coolant YAMAHA YZ450F 2014 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 272 of 360

RADIATOR

6-1

EAS1SL1294

TIP

This section is intended for those who have basic knowledge and skill concerning the servicing of

Yamaha motorcycles (e.g., Yamaha dealers, service engineers, etc.). Those who have little knowl

-

edge and skill concerning servicing are requested not to undertake inspection, adjustment, disas-

sembly, or reassembly only by reference to this manual. It may lead to servicing trouble and

mechanical damage.

EAS1SL1295

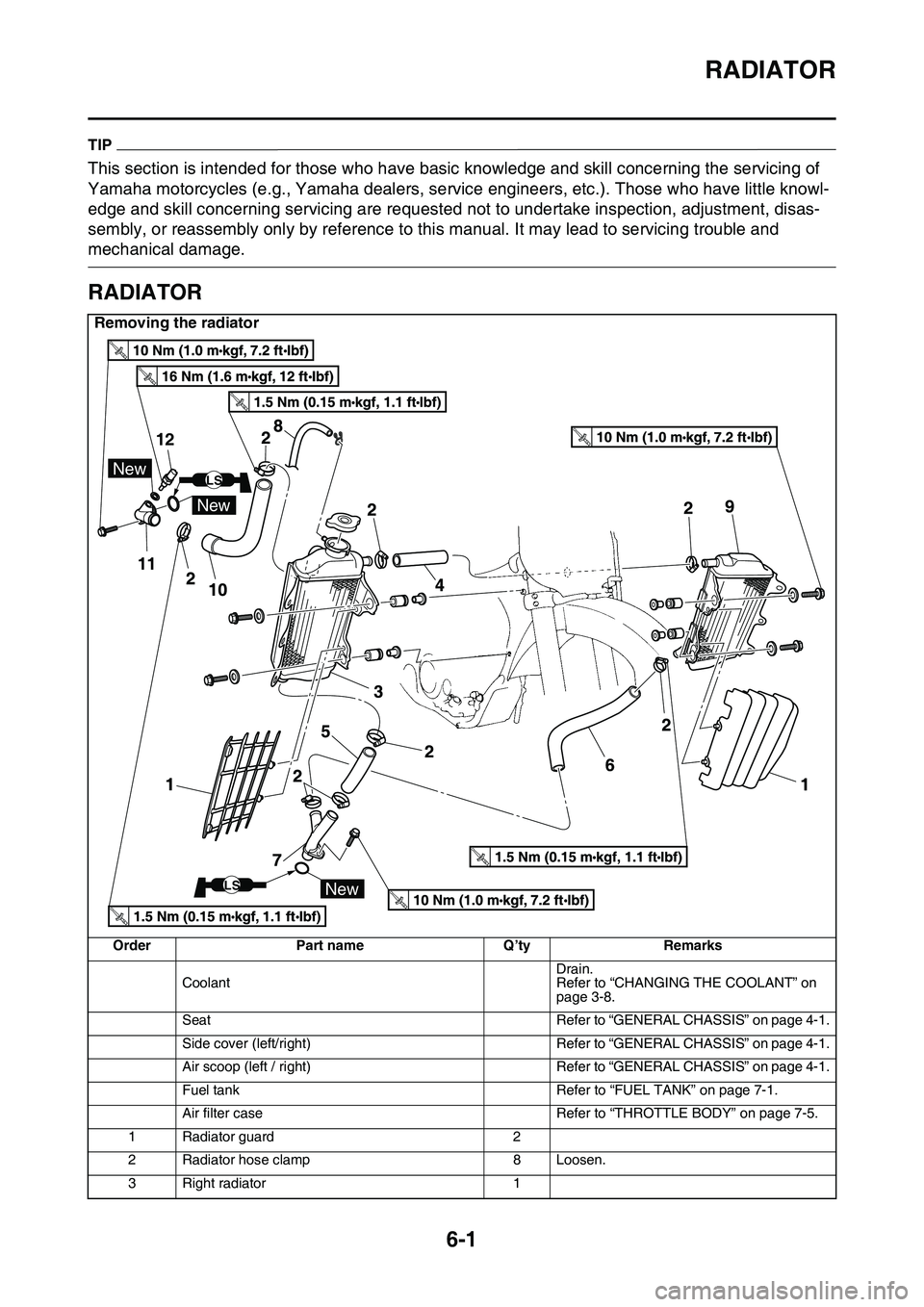

RADIATOR

Removing the radiator

OrderPart nameQ’tyRemarks

CoolantDrain.Refer to “CHANGING THE COOLANT” on page 3-8.

SeatRefer to “GENERAL CHASSIS” on page 4-1.

Side cover (left/right)Refer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left / right)Refer to “GENERAL CHASSIS” on page 4-1.

Fuel tankRefer to “FUEL TANK” on page 7-1.

Air filter caseRefer to “THROTTLE BODY” on page 7-5.

1Radiator guard2

2Radiator hose clamp8Loosen.

3Right radiator1

11

12

New

New

New

LS

LS

Page 273 of 360

RADIATOR

6-2

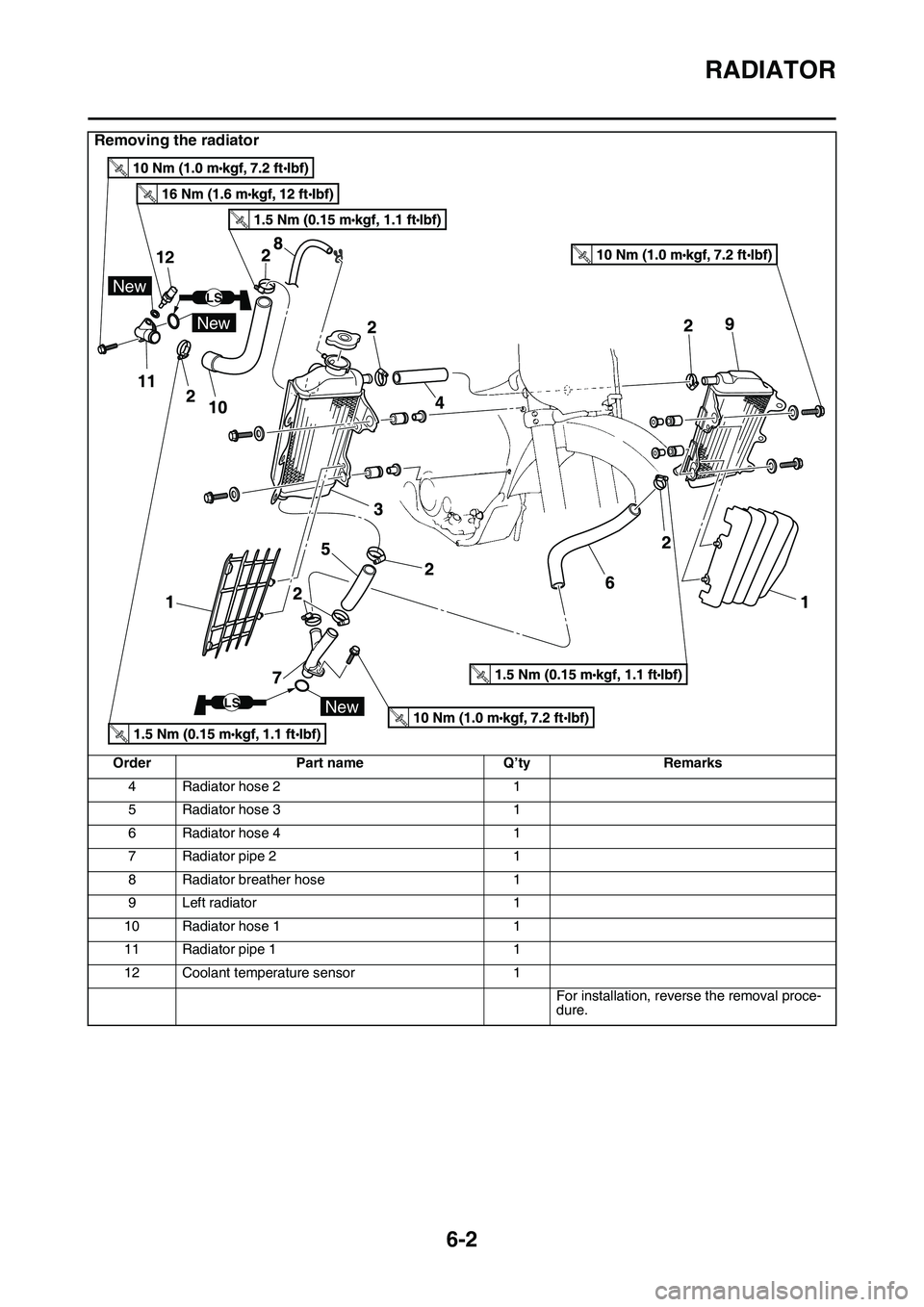

4Radiator hose 21

5Radiator hose 31

6Radiator hose 41

7Radiator pipe 21

8Radiator breather hose1

9Left radiator1

10Radiator hose 11

11Radiator pipe 11

12Coolant temperature sensor1

For installation, reverse the removal proce-dure.

Removing the radiator

Order Part name Q’ty Remarks

11

12

New

New

New

LS

LS

Page 274 of 360

RADIATOR

6-3

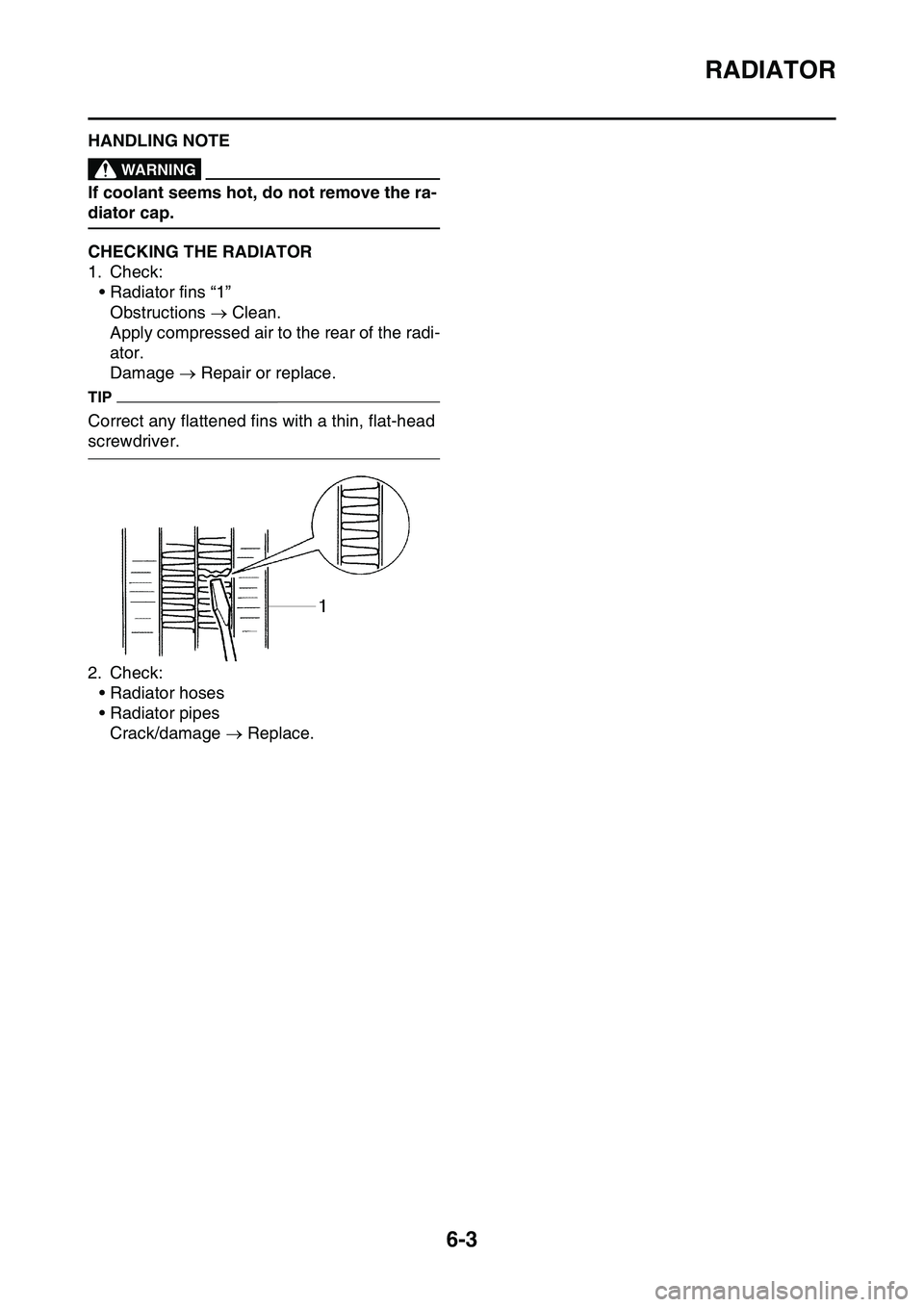

EAS1SL1296HANDLING NOTEEWA1DX1007

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

EAS1SL1297CHECKING THE RADIATOR

1. Check:

• Radiator fins “1”

Obstructions Clean.

Apply compressed air to the rear of the radi-

ator.

Damage Repair or replace.

TIP

Correct any flattened fins with a thin, flat-head

screwdriver.

2. Check:

• Radiator hoses

• Radiator pipes

Crack/damage Replace.

Page 275 of 360

WATER PUMP

6-4

EAS1SL1298

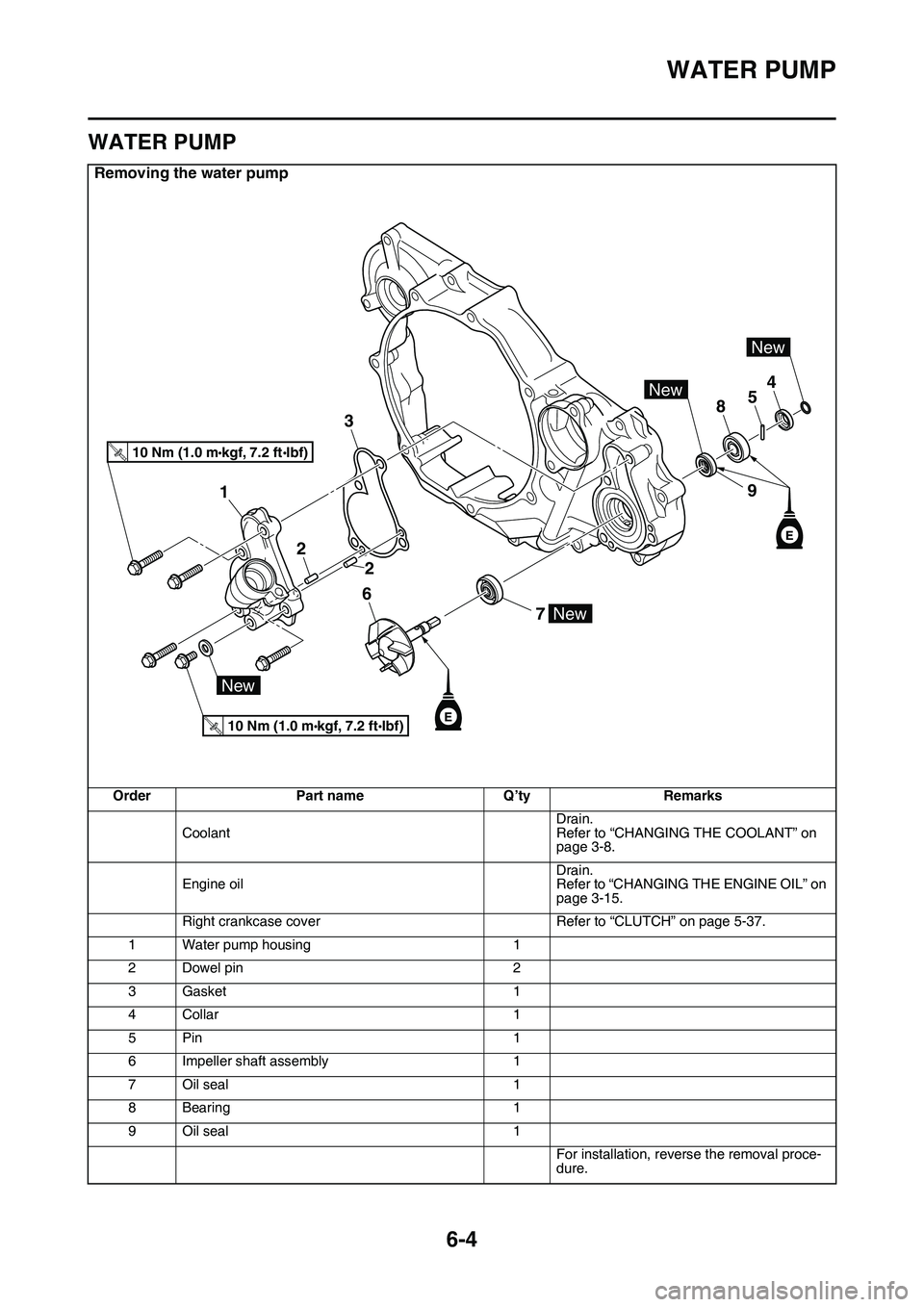

WATER PUMP

Removing the water pump

OrderPart nameQ’tyRemarks

CoolantDrain.Refer to “CHANGING THE COOLANT” on page 3-8.

Engine oilDrain.Refer to “CHANGING THE ENGINE OIL” on page 3-15.

Right crankcase coverRefer to “CLUTCH” on page 5-37.

1Water pump housing1

2Dowel pin2

3Gasket1

4Collar1

5Pin1

6Impeller shaft assembly1

7Oil seal1

8Bearing1

9Oil seal1

For installation, reverse the removal proce-dure.

7

6

2

2

3

1

854

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

New

New

New

E

9

New

E

Page 276 of 360

WATER PUMP

6-5

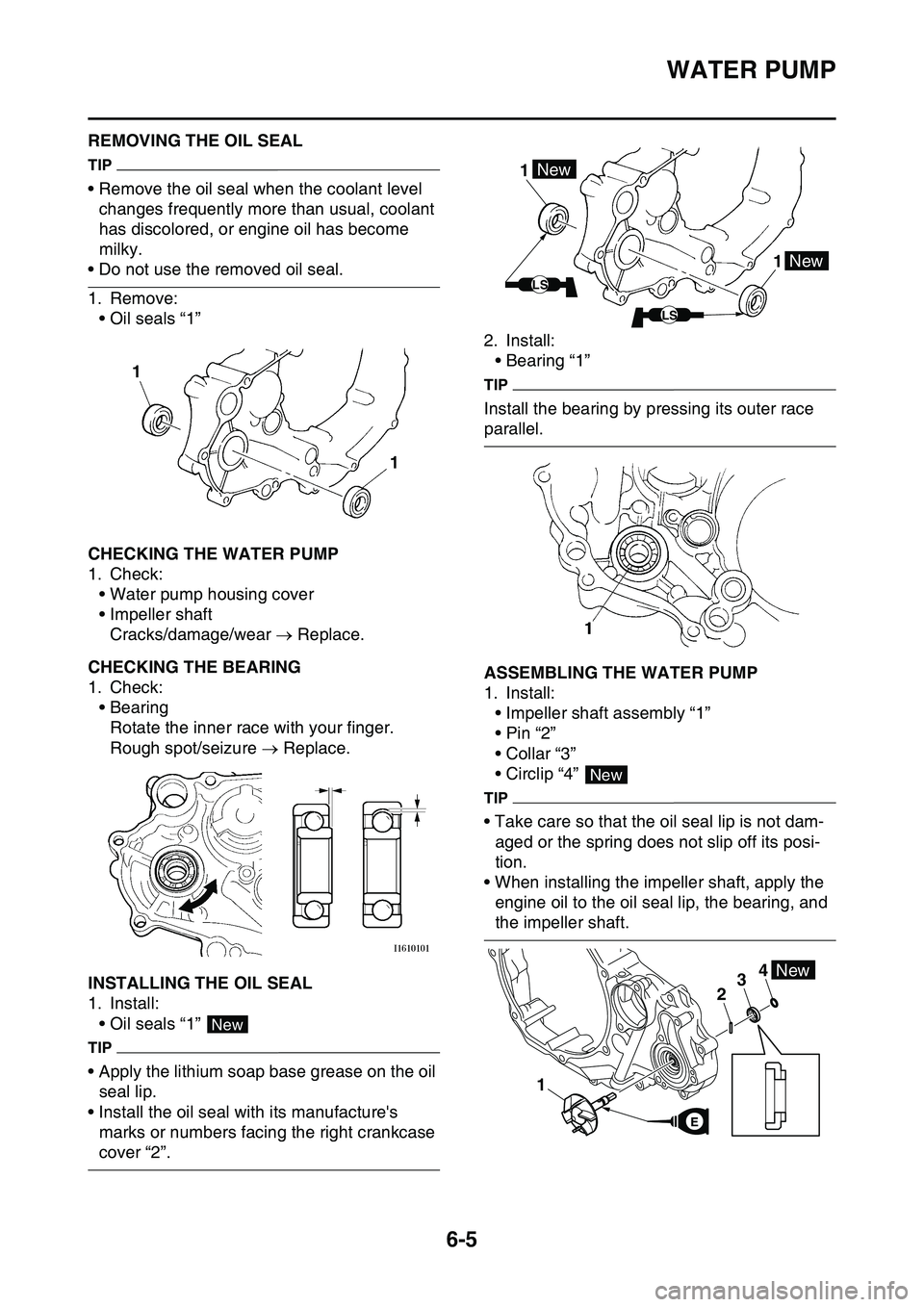

EAS1SL1299REMOVING THE OIL SEAL

TIP

• Remove the oil seal when the coolant level

changes frequently more than usual, coolant

has discolored, or engine oil has become

milky.

• Do not use the removed oil seal.

1. Remove:

• Oil seals “1”

EAS1SL1300CHECKING THE WATER PUMP

1. Check:

• Water pump housing cover

• Impeller shaft

Cracks/damage/wear Replace.

EAS1SL1301CHECKING THE BEARING

1. Check:

• Bearing

Rotate the inner race with your finger.

Rough spot/seizure Replace.

EAS1SL1302INSTALLING THE OIL SEAL

1. Install:

• Oil seals “1”

TIP

• Apply the lithium soap base grease on the oil

seal lip.

• Install the oil seal with its manufacture's

marks or numbers facing the right crankcase

cover “2”.

2. Install:

• Bearing “1”

TIP

Install the bearing by pressing its outer race

parallel.

EAS1SL1303ASSEMBLING THE WATER PUMP

1. Install:

• Impeller shaft assembly “1”

•Pin “2”

• Collar “3”

• Circlip “4”

TIP

• Take care so that the oil seal lip is not dam-

aged or the spring does not slip off its posi-

tion.

• When installing the impeller shaft, apply the

engine oil to the oil seal lip, the bearing, and

the impeller shaft.

1 1

New

1 1New

New

LS

LS

New

4

1

23New

E

Page 277 of 360

WATER PUMP

6-6

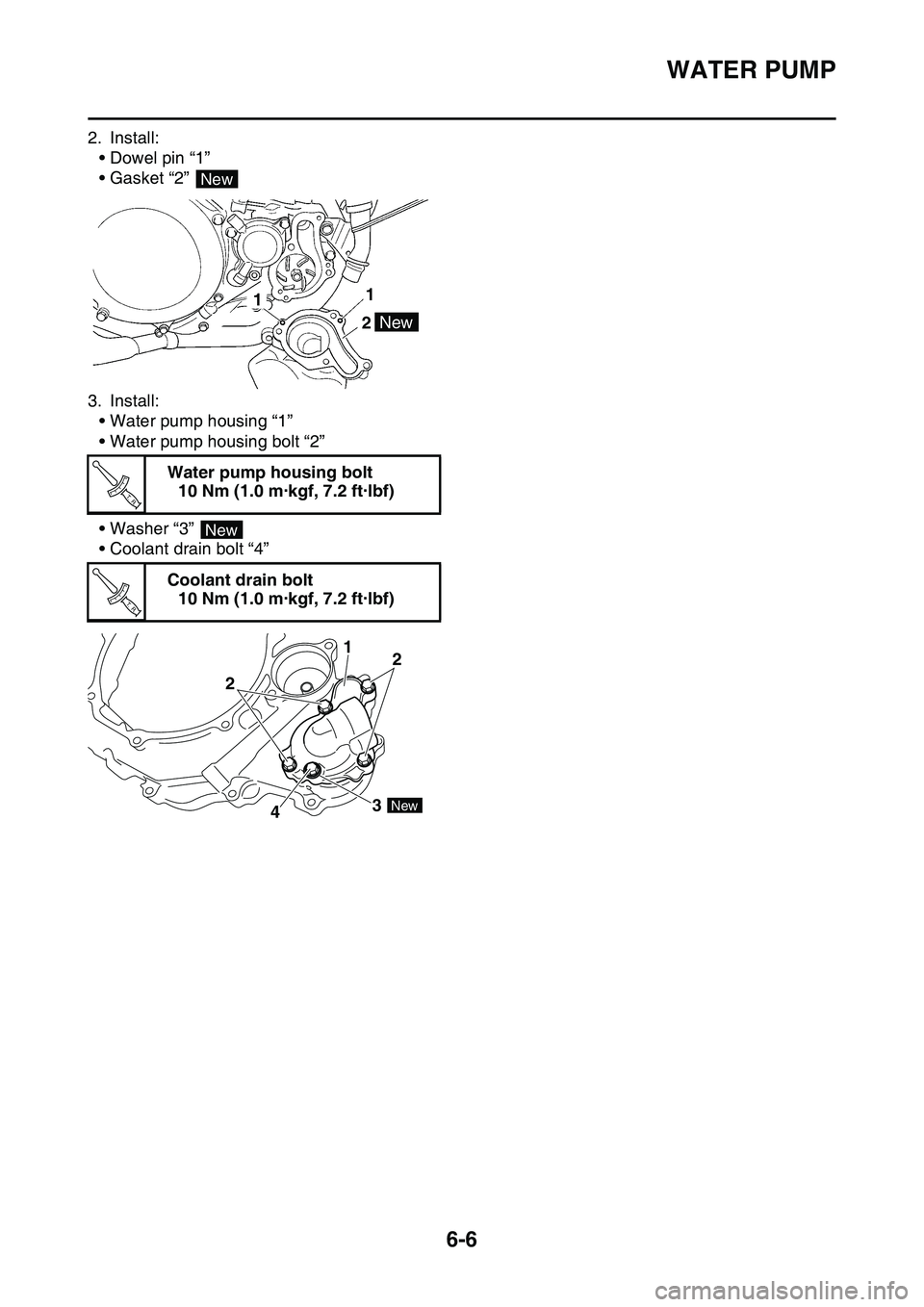

2. Install:

• Dowel pin “1”

• Gasket “2”

3. Install:

• Water pump housing “1”

• Water pump housing bolt “2”

• Washer “3”

• Coolant drain bolt “4”

Water pump housing bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Coolant drain bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

New

21

1New

T R..

New

T R..

2

2

43 1

New

Page 289 of 360

8

ELECTRICAL SYSTEM

IGNITION SYSTEM.......................................................................................... 8-2

CIRCUIT DIAGRAM ................................................................................... 8-2

TROUBLESHOOTING ............................................................................... 8-4

CHARGING SYSTEM....................................................................................... 8-6

CIRCUIT DIAGRAM ................................................................................... 8-6

TROUBLE SHOOTING .............................................................................. 8-8

FUEL INJECTION SYSTEM........................................................................... 8-10

CIRCUIT DIAGRAM ................................................................................. 8-10

YAMAHA DIAGNOSTIC TOOL ................................................................ 8-12

TROUBLESHOOTING DETAILS ............................................................. 8-13

FUEL PUMP SYSTEM.................................................................................... 8-32

CIRCUIT DIAGRAM ................................................................................. 8-32

TROUBLESHOOTING ............................................................................. 8-34

ELECTRICAL COMPONENTS....................................................................... 8-36

CHECKING THE SWITCHES .................................................................. 8-38

CHECKING THE IGNITION SPARK GAP................................................ 8-41

CHECKING THE SPARK PLUG CAP ...................................................... 8-41

CHECKING THE IGNITION COIL ............................................................ 8-41

CHECKING THE CRANKSHAFT POSITION SENSOR........................... 8-42

CHECKING THE ECU .............................................................................. 8-43

CHECKING THE STATOR COIL ............................................................. 8-43

CHECKING THE RECTIFIER/REGULATOR ........................................... 8-43

CHECKING THE COOLANT TEMPERATURE SENSOR........................ 8-44

CHECKING THE THROTTLE POSITION SENSOR ................................ 8-44

CHECKING THE THROTTLE POSITION SENSOR

INPUT VOLTAGE .................................................................................... 8-43

CHECKING THE INTAKE AIR PRESSURE SENSOR ............................ 8-46

CHECKING THE INTAKE AIR TEMPERATURE SENSOR ..................... 8-46

CHECKING THE NEUTRAL SWITCH ..................................................... 8-46

CHECKING THE FUEL INJECTOR ......................................................... 8-47

Page 301 of 360

FUEL INJECTION SYSTEM

8-11

EAS1SL1327

1. Crankshaft position sensor

2. AC magneto

3. Rectifier/regulator

4. Joint connector

5. Condenser

7. Engine stop switch

8. Neutral switch

9. ECU

12.Fuel injector

14.Intake air temperature sensor

15.Coolant temperature sensor

16.Throttle position sensor

17.Intake air pressure sensor

Page 310 of 360

FUEL INJECTION SYSTEM

8-20

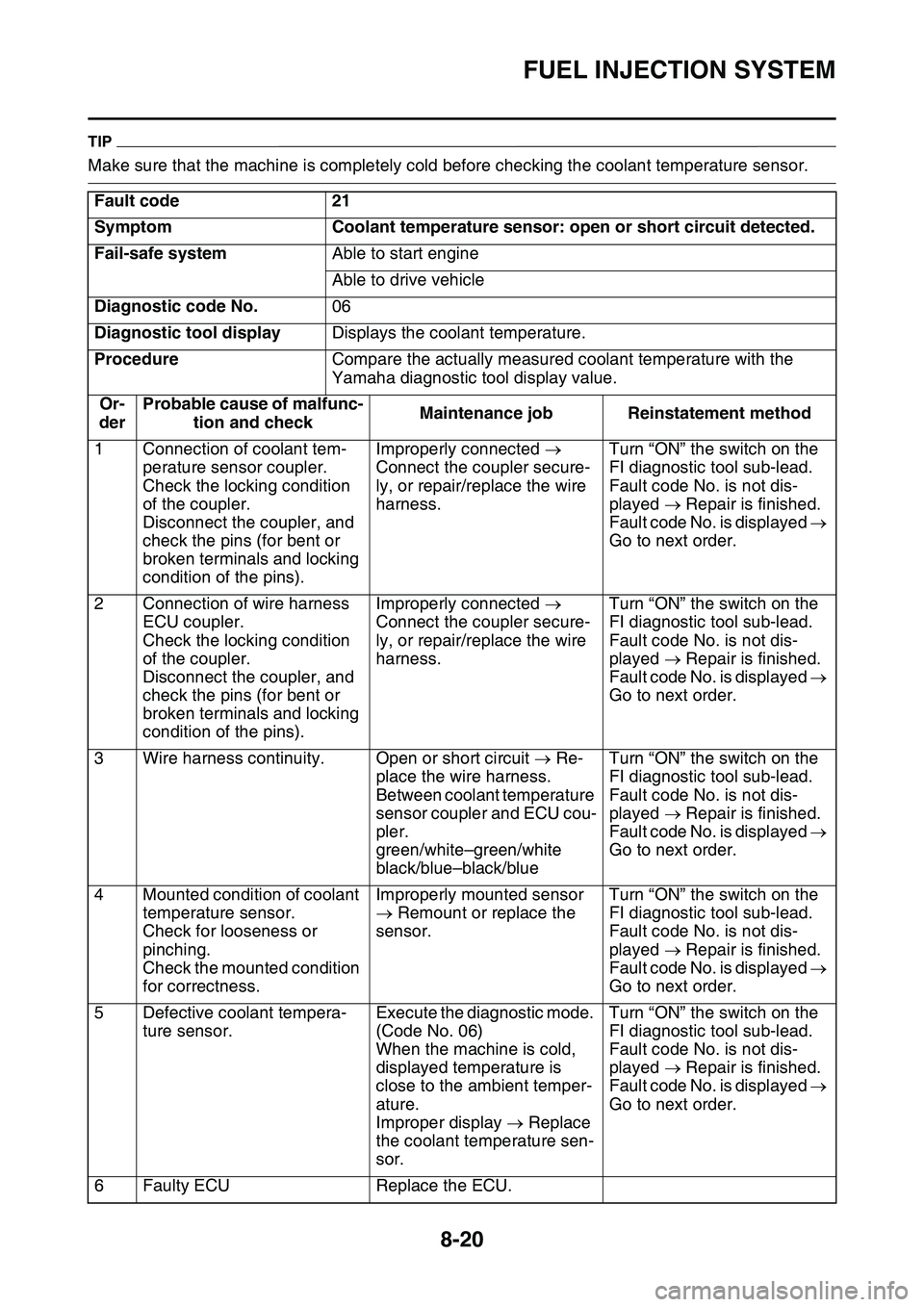

TIP

Make sure that the machine is completely cold before checking the coolant temperature sensor.

Fault code21

SymptomCoolant temperature sensor: open or short circuit detected.

Fail-safe systemAble to start engine

Able to drive vehicle

Diagnostic code No.06

Diagnostic tool displayDisplays the coolant temperature.

ProcedureCompare the actually measured coolant temperature with the

Yamaha diagnostic tool display value.

Or-

der

Probable cause of malfunc-

tion and checkMaintenance jobReinstatement method

1Connection of coolant tem-

perature sensor coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).

Improperly connected

Connect the coupler secure

-

ly, or repair/replace the wire

harness.

Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

2Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).

Improperly connected

Connect the coupler secure

-

ly, or repair/replace the wire

harness.

Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

3Wire harness continuity.Open or short circuit Re-

place the wire harness.

Between coolant temperature

sensor coupler and ECU cou

-

pler.

green/white–green/white

black/blue–black/blue

Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

4Mounted condition of coolant

temperature sensor.

Check for looseness or

pinching.

Check the mounted condition

for correctness.

Improperly mounted sensor

Remount or replace the

sensor.Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

5Defective coolant tempera-

ture sensor.

Execute the diagnostic mode.

(Code No. 06)

When the machine is cold,

displayed temperature is

close to the ambient temper

-

ature.

Improper display Replace

the coolant temperature sen

-

sor.

Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

6Faulty ECUReplace the ECU.

Page 327 of 360

ELECTRICAL COMPONENTS

8-37

EAS1SL1334

1. Rectifier/regulator

2. Intake air pressure sensor

3. Throttle position sensor

4. Injector

5. Intake air temperature sensor

6. ECU

7. Ignition coil

8. Condenser

9. Neutral switch

10.Coolant temperature sensor