sensor YAMAHA YZ450F 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 254 of 360

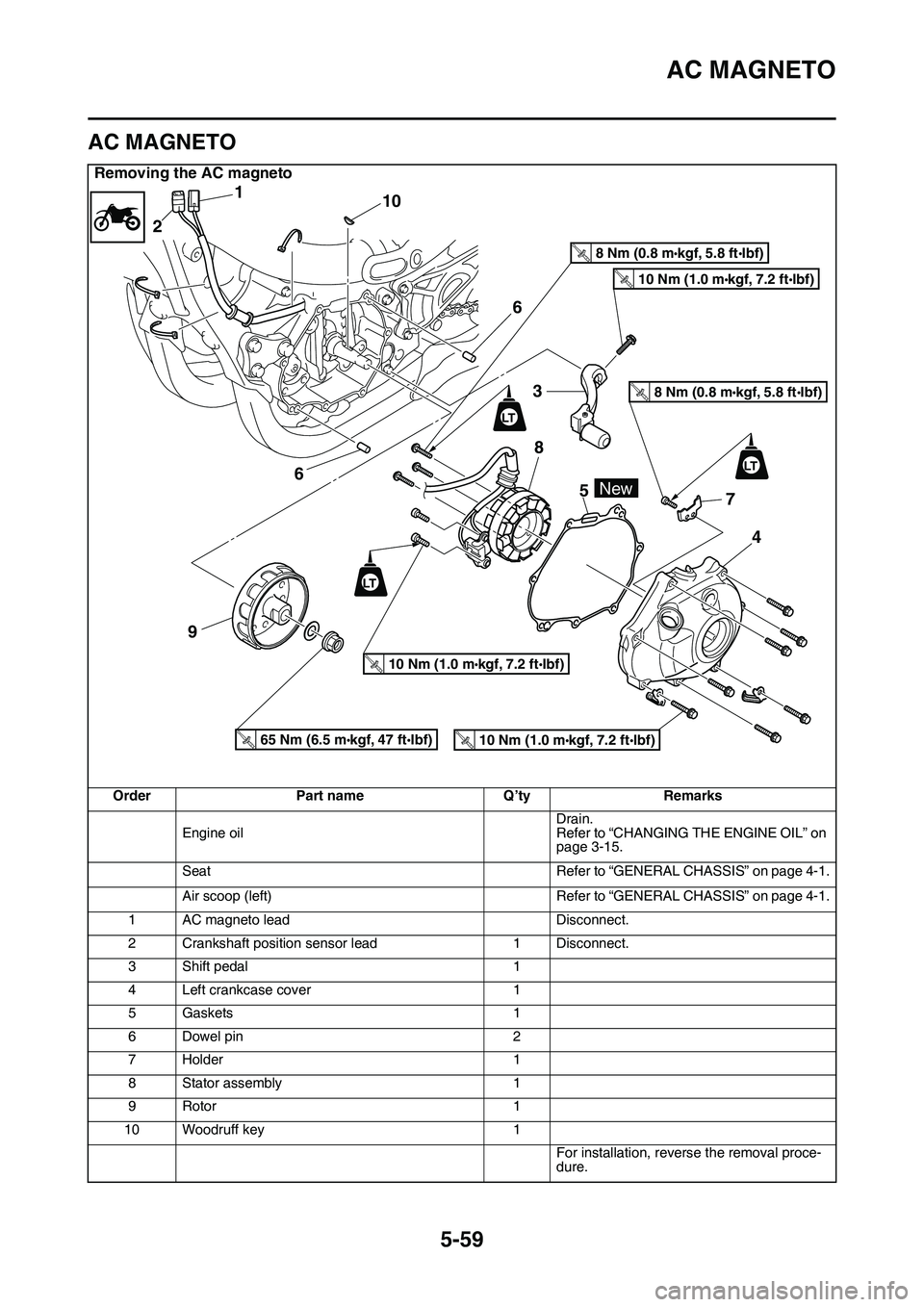

AC MAGNETO

5-59

EAS1SL1272

AC MAGNETO

Removing the AC magneto

OrderPart nameQ’tyRemarks

Engine oilDrain.Refer to “CHANGING THE ENGINE OIL” on page 3-15.

SeatRefer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left)Refer to “GENERAL CHASSIS” on page 4-1.

1AC magneto leadDisconnect.

2Crankshaft position sensor lead1Disconnect.

3Shift pedal1

4Left crankcase cover1

5Gaskets1

6Dowel pin2

7Holder1

8Stator assembly1

9Rotor1

10Woodruff key1

For installation, reverse the removal proce-dure.

110

2

4 7 5 8 3

96

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

8 Nm (0.8 mkgf, 5.8 ftIbf)T.R.

8 Nm (0.8 mkgf, 5.8 ftIbf)T.R.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

65 Nm (6.5 mkgf, 47 ftIbf)T.R.

New

LT

6

LT

LT

Page 255 of 360

AC MAGNETO

5-60

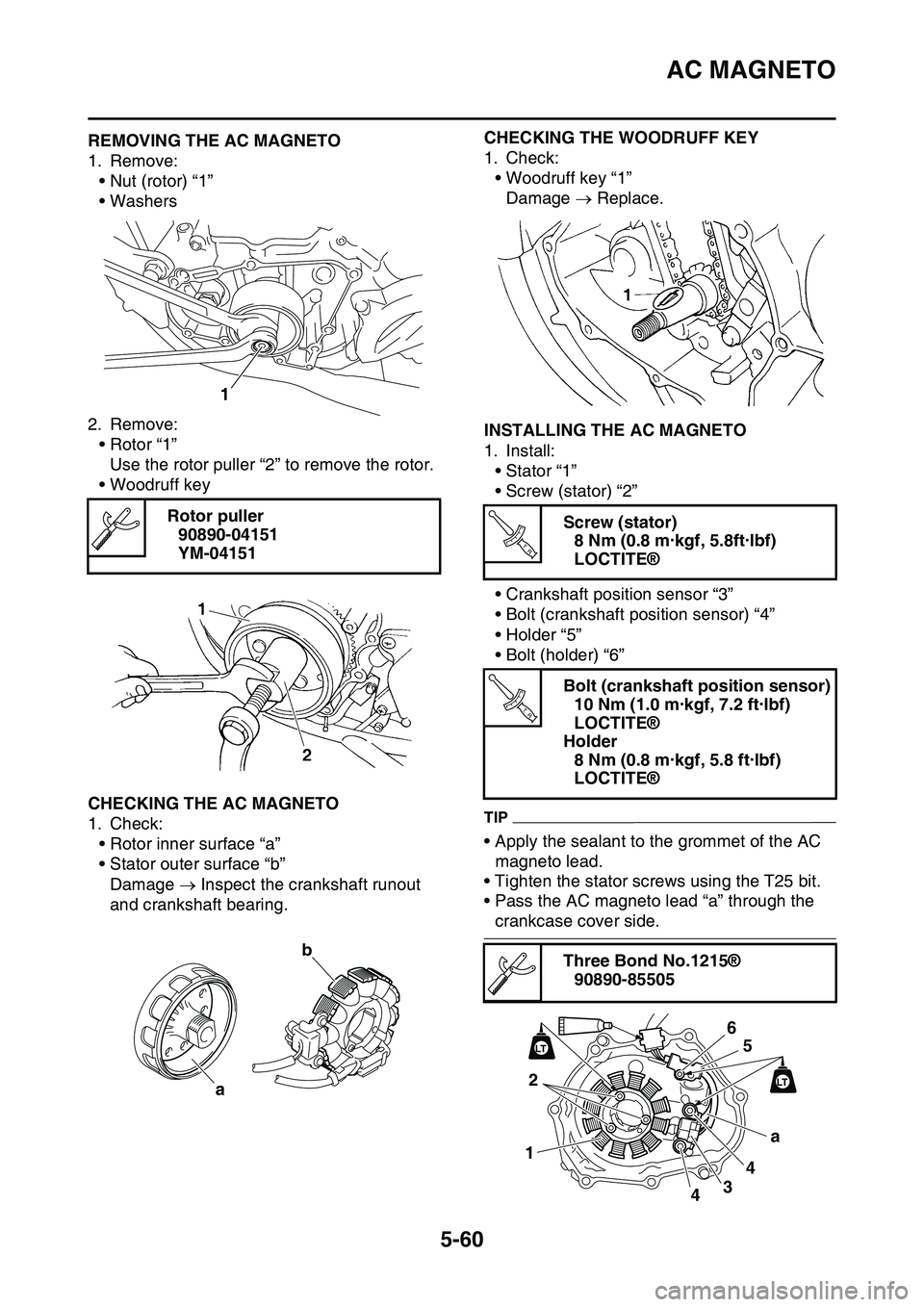

EAS1SL1273REMOVING THE AC MAGNETO

1. Remove:

• Nut (rotor) “1”

• Washers

2. Remove:

• Rotor “1”

Use the rotor puller “2” to remove the rotor.

• Woodruff key

EAS1SL1274CHECKING THE AC MAGNETO

1. Check:

• Rotor inner surface “a”

• Stator outer surface “b”

Damage Inspect the crankshaft runout

and crankshaft bearing.

EAS1SL1275

CHECKING THE WOODRUFF KEY

1. Check:

• Woodruff key “1”

Damage Replace.

EAS1SL1276INSTALLING THE AC MAGNETO

1. Install:

• Stator “1”

• Screw (stator) “2”

• Crankshaft position sensor “3”

• Bolt (crankshaft position sensor) “4”

• Holder “5”

• Bolt (holder) “6”

TIP

• Apply the sealant to the grommet of the AC

magneto lead.

• Tighten the stator screws using the T25 bit.

• Pass the AC magneto lead “a” through the

crankcase cover side.

Rotor puller

90890-04151

YM-04151

1

ab

Screw (stator)

8 Nm (0.8 m·kgf, 5.8ft·lbf)

LOCTITE®

Bolt (crankshaft position sensor)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

LOCTITE®

Holder

8 Nm (0.8 m·kgf, 5.8 ft·lbf)

LOCTITE®

Three Bond No.1215®

90890-85505

T R..

T R..

26

5

4

3

4a

1

LT

LT

Page 273 of 360

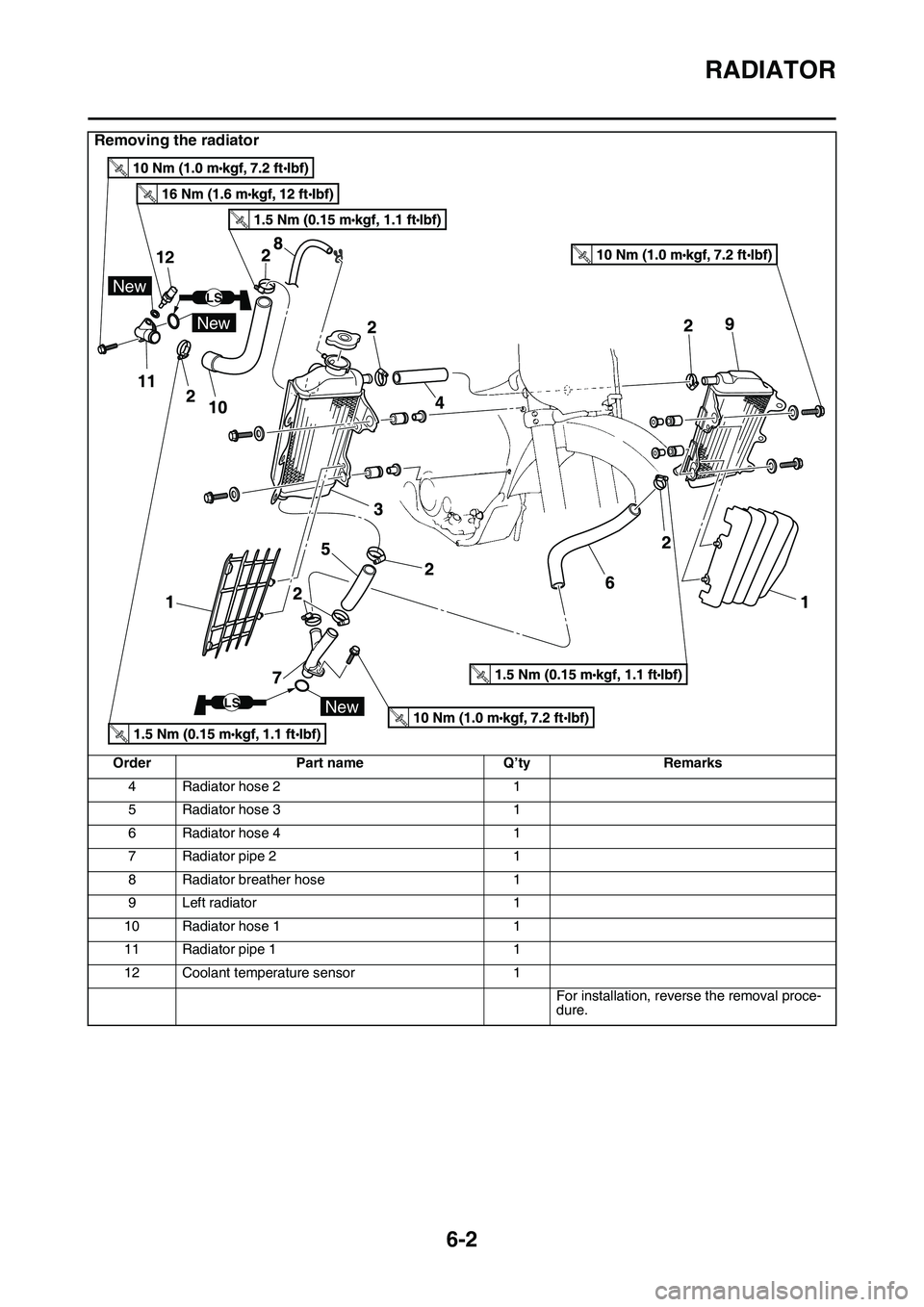

RADIATOR

6-2

4Radiator hose 21

5Radiator hose 31

6Radiator hose 41

7Radiator pipe 21

8Radiator breather hose1

9Left radiator1

10Radiator hose 11

11Radiator pipe 11

12Coolant temperature sensor1

For installation, reverse the removal proce-dure.

Removing the radiator

Order Part name Q’ty Remarks

11

12

New

New

New

LS

LS

Page 279 of 360

7

FUEL SYSTEM

FUEL TANK...................................................................................................... 7-1

REMOVING THE FUEL TANK ................................................................... 7-2

REMOVING THE FUEL PUMP .................................................................. 7-2

CHECKING THE FUEL PUMP BODY........................................................ 7-2

INSTALLING THE FUEL PUMP ................................................................. 7-2

INSTALLING THE FUEL TANK.................................................................. 7-3

CHECKING THE FUEL PRESSURE ......................................................... 7-3

CHECKING THE DAMPER ........................................................................ 7-4

CHECKING AND REPLACING THE PROTECTOR .................................. 7-4

THROTTLE BODY............................................................................................ 7-5

CHECKING THE INJECTOR ..................................................................... 7-8

CHECKING THE THROTTLE BODY ......................................................... 7-8

CHECKING THE THROTTLE BODY JOINT .............................................. 7-8

ADJUSTING THE THROTTLE POSITION SENSOR................................. 7-9

Page 284 of 360

THROTTLE BODY

7-5

EAS1SL1314

THROTTLE BODY

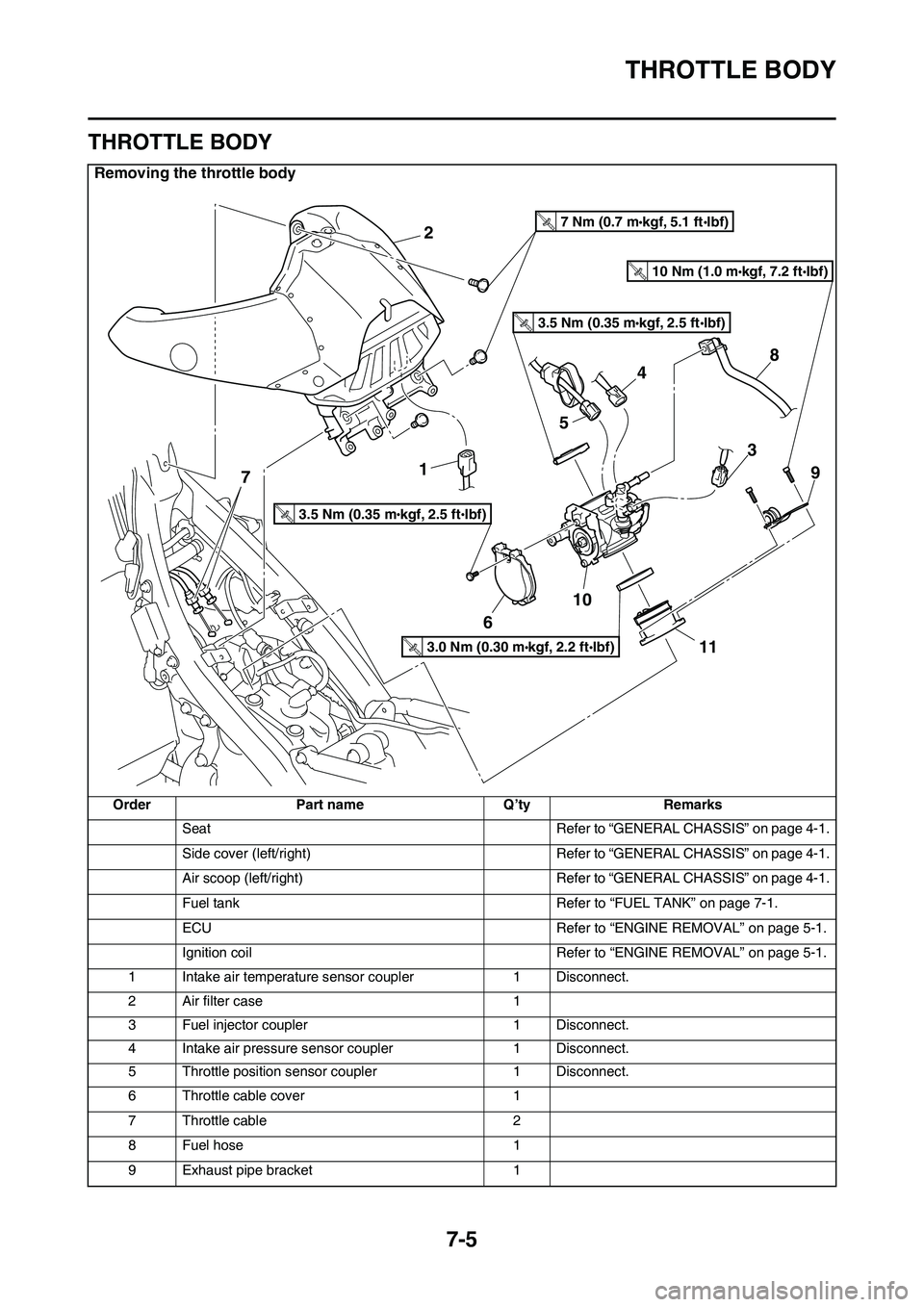

Removing the throttle body

OrderPart nameQ’tyRemarks

SeatRefer to “GENERAL CHASSIS” on page 4-1.

Side cover (left/right)Refer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left/right)Refer to “GENERAL CHASSIS” on page 4-1.

Fuel tankRefer to “FUEL TANK” on page 7-1.

ECURefer to “ENGINE REMOVAL” on page 5-1.

Ignition coilRefer to “ENGINE REMOVAL” on page 5-1.

1Intake air temperature sensor coupler1Disconnect.

2Air filter case1

3Fuel injector coupler1Disconnect.

4Intake air pressure sensor coupler1Disconnect.

5Throttle position sensor coupler1Disconnect.

6Throttle cable cover1

7Throttle cable2

8Fuel hose1

9Exhaust pipe bracket1

2

1

6

10

11

9

8

3

7

5

4

3.5 Nm (0.35 mkgf, 2.5 ftIbf)T.R.

3.5 Nm (0.35 mkgf, 2.5 ftIbf)T.R.

7 Nm (0.7 mkgf, 5.1 ftIbf)T.R.

3.0 Nm (0.30 mkgf, 2.2 ftIbf)T.R.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

Page 286 of 360

THROTTLE BODY

7-7

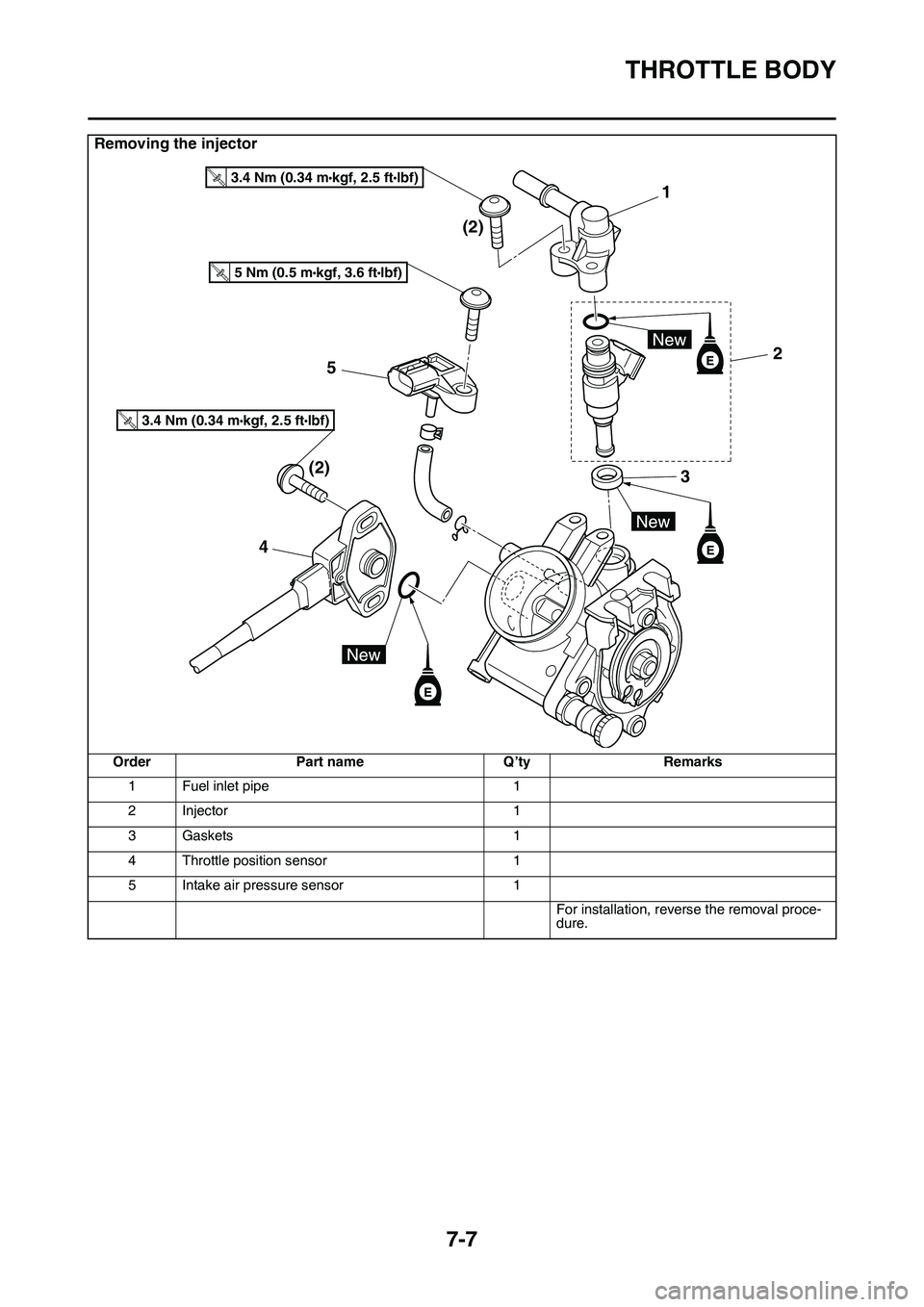

Removing the injector

OrderPart nameQ’tyRemarks

1Fuel inlet pipe1

2Injector1

3Gaskets1

4Throttle position sensor1

5Intake air pressure sensor1

For installation, reverse the removal proce-dure.

1

2 (2)

(2)5

43

T.R.3.4 Nm (0.34 mlbf) kgf, 2.5 ft

T.R.5 Nm (0.5 mlbf) kgf, 3.6 ft

T.R.3.4 Nm (0.34 mlbf) kgf, 2.5 ft

Page 287 of 360

THROTTLE BODY

7-8

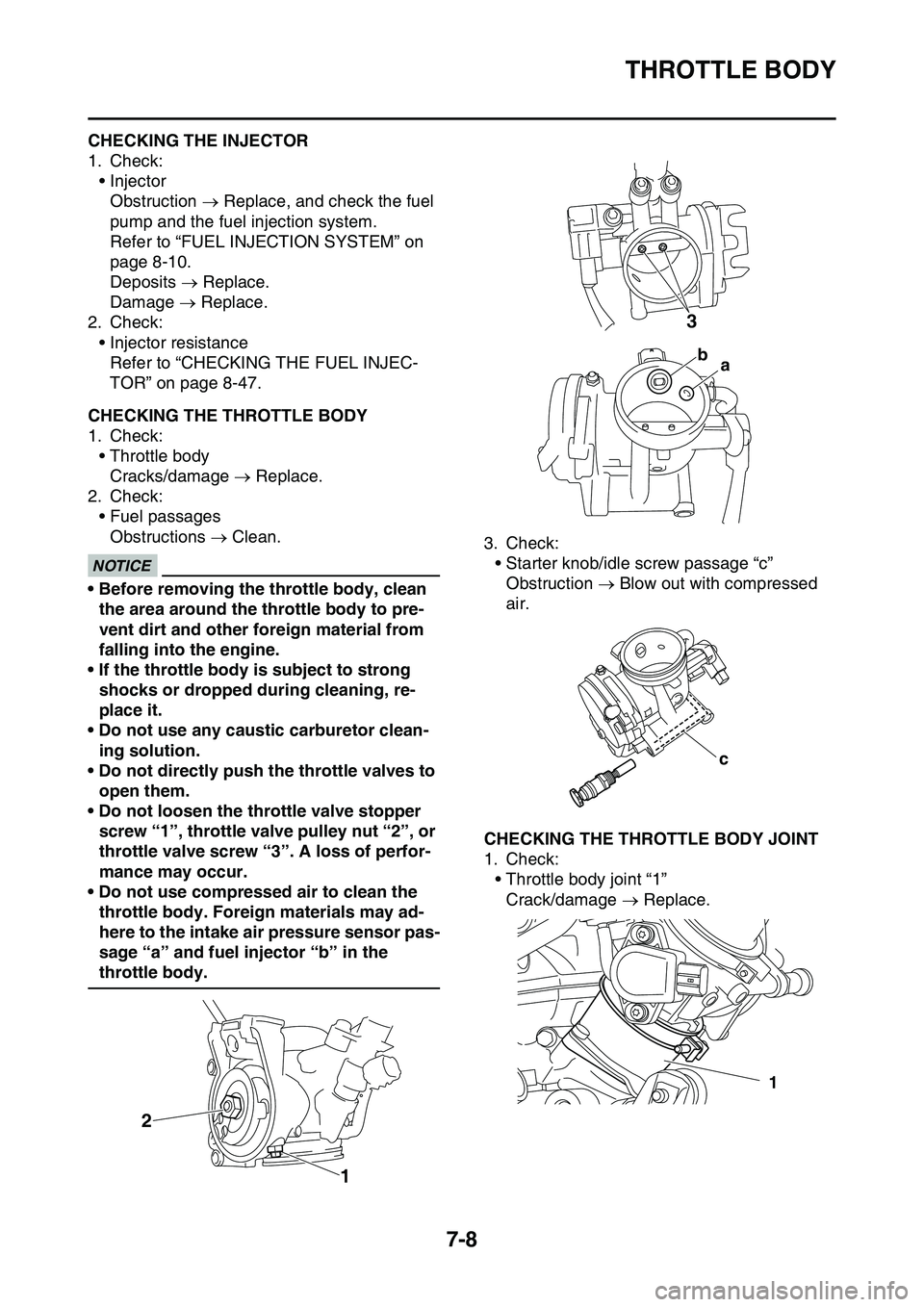

EAS1SL1315CHECKING THE INJECTOR

1. Check:

• Injector

Obstruction Replace, and check the fuel

pump and the fuel injection system.

Refer to “FUEL INJECTION SYSTEM” on

page 8-10.

Deposits Replace.

Damage Replace.

2. Check:

• Injector resistance

Refer to “CHECKING THE FUEL INJEC-

TOR” on page 8-47.

EAS1SL1316CHECKING THE THROTTLE BODY

1. Check:

• Throttle body

Cracks/damage Replace.

2. Check:

• Fuel passages

Obstructions Clean.ECA1DX1027

NOTICE

• Before removing the throttle body, clean

the area around the throttle body to pre

-

vent dirt and other foreign material from

falling into the engine.

• If the throttle body is subject to strong

shocks or dropped during cleaning, re

-

place it.

• Do not use any caustic carburetor clean-

ing solution.

• Do not directly push the throttle valves to

open them.

• Do not loosen the throttle valve stopper

screw “1”, throttle valve pulley nut “2”, or

throttle valve screw “3”. A loss of perfor

-

mance may occur.

• Do not use compressed air to clean the

throttle body. Foreign materials may ad

-

here to the intake air pressure sensor pas-

sage “a” and fuel injector “b” in the

throttle body.

3. Check:

• Starter knob/idle screw passage “c”

Obstruction Blow out with compressed

air.

EAS1SL1317CHECKING THE THROTTLE BODY JOINT

1. Check:

• Throttle body joint “1”

Crack/damage Replace.

EAS1SL1318

1 2

3

ba

c

1

Page 288 of 360

THROTTLE BODY

7-9

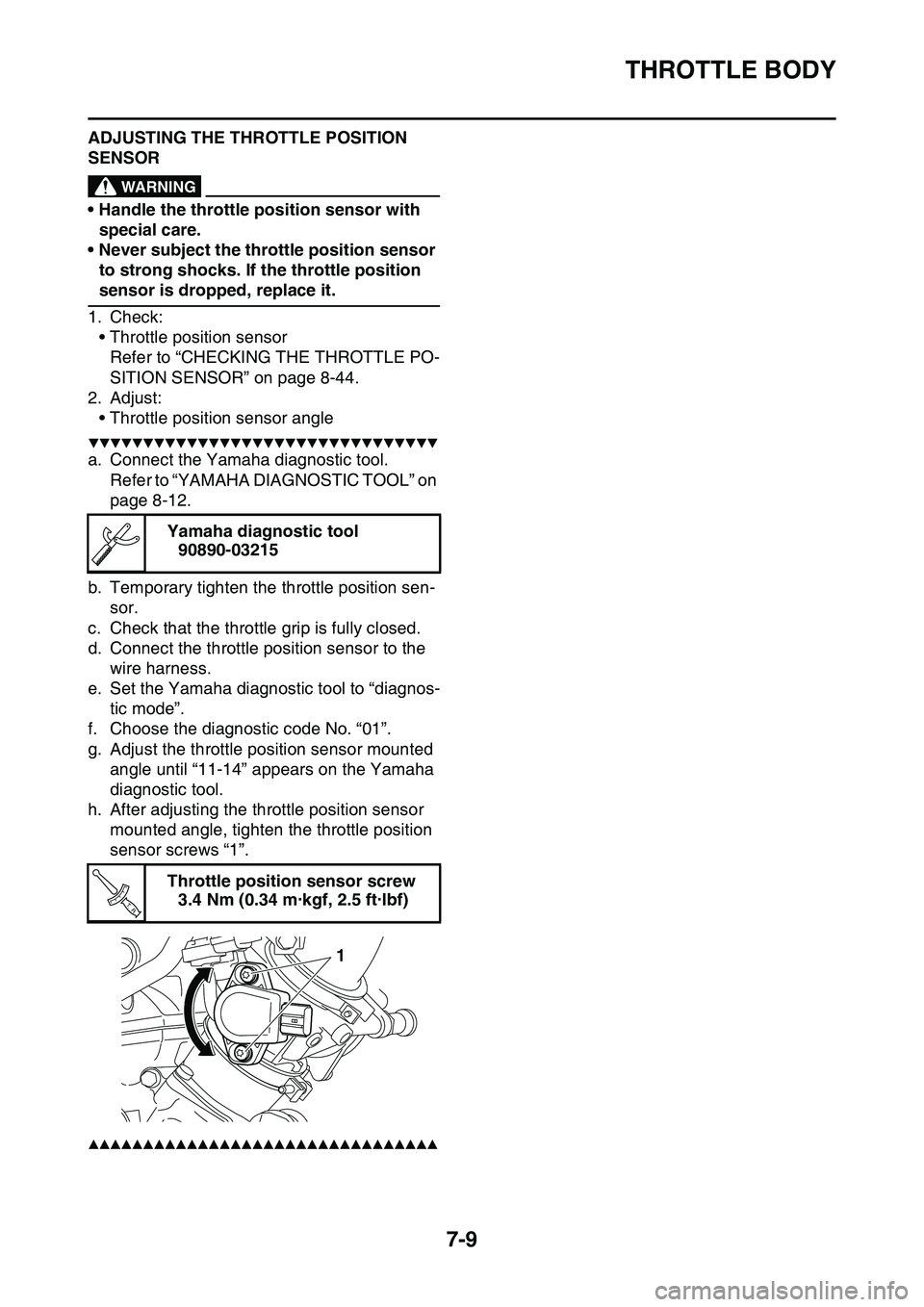

ADJUSTING THE THROTTLE POSITION

SENSOR

EWA32D1011

WARNING

• Handle the throttle position sensor with

special care.

• Never subject the throttle position sensor

to strong shocks. If the throttle position

sensor is dropped, replace it.

1. Check:

• Throttle position sensor

Refer to “CHECKING THE THROTTLE PO-

SITION SENSOR” on page 8-44.

2. Adjust:

• Throttle position sensor angle

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the Yamaha diagnostic tool.

Refer to “YAMAHA DIAGNOSTIC TOOL” on

page 8-12.

b. Temporary tighten the throttle position sen-

sor.

c. Check that the throttle grip is fully closed.

d. Connect the throttle position sensor to the

wire harness.

e. Set the Yamaha diagnostic tool to “diagnos-

tic mode”.

f. Choose the diagnostic code No. “01”.

g. Adjust the throttle position sensor mounted

angle until “11-14” appears on the Yamaha

diagnostic tool.

h. After adjusting the throttle position sensor

mounted angle, tighten the throttle position

sensor screws “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Yamaha diagnostic tool

90890-03215

Throttle position sensor screw

3.4 Nm (0.34 m·kgf, 2.5 ft·lbf)T R..

1

Page 289 of 360

8

ELECTRICAL SYSTEM

IGNITION SYSTEM.......................................................................................... 8-2

CIRCUIT DIAGRAM ................................................................................... 8-2

TROUBLESHOOTING ............................................................................... 8-4

CHARGING SYSTEM....................................................................................... 8-6

CIRCUIT DIAGRAM ................................................................................... 8-6

TROUBLE SHOOTING .............................................................................. 8-8

FUEL INJECTION SYSTEM........................................................................... 8-10

CIRCUIT DIAGRAM ................................................................................. 8-10

YAMAHA DIAGNOSTIC TOOL ................................................................ 8-12

TROUBLESHOOTING DETAILS ............................................................. 8-13

FUEL PUMP SYSTEM.................................................................................... 8-32

CIRCUIT DIAGRAM ................................................................................. 8-32

TROUBLESHOOTING ............................................................................. 8-34

ELECTRICAL COMPONENTS....................................................................... 8-36

CHECKING THE SWITCHES .................................................................. 8-38

CHECKING THE IGNITION SPARK GAP................................................ 8-41

CHECKING THE SPARK PLUG CAP ...................................................... 8-41

CHECKING THE IGNITION COIL ............................................................ 8-41

CHECKING THE CRANKSHAFT POSITION SENSOR........................... 8-42

CHECKING THE ECU .............................................................................. 8-43

CHECKING THE STATOR COIL ............................................................. 8-43

CHECKING THE RECTIFIER/REGULATOR ........................................... 8-43

CHECKING THE COOLANT TEMPERATURE SENSOR........................ 8-44

CHECKING THE THROTTLE POSITION SENSOR ................................ 8-44

CHECKING THE THROTTLE POSITION SENSOR

INPUT VOLTAGE .................................................................................... 8-43

CHECKING THE INTAKE AIR PRESSURE SENSOR ............................ 8-46

CHECKING THE INTAKE AIR TEMPERATURE SENSOR ..................... 8-46

CHECKING THE NEUTRAL SWITCH ..................................................... 8-46

CHECKING THE FUEL INJECTOR ......................................................... 8-47

Page 293 of 360

IGNITION SYSTEM

8-3

EAS1SL1322

1. Crankshaft position sensor

2. AC magneto

3. Rectifier/regulator

4. Joint connector

5. Condenser

7. Engine stop switch

9. ECU

10.Ignition coil

11.Spark plug