warning YAMAHA YZ450F 2014 Workshop Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 274 of 360

RADIATOR

6-3

EAS1SL1296HANDLING NOTEEWA1DX1007

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

EAS1SL1297CHECKING THE RADIATOR

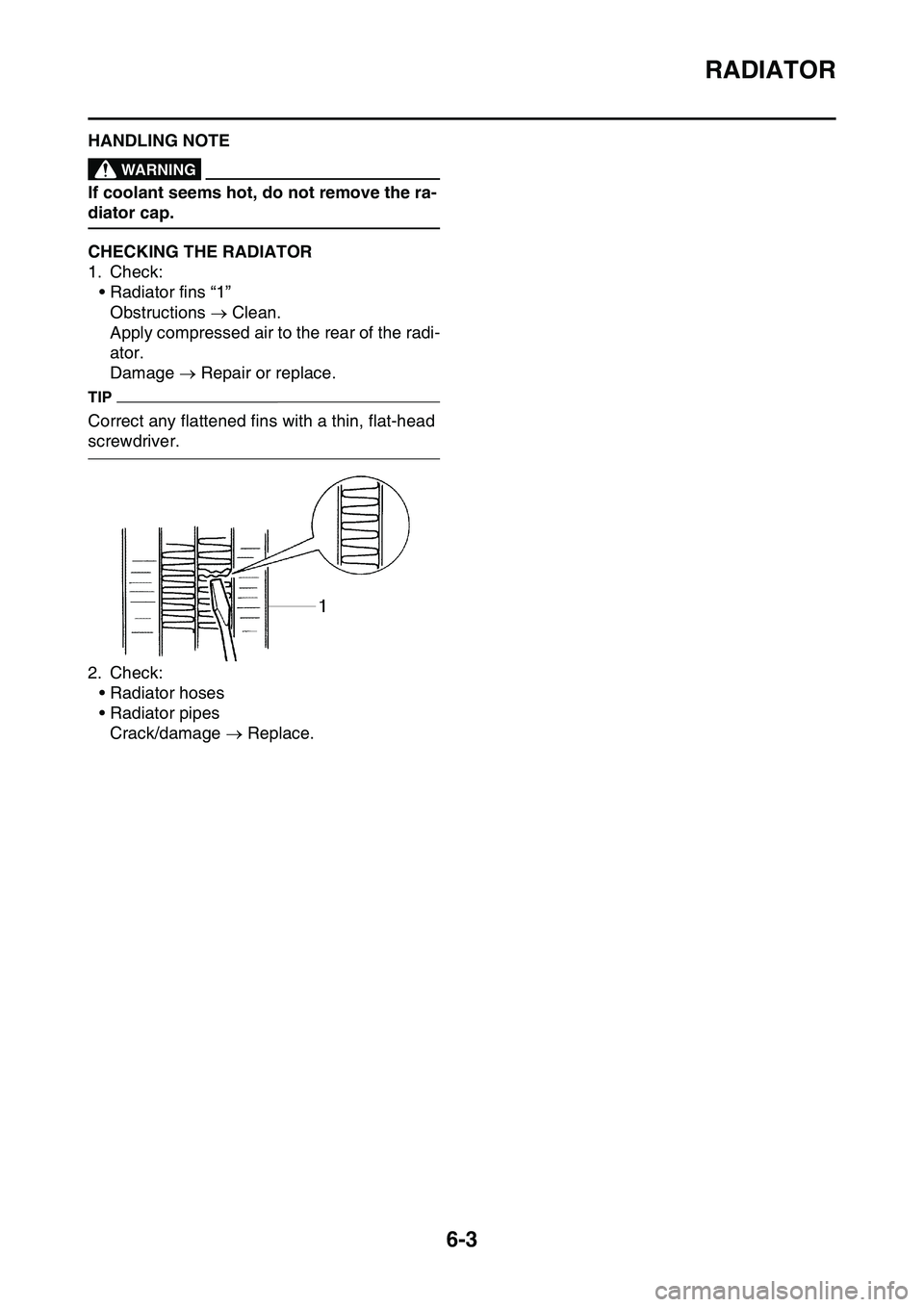

1. Check:

• Radiator fins “1”

Obstructions Clean.

Apply compressed air to the rear of the radi-

ator.

Damage Repair or replace.

TIP

Correct any flattened fins with a thin, flat-head

screwdriver.

2. Check:

• Radiator hoses

• Radiator pipes

Crack/damage Replace.

Page 281 of 360

FUEL TANK

7-2

EAS1SL1306REMOVING THE FUEL TANK

1. Extract the fuel in the fuel tank through the

fuel tank cap with a pump.

2. Remove:

• Fuel hose couplerEWA23P1001

WARNING

Cover the fuel hose connection with a cloth

when disconnecting it. This is because re

-

sidual pressure in the fuel hose could cause

fuel to spurt out when the hose is removed.

ECA23P1090

NOTICE

Make sure that the fuel hose is disconnect-

ed by hand. Do not forcefully disconnect the

hose with tools.

TIP

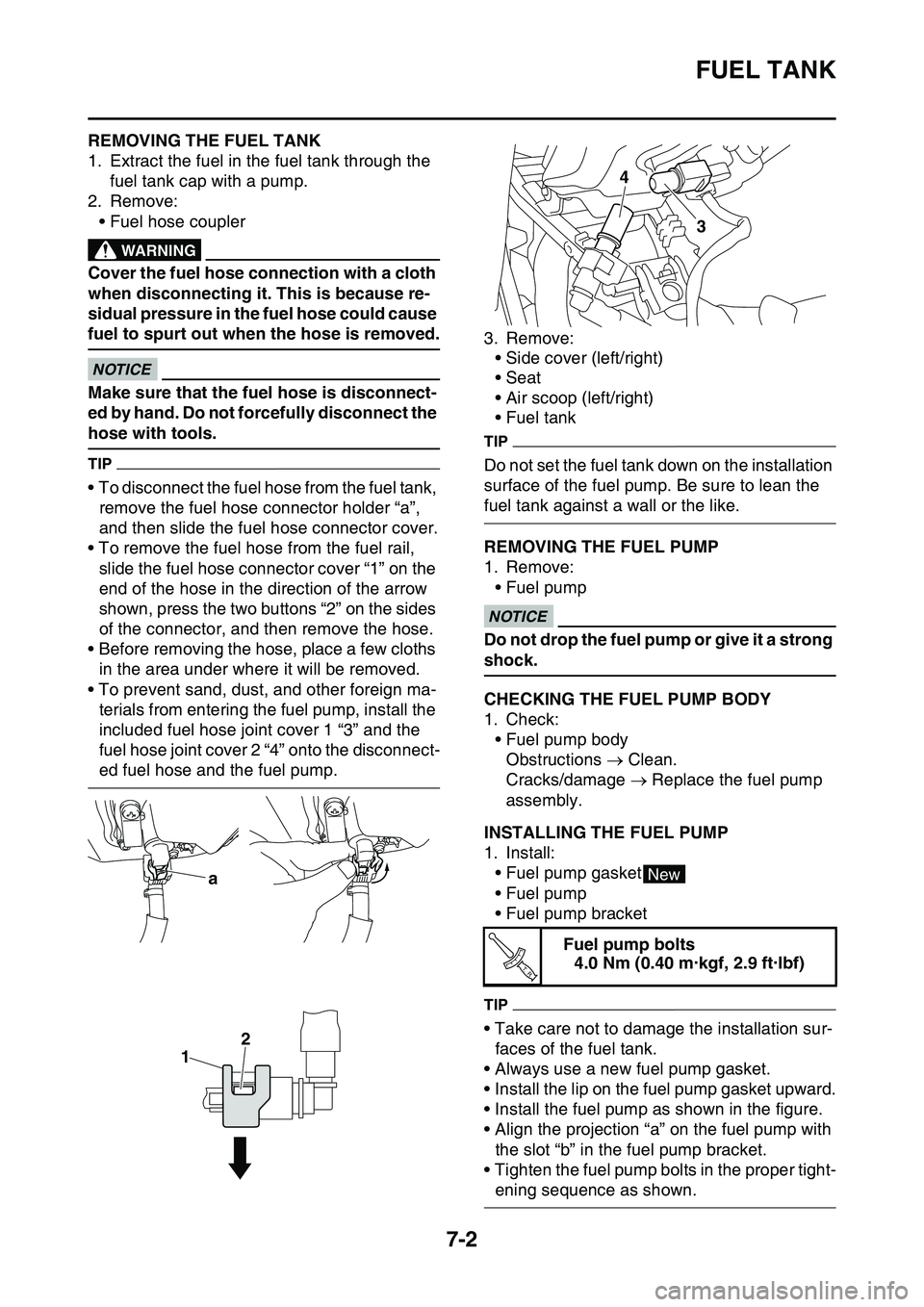

• To disconnect the fuel hose from the fuel tank,

remove the fuel hose connector holder “a”,

and then slide the fuel hose connector cover.

• To remove the fuel hose from the fuel rail,

slide the fuel hose connector cover “1” on the

end of the hose in the direction of the arrow

shown, press the two buttons “2” on the sides

of the connector, and then remove the hose.

• Before removing the hose, place a few cloths

in the area under where it will be removed.

• To prevent sand, dust, and other foreign ma-

terials from entering the fuel pump, install the

included fuel hose joint cover 1 “3” and the

fuel hose joint cover 2 “4” onto the disconnect

-

ed fuel hose and the fuel pump.

3. Remove:

• Side cover (left/right)

• Seat

• Air scoop (left/right)

• Fuel tank

TIP

Do not set the fuel tank down on the installation

surface of the fuel pump. Be sure to lean the

fuel tank against a wall or the like.

EAS1SL1307REMOVING THE FUEL PUMP

1. Remove:

• Fuel pumpECA14720

NOTICE

Do not drop the fuel pump or give it a strong

shock.

EAS1SL1308CHECKING THE FUEL PUMP BODY

1. Check:

• Fuel pump body

Obstructions Clean.

Cracks/damage Replace the fuel pump

assembly.

EAS1SL1309INSTALLING THE FUEL PUMP

1. Install:

• Fuel pump gasket

• Fuel pump

• Fuel pump bracket

TIP

• Take care not to damage the installation sur-

faces of the fuel tank.

• Always use a new fuel pump gasket.

• Install the lip on the fuel pump gasket upward.

• Install the fuel pump as shown in the figure.

• Align the projection “a” on the fuel pump with

the slot “b” in the fuel pump bracket.

• Tighten the fuel pump bolts in the proper tight-

ening sequence as shown.

a

1

2

Fuel pump bolts

4.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

3 4

New

T R..

Page 282 of 360

FUEL TANK

7-3

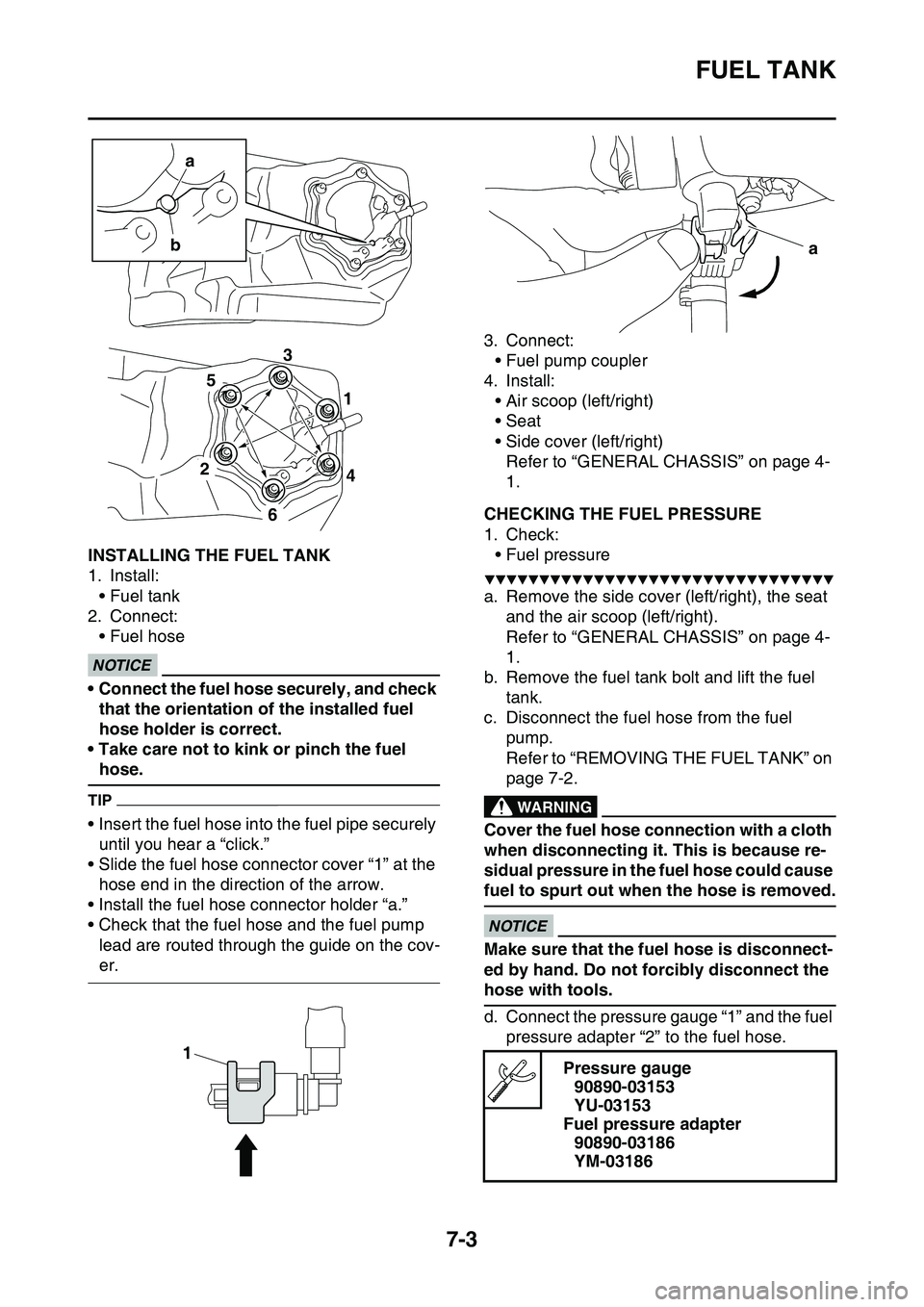

EAS1SL1310INSTALLING THE FUEL TANK

1. Install:

• Fuel tank

2. Connect:

• Fuel hoseECA33DD069

NOTICE

• Connect the fuel hose securely, and check

that the orientation of the installed fuel

hose holder is correct.

• Take care not to kink or pinch the fuel

hose.

TIP

• Insert the fuel hose into the fuel pipe securely

until you hear a “click.”

• Slide the fuel hose connector cover “1” at the

hose end in the direction of the arrow.

• Install the fuel hose connector holder “a.”

• Check that the fuel hose and the fuel pump

lead are routed through the guide on the cov

-

er.

3. Connect:

• Fuel pump coupler

4. Install:

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

EAS1SL1311CHECKING THE FUEL PRESSURE

1. Check:

• Fuel pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the side cover (left/right), the seat

and the air scoop (left/right).

Refer to “GENERAL CHASSIS” on page 4-

1.

b. Remove the fuel tank bolt and lift the fuel

tank.

c. Disconnect the fuel hose from the fuel

pump.

Refer to “REMOVING THE FUEL TANK” on

page 7-2.EWA1DX1008

WARNING

Cover the fuel hose connection with a cloth

when disconnecting it. This is because re

-

sidual pressure in the fuel hose could cause

fuel to spurt out when the hose is removed.

ECA1DX1025

NOTICE

Make sure that the fuel hose is disconnect-

ed by hand. Do not forcibly disconnect the

hose with tools.

d. Connect the pressure gauge “1” and the fuel

pressure adapter “2” to the fuel hose.

a

b

4 1

2

6

53

1Pressure gauge

90890-03153

YU-03153

Fuel pressure adapter

90890-03186

YM-03186

a

Page 288 of 360

THROTTLE BODY

7-9

ADJUSTING THE THROTTLE POSITION

SENSOR

EWA32D1011

WARNING

• Handle the throttle position sensor with

special care.

• Never subject the throttle position sensor

to strong shocks. If the throttle position

sensor is dropped, replace it.

1. Check:

• Throttle position sensor

Refer to “CHECKING THE THROTTLE PO-

SITION SENSOR” on page 8-44.

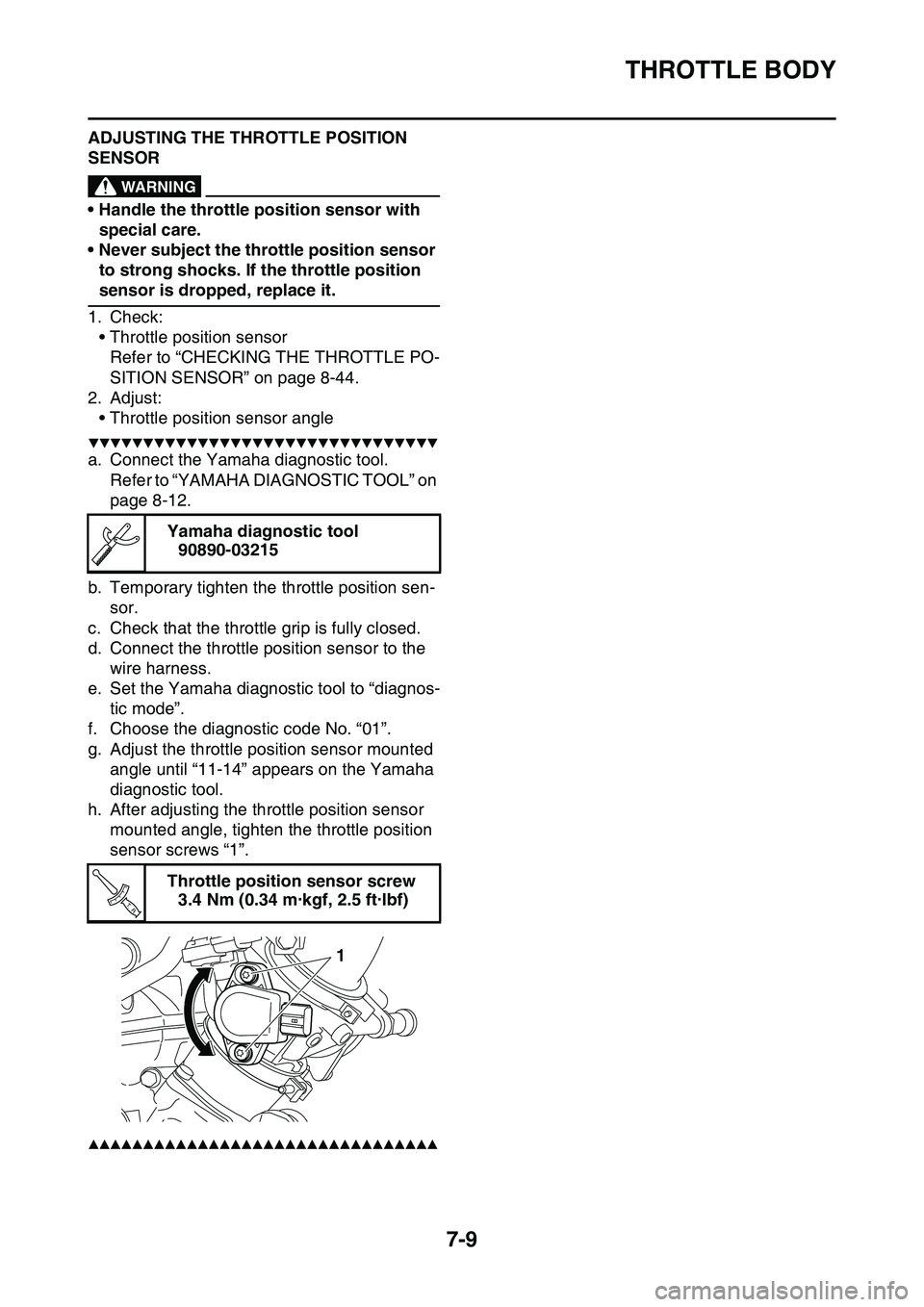

2. Adjust:

• Throttle position sensor angle

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the Yamaha diagnostic tool.

Refer to “YAMAHA DIAGNOSTIC TOOL” on

page 8-12.

b. Temporary tighten the throttle position sen-

sor.

c. Check that the throttle grip is fully closed.

d. Connect the throttle position sensor to the

wire harness.

e. Set the Yamaha diagnostic tool to “diagnos-

tic mode”.

f. Choose the diagnostic code No. “01”.

g. Adjust the throttle position sensor mounted

angle until “11-14” appears on the Yamaha

diagnostic tool.

h. After adjusting the throttle position sensor

mounted angle, tighten the throttle position

sensor screws “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Yamaha diagnostic tool

90890-03215

Throttle position sensor screw

3.4 Nm (0.34 m·kgf, 2.5 ft·lbf)T R..

1

Page 313 of 360

FUEL INJECTION SYSTEM

8-23

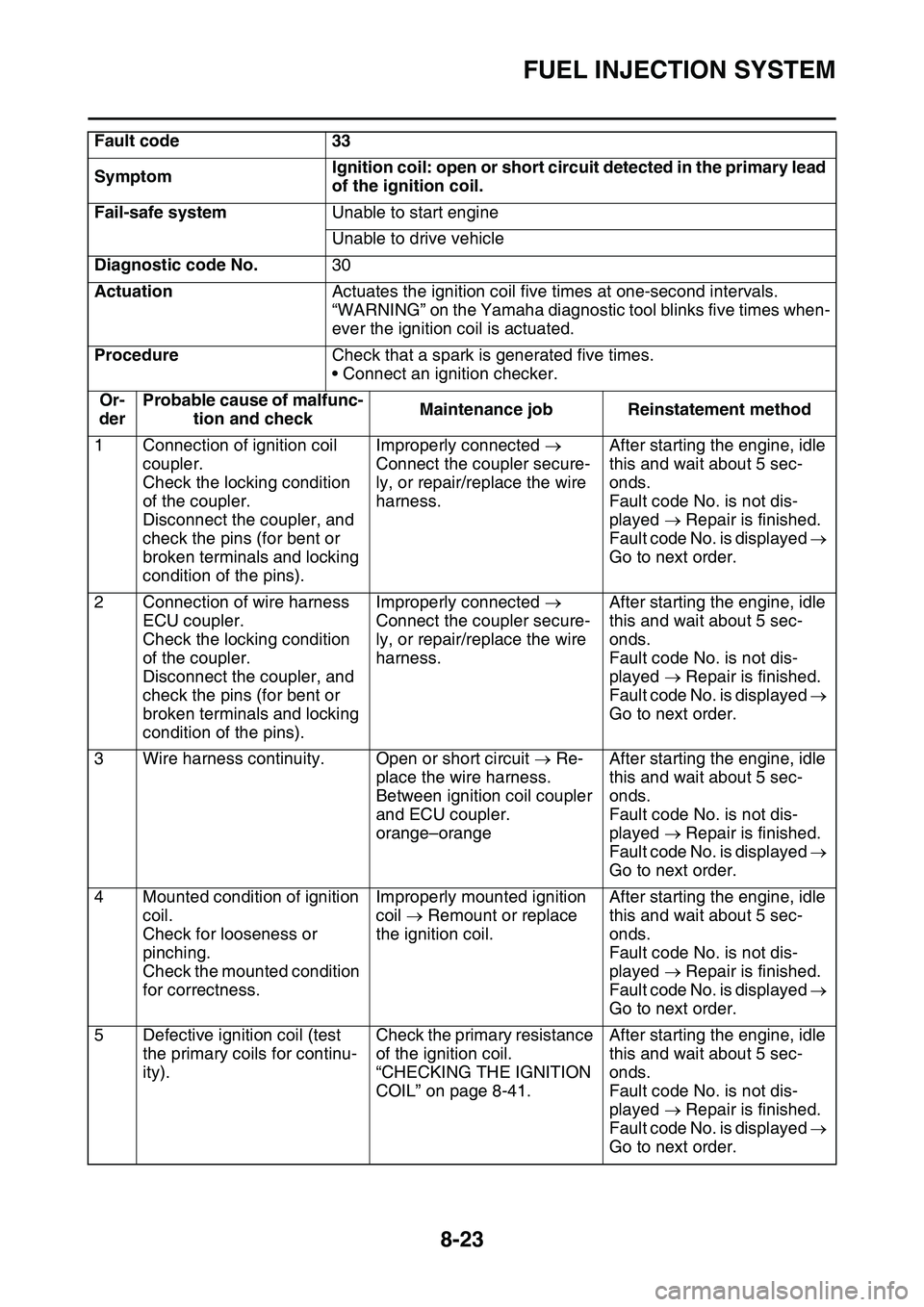

Fault code33

SymptomIgnition coil: open or short circuit detected in the primary lead

of the ignition coil.

Fail-safe systemUnable to start engine

Unable to drive vehicle

Diagnostic code No.30

ActuationActuates the ignition coil five times at one-second intervals.

“WARNING” on the Yamaha diagnostic tool blinks five times when-

ever the ignition coil is actuated.

ProcedureCheck that a spark is generated five times.

• Connect an ignition checker.

Or-

der

Probable cause of malfunc-

tion and checkMaintenance jobReinstatement method

1Connection of ignition coil

coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).

Improperly connected

Connect the coupler secure

-

ly, or repair/replace the wire

harness.

After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

2Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).

Improperly connected

Connect the coupler secure

-

ly, or repair/replace the wire

harness.

After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

3Wire harness continuity.Open or short circuit Re-

place the wire harness.

Between ignition coil coupler

and ECU coupler.

orange–orange

After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

4Mounted condition of ignition

coil.

Check for looseness or

pinching.

Check the mounted condition

for correctness.

Improperly mounted ignition

coil Remount or replace

the ignition coil.After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

5Defective ignition coil (test

the primary coils for continu

-

ity).

Check the primary resistance

of the ignition coil.

“CHECKING THE IGNITION

COIL” on page 8-41.

After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

Page 314 of 360

FUEL INJECTION SYSTEM

8-24

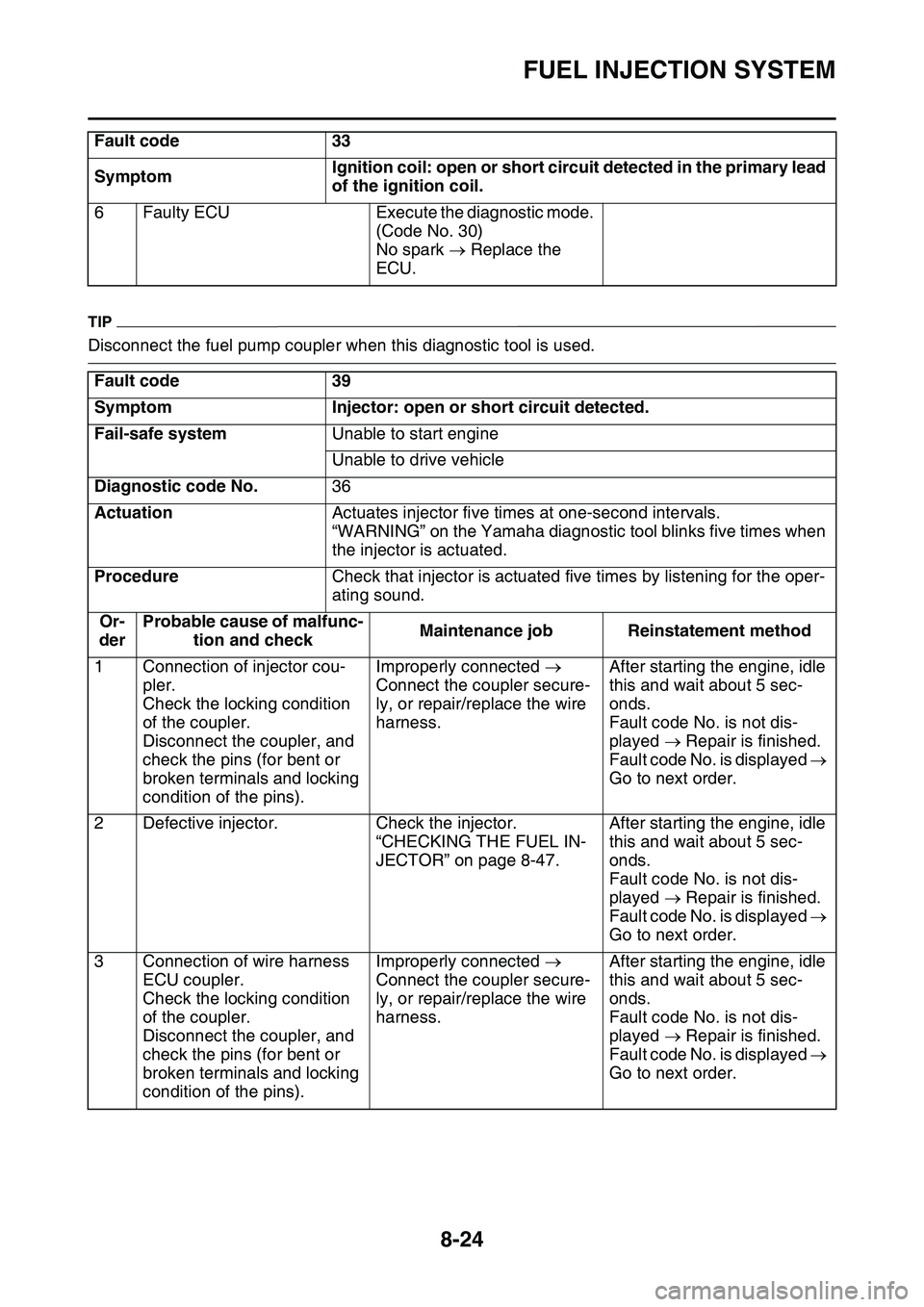

TIP

Disconnect the fuel pump coupler when this diagnostic tool is used.

6Faulty ECUExecute the diagnostic mode.

(Code No. 30)

No spark Replace the

ECU.

Fault code39

SymptomInjector: open or short circuit detected.

Fail-safe systemUnable to start engine

Unable to drive vehicle

Diagnostic code No.36

ActuationActuates injector five times at one-second intervals.

“WARNING” on the Yamaha diagnostic tool blinks five times when

the injector is actuated.

ProcedureCheck that injector is actuated five times by listening for the oper-

ating sound.

Or-

der

Probable cause of malfunc-

tion and checkMaintenance jobReinstatement method

1Connection of injector cou-

pler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).

Improperly connected

Connect the coupler secure

-

ly, or repair/replace the wire

harness.

After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

2Defective injector.Check the injector.

“CHECKING THE FUEL IN-

JECTOR” on page 8-47.

After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

3Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).

Improperly connected

Connect the coupler secure

-

ly, or repair/replace the wire

harness.

After starting the engine, idle

this and wait about 5 sec

-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

Fault code 33

SymptomIgnition coil: open or short circuit detected in the primary lead

of the ignition coil.

Page 334 of 360

ELECTRICAL COMPONENTS

8-44

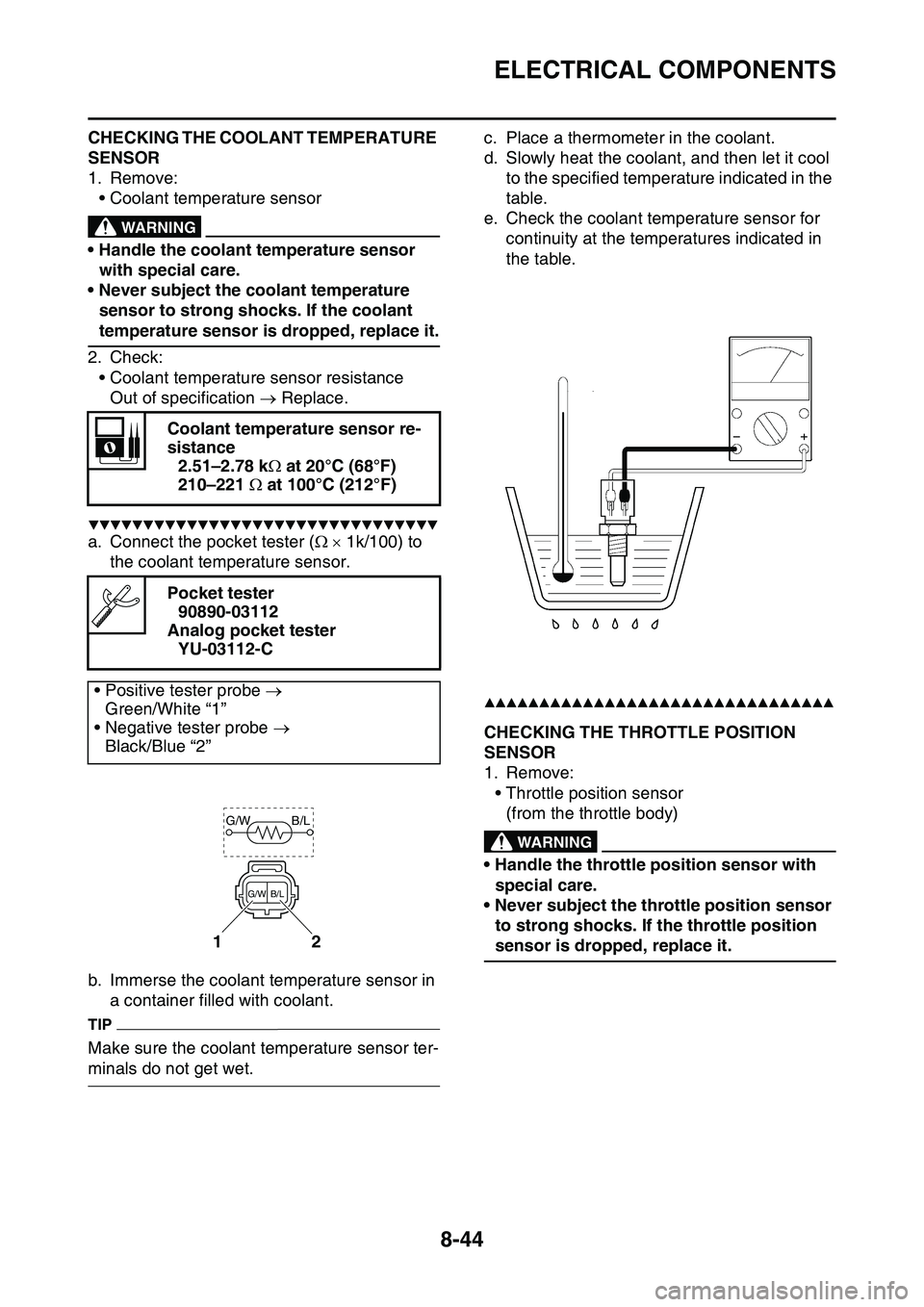

CHECKING THE COOLANT TEMPERATURE

SENSOR

1. Remove:

• Coolant temperature sensorEWA14130

WARNING

• Handle the coolant temperature sensor

with special care.

• Never subject the coolant temperature

sensor to strong shocks. If the coolant

temperature sensor is dropped, replace it.

2. Check:

• Coolant temperature sensor resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k/100) to

the coolant temperature sensor.

b. Immerse the coolant temperature sensor in

a container filled with coolant.

TIP

Make sure the coolant temperature sensor ter-

minals do not get wet.

c. Place a thermometer in the coolant.

d. Slowly heat the coolant, and then let it cool

to the specified temperature indicated in the

table.

e. Check the coolant temperature sensor for

continuity at the temperatures indicated in

the table.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1343CHECKING THE THROTTLE POSITION

SENSOR

1. Remove:

• Throttle position sensor

(from the throttle body)EWA1DX1009

WARNING

• Handle the throttle position sensor with

special care.

• Never subject the throttle position sensor

to strong shocks. If the throttle position

sensor is dropped, replace it.

Coolant temperature sensor re-

sistance

2.51–2.78 k at 20°C (68°F)

210–221 at 100°C (212°F)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Green/White “1”

• Negative tester probe

Black/Blue “2”

12

G/W B/L

B/L G/W

Page 336 of 360

ELECTRICAL COMPONENTS

8-46

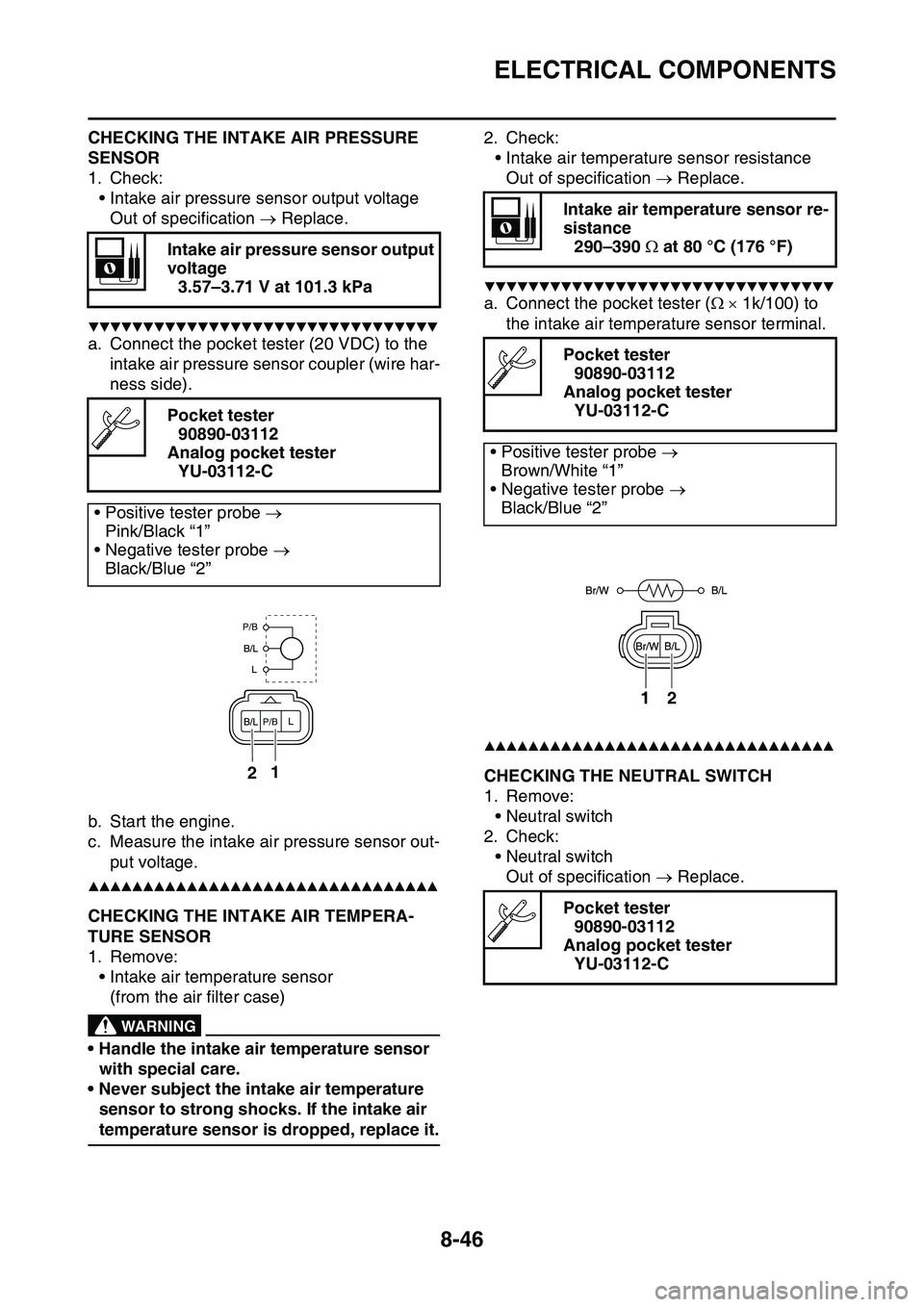

CHECKING THE INTAKE AIR PRESSURE

SENSOR

1. Check:

• Intake air pressure sensor output voltage

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester (20 VDC) to the

intake air pressure sensor coupler (wire har

-

ness side).

b. Start the engine.

c. Measure the intake air pressure sensor out-

put voltage.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1346CHECKING THE INTAKE AIR TEMPERA-

TURE SENSOR

1. Remove:

• Intake air temperature sensor

(from the air filter case)EWA1DX1010

WARNING

• Handle the intake air temperature sensor

with special care.

• Never subject the intake air temperature

sensor to strong shocks. If the intake air

temperature sensor is dropped, replace it.

2. Check:

• Intake air temperature sensor resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k/100) to

the intake air temperature sensor terminal.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1347CHECKING THE NEUTRAL SWITCH

1. Remove:

• Neutral switch

2. Check:

• Neutral switch

Out of specification Replace.

Intake air pressure sensor output

voltage

3.57–3.71 V at 101.3 kPa

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Pink/Black “1”

• Negative tester probe

Black/Blue “2”

12

P/B

P/B

Intake air temperature sensor re-

sistance

290–390 at 80 °C (176 °F)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Brown/White “1”

• Negative tester probe

Black/Blue “2”

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

12

Page 345 of 360

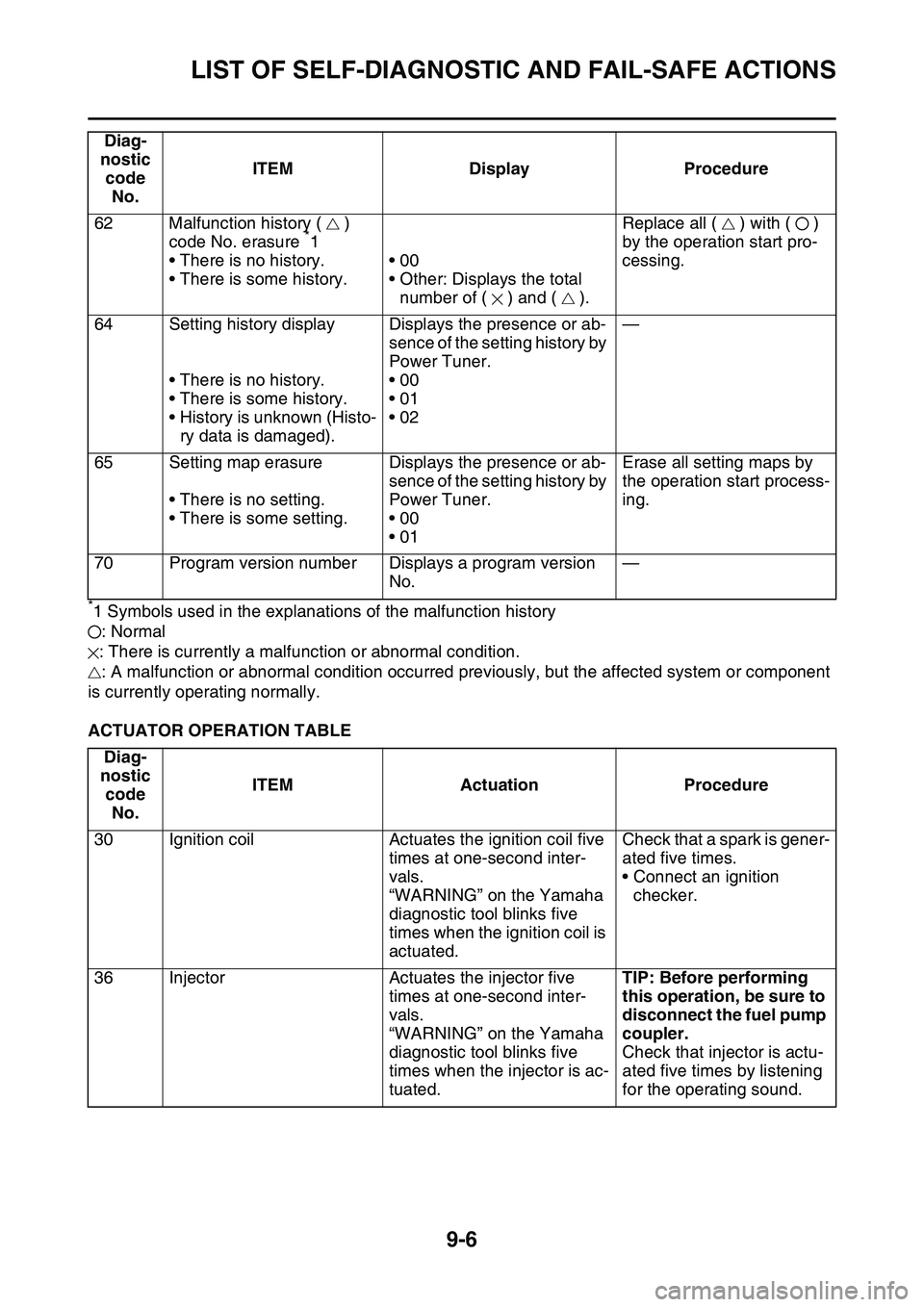

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

9-6

*1 Symbols used in the explanations of the malfunction history: Normal

: There is currently a malfunction or abnormal condition. : A malfunction or abnormal condition occurred prev iously, but the affected system or component

is currently operating normally.

ACTUATOR OPERATION TABLE 62 Malfunction history ( )

code No. erasure

*1

• There is no history.

• There is some history. •00

• Other: Displays the total

number of ( ) and ( ). Replace all ( ) with ( )

by the operation start pro-

cessing.

64 Setting history display • There is no history.

• There is some history.

• History is unknown (Histo-ry data is damaged). Displays the presence or ab-

sence of the setting history by

Power Tuner.

•00

•01

•02

—

65 Setting map erasure • There is no setting.

• There is some setting. Displays the presence or ab-

sence of the setting history by

Power Tuner.

•00

•01 Erase all setting maps by

the operation start process-

ing.

70 Program version number Displays a program version No.—

Diag-

nostic code No. ITEM Actuation Procedure

30 Ignition coil Actuates the ignition coil five times at one-second inter-

vals.

“WARNING” on the Yamaha

diagnostic tool blinks five

times when the ignition coil is

actuated.Check that a spark is gener-

ated five times.

• Connect an ignition

checker.

36 Injector Actuates the injector five times at one-second inter-

vals.

“WARNING” on the Yamaha

diagnostic tool blinks five

times when the injector is ac-

tuated.TIP: Before performing

this operation, be sure to

disconnect the fuel pump

coupler.

Check that injector is actu-

ated five times by listening

for the operating sound.

Diag-

nostic code No. ITEM Display Procedure

Page 349 of 360

CHASSIS

10-2

TIRE PRESSURE

Tire pressure should be adjusted to suit the

road surface condition of the circuit.

• Under a rainy, a muddy, a sandy, or a slippery

condition, the tire pressure should be lower

for a larger area of contact with the road sur

-

face.

• Under a stony or a hard road condition, the

tire pressure should be higher to prevent a flat

tire.

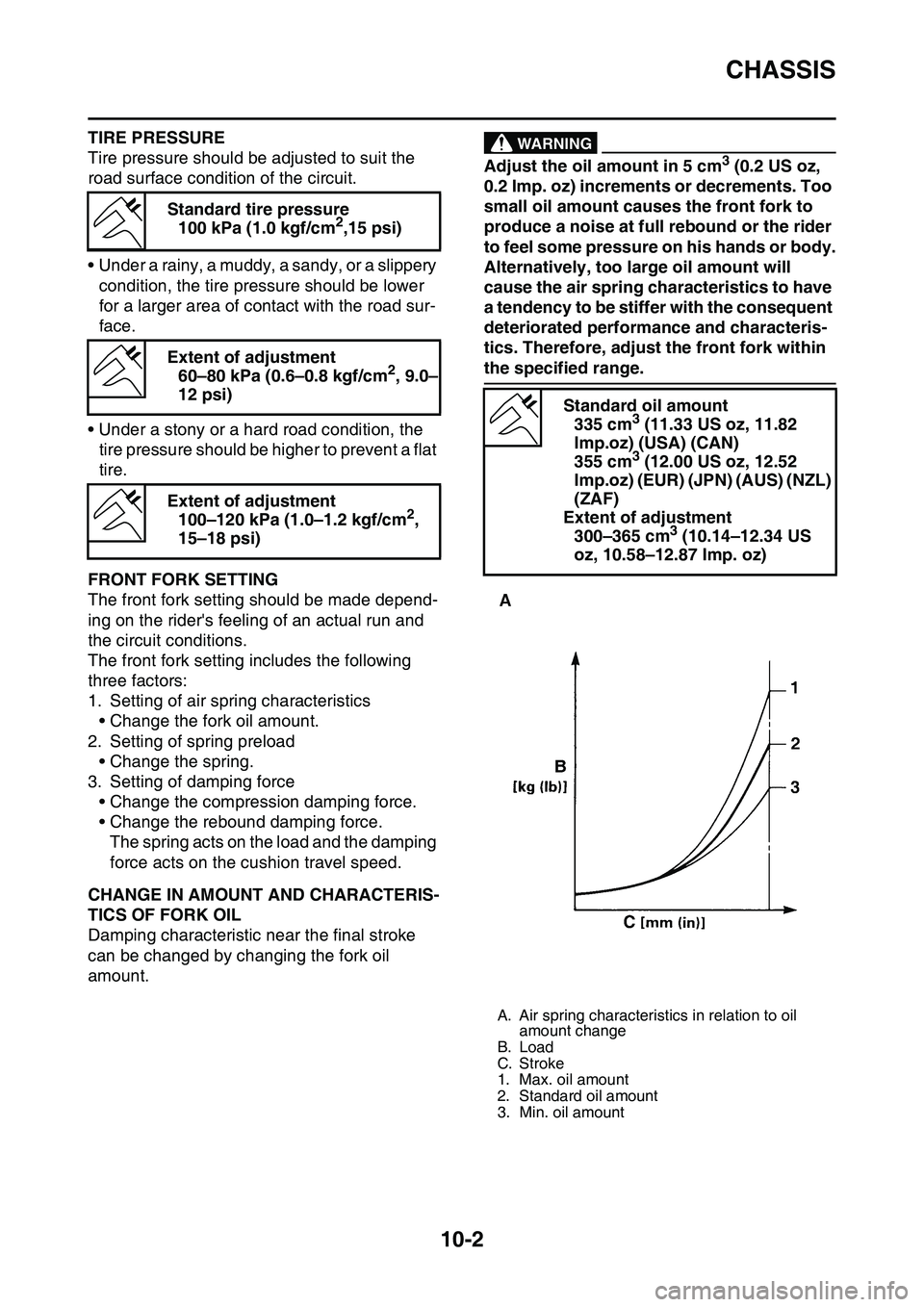

EAS1SL1369FRONT FORK SETTING

The front fork setting should be made depend-

ing on the rider's feeling of an actual run and

the circuit conditions.

The front fork setting includes the following

three factors:

1. Setting of air spring characteristics

• Change the fork oil amount.

2. Setting of spring preload

• Change the spring.

3. Setting of damping force

• Change the compression damping force.

• Change the rebound damping force.

The spring acts on the load and the damping

force acts on the cushion travel speed.

EAS1SL1370CHANGE IN AMOUNT AND CHARACTERIS-

TICS OF FORK OIL

Damping characteristic near the final stroke

can be changed by changing the fork oil

amount.

EWA1DX4001

WARNING

Adjust the oil amount in 5 cm3 (0.2 US oz,

0.2 Imp. oz) increments or decrements. Too

small oil amount causes the front fork to

produce a noise at full rebound or the rider

to feel some pressure on his hands or body.

Alternatively, too large oil amount will

cause the air spring characteristics to have

a tendency to be stiffer with the consequent

deteriorated performance and characteris

-

tics. Therefore, adjust the front fork within

the specified range.

EAS1SL1371

Standard tire pressure

100 kPa (1.0 kgf/cm2,15 psi)

Extent of adjustment

60–80 kPa (0.6–0.8 kgf/cm2, 9.0–

12 psi)

Extent of adjustment

100–120 kPa (1.0–1.2 kgf/cm2,

15–18 psi)

Standard oil amount

335 cm3 (11.33 US oz, 11.82

lmp.oz) (USA) (CAN)

355 cm3 (12.00 US oz, 12.52

lmp.oz) (EUR) (JPN) (AUS) (NZL)

(ZAF)

Extent of adjustment

300–365 cm3 (10.14–12.34 US

oz, 10.58–12.87 Imp. oz)

A. Air spring characteristics in relation to oil

amount change

B. Load

C. Stroke

1. Max. oil amount

2. Standard oil amount

3. Min. oil amount