clock YAMAHA YZ450F 2012 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2012, Model line: YZ450F, Model: YAMAHA YZ450F 2012Pages: 228, PDF Size: 11.42 MB

Page 35 of 228

2-5

MAINTENANCE SPECIFICATIONS

Stem-to-guide clearance (IN) 0.010–0.037 mm (0.0004–0.0015 in) 0.08 mm (0.003

in)

Stem-to-guide clearance (EX) 0.020–0.047 mm (0.0008–0.0019 in) 0.10 mm (0.004

in)

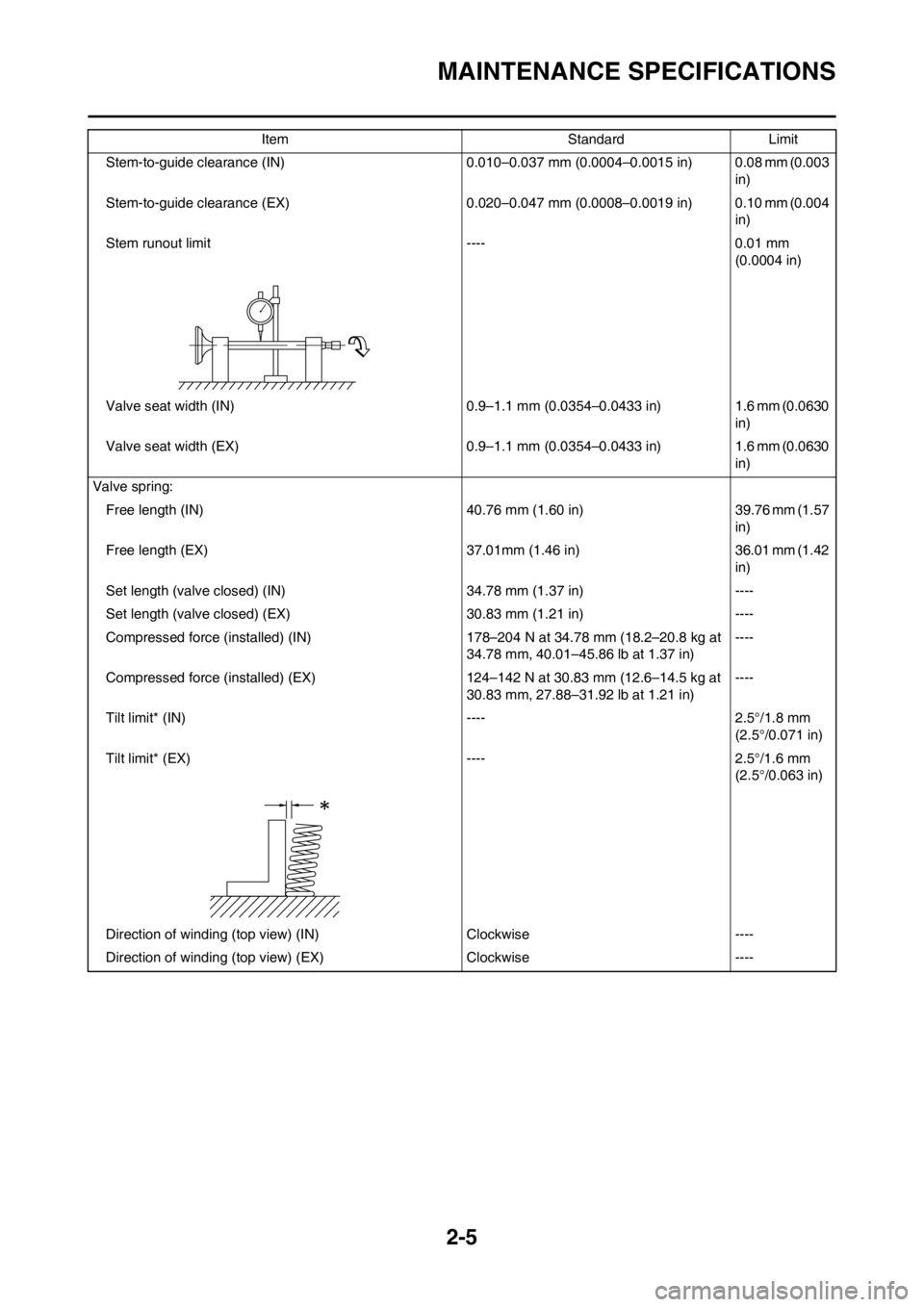

Stem runout limit ---- 0.01 mm

(0.0004 in)

Valve seat width (IN) 0.9–1.1 mm (0.0354–0.0433 in) 1.6 mm (0.0630

in)

Valve seat width (EX) 0.9–1.1 mm (0.0354–0.0433 in) 1.6 mm (0.0630

in)

Valve spring:

Free length (IN) 40.76 mm (1.60 in) 39.76 mm (1.57

in)

Free length (EX) 37.01mm (1.46 in) 36.01 mm (1.42

in)

Set length (valve closed) (IN) 34.78 mm (1.37 in) ----

Set length (valve closed) (EX) 30.83 mm (1.21 in) ----

Compressed force (installed) (IN) 178–204 N at 34.78 mm (18.2–20.8 kg at

34.78 mm, 40.01–45.86 lb at 1.37 in)----

Compressed force (installed) (EX) 124–142 N at 30.83 mm (12.6–14.5 kg at

30.83 mm, 27.88–31.92 lb at 1.21 in)----

Tilt limit* (IN) ---- 2.5°/1.8 mm

(2.5°/0.071 in)

Tilt limit* (EX) ---- 2.5°/1.6 mm

(2.5°/0.063 in)

Direction of winding (top view) (IN) Clockwise ----

Direction of winding (top view) (EX) Clockwise ----Item Standard Limit

Page 62 of 228

3-6

ENGINE

ENGINE

CHECKING THE COOLANT LEVEL

Do not remove the radiator cap

"1", drain bolt and hoses when the

engine and radiator are hot. Scald-

ing hot fluid and steam may be

blown out under pressure, which

could cause serious injury. When

the engine has cooled, place a

thick towel over the radiator cap,

slowly rotate the cap counter-

clockwise to the detent. This pro-

cedure allows any residual

pressure to escape. When the

hissing sound has stopped, press

down on the cap while turning

counterclockwise and remove it.

Hard water or salt water is harmful

to the engine parts. You may use

distilled water, if you can't get soft

water.

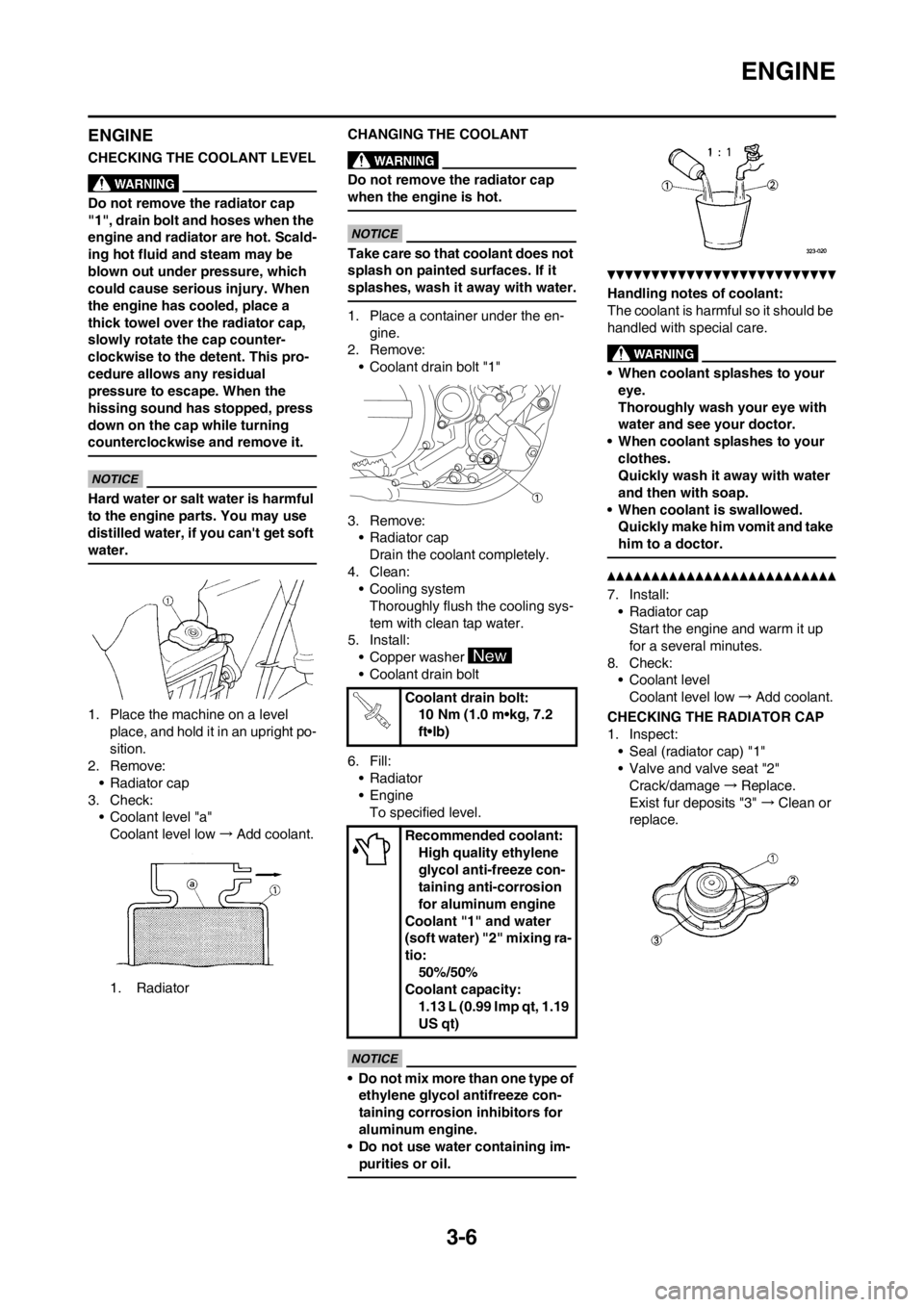

1. Place the machine on a level

place, and hold it in an upright po-

sition.

2. Remove:

• Radiator cap

3. Check:

• Coolant level "a"

Coolant level low→Add coolant.

1. RadiatorCHANGING THE COOLANT

Do not remove the radiator cap

when the engine is hot.

Take care so that coolant does not

splash on painted surfaces. If it

splashes, wash it away with water.

1. Place a container under the en-

gine.

2. Remove:

• Coolant drain bolt "1"

3. Remove:

• Radiator cap

Drain the coolant completely.

4. Clean:

• Cooling system

Thoroughly flush the cooling sys-

tem with clean tap water.

5. Install:

• Copper washer

• Coolant drain bolt

6. Fill:

• Radiator

•Engine

To specified level.

• Do not mix more than one type of

ethylene glycol antifreeze con-

taining corrosion inhibitors for

aluminum engine.

• Do not use water containing im-

purities or oil.

Handling notes of coolant:

The coolant is harmful so it should be

handled with special care.

• When coolant splashes to your

eye.

Thoroughly wash your eye with

water and see your doctor.

• When coolant splashes to your

clothes.

Quickly wash it away with water

and then with soap.

• When coolant is swallowed.

Quickly make him vomit and take

him to a doctor.

7. Install:

• Radiator cap

Start the engine and warm it up

for a several minutes.

8. Check:

• Coolant level

Coolant level low→Add coolant.

CHECKING THE RADIATOR CAP

1. Inspect:

• Seal (radiator cap) "1"

• Valve and valve seat "2"

Crack/damage→Replace.

Exist fur deposits "3" →Clean or

replace.

Coolant drain bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Recommended coolant:

High quality ethylene

glycol anti-freeze con-

taining anti-corrosion

for aluminum engine

Coolant "1" and water

(soft water) "2" mixing ra-

tio:

50%/50%

Coolant capacity:

1.13 L (0.99 Imp qt, 1.19

US qt)

Page 66 of 228

3-10

ENGINE

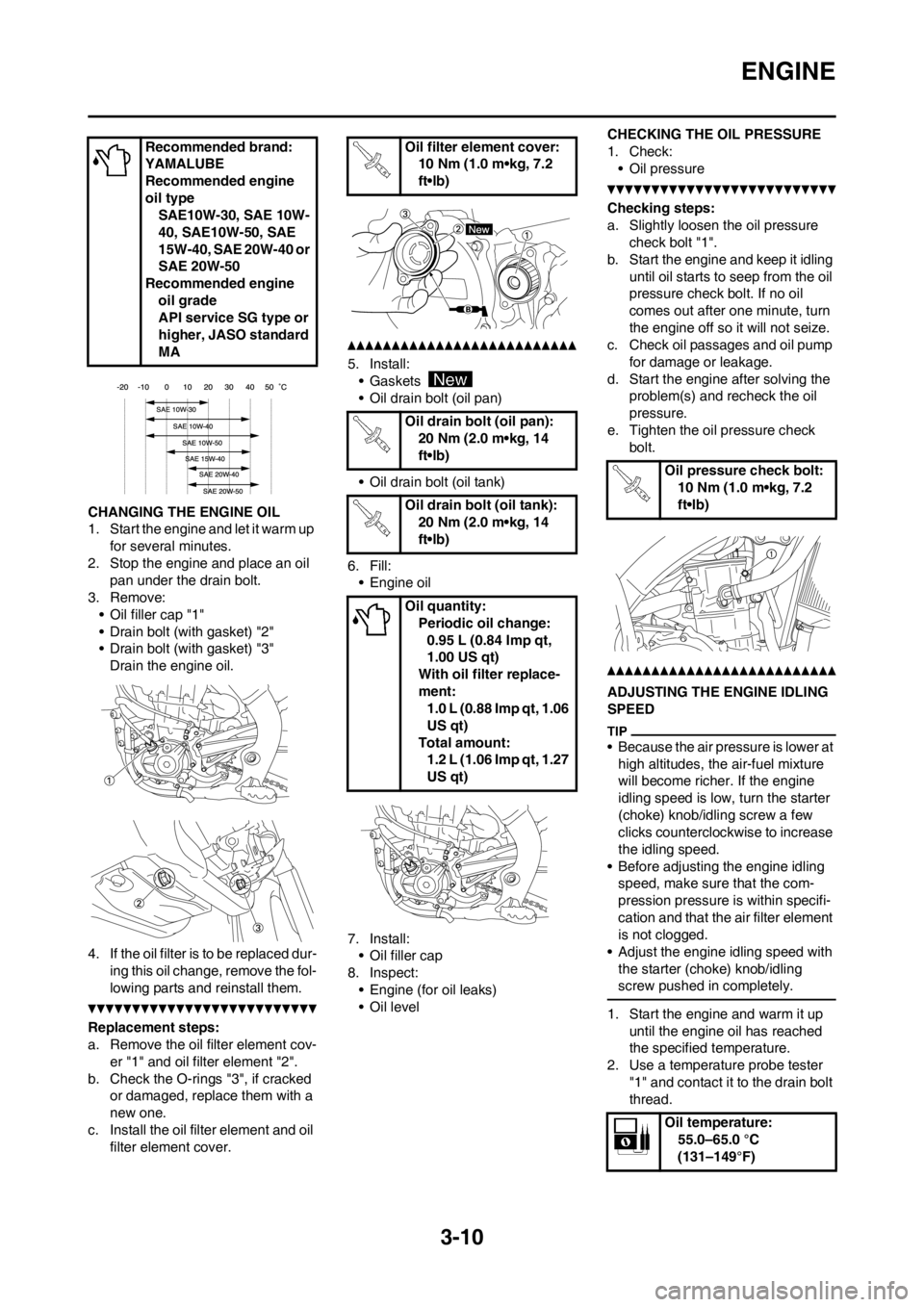

CHANGING THE ENGINE OIL

1. Start the engine and let it warm up

for several minutes.

2. Stop the engine and place an oil

pan under the drain bolt.

3. Remove:

• Oil filler cap "1"

• Drain bolt (with gasket) "2"

• Drain bolt (with gasket) "3"

Drain the engine oil.

4. If the oil filter is to be replaced dur-

ing this oil change, remove the fol-

lowing parts and reinstall them.

Replacement steps:

a. Remove the oil filter element cov-

er "1" and oil filter element "2".

b. Check the O-rings "3", if cracked

or damaged, replace them with a

new one.

c. Install the oil filter element and oil

filter element cover.

5. Install:

• Gaskets

• Oil drain bolt (oil pan)

• Oil drain bolt (oil tank)

6. Fill:

• Engine oil

7. Install:

• Oil filler cap

8. Inspect:

• Engine (for oil leaks)

• Oil levelCHECKING THE OIL PRESSURE

1. Check:

• Oil pressure

Checking steps:

a. Slightly loosen the oil pressure

check bolt "1".

b. Start the engine and keep it idling

until oil starts to seep from the oil

pressure check bolt. If no oil

comes out after one minute, turn

the engine off so it will not seize.

c. Check oil passages and oil pump

for damage or leakage.

d. Start the engine after solving the

problem(s) and recheck the oil

pressure.

e. Tighten the oil pressure check

bolt.

ADJUSTING THE ENGINE IDLING

SPEED

• Because the air pressure is lower at

high altitudes, the air-fuel mixture

will become richer. If the engine

idling speed is low, turn the starter

(choke) knob/idling screw a few

clicks counterclockwise to increase

the idling speed.

• Before adjusting the engine idling

speed, make sure that the com-

pression pressure is within specifi-

cation and that the air filter element

is not clogged.

• Adjust the engine idling speed with

the starter (choke) knob/idling

screw pushed in completely.

1. Start the engine and warm it up

until the engine oil has reached

the specified temperature.

2. Use a temperature probe tester

"1" and contact it to the drain bolt

thread. Recommended brand:

YAMALUBE

Recommended engine

oil type

SAE10W-30, SAE 10W-

40, SAE10W-50, SAE

15W-40, SAE 20W-40 or

SAE 20W-50

Recommended engine

oil grade

API service SG type or

higher, JASO standard

MA

Oil filter element cover:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Oil drain bolt (oil pan):

20 Nm (2.0 m•kg, 14

ft•lb)

Oil drain bolt (oil tank):

20 Nm (2.0 m•kg, 14

ft•lb)

Oil quantity:

Periodic oil change:

0.95 L (0.84 Imp qt,

1.00 US qt)

With oil filter replace-

ment:

1.0 L (0.88 Imp qt, 1.06

US qt)

Total amount:

1.2 L (1.06 Imp qt, 1.27

US qt)

Oil pressure check bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Oil temperature:

55.0–65.0 °C

(131–149°F)

Page 67 of 228

3-11

ENGINE

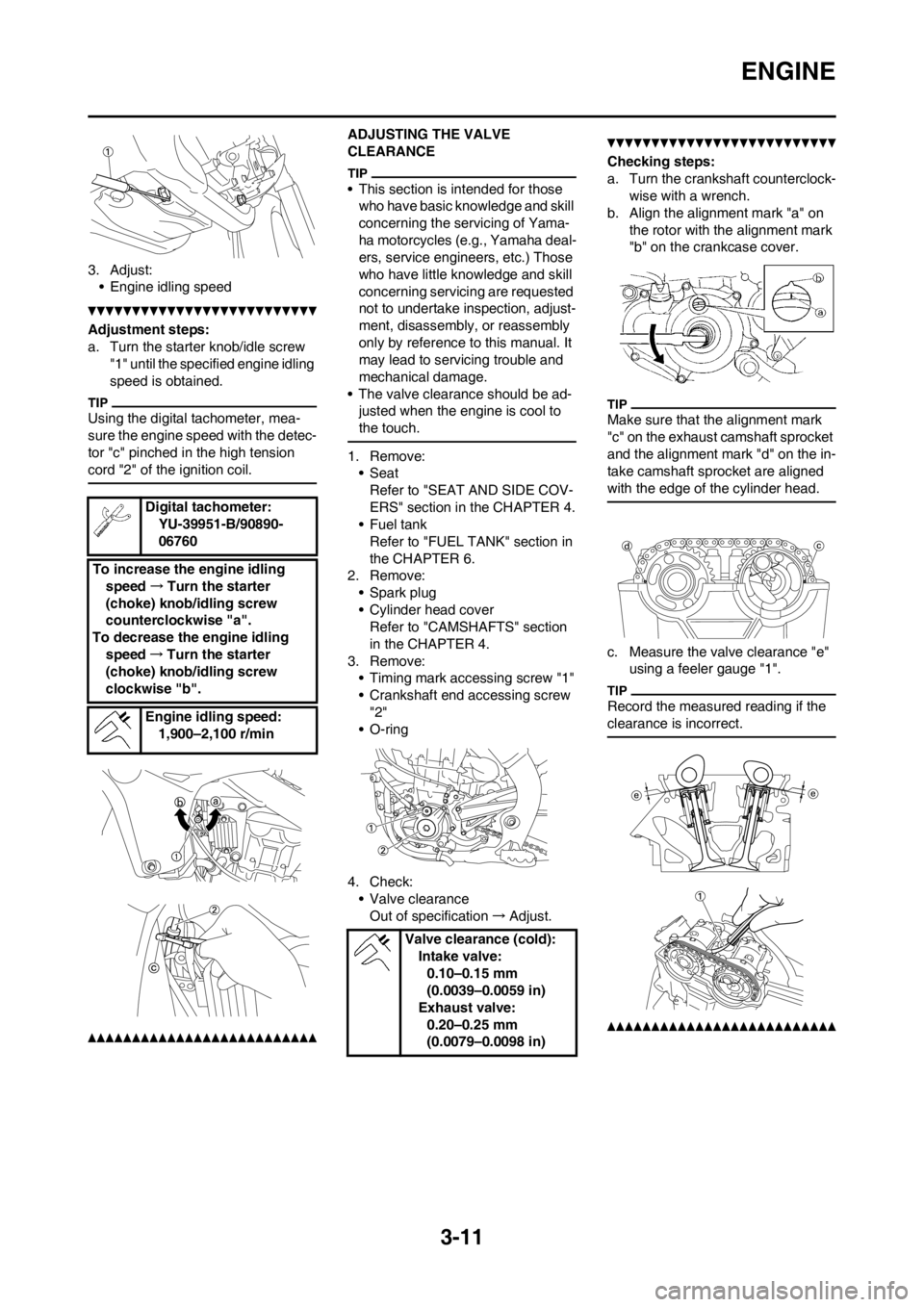

3. Adjust:

• Engine idling speed

Adjustment steps:

a. Turn the starter knob/idle screw

"1" until the specified engine idling

speed is obtained.

Using the digital tachometer, mea-

sure the engine speed with the detec-

tor "c" pinched in the high tension

cord "2" of the ignition coil.

ADJUSTING THE VALVE

CLEARANCE

• This section is intended for those

who have basic knowledge and skill

concerning the servicing of Yama-

ha motorcycles (e.g., Yamaha deal-

ers, service engineers, etc.) Those

who have little knowledge and skill

concerning servicing are requested

not to undertake inspection, adjust-

ment, disassembly, or reassembly

only by reference to this manual. It

may lead to servicing trouble and

mechanical damage.

• The valve clearance should be ad-

justed when the engine is cool to

the touch.

1. Remove:

•Seat

Refer to "SEAT AND SIDE COV-

ERS" section in the CHAPTER 4.

•Fuel tank

Refer to "FUEL TANK" section in

the CHAPTER 6.

2. Remove:

• Spark plug

• Cylinder head cover

Refer to "CAMSHAFTS" section

in the CHAPTER 4.

3. Remove:

• Timing mark accessing screw "1"

• Crankshaft end accessing screw

"2"

• O-ring

4. Check:

• Valve clearance

Out of specification→Adjust.

Checking steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

b. Align the alignment mark "a" on

the rotor with the alignment mark

"b" on the crankcase cover.

Make sure that the alignment mark

"c" on the exhaust camshaft sprocket

and the alignment mark "d" on the in-

take camshaft sprocket are aligned

with the edge of the cylinder head.

c. Measure the valve clearance "e"

using a feeler gauge "1".

Record the measured reading if the

clearance is incorrect.

Digital tachometer:

YU-39951-B/90890-

06760

To increase the engine idling

speed→Turn the starter

(choke) knob/idling screw

counterclockwise "a".

To decrease the engine idling

speed→Turn the starter

(choke) knob/idling screw

clockwise "b".

Engine idling speed:

1,900–2,100 r/min

Valve clearance (cold):

Intake valve:

0.10–0.15 mm

(0.0039–0.0059 in)

Exhaust valve:

0.20–0.25 mm

(0.0079–0.0098 in)

Page 73 of 228

3-17

CHASSIS

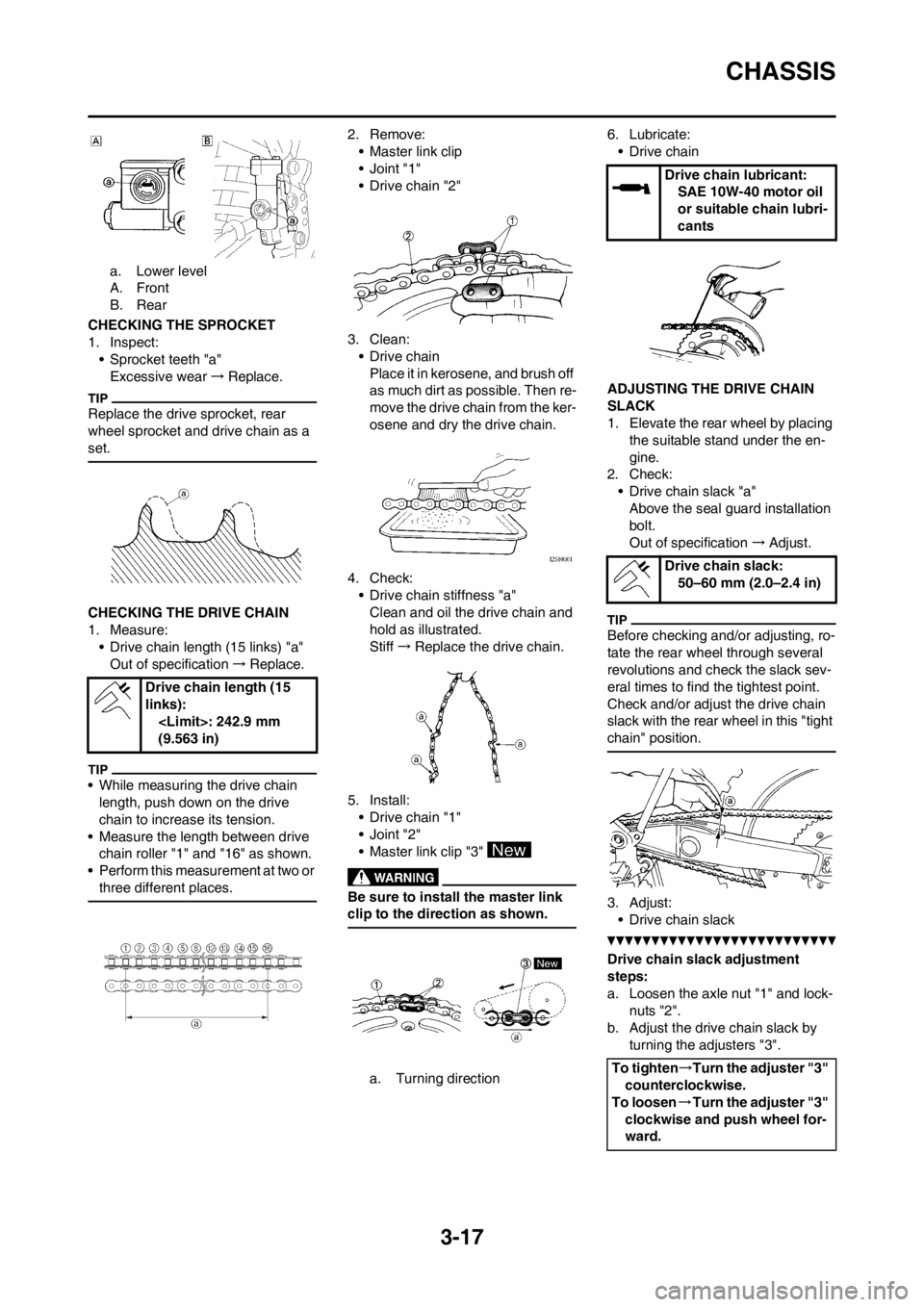

a. Lower level

A. Front

B. Rear

CHECKING THE SPROCKET

1. Inspect:

• Sprocket teeth "a"

Excessive wear→Replace.

Replace the drive sprocket, rear

wheel sprocket and drive chain as a

set.

CHECKING THE DRIVE CHAIN

1. Measure:

• Drive chain length (15 links) "a"

Out of specification→Replace.

• While measuring the drive chain

length, push down on the drive

chain to increase its tension.

• Measure the length between drive

chain roller "1" and "16" as shown.

• Perform this measurement at two or

three different places.

2. Remove:

• Master link clip

•Joint "1"

• Drive chain "2"

3. Clean:

• Drive chain

Place it in kerosene, and brush off

as much dirt as possible. Then re-

move the drive chain from the ker-

osene and dry the drive chain.

4. Check:

• Drive chain stiffness "a"

Clean and oil the drive chain and

hold as illustrated.

Stiff→Replace the drive chain.

5. Install:

• Drive chain "1"

•Joint "2"

• Master link clip "3"

Be sure to install the master link

clip to the direction as shown.

a. Turning direction6. Lubricate:

• Drive chain

ADJUSTING THE DRIVE CHAIN

SLACK

1. Elevate the rear wheel by placing

the suitable stand under the en-

gine.

2. Check:

• Drive chain slack "a"

Above the seal guard installation

bolt.

Out of specification→Adjust.

Before checking and/or adjusting, ro-

tate the rear wheel through several

revolutions and check the slack sev-

eral times to find the tightest point.

Check and/or adjust the drive chain

slack with the rear wheel in this "tight

chain" position.

3. Adjust:

• Drive chain slack

Drive chain slack adjustment

steps:

a. Loosen the axle nut "1" and lock-

nuts "2".

b. Adjust the drive chain slack by

turning the adjusters "3". Drive chain length (15

links):

(9.563 in)

Drive chain lubricant:

SAE 10W-40 motor oil

or suitable chain lubri-

cants

Drive chain slack:

50–60 mm (2.0–2.4 in)

To tighten→Turn the adjuster "3"

counterclockwise.

To loosen→Turn the adjuster "3"

clockwise and push wheel for-

ward.

Page 88 of 228

4-7

RADIATOR

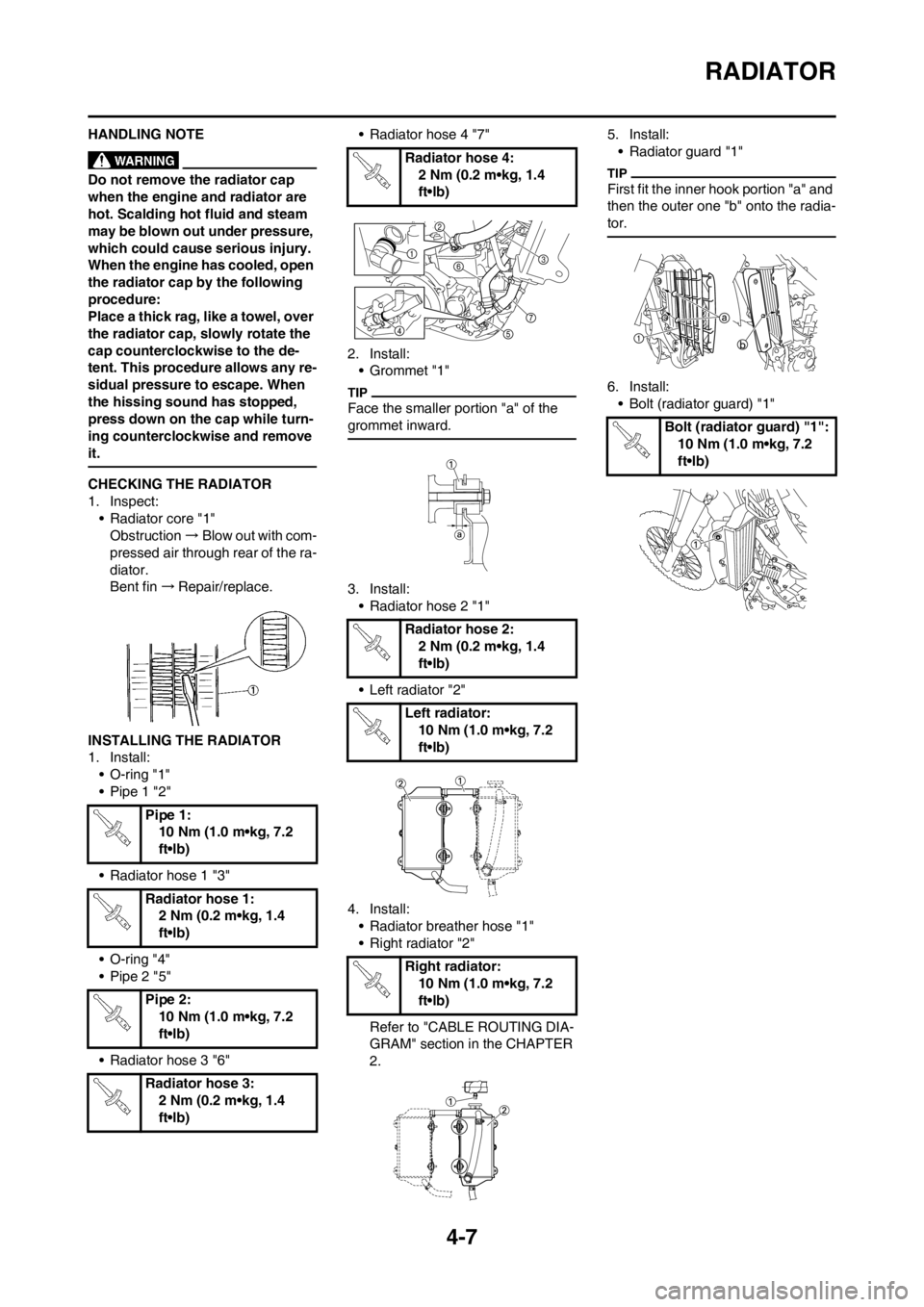

HANDLING NOTE

Do not remove the radiator cap

when the engine and radiator are

hot. Scalding hot fluid and steam

may be blown out under pressure,

which could cause serious injury.

When the engine has cooled, open

the radiator cap by the following

procedure:

Place a thick rag, like a towel, over

the radiator cap, slowly rotate the

cap counterclockwise to the de-

tent. This procedure allows any re-

sidual pressure to escape. When

the hissing sound has stopped,

press down on the cap while turn-

ing counterclockwise and remove

it.

CHECKING THE RADIATOR

1. Inspect:

• Radiator core "1"

Obstruction→Blow out with com-

pressed air through rear of the ra-

diator.

Bent fin→Repair/replace.

INSTALLING THE RADIATOR

1. Install:

• O-ring "1"

• Pipe 1 "2"

• Radiator hose 1 "3"

• O-ring "4"

• Pipe 2 "5"

• Radiator hose 3 "6"• Radiator hose 4 "7"

2. Install:

• Grommet "1"

Face the smaller portion "a" of the

grommet inward.

3. Install:

• Radiator hose 2 "1"

• Left radiator "2"

4. Install:

• Radiator breather hose "1"

• Right radiator "2"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.5. Install:

• Radiator guard "1"

First fit the inner hook portion "a" and

then the outer one "b" onto the radia-

tor.

6. Install:

• Bolt (radiator guard) "1"

Pipe 1:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Radiator hose 1:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Pipe 2:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Radiator hose 3:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Radiator hose 4:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Radiator hose 2:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Left radiator:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Right radiator:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (radiator guard) "1":

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 91 of 228

4-10

CAMSHAFTS

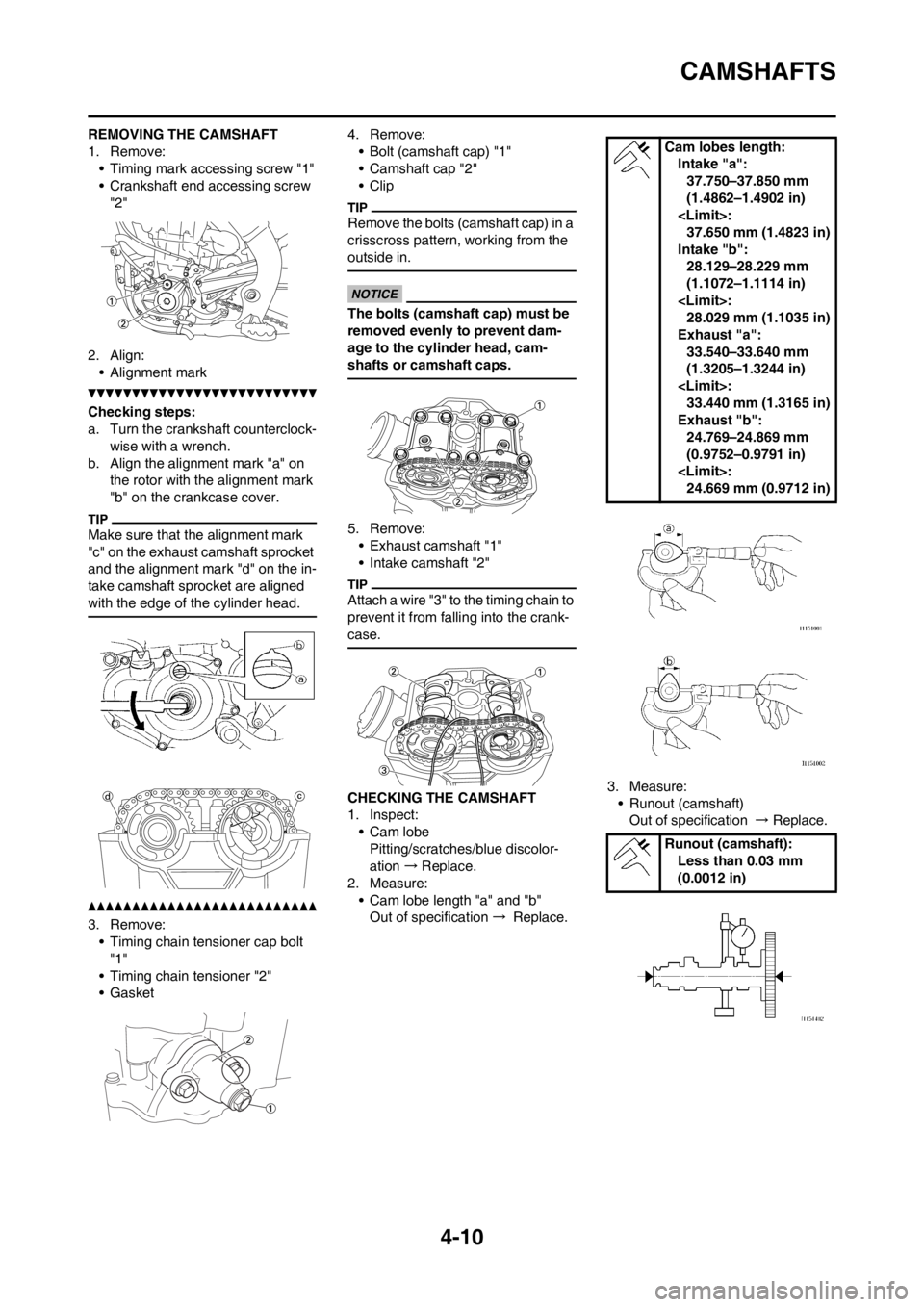

REMOVING THE CAMSHAFT

1. Remove:

• Timing mark accessing screw "1"

• Crankshaft end accessing screw

"2"

2. Align:

• Alignment mark

Checking steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

b. Align the alignment mark "a" on

the rotor with the alignment mark

"b" on the crankcase cover.

Make sure that the alignment mark

"c" on the exhaust camshaft sprocket

and the alignment mark "d" on the in-

take camshaft sprocket are aligned

with the edge of the cylinder head.

3. Remove:

• Timing chain tensioner cap bolt

"1"

• Timing chain tensioner "2"

• Gasket4. Remove:

• Bolt (camshaft cap) "1"

• Camshaft cap "2"

• Clip

Remove the bolts (camshaft cap) in a

crisscross pattern, working from the

outside in.

The bolts (camshaft cap) must be

removed evenly to prevent dam-

age to the cylinder head, cam-

shafts or camshaft caps.

5. Remove:

• Exhaust camshaft "1"

• Intake camshaft "2"

Attach a wire "3" to the timing chain to

prevent it from falling into the crank-

case.

CHECKING THE CAMSHAFT

1. Inspect:

• Cam lobe

Pitting/scratches/blue discolor-

ation → Replace.

2. Measure:

• Cam lobe length "a" and "b"

Out of specification → Replace.3. Measure:

• Runout (camshaft)

Out of specification → Replace.

Cam lobes length:

Intake "a":

37.750–37.850 mm

(1.4862–1.4902 in)

37.650 mm (1.4823 in)

Intake "b":

28.129–28.229 mm

(1.1072–1.1114 in)

28.029 mm (1.1035 in)

Exhaust "a":

33.540–33.640 mm

(1.3205–1.3244 in)

33.440 mm (1.3165 in)

Exhaust "b":

24.769–24.869 mm

(0.9752–0.9791 in)

24.669 mm (0.9712 in)

Runout (camshaft):

Less than 0.03 mm

(0.0012 in)

Page 92 of 228

4-11

CAMSHAFTS

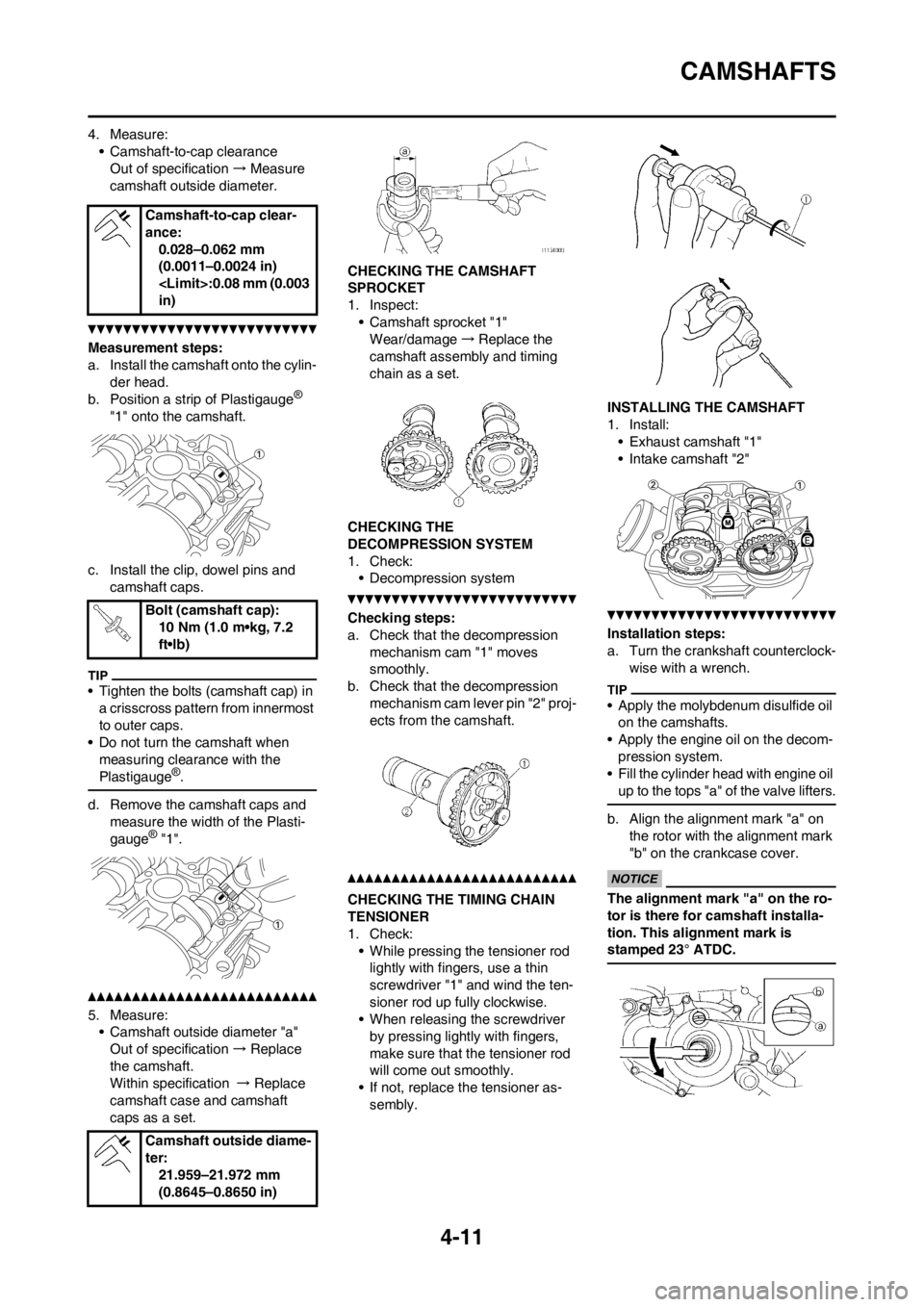

4. Measure:

• Camshaft-to-cap clearance

Out of specification → Measure

camshaft outside diameter.

Measurement steps:

a. Install the camshaft onto the cylin-

der head.

b. Position a strip of Plastigauge

®

"1" onto the camshaft.

c. Install the clip, dowel pins and

camshaft caps.

• Tighten the bolts (camshaft cap) in

a crisscross pattern from innermost

to outer caps.

• Do not turn the camshaft when

measuring clearance with the

Plastigauge

®.

d. Remove the camshaft caps and

measure the width of the Plasti-

gauge

® "1".

5. Measure:

• Camshaft outside diameter "a"

Out of specification → Replace

the camshaft.

Within specification → Replace

camshaft case and camshaft

caps as a set.CHECKING THE CAMSHAFT

SPROCKET

1. Inspect:

• Camshaft sprocket "1"

Wear/damage→Replace the

camshaft assembly and timing

chain as a set.

CHECKING THE

DECOMPRESSION SYSTEM

1. Check:

• Decompression system

Checking steps:

a. Check that the decompression

mechanism cam "1" moves

smoothly.

b. Check that the decompression

mechanism cam lever pin "2" proj-

ects from the camshaft.

CHECKING THE TIMING CHAIN

TENSIONER

1. Check:

• While pressing the tensioner rod

lightly with fingers, use a thin

screwdriver "1" and wind the ten-

sioner rod up fully clockwise.

• When releasing the screwdriver

by pressing lightly with fingers,

make sure that the tensioner rod

will come out smoothly.

• If not, replace the tensioner as-

sembly.INSTALLING THE CAMSHAFT

1. Install:

• Exhaust camshaft "1"

• Intake camshaft "2"

Installation steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

• Apply the molybdenum disulfide oil

on the camshafts.

• Apply the engine oil on the decom-

pression system.

• Fill the cylinder head with engine oil

up to the tops "a" of the valve lifters.

b. Align the alignment mark "a" on

the rotor with the alignment mark

"b" on the crankcase cover.

The alignment mark "a" on the ro-

tor is there for camshaft installa-

tion. This alignment mark is

stamped 23° ATDC.

Camshaft-to-cap clear-

ance:

0.028–0.062 mm

(0.0011–0.0024 in)

in)

Bolt (camshaft cap):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Camshaft outside diame-

ter:

21.959–21.972 mm

(0.8645–0.8650 in)

Page 93 of 228

4-12

CAMSHAFTS

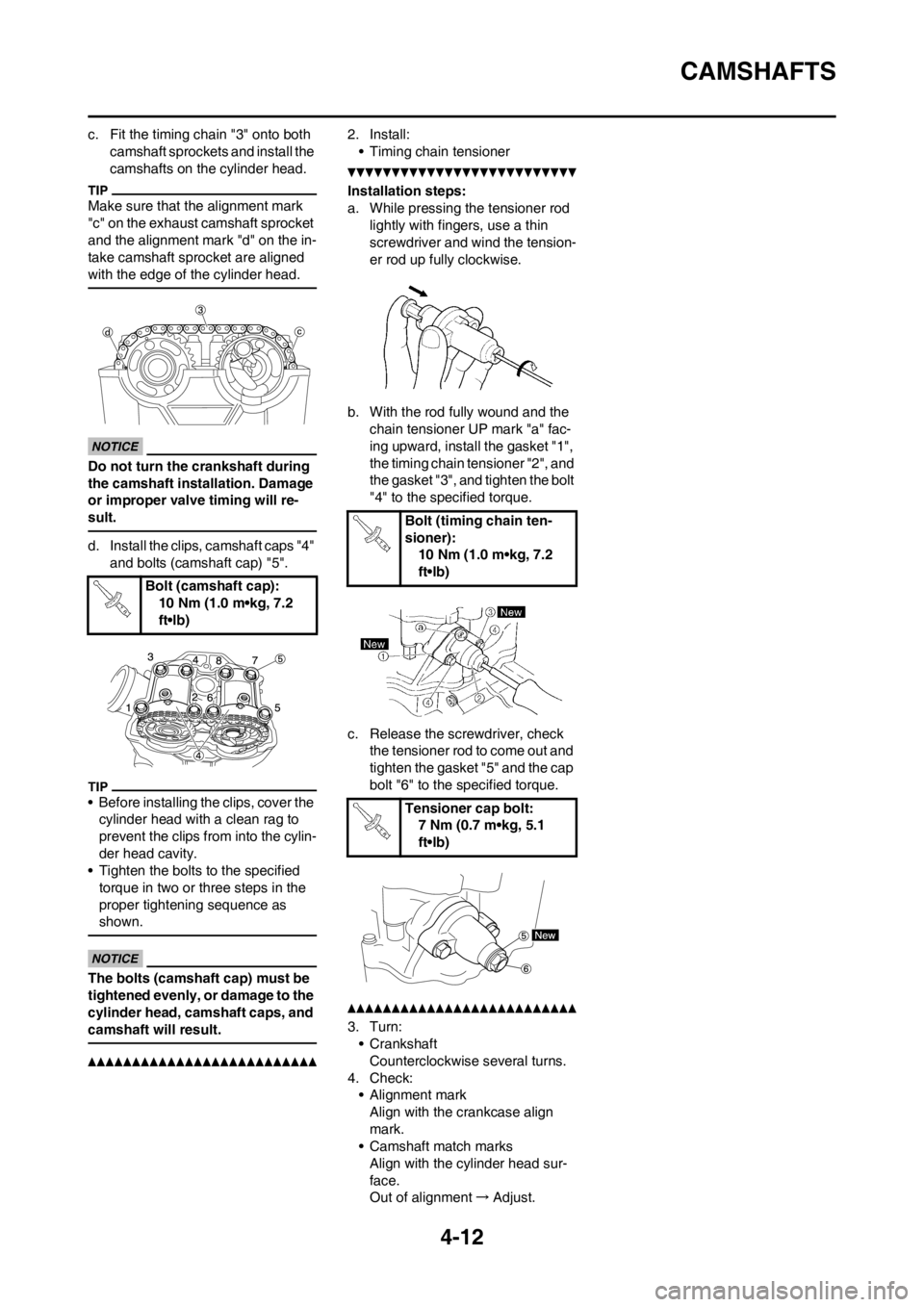

c. Fit the timing chain "3" onto both

camshaft sprockets and install the

camshafts on the cylinder head.

Make sure that the alignment mark

"c" on the exhaust camshaft sprocket

and the alignment mark "d" on the in-

take camshaft sprocket are aligned

with the edge of the cylinder head.

Do not turn the crankshaft during

the camshaft installation. Damage

or improper valve timing will re-

sult.

d. Install the clips, camshaft caps "4"

and bolts (camshaft cap) "5".

• Before installing the clips, cover the

cylinder head with a clean rag to

prevent the clips from into the cylin-

der head cavity.

• Tighten the bolts to the specified

torque in two or three steps in the

proper tightening sequence as

shown.

The bolts (camshaft cap) must be

tightened evenly, or damage to the

cylinder head, camshaft caps, and

camshaft will result.

2. Install:

• Timing chain tensioner

Installation steps:

a. While pressing the tensioner rod

lightly with fingers, use a thin

screwdriver and wind the tension-

er rod up fully clockwise.

b. With the rod fully wound and the

chain tensioner UP mark "a" fac-

ing upward, install the gasket "1",

the timing chain tensioner "2", and

the gasket "3", and tighten the bolt

"4" to the specified torque.

c. Release the screwdriver, check

the tensioner rod to come out and

tighten the gasket "5" and the cap

bolt "6" to the specified torque.

3. Turn:

• Crankshaft

Counterclockwise several turns.

4. Check:

• Alignment mark

Align with the crankcase align

mark.

• Camshaft match marks

Align with the cylinder head sur-

face.

Out of alignment→Adjust. Bolt (camshaft cap):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (timing chain ten-

sioner):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Tensioner cap bolt:

7 Nm (0.7 m•kg, 5.1

ft•lb)

Page 121 of 228

4-40

KICK SHAFT AND SHIFT SHAFT

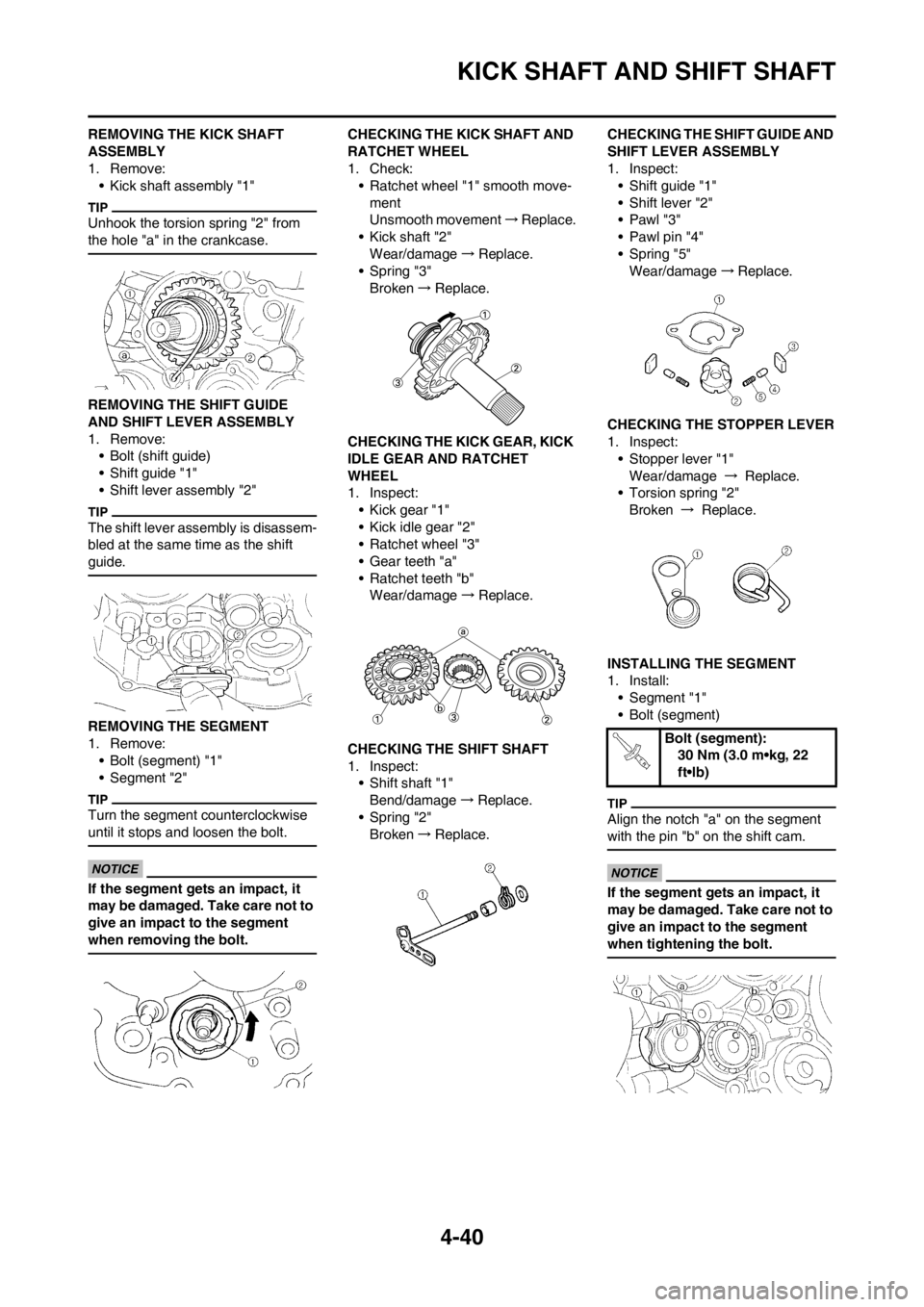

REMOVING THE KICK SHAFT

ASSEMBLY

1. Remove:

• Kick shaft assembly "1"

Unhook the torsion spring "2" from

the hole "a" in the crankcase.

REMOVING THE SHIFT GUIDE

AND SHIFT LEVER ASSEMBLY

1. Remove:

• Bolt (shift guide)

• Shift guide "1"

• Shift lever assembly "2"

The shift lever assembly is disassem-

bled at the same time as the shift

guide.

REMOVING THE SEGMENT

1. Remove:

• Bolt (segment) "1"

• Segment "2"

Turn the segment counterclockwise

until it stops and loosen the bolt.

If the segment gets an impact, it

may be damaged. Take care not to

give an impact to the segment

when removing the bolt.

CHECKING THE KICK SHAFT AND

RATCHET WHEEL

1. Check:

• Ratchet wheel "1" smooth move-

ment

Unsmooth movement→Replace.

• Kick shaft "2"

Wear/damage→Replace.

• Spring "3"

Broken→Replace.

CHECKING THE KICK GEAR, KICK

IDLE GEAR AND RATCHET

WHEEL

1. Inspect:

• Kick gear "1"

• Kick idle gear "2"

• Ratchet wheel "3"

• Gear teeth "a"

• Ratchet teeth "b"

Wear/damage→Replace.

CHECKING THE SHIFT SHAFT

1. Inspect:

• Shift shaft "1"

Bend/damage→Replace.

• Spring "2"

Broken→Replace.CHECKING THE SHIFT GUIDE AND

SHIFT LEVER ASSEMBLY

1. Inspect:

• Shift guide "1"

• Shift lever "2"

•Pawl "3"

• Pawl pin "4"

• Spring "5"

Wear/damage→Replace.

CHECKING THE STOPPER LEVER

1. Inspect:

• Stopper lever "1"

Wear/damage → Replace.

• Torsion spring "2"

Broken → Replace.

INSTALLING THE SEGMENT

1. Install:

• Segment "1"

• Bolt (segment)

Align the notch "a" on the segment

with the pin "b" on the shift cam.

If the segment gets an impact, it

may be damaged. Take care not to

give an impact to the segment

when tightening the bolt.

Bolt (segment):

30 Nm (3.0 m•kg, 22

ft•lb)