil filter replacement 1.0 L (0.88 Imp qt, 1.06 US qt)

Total amount 1.2 L (1.06 Imp qt, 1.27 US qt)

Coolant capacity (including all routes): 1.13 L (0.99 Imp qt, 1.19 US qt)

Air filter: Wet type element

2

Page 37 of 228

2-7

MAINTENANCE SPECIFICATIONS

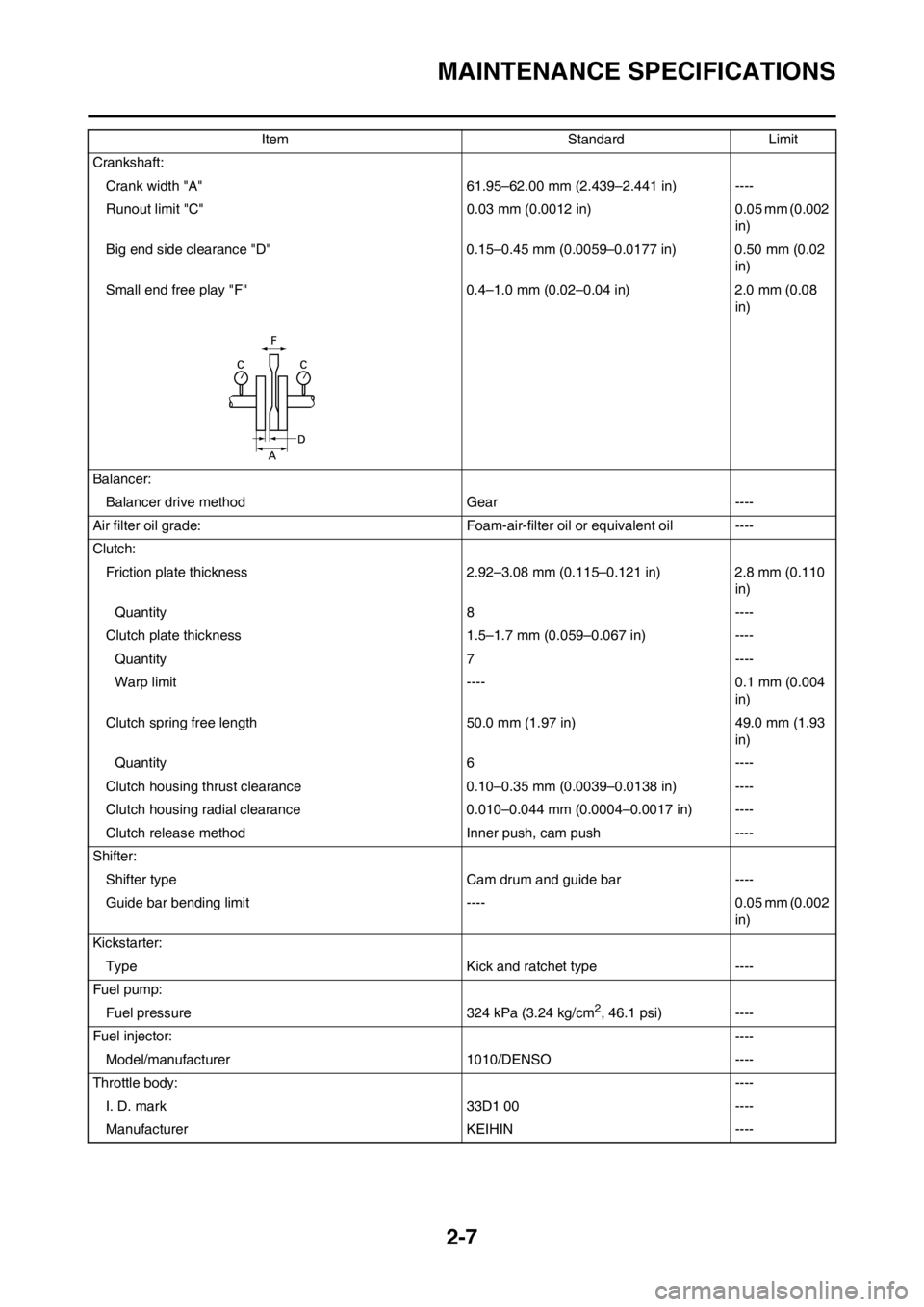

Crankshaft:

Crank width "A" 61.95–62.00 mm (2.439–2.441 in) ----

Runout limit "C" 0.03 mm (0.0012 in) 0.05 mm (0.002

in)

Big end side clearance "D" 0.15–0.45 mm (0.0059–0.0177 in) 0.50 mm (0.02

in)

Small end free play "F" 0.4–1.0 mm (0.02–0.04 in) 2.0 mm (0.08

in)

Balancer:

Balancer drive method Gear ----

Air filter oil grade: Foam-air-filter oil or equivalent oil ----

Clutch:

Friction plate thickness 2.92–3.08 mm (0.115–0.121 in) 2.8 mm (0.110

in)

Quantity 8 ----

Clutch plate thickness 1.5–1.7 mm (0.059–0.067 in) ----

Quantity 7 ----

Warp limit ---- 0.1 mm (0.004

in)

Clutch spring free length 50.0 mm (1.97 in) 49.0 mm (1.93

in)

Quantity 6 ----

Clutch housing thrust clearance 0.10–0.35 mm (0.0039–0.0138 in) ----

Clutch housing radial clearance 0.010–0.044 mm (0.0004–0.0017 in) ----

Clutch release method Inner push, cam push ----

Shifter:

Shifter type Cam drum and guide bar ----

Guide bar bending limit ---- 0.05 mm (0.002

in)

Kickstarter:

Type Kick and ratchet type ----

Fuel pump:

Fuel pressure 324 kPa (3.24 kg/cm

2, 46.1 psi) ----

Fuel injector:----

Model/manufacturer 1010/DENSO ----

Throttle body:----

I. D. mark 33D1 00 ----

Manufacturer KEIHIN ----Item Standard Limit

Page 38 of 228

2-8

MAINTENANCE SPECIFICATIONS

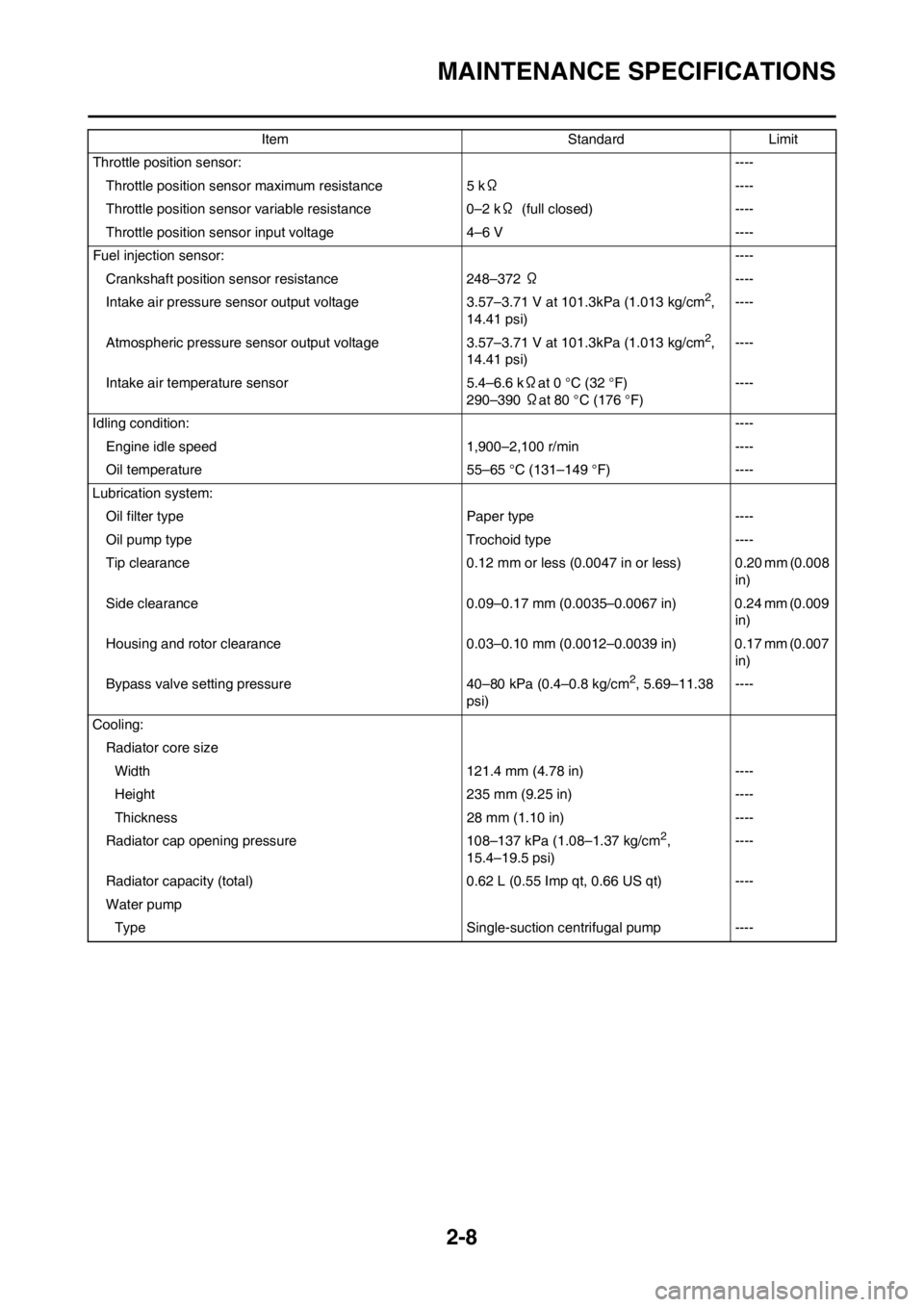

Throttle position sensor:----

Throttle position sensor maximum resistance 5 kΩ----

Throttle position sensor variable resistance 0–2 kΩ (full closed) ----

Throttle position sensor input voltage 4–6 V ----

Fuel injection sensor:----

Crankshaft position sensor resistance 248–372 Ω----

Intake air pressure sensor output voltage 3.57–3.71 V at 101.3kPa (1.013 kg/cm

2,

14.41 psi)----

Atmospheric pressure sensor output voltage 3.57–3.71 V at 101.3kPa (1.013 kg/cm

2,

14.41 psi)----

Intake air temperature sensor 5.4–6.6 kΩat 0 °C (32 °F)

290–390 Ωat 80 °C (176 °F)----

Idling condition:----

Engine idle speed 1,900–2,100 r/min ----

Oil temperature 55–65 °C (131–149 °F) ----

Lubrication system:

Oil filter type Paper type ----

Oil pump type Trochoid type ----

Tip clearance 0.12 mm or less (0.0047 in or less) 0.20 mm (0.008

in)

Side clearance 0.09–0.17 mm (0.0035–0.0067 in) 0.24 mm (0.009

in)

Housing and rotor clearance 0.03–0.10 mm (0.0012–0.0039 in) 0.17 mm (0.007

in)

Bypass valve setting pressure 40–80 kPa (0.4–0.8 kg/cm

2, 5.69–11.38

psi)----

Cooling:

Radiator core size

Width 121.4 mm (4.78 in) ----

Height 235 mm (9.25 in) ----

Thickness 28 mm (1.10 in) ----

Radiator cap opening pressure 108–137 kPa (1.08–1.37 kg/cm

2,

15.4–19.5 psi)----

Radiator capacity (total) 0.62 L (0.55 Imp qt, 0.66 US qt) ----

Water pump

Type Single-suction centrifugal pump ----Item Standard Limit

Page 41 of 228

2-11

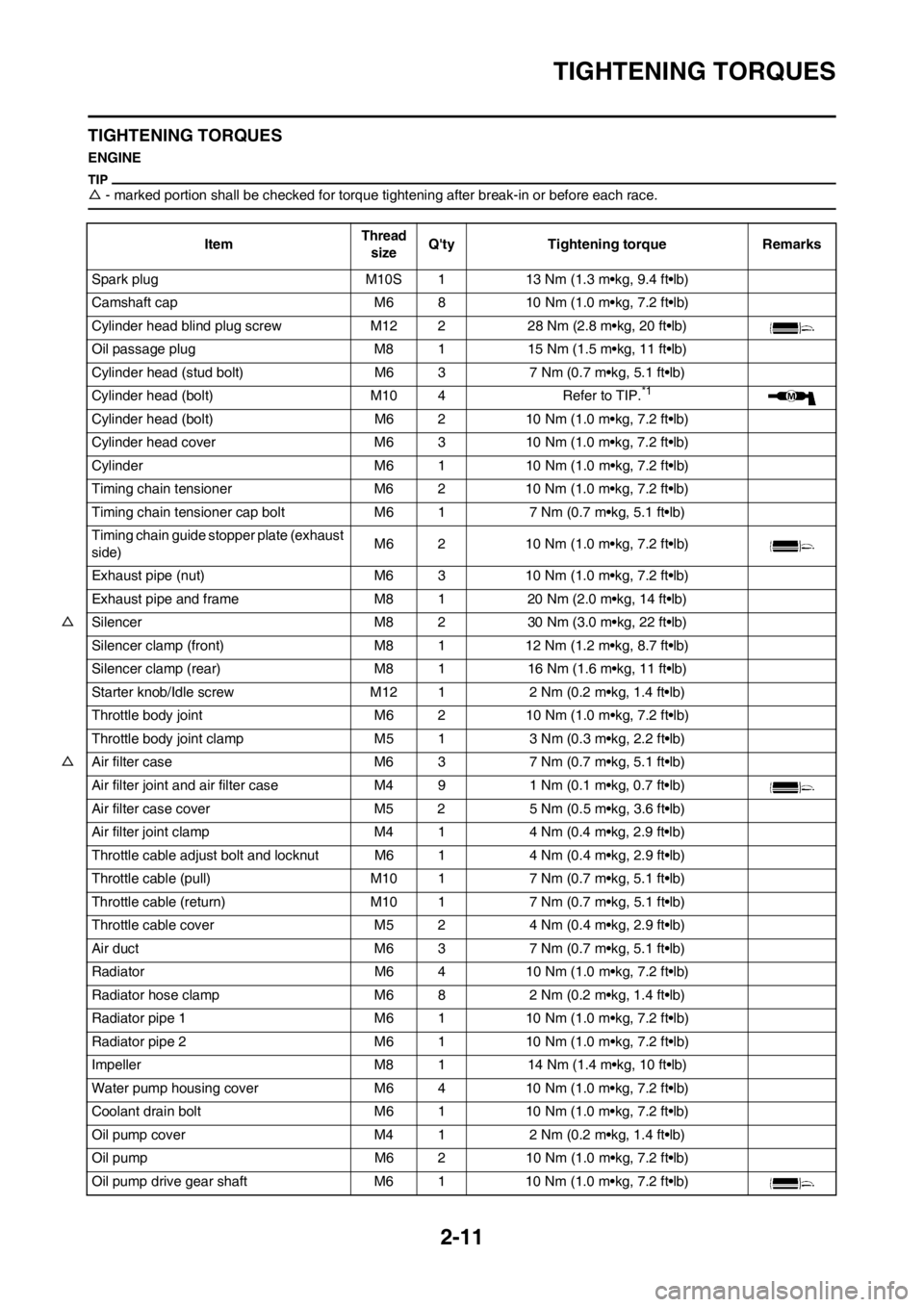

TIGHTENING TORQUES

TIGHTENING TORQUES

ENGINE

△- marked portion shall be checked for torque tightening after break-in or before each race.

ItemThread

sizeQ'ty Tightening torque Remarks

Spark plug M10S 1 13 Nm (1.3 m•kg, 9.4 ft•lb)

Camshaft cap M6 8 10 Nm (1.0 m•kg, 7.2 ft•lb)

Cylinder head blind plug screw M12 2 28 Nm (2.8 m•kg, 20 ft•lb)

Oil passage plug M8 1 15 Nm (1.5 m•kg, 11 ft•lb)

Cylinder head (stud bolt) M6 3 7 Nm (0.7 m•kg, 5.1 ft•lb)

Cylinder head (bolt) M10 4 Refer to TIP.

*1

Cylinder head (bolt) M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Cylinder head cover M6 3 10 Nm (1.0 m•kg, 7.2 ft•lb)

Cylinder M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)

Timing chain tensioner M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Timing chain tensioner cap bolt M6 1 7 Nm (0.7 m•kg, 5.1 ft•lb)

Timing chain guide stopper plate (exhaust

side)M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Exhaust pipe (nut) M6 3 10 Nm (1.0 m•kg, 7.2 ft•lb)

Exhaust pipe and frame M8 1 20 Nm (2.0 m•kg, 14 ft•lb)

△Silencer M8 2 30 Nm (3.0 m•kg, 22 ft•lb)

Silencer clamp (front) M8 1 12 Nm (1.2 m•kg, 8.7 ft•lb)

Silencer clamp (rear) M8 1 16 Nm (1.6 m•kg, 11 ft•lb)

Starter knob/Idle screw M12 1 2 Nm (0.2 m•kg, 1.4 ft•lb)

Throttle body joint M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Throttle body joint clamp M5 1 3 Nm (0.3 m•kg, 2.2 ft•lb)

△Air filter case M6 3 7 Nm (0.7 m•kg, 5.1 ft•lb)

Air filter joint and air filter case M4 9 1 Nm (0.1 m•kg, 0.7 ft•lb)

Air filter case cover M5 2 5 Nm (0.5 m•kg, 3.6 ft•lb)

Air filter joint clamp M4 1 4 Nm (0.4 m•kg, 2.9 ft•lb)

Throttle cable adjust bolt and locknut M6 1 4 Nm (0.4 m•kg, 2.9 ft•lb)

Throttle cable (pull) M10 1 7 Nm (0.7 m•kg, 5.1 ft•lb)

Throttle cable (return) M10 1 7 Nm (0.7 m•kg, 5.1 ft•lb)

Throttle cable cover M5 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Air duct M6 3 7 Nm (0.7 m•kg, 5.1 ft•lb)

Radiator M6 4 10 Nm (1.0 m•kg, 7.2 ft•lb)

Radiator hose clamp M6 8 2 Nm (0.2 m•kg, 1.4 ft•lb)

Radiator pipe 1 M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)

Radiator pipe 2 M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)

Impeller M8 1 14 Nm (1.4 m•kg, 10 ft•lb)

Water pump housing cover M6 4 10 Nm (1.0 m•kg, 7.2 ft•lb)

Coolant drain bolt M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)

Oil pump cover M4 1 2 Nm (0.2 m•kg, 1.4 ft•lb)

Oil pump M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Oil pump drive gear shaft M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)

Page 54 of 228

2-24

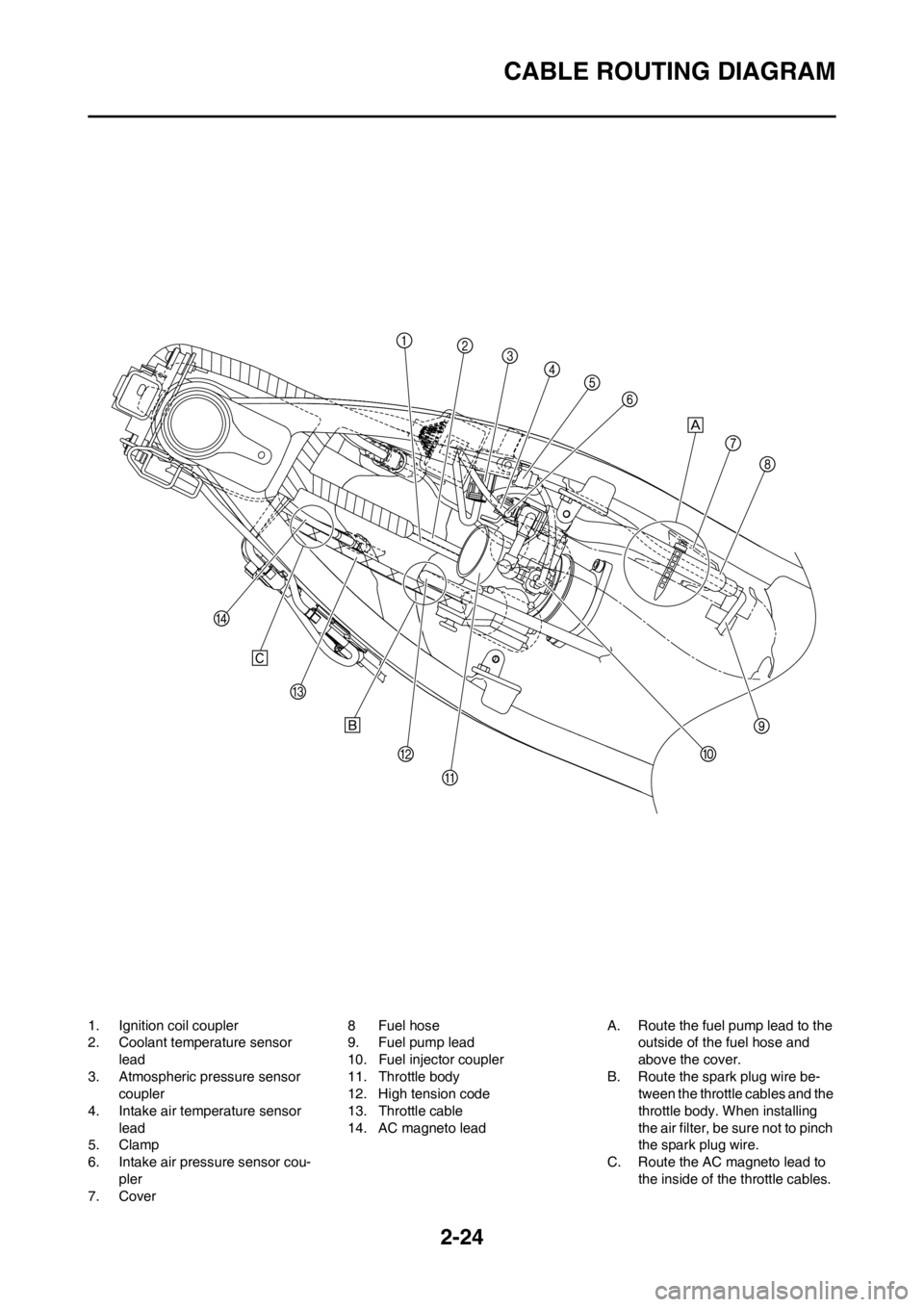

CABLE ROUTING DIAGRAM

1. Ignition coil coupler

2. Coolant temperature sensor

lead

3. Atmospheric pressure sensor

coupler

4. Intake air temperature sensor

lead

5. Clamp

6. Intake air pressure sensor cou-

pler

7. Cover8Fuel hose

9. Fuel pump lead

10. Fuel injector coupler

11. Throttle body

12. High tension code

13. Throttle cable

14. AC magneto leadA. Route the fuel pump lead to the

outside of the fuel hose and

above the cover.

B. Route the spark plug wire be-

tween the throttle cables and the

throttle body. When installing

the air filter, be sure not to pinch

the spark plug wire.

C. Route the AC magneto lead to

the inside of the throttle cables.

Page 59 of 228

3-3

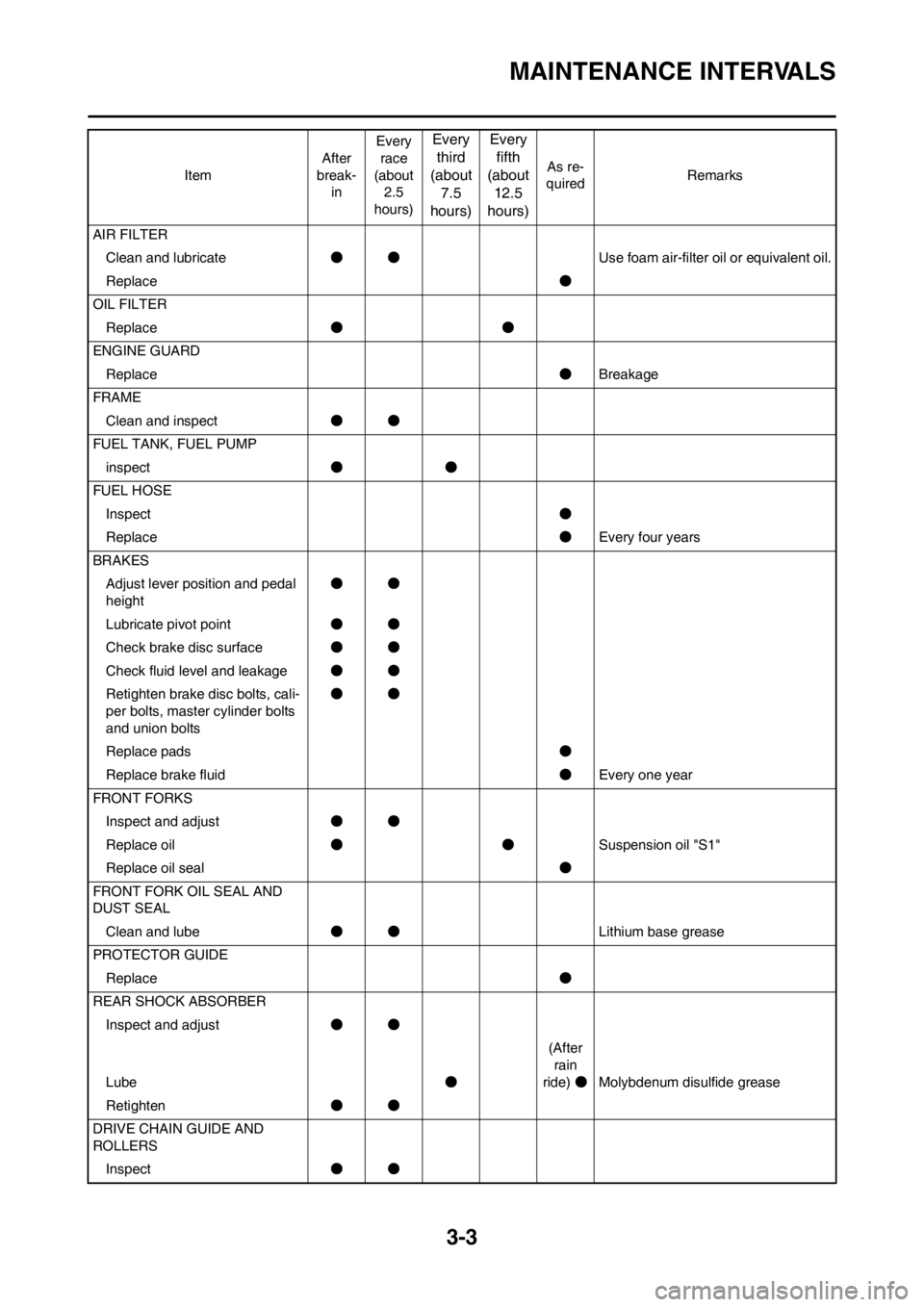

MAINTENANCE INTERVALS

AIR FILTER

Clean and lubricate●●Use foam air-filter oil or equivalent oil.

Replace●

OIL FILTER

Replace●●

ENGINE GUARD

Replace●Breakage

FRAME

Clean and inspect●●

FUEL TANK, FUEL PUMP

inspect●●

FUEL HOSE

Inspect●

Replace●Every four years

BRAKES

Adjust lever position and pedal

height●●

Lubricate pivot point●●

Check brake disc surface●●

Check fluid level and leakage●●

Retighten brake disc bolts, cali-

per bolts, master cylinder bolts

and union bolts●●

Replace pads●

Replace brake fluid●Every one year

FRONT FORKS

Inspect and adjust●●

Replace oil●●Suspension oil "S1"

Replace oil seal●

FRONT FORK OIL SEAL AND

DUST SEAL

Clean and lube●●Lithium base grease

PROTECTOR GUIDE

Replace●

REAR SHOCK ABSORBER

Inspect and adjust●●

Lube●(After

rain

ride)●Molybdenum disulfide grease

Retighten●●

DRIVE CHAIN GUIDE AND

ROLLERS

Inspect●● ItemAfter

break-

inEvery

race

(about

2.5

hours)

Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)

As re-

quiredRemarks

Page 64 of 228

3-8

ENGINE

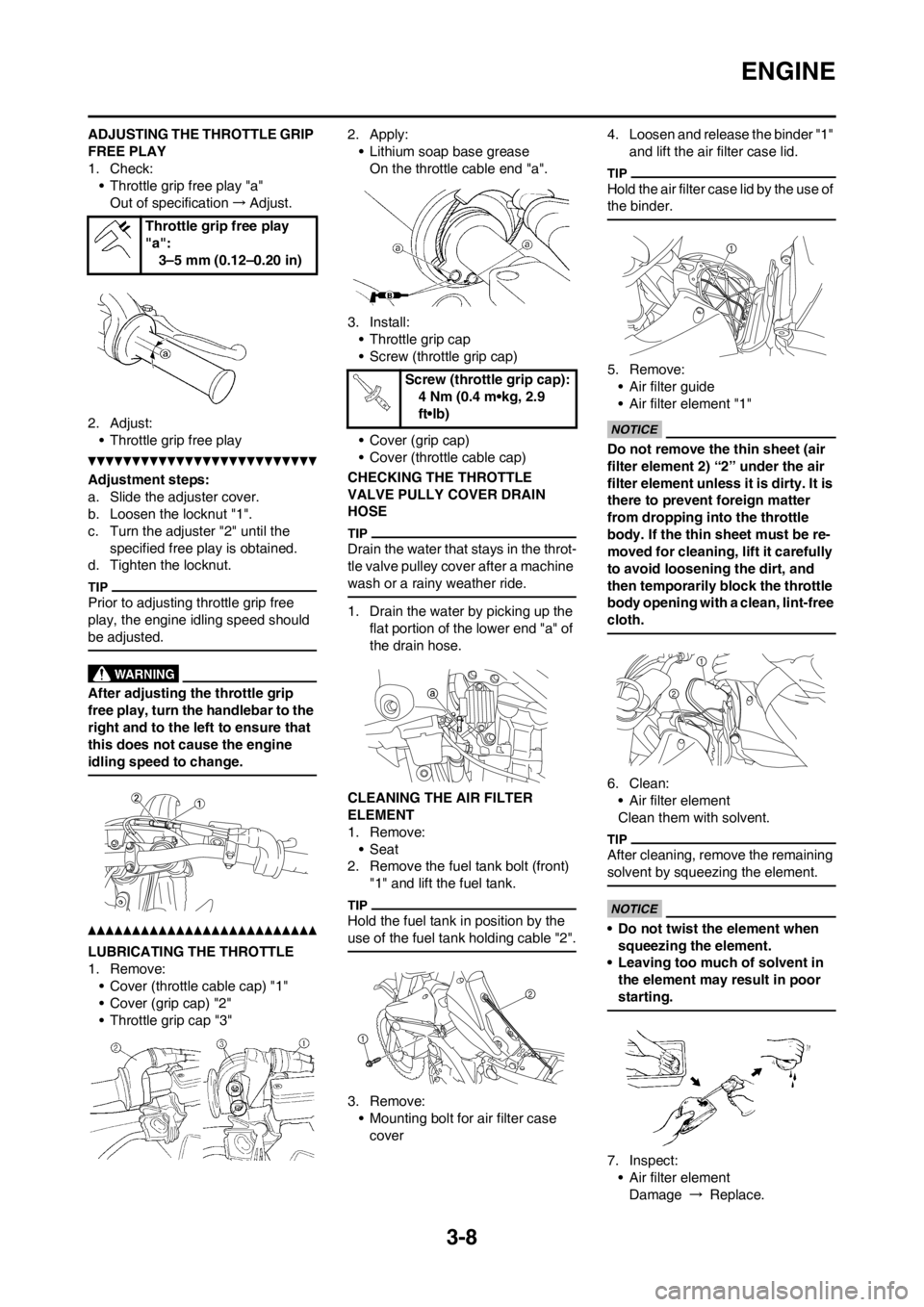

ADJUSTING THE THROTTLE GRIP

FREE PLAY

1. Check:

• Throttle grip free play "a"

Out of specification→Adjust.

2. Adjust:

• Throttle grip free play

Adjustment steps:

a. Slide the adjuster cover.

b. Loosen the locknut "1".

c. Turn the adjuster "2" until the

specified free play is obtained.

d. Tighten the locknut.

Prior to adjusting throttle grip free

play, the engine idling speed should

be adjusted.

After adjusting the throttle grip

free play, turn the handlebar to the

right and to the left to ensure that

this does not cause the engine

idling speed to change.

LUBRICATING THE THROTTLE

1. Remove:

• Cover (throttle cable cap) "1"

• Cover (grip cap) "2"

• Throttle grip cap "3"2. Apply:

• Lithium soap base grease

On the throttle cable end "a".

3. Install:

• Throttle grip cap

• Screw (throttle grip cap)

• Cover (grip cap)

• Cover (throttle cable cap)

CHECKING THE THROTTLE

VALVE PULLY COVER DRAIN

HOSE

Drain the water that stays in the throt-

tle valve pulley cover after a machine

wash or a rainy weather ride.

1. Drain the water by picking up the

flat portion of the lower end "a" of

the drain hose.

CLEANING THE AIR FILTER

ELEMENT

1. Remove:

•Seat

2. Remove the fuel tank bolt (front)

"1" and lift the fuel tank.

Hold the fuel tank in position by the

use of the fuel tank holding cable "2".

3. Remove:

• Mounting bolt for air filter case

cover4. Loosen and release the binder "1"

and lift the air filter case lid.

Hold the air filter case lid by the use of

the binder.

5. Remove:

• Air filter guide

• Air filter element "1"

Do not remove the thin sheet (air

filter element 2) “2” under the air

filter element unless it is dirty. It is

there to prevent foreign matter

from dropping into the throttle

body. If the thin sheet must be re-

moved for cleaning, lift it carefully

to avoid loosening the dirt, and

then temporarily block the throttle

body opening with a clean, lint-free

cloth.

6. Clean:

• Air filter element

Clean them with solvent.

After cleaning, remove the remaining

solvent by squeezing the element.

• Do not twist the element when

squeezing the element.

• Leaving too much of solvent in

the element may result in poor

starting.

7. Inspect:

• Air filter element

Damage → Replace. Throttle grip free play

"a":

3–5 mm (0.12–0.20 in)

Screw (throttle grip cap):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Page 65 of 228

3-9

ENGINE

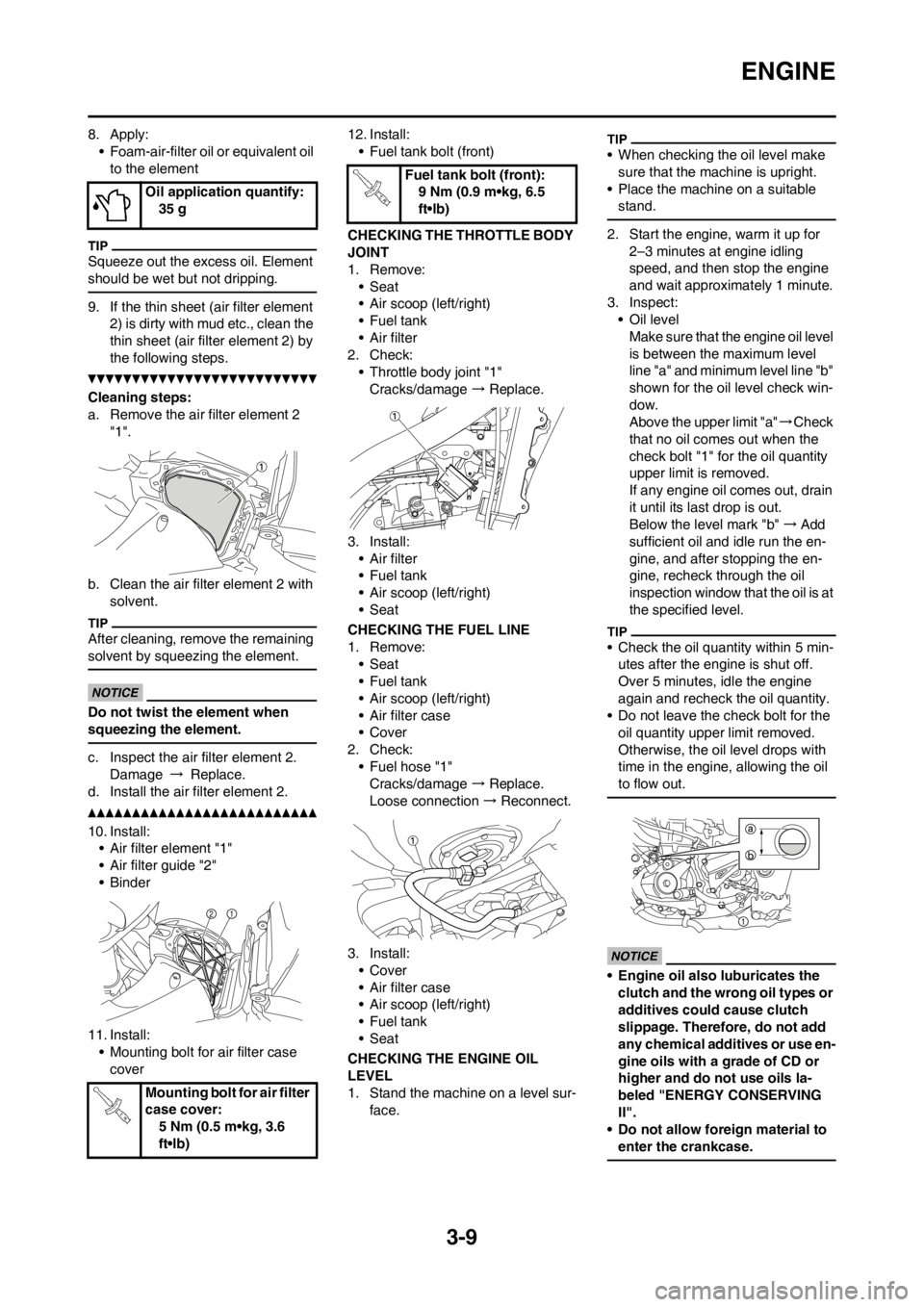

8. Apply:

• Foam-air-filter oil or equivalent oil

to the element

Squeeze out the excess oil. Element

should be wet but not dripping.

9. If the thin sheet (air filter element

2) is dirty with mud etc., clean the

thin sheet (air filter element 2) by

the following steps.

Cleaning steps:

a. Remove the air filter element 2

"1".

b. Clean the air filter element 2 with

solvent.

After cleaning, remove the remaining

solvent by squeezing the element.

Do not twist the element when

squeezing the element.

c. Inspect the air filter element 2.

Damage → Replace.

d. Install the air filter element 2.

10. Install:

• Air filter element "1"

• Air filter guide "2"

•Binder

11. Install:

• Mounting bolt for air filter case

cover12. Install:

• Fuel tank bolt (front)

CHECKING THE THROTTLE BODY

JOINT

1. Remove:

•Seat

• Air scoop (left/right)

•Fuel tank

• Air filter

2. Check:

• Throttle body joint "1"

Cracks/damage → Replace.

3. Install:

• Air filter

•Fuel tank

• Air scoop (left/right)

•Seat

CHECKING THE FUEL LINE

1. Remove:

•Seat

•Fuel tank

• Air scoop (left/right)

• Air filter case

• Cover

2. Check:

• Fuel hose "1"

Cracks/damage → Replace.

Loose connection → Reconnect.

3. Install:

• Cover

• Air filter case

• Air scoop (left/right)

•Fuel tank

•Seat

CHECKING THE ENGINE OIL

LEVEL

1. Stand the machine on a level sur-

face.

• When checking the oil level make

sure that the machine is upright.

• Place the machine on a suitable

stand.

2. Start the engine, warm it up for

2–3 minutes at engine idling

speed, and then stop the engine

and wait approximately 1 minute.

3. Inspect:

• Oil level

Make sure that the engine oil level

is between the maximum level

line "a" and minimum level line "b"

shown for the oil level check win-

dow.

Above the upper limit "a"→Check

that no oil comes out when the

check bolt "1" for the oil quantity

upper limit is removed.

If any engine oil comes out, drain

it until its last drop is out.

Below the level mark "b"→Add

sufficient oil and idle run the en-

gine, and after stopping the en-

gine, recheck through the oil

inspection window that the oil is at

the specified level.

• Check the oil quantity within 5 min-

utes after the engine is shut off.

Over 5 minutes, idle the engine

again and recheck the oil quantity.

• Do not leave the check bolt for the

oil quantity upper limit removed.

Otherwise, the oil level drops with

time in the engine, allowing the oil

to flow out.

• Engine oil also luburicates the

clutch and the wrong oil types or

additives could cause clutch

slippage. Therefore, do not add

any chemical additives or use en-

gine oils with a grade of CD or

higher and do not use oils la-

beled "ENERGY CONSERVING

II".

• Do not allow foreign material to

enter the crankcase.

Oil application quantify:

35 g

Mounting bolt for air filter

case cover:

5 Nm (0.5 m•kg, 3.6

ft•lb)

Fuel tank bolt (front):

9 Nm (0.9 m•kg, 6.5

ft•lb)