clock YAMAHA YZ450F 2014 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 48 of 360

ENGINE SPECIFICATIONS

2-5

Winding direction (intake) Clockwise

Winding direction (exhaust) Clockwise

Cylinder

Bore 97.000–97.010 mm (3.8189–3.8193 in)

Taper limit 0.050 mm (0.0020 in)

Out of round limit 0.050 mm (0.0020 in)

Piston

Piston-to-cylinder clearance 0.030–0.055 mm (0.0012–0.0022 in)

Limit 0.15 mm (0.006 in)

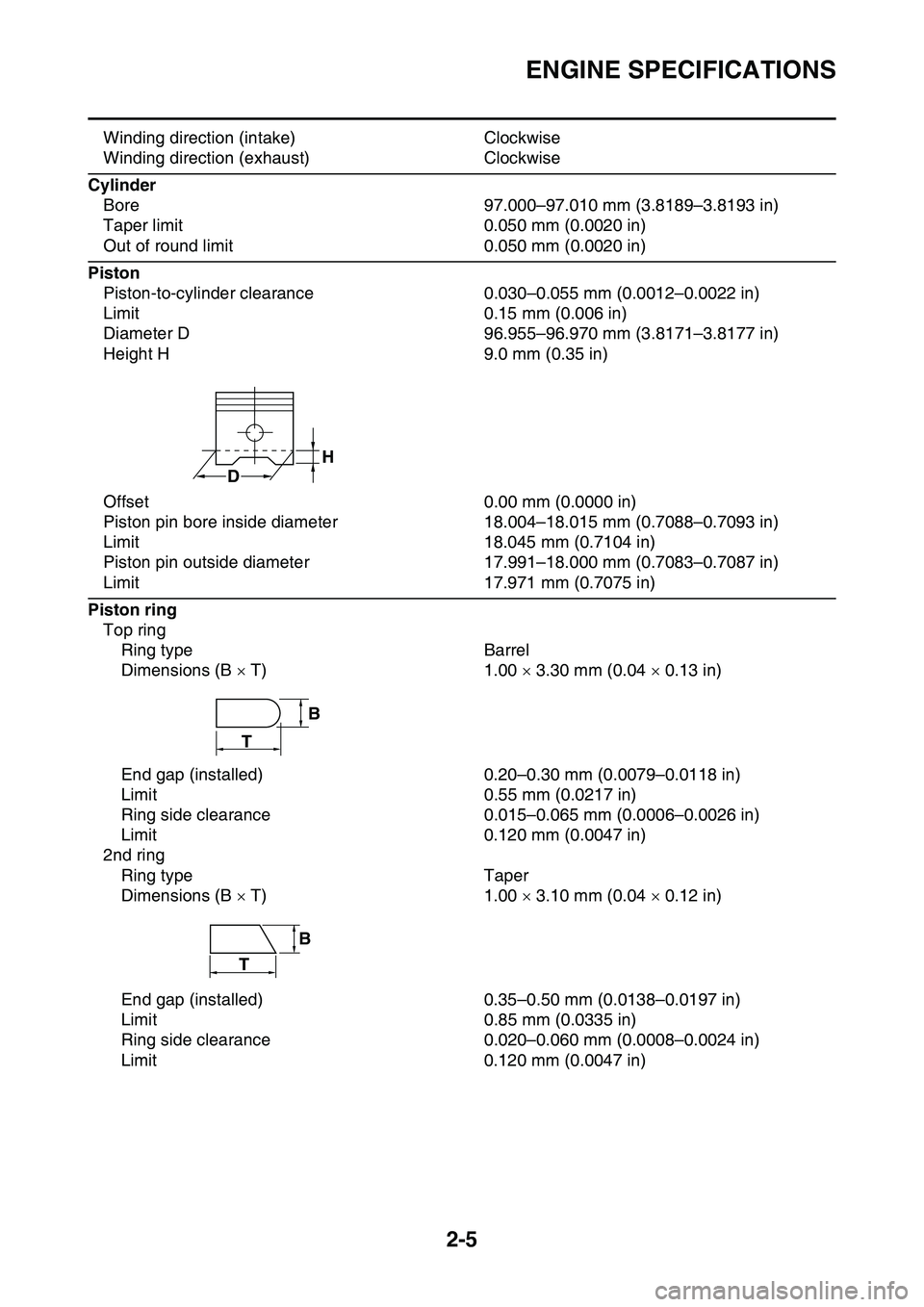

Diameter D 96.955–96.970 mm (3.8171–3.8177 in)

Height H 9.0 mm (0.35 in)

Offset 0.00 mm (0.0000 in)

Piston pin bore inside diameter 18.004–18.015 mm (0.7088–0.7093 in)

Limit 18.045 mm (0.7104 in)

Piston pin outside diameter 17.991–18.000 mm (0.7083–0.7087 in)

Limit 17.971 mm (0.7075 in)

Piston ring

Top ring

Ring type Barrel

Dimensions (B T) 1.00 3.30 mm (0.04 0.13 in)

End gap (installed) 0.20–0.30 mm (0.0079–0.0118 in)

Limit 0.55 mm (0.0217 in)

Ring side clearance 0.015–0.065 mm (0.0006–0.0026 in)

Limit 0.120 mm (0.0047 in)

2nd ring

Ring type Taper

Dimensions (B T) 1.00 3.10 mm (0.04 0.12 in)

End gap (installed) 0.35–0.50 mm (0.0138–0.0197 in)

Limit 0.85 mm (0.0335 in)

Ring side clearance 0.020–0.060 mm (0.0008–0.0024 in)

Limit 0.120 mm (0.0047 in)

H

D

T

B

B

T

Page 104 of 360

ENGINE

3-16

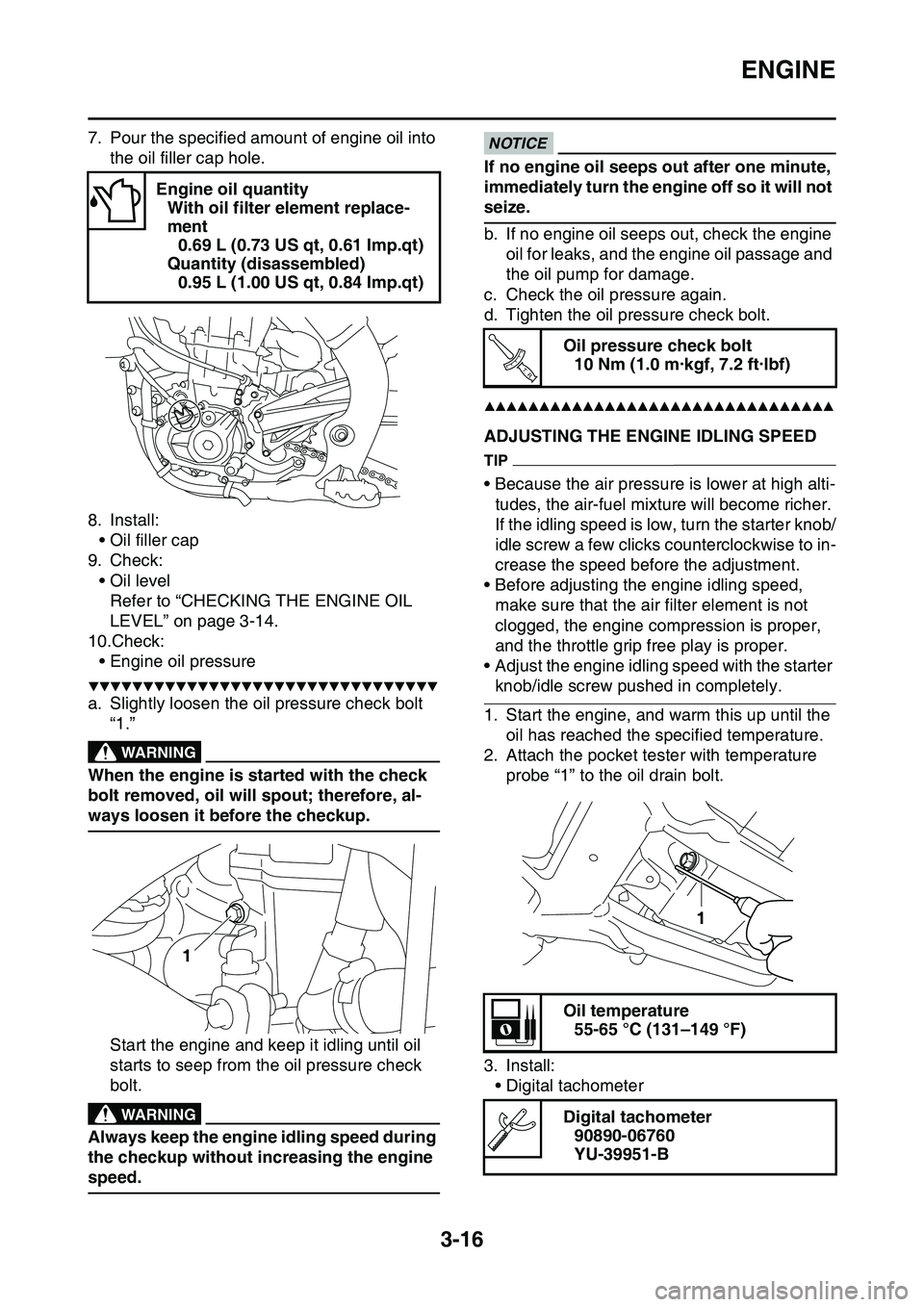

7. Pour the specified amount of engine oil into

the oil filler cap hole.

8. Install:

• Oil filler cap

9. Check:

• Oil level

Refer to “CHECKING THE ENGINE OIL

LEVEL” on page 3-14.

10.Check:

• Engine oil pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Slightly loosen the oil pressure check bolt

“1.”

EWA

WARNING

When the engine is started with the check

bolt removed, oil will spout; therefore, al

-

ways loosen it before the checkup.

Start the engine and keep it idling until oil

starts to seep from the oil pressure check

bolt.

EWA

WARNING

Always keep the engine idling speed during

the checkup without increasing the engine

speed.

ECA

NOTICE

If no engine oil seeps out after one minute,

immediately turn the engine off so it will not

seize.

b. If no engine oil seeps out, check the engine

oil for leaks, and the engine oil passage and

the oil pump for damage.

c. Check the oil pressure again.

d. Tighten the oil pressure check bolt.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1087ADJUSTING THE ENGINE IDLING SPEED

TIP

• Because the air pressure is lower at high alti-

tudes, the air-fuel mixture will become richer.

If the idling speed is low, turn the starter knob/

idle screw a few clicks counterclockwise to in

-

crease the speed before the adjustment.

• Before adjusting the engine idling speed,

make sure that the air filter element is not

clogged, the engine compression is proper,

and the throttle grip free play is proper.

• Adjust the engine idling speed with the starter

knob/idle screw pushed in completely.

1. Start the engine, and warm this up until the

oil has reached the specified temperature.

2. Attach the pocket tester with temperature

probe “1” to the oil drain bolt.

3. Install:

• Digital tachometer

Engine oil quantity

With oil filter element replace-

ment

0.69 L (0.73 US qt, 0.61 Imp.qt)

Quantity (disassembled)

0.95 L (1.00 US qt, 0.84 Imp.qt)

1

Oil pressure check bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil temperature

55-65 °C (131–149 °F)

Digital tachometer

90890-06760

YU-39951-B

T R..

1

Page 105 of 360

ENGINE

3-17

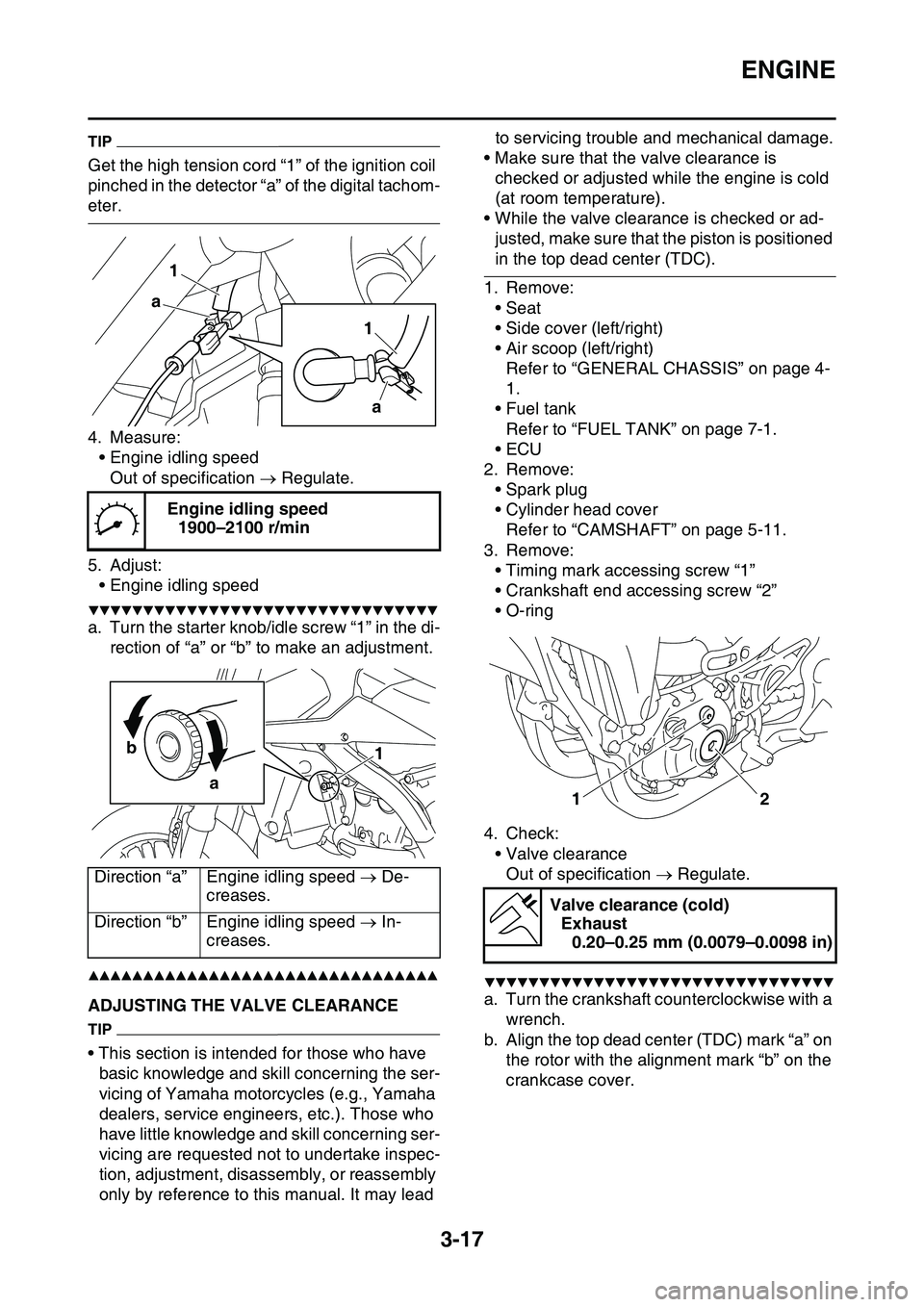

TIP

Get the high tension cord “1” of the ignition coil

pinched in the detector “a” of the digital tachom

-

eter.

4. Measure:

• Engine idling speed

Out of specification Regulate.

5. Adjust:

• Engine idling speed

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the starter knob/idle screw “1” in the di-

rection of “a” or “b” to make an adjustment.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1088ADJUSTING THE VALVE CLEARANCE

TIP

• This section is intended for those who have

basic knowledge and skill concerning the ser

-

vicing of Yamaha motorcycles (e.g., Yamaha

dealers, service engineers, etc.). Those who

have little knowledge and skill concerning ser

-

vicing are requested not to undertake inspec-

tion, adjustment, disassembly, or reassembly

only by reference to this manual. It may lead to servicing trouble and mechanical damage.

• Make sure that the valve clearance is

checked or adjusted while the engine is cold

(at room temperature).

• While the valve clearance is checked or ad-

justed, make sure that the piston is positioned

in the top dead center (TDC).

1. Remove:

• Seat

• Side cover (left/right)

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

•ECU

2. Remove:

• Spark plug

• Cylinder head cover

Refer to “CAMSHAFT” on page 5-11.

3. Remove:

• Timing mark accessing screw “1”

• Crankshaft end accessing screw “2”

• O-ring

4. Check:

• Valve clearance

Out of specification Regulate.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft counterclockwise with a

wrench.

b. Align the top dead center (TDC) mark “a” on

the rotor with the alignment mark “b” on the

crankcase cover.

Engine idling speed

1900–2100 r/min

Direction “a”Engine idling speed De-

creases.

Direction “b”Engine idling speed In-

creases.

1 1

a a

1 b

a

Valve clearance (cold)

Exhaust

0.20–0.25 mm (0.0079–0.0098 in)

1

2

Page 123 of 360

ELECTRICAL SYSTEM

3-35

EAS1SL1114

ELECTRICAL SYSTEM

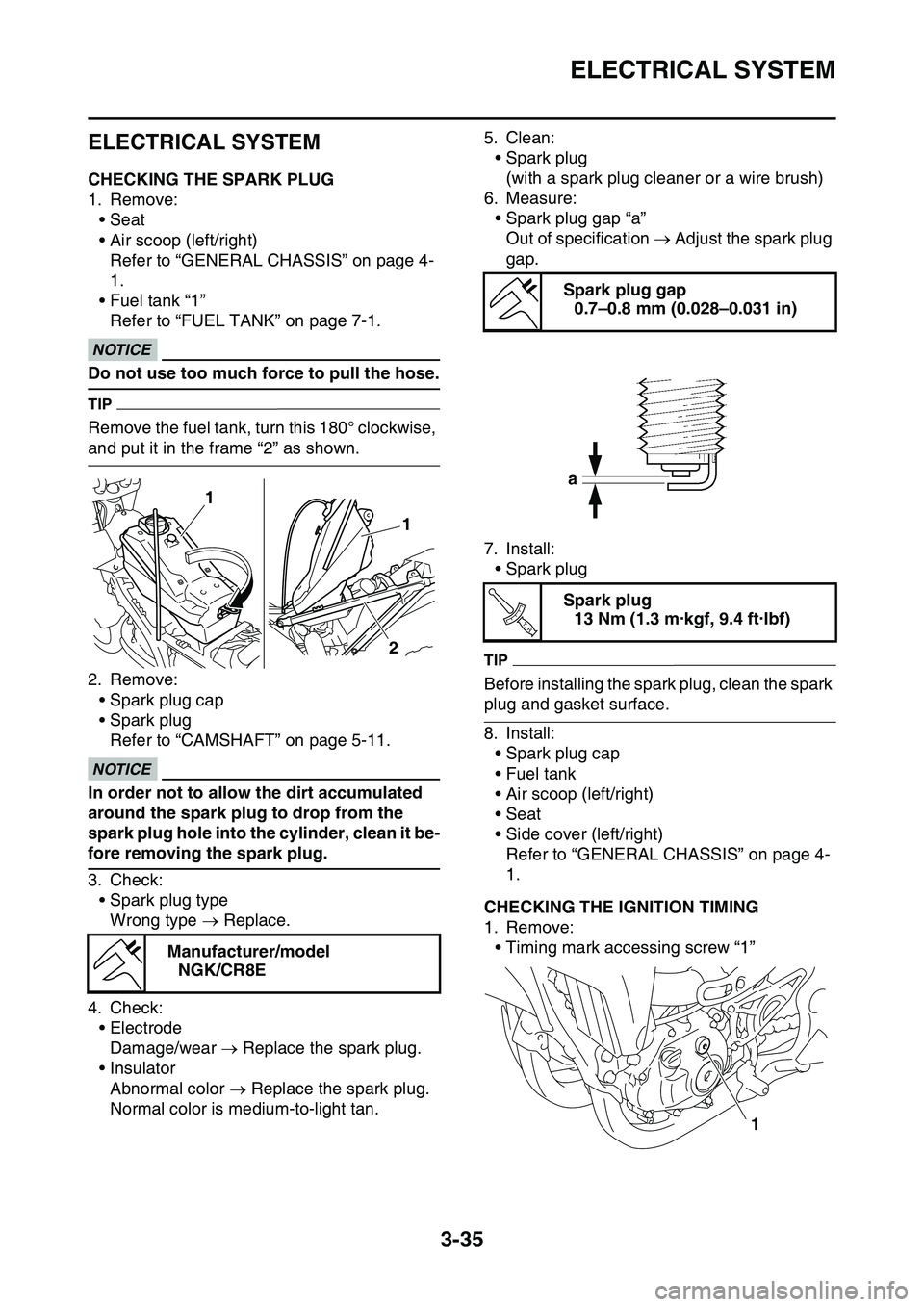

EAS1SL1115CHECKING THE SPARK PLUG

1. Remove:

• Seat

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

• Fuel tank “1”

Refer to “FUEL TANK” on page 7-1.ECA1DX1001

NOTICE

Do not use too much force to pull the hose.

TIP

Remove the fuel tank, turn this 180° clockwise,

and put it in the frame “2” as shown.

2. Remove:

• Spark plug cap

• Spark plug

Refer to “CAMSHAFT” on page 5-11.ECA13330

NOTICE

In order not to allow the dirt accumulated

around the spark plug to drop from the

spark plug hole into the cylinder, clean it be

-

fore removing the spark plug.

3. Check:

• Spark plug type

Wrong type Replace.

4. Check:

• Electrode

Damage/wear Replace the spark plug.

• Insulator

Abnormal color Replace the spark plug.

Normal color is medium-to-light tan.

5. Clean:

• Spark plug

(with a spark plug cleaner or a wire brush)

6. Measure:

• Spark plug gap “a”

Out of specification Adjust the spark plug

gap.

7. Install:

• Spark plug

TIP

Before installing the spark plug, clean the spark

plug and gasket surface.

8. Install:

• Spark plug cap

• Fuel tank

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

EAS1SL1116CHECKING THE IGNITION TIMING

1. Remove:

• Timing mark accessing screw “1”Manufacturer/model

NGK/CR8E

1

1

2

Spark plug gap

0.7–0.8 mm (0.028–0.031 in)

Spark plug

13 Nm (1.3 m·kgf, 9.4 ft·lbf)T R..

1

Page 208 of 360

CAMSHAFT

5-13

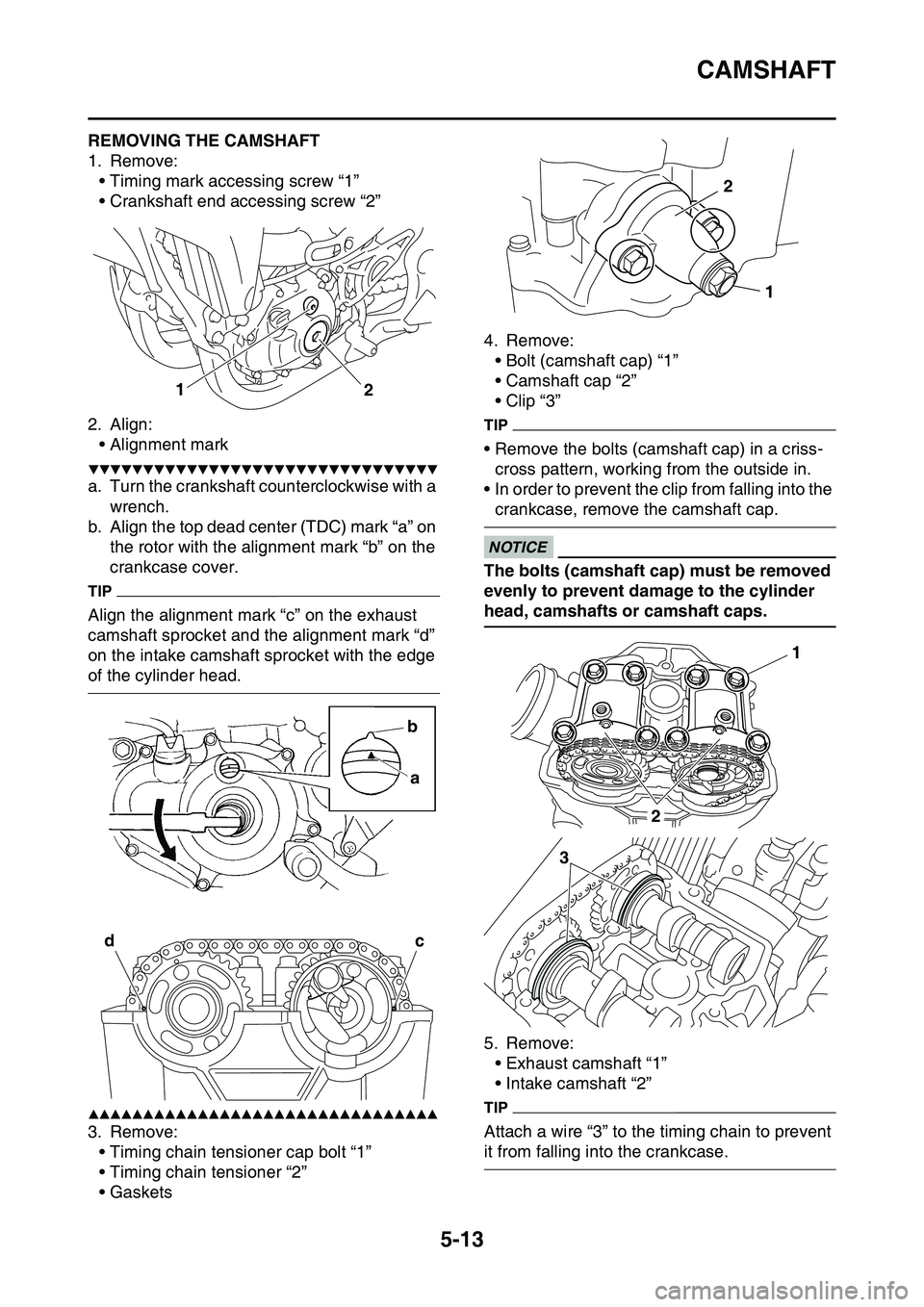

EAS1SL1208REMOVING THE CAMSHAFT

1. Remove:

• Timing mark accessing screw “1”

• Crankshaft end accessing screw “2”

2. Align:

• Alignment mark

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft counterclockwise with a

wrench.

b. Align the top dead center (TDC) mark “a” on

the rotor with the alignment mark “b” on the

crankcase cover.

TIP

Align the alignment mark “c” on the exhaust

camshaft sprocket and the alignment mark “d”

on the intake camshaft sprocket with the edge

of the cylinder head.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Remove:

• Timing chain tensioner cap bolt “1”

• Timing chain tensioner “2”

•Gaskets

4. Remove:

• Bolt (camshaft cap) “1”

• Camshaft cap “2”

• Clip “3”

TIP

• Remove the bolts (camshaft cap) in a criss-

cross pattern, working from the outside in.

• In order to prevent the clip from falling into the

crankcase, remove the camshaft cap.

ECA33DD027

NOTICE

The bolts (camshaft cap) must be removed

evenly to prevent damage to the cylinder

head, camshafts or camshaft caps.

5. Remove:

• Exhaust camshaft “1”

• Intake camshaft “2”

TIP

Attach a wire “3” to the timing chain to prevent

it from falling into the crankcase.

1

2

b

a

dc

1 2

1

2

3

Page 210 of 360

CAMSHAFT

5-15

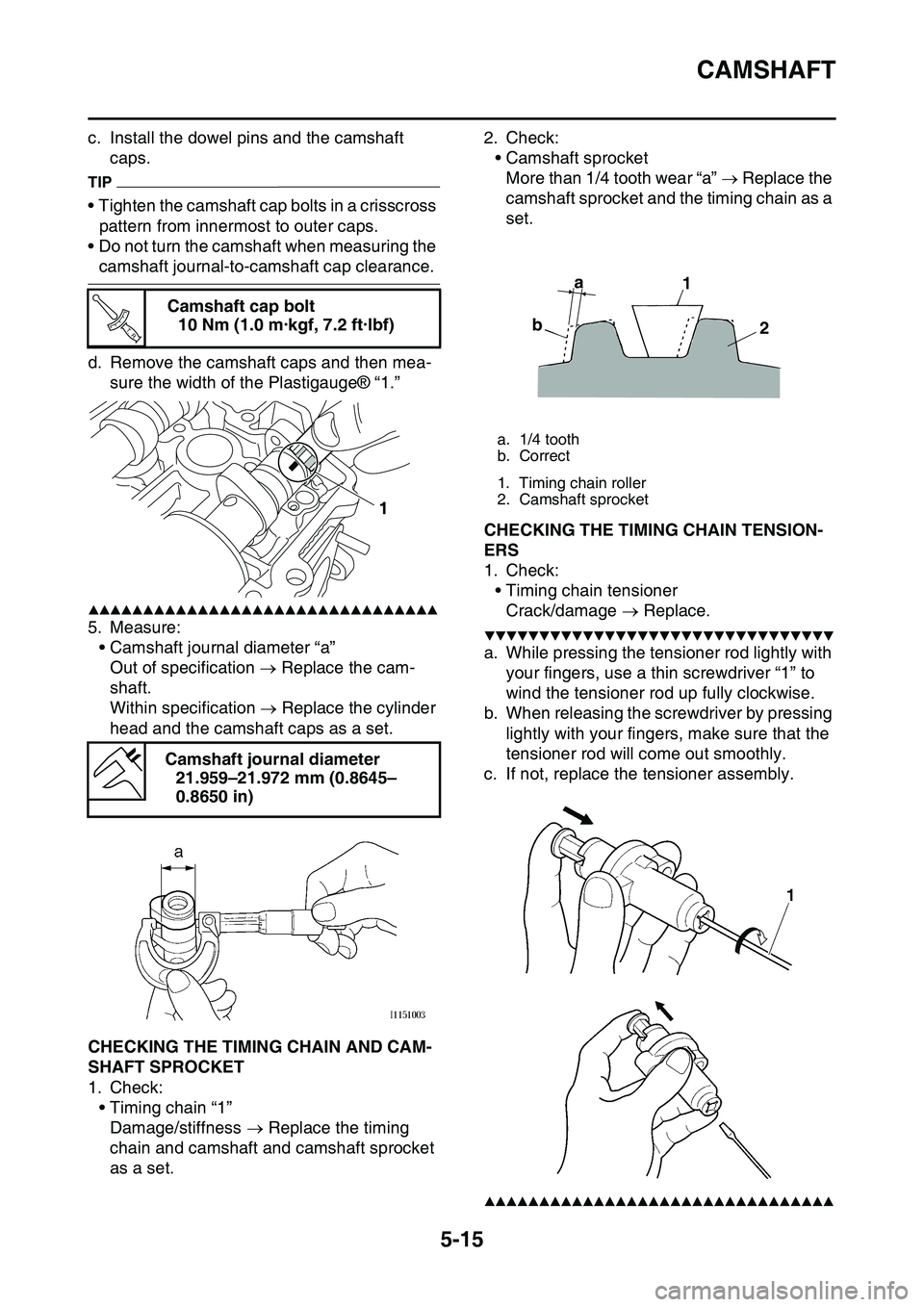

c. Install the dowel pins and the camshaft

caps.

TIP

• Tighten the camshaft cap bolts in a crisscross

pattern from innermost to outer caps.

• Do not turn the camshaft when measuring the

camshaft journal-to-camshaft cap clearance.

d. Remove the camshaft caps and then mea-

sure the width of the Plastigauge® “1.”

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Measure:

• Camshaft journal diameter “a”

Out of specification Replace the cam-

shaft.

Within specification Replace the cylinder

head and the camshaft caps as a set.

EAS1SL1210CHECKING THE TIMING CHAIN AND CAM-

SHAFT SPROCKET

1. Check:

• Timing chain “1”

Damage/stiffness Replace the timing

chain and camshaft and camshaft sprocket

as a set.

2. Check:

• Camshaft sprocket

More than 1/4 tooth wear “a” Replace the

camshaft sprocket and the timing chain as a

set.

EAS1SL1211CHECKING THE TIMING CHAIN TENSION-

ERS

1. Check:

• Timing chain tensioner

Crack/damage Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. While pressing the tensioner rod lightly with

your fingers, use a thin screwdriver “1” to

wind the tensioner rod up fully clockwise.

b. When releasing the screwdriver by pressing

lightly with your fingers, make sure that the

tensioner rod will come out smoothly.

c. If not, replace the tensioner assembly.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Camshaft cap bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Camshaft journal diameter

21.959–21.972 mm (0.8645–

0.8650 in)

T R..

1

a. 1/4 tooth

b. Correct

1. Timing chain roller

2. Camshaft sprocket

a

b1

2

Page 211 of 360

CAMSHAFT

5-16

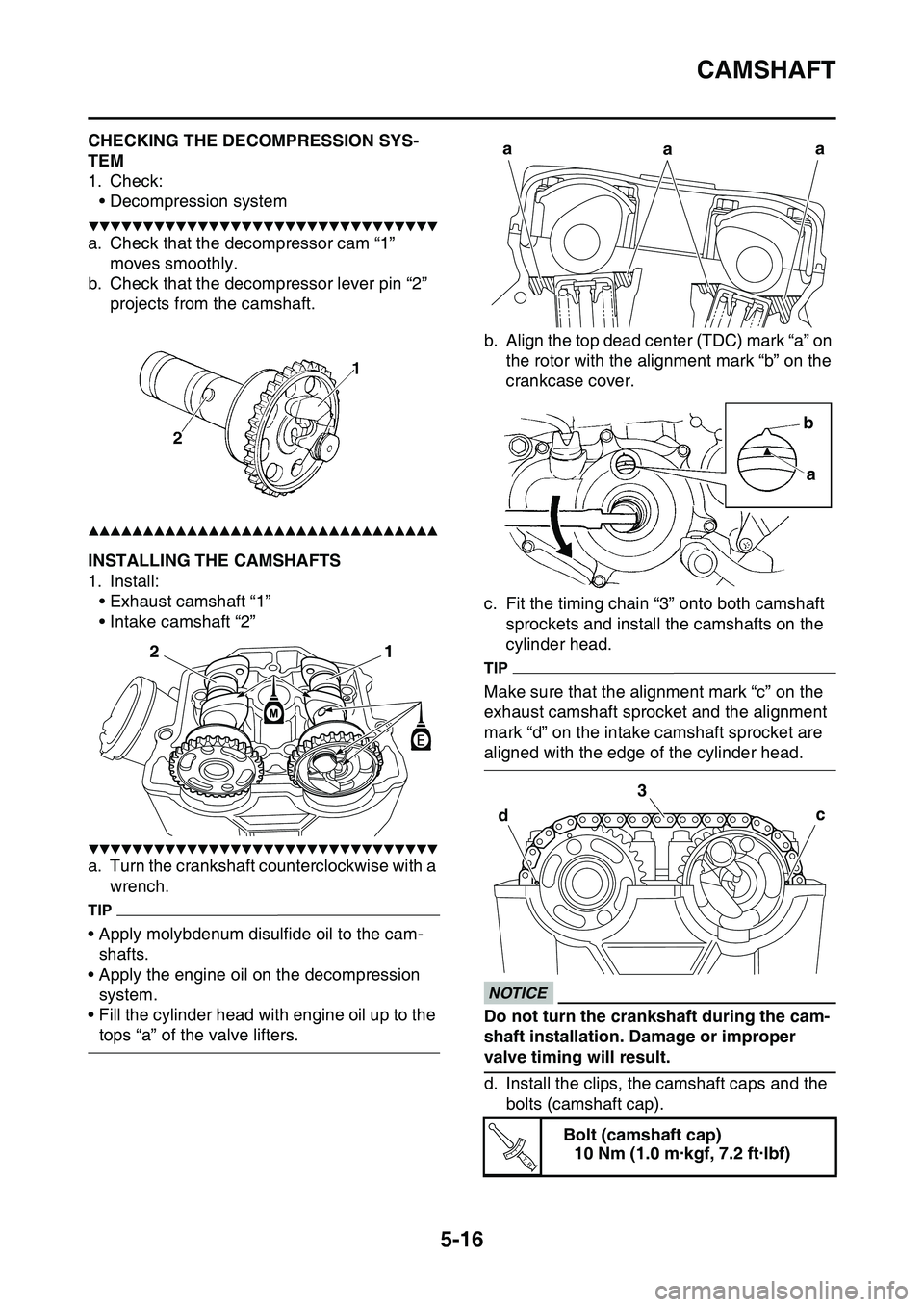

EAS1SL1212CHECKING THE DECOMPRESSION SYS-

TEM

1. Check:

• Decompression system

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Check that the decompressor cam “1”

moves smoothly.

b. Check that the decompressor lever pin “2”

projects from the camshaft.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1213INSTALLING THE CAMSHAFTS

1. Install:

• Exhaust camshaft “1”

• Intake camshaft “2”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft counterclockwise with a

wrench.

TIP

• Apply molybdenum disulfide oil to the cam-

shafts.

• Apply the engine oil on the decompression

system.

• Fill the cylinder head with engine oil up to the

tops “a” of the valve lifters.

b. Align the top dead center (TDC) mark “a” on

the rotor with the alignment mark “b” on the

crankcase cover.

c. Fit the timing chain “3” onto both camshaft

sprockets and install the camshafts on the

cylinder head.

TIP

Make sure that the alignment mark “c” on the

exhaust camshaft sprocket and the alignment

mark “d” on the intake camshaft sprocket are

aligned with the edge of the cylinder head.

ECA33DD029

NOTICE

Do not turn the crankshaft during the cam-

shaft installation. Damage or improper

valve timing will result.

d. Install the clips, the camshaft caps and the

bolts (camshaft cap).

1

2

Bolt (camshaft cap)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

a

aa

b

a

c 3

d

T R..

Page 212 of 360

CAMSHAFT

5-17

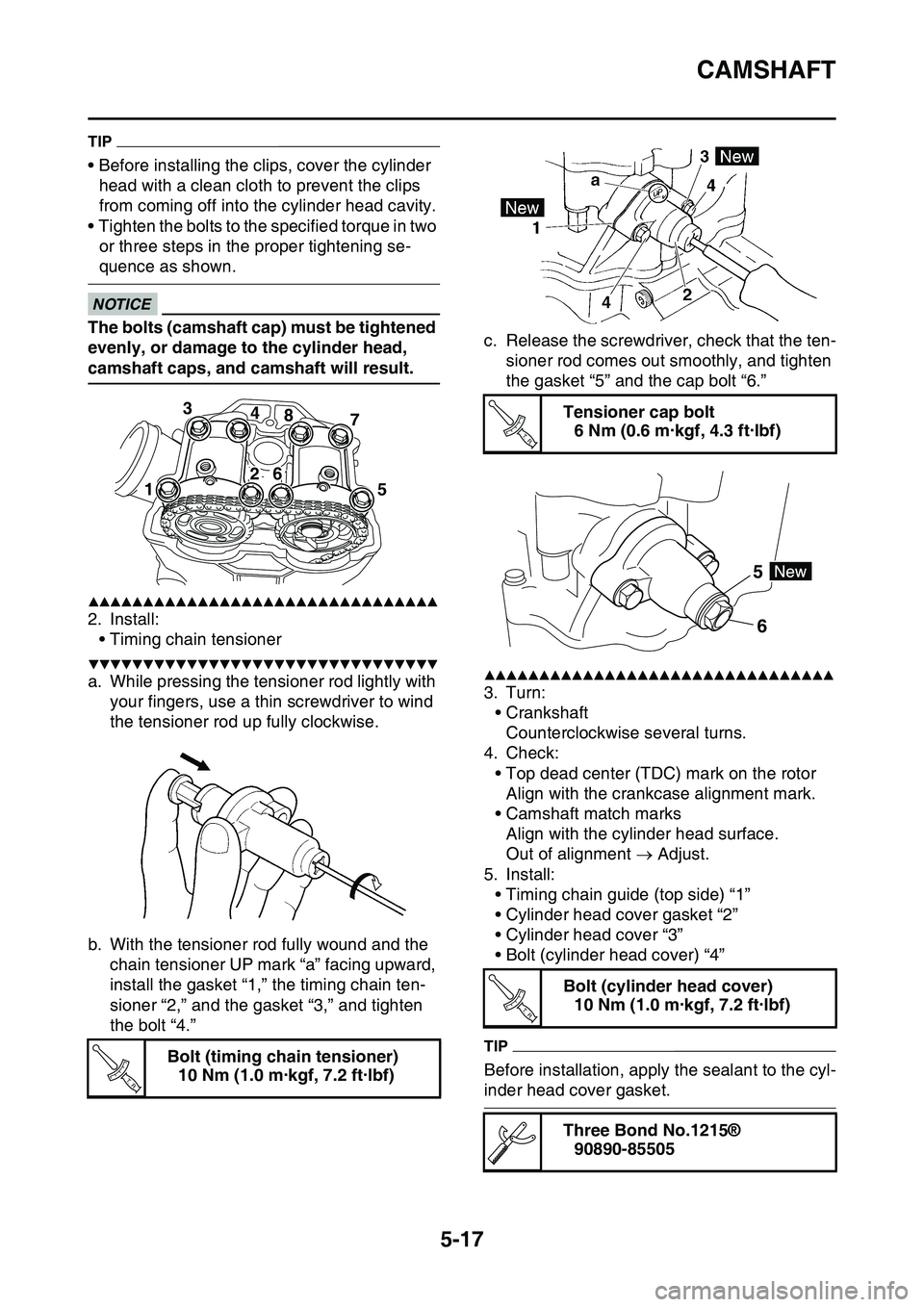

TIP

• Before installing the clips, cover the cylinder

head with a clean cloth to prevent the clips

from coming off into the cylinder head cavity.

• Tighten the bolts to the specified torque in two

or three steps in the proper tightening se

-

quence as shown.

ECA33DD030

NOTICE

The bolts (camshaft cap) must be tightened

evenly, or damage to the cylinder head,

camshaft caps, and camshaft will result.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

2. Install:

• Timing chain tensioner

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. While pressing the tensioner rod lightly with

your fingers, use a thin screwdriver to wind

the tensioner rod up fully clockwise.

b. With the tensioner rod fully wound and the

chain tensioner UP mark “a” facing upward,

install the gasket “1,” the timing chain ten

-

sioner “2,” and the gasket “3,” and tighten

the bolt “4.”

c. Release the screwdriver, check that the ten-

sioner rod comes out smoothly, and tighten

the gasket “5” and the cap bolt “6.”

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Turn:

• Crankshaft

Counterclockwise several turns.

4. Check:

• Top dead center (TDC) mark on the rotor

Align with the crankcase alignment mark.

• Camshaft match marks

Align with the cylinder head surface.

Out of alignment Adjust.

5. Install:

• Timing chain guide (top side) “1”

• Cylinder head cover gasket “2”

• Cylinder head cover “3”

• Bolt (cylinder head cover) “4”

TIP

Before installation, apply the sealant to the cyl-

inder head cover gasket.

Bolt (timing chain tensioner)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

3

4

8

7

15

26

T R..

Tensioner cap bolt

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Bolt (cylinder head cover)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Three Bond No.1215®

90890-85505

T R..

6 5

T R..

Page 243 of 360

KICKSTATER

5-48

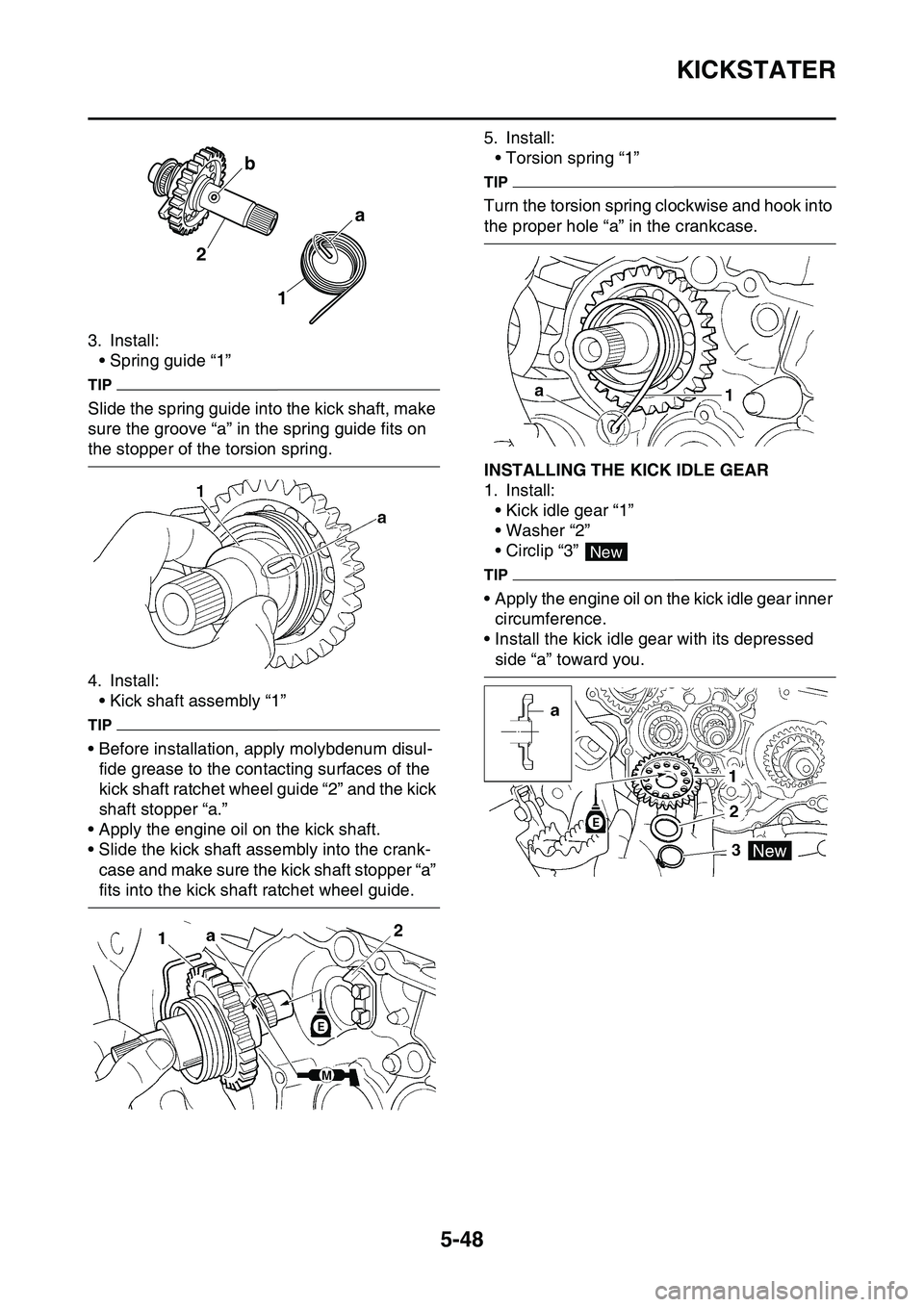

3. Install:

• Spring guide “1”

TIP

Slide the spring guide into the kick shaft, make

sure the groove “a” in the spring guide fits on

the stopper of the torsion spring.

4. Install:

• Kick shaft assembly “1”

TIP

• Before installation, apply molybdenum disul-

fide grease to the contacting surfaces of the

kick shaft ratchet wheel guide “2” and the kick

shaft stopper “a.”

• Apply the engine oil on the kick shaft.

• Slide the kick shaft assembly into the crank-

case and make sure the kick shaft stopper “a”

fits into the kick shaft ratchet wheel guide.

5. Install:

• Torsion spring “1”

TIP

Turn the torsion spring clockwise and hook into

the proper hole “a” in the crankcase.

EAS1SL1253INSTALLING THE KICK IDLE GEAR

1. Install:

• Kick idle gear “1”

• Washer “2”

• Circlip “3”

TIP

• Apply the engine oil on the kick idle gear inner

circumference.

• Install the kick idle gear with its depressed

side “a” toward you.

1 2a b

New

Page 246 of 360

SHIFT SHAFT

5-51

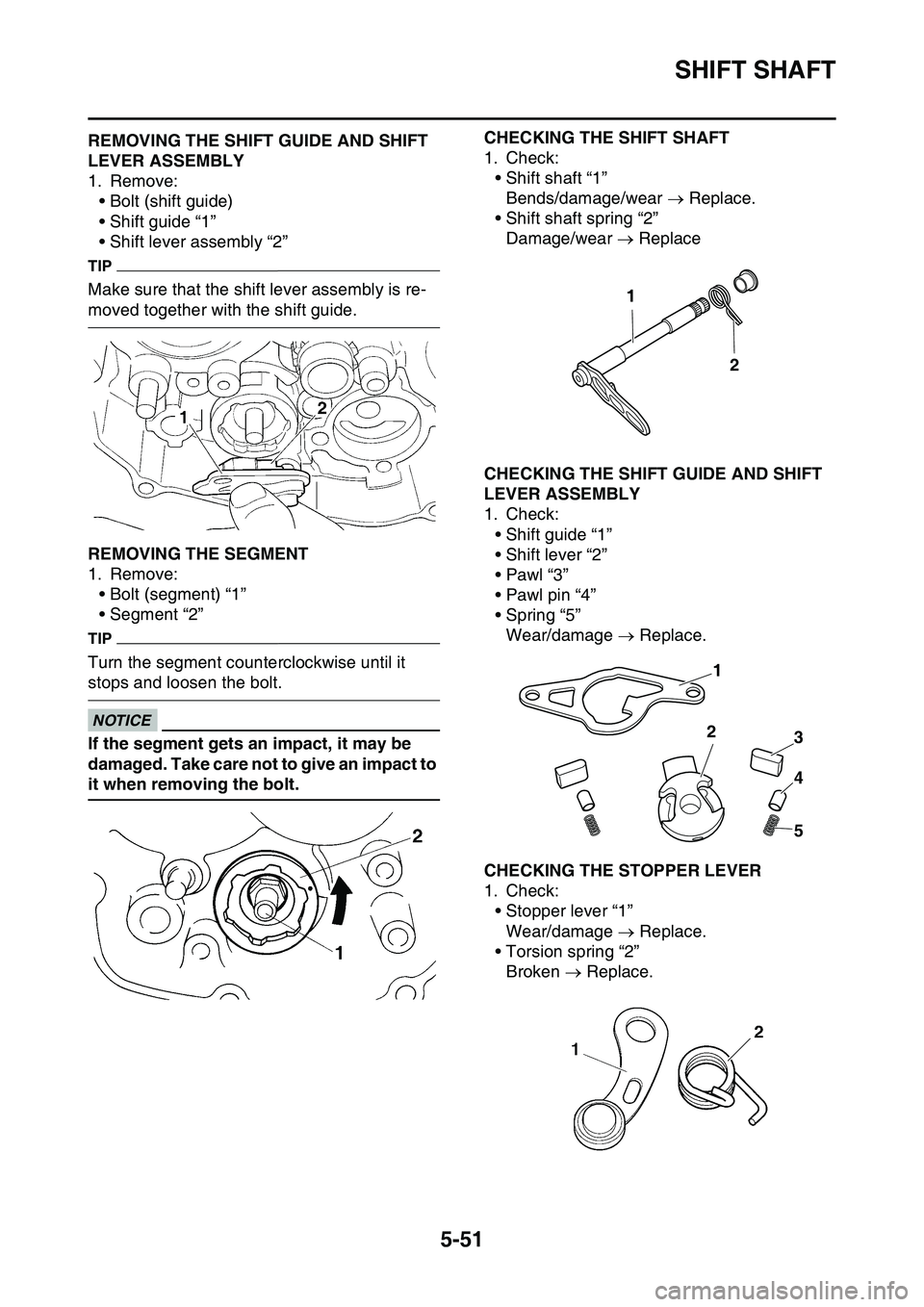

EAS1SL1255REMOVING THE SHIFT GUIDE AND SHIFT

LEVER ASSEMBLY

1. Remove:

• Bolt (shift guide)

• Shift guide “1”

• Shift lever assembly “2”

TIP

Make sure that the shift lever assembly is re-

moved together with the shift guide.

EAS1SL1256REMOVING THE SEGMENT

1. Remove:

• Bolt (segment) “1”

• Segment “2”

TIP

Turn the segment counterclockwise until it

stops and loosen the bolt.

ECA1DX1021

NOTICE

If the segment gets an impact, it may be

damaged. Take care not to give an impact to

it when removing the bolt.

EAS1SL1257

CHECKING THE SHIFT SHAFT

1. Check:

• Shift shaft “1”

Bends/damage/wear Replace.

• Shift shaft spring “2”

Damage/wear Replace

EAS1SL1258CHECKING THE SHIFT GUIDE AND SHIFT

LEVER ASSEMBLY

1. Check:

• Shift guide “1”

• Shift lever “2”

•Pawl “3”

• Pawl pin “4”

• Spring “5”

Wear/damage Replace.

EAS1SL1259CHECKING THE STOPPER LEVER

1. Check:

• Stopper lever “1”

Wear/damage Replace.

• Torsion spring “2”

Broken Replace.

1

2

1

2

3

4

5