gas type YAMAHA YZ450F 2015 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: YZ450F, Model: YAMAHA YZ450F 2015Pages: 360, PDF Size: 10.82 MB

Page 36 of 360

STARTING AND BREAK-IN

1-22

EAS1SL5042

STARTING AND BREAK-IN

EAS1SL5043FUEL

Always use the recommended fuel as stated

below. Also, be sure to use new gasoline the

day of a race.

JCA

NOTICE

Use only unleaded gasoline. The use of

leaded gasoline will cause severe damage

to the engine internal parts such as valves,

piston rings, and exhaust system, etc.

TIP

Your Yamaha engine has been designed to use

premium unleaded gasoline with a pump oc-

tane number [(R+M)/2] of 91 or higher, or a re-

search octane number of 95 or higher. If

knocking (or pinging) occurs, use a gasoline of

a different brand.

JWA

WARNING

• For refueling, be sure to stop the engine

and use enough care not to spill any fuel.

Also be sure to avoid refueling close to a

fire.

• Refuel after the engine, exhaust pipe, etc.

have cooled off.

Gasohol (For USA and Canada)

There are two types of gasohol: gasohol con-

taining ethanol and that containing methanol.

Gasohol containing ethanol can be used if the

ethanol content does not exceed 10%. Gasohol

containing methanol is not recommended by

Yamaha because it can cause damage to the

fuel system or vehicle performance problems.

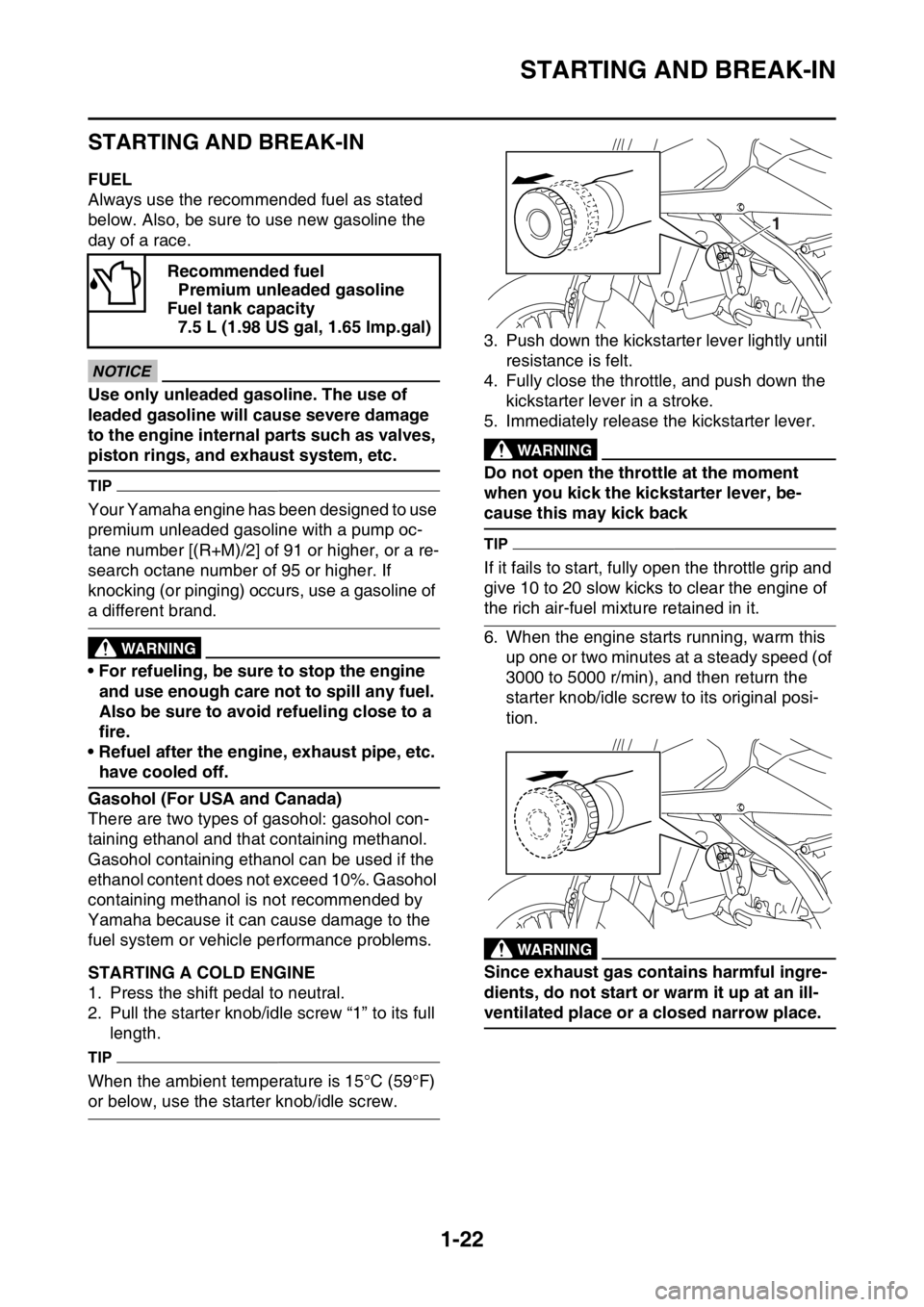

EAS1SL5044STARTING A COLD ENGINE

1. Press the shift pedal to neutral.

2. Pull the starter knob/idle screw “1” to its full

length.

TIP

When the ambient temperature is 15°C (59°F)

or below, use the starter knob/idle screw.3. Push down the kickstarter lever lightly until

resistance is felt.

4. Fully close the throttle, and push down the

kickstarter lever in a stroke.

5. Immediately release the kickstarter lever.

EWA

WARNING

Do not open the throttle at the moment

when you kick the kickstarter lever, be-

cause this may kick back

TIP

If it fails to start, fully open the throttle grip and

give 10 to 20 slow kicks to clear the engine of

the rich air-fuel mixture retained in it.

6. When the engine starts running, warm this

up one or two minutes at a steady speed (of

3000 to 5000 r/min), and then return the

starter knob/idle screw to its original posi-

tion.

EWA

WARNING

Since exhaust gas contains harmful ingre-

dients, do not start or warm it up at an ill-

ventilated place or a closed narrow place. Recommended fuel

Premium unleaded gasoline

Fuel tank capacity

7.5 L (1.98 US gal, 1.65 lmp.gal)

1

Page 45 of 360

ENGINE SPECIFICATIONS

2-2

EAS1SL5054

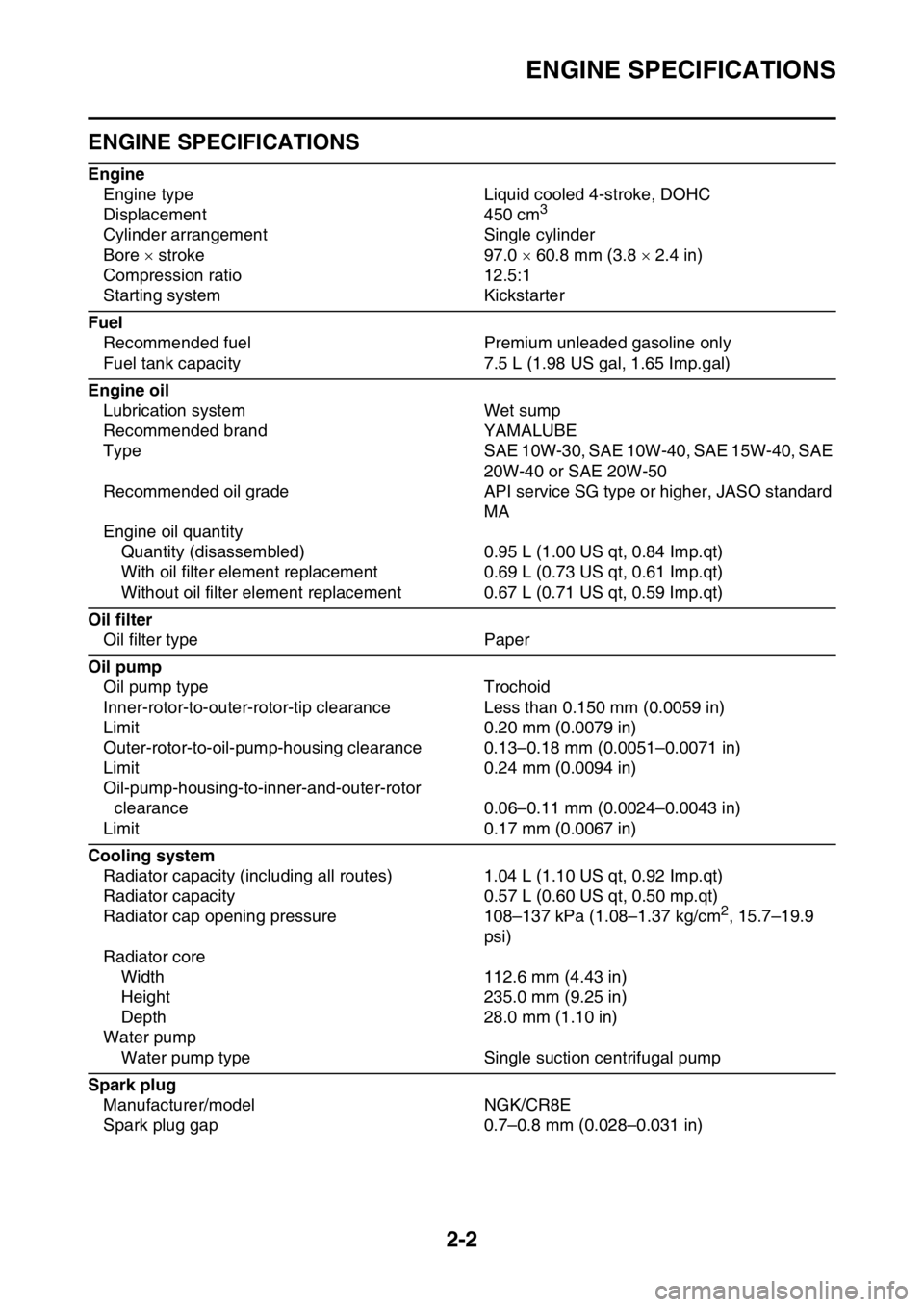

ENGINE SPECIFICATIONS

Engine

Engine type Liquid cooled 4-stroke, DOHC

Displacement 450 cm

3

Cylinder arrangement Single cylinder

Bore stroke 97.0 60.8 mm (3.8 2.4 in)

Compression ratio 12.5:1

Starting system Kickstarter

Fuel

Recommended fuel Premium unleaded gasoline only

Fuel tank capacity 7.5 L (1.98 US gal, 1.65 Imp.gal)

Engine oil

Lubrication system Wet sump

Recommended brand YAMALUBE

Type SAE 10W-30, SAE 10W-40, SAE 15W-40, SAE

20W-40 or SAE 20W-50

Recommended oil grade API service SG type or higher, JASO standard

MA

Engine oil quantity

Quantity (disassembled) 0.95 L (1.00 US qt, 0.84 Imp.qt)

With oil filter element replacement 0.69 L (0.73 US qt, 0.61 Imp.qt)

Without oil filter element replacement 0.67 L (0.71 US qt, 0.59 Imp.qt)

Oil filter

Oil filter type Paper

Oil pump

Oil pump type Trochoid

Inner-rotor-to-outer-rotor-tip clearance Less than 0.150 mm (0.0059 in)

Limit 0.20 mm (0.0079 in)

Outer-rotor-to-oil-pump-housing clearance 0.13–0.18 mm (0.0051–0.0071 in)

Limit 0.24 mm (0.0094 in)

Oil-pump-housing-to-inner-and-outer-rotor

clearance 0.06–0.11 mm (0.0024–0.0043 in)

Limit 0.17 mm (0.0067 in)

Cooling system

Radiator capacity (including all routes) 1.04 L (1.10 US qt, 0.92 Imp.qt)

Radiator capacity 0.57 L (0.60 US qt, 0.50 mp.qt)

Radiator cap opening pressure 108–137 kPa (1.08–1.37 kg/cm

2, 15.7–19.9

psi)

Radiator core

Width 112.6 mm (4.43 in)

Height 235.0 mm (9.25 in)

Depth 28.0 mm (1.10 in)

Water pump

Water pump type Single suction centrifugal pump

Spark plug

Manufacturer/model NGK/CR8E

Spark plug gap 0.7–0.8 mm (0.028–0.031 in)

Page 53 of 360

CHASSIS SPECIFICATIONS

2-10

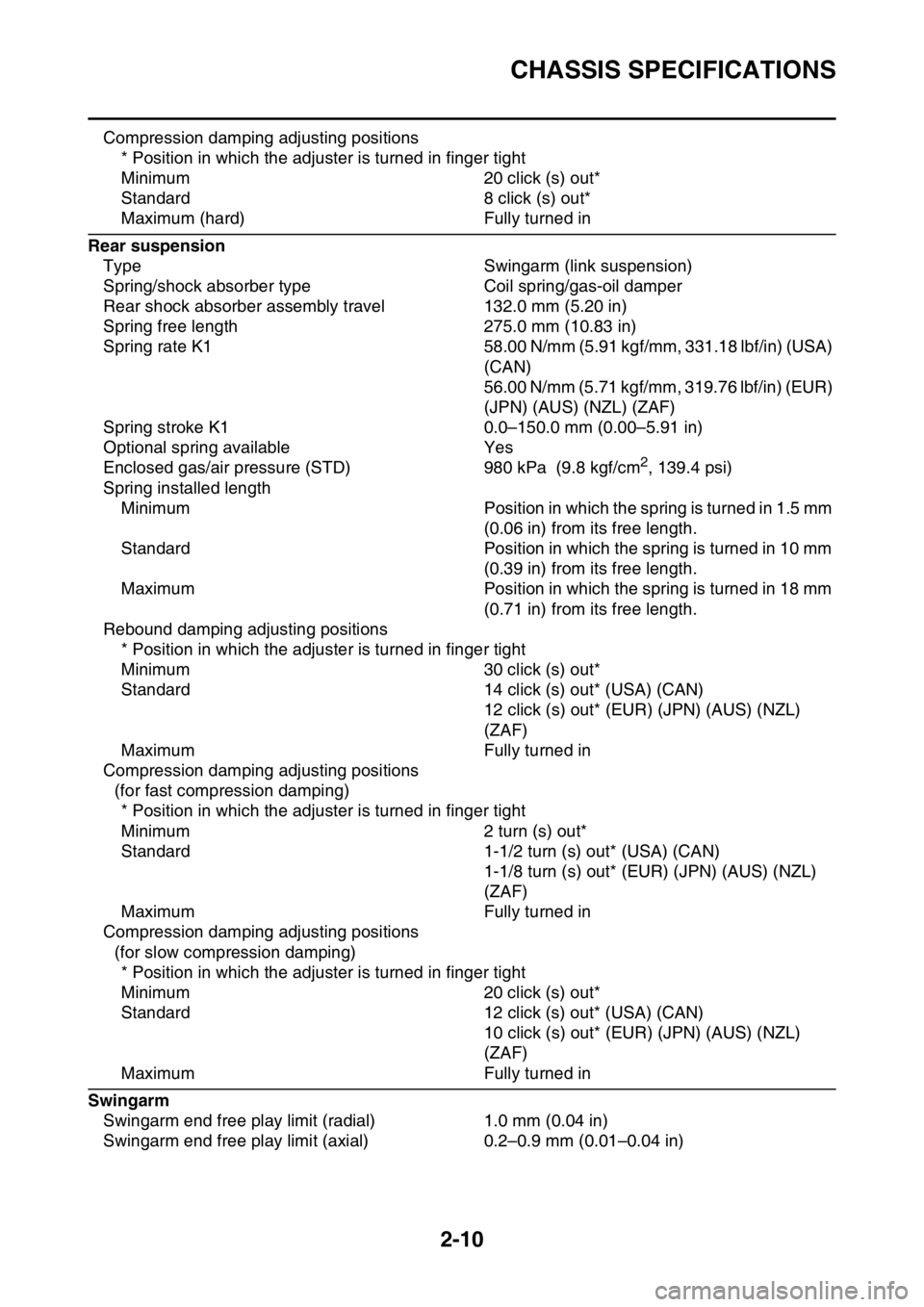

Compression damping adjusting positions

* Position in which the adjuster is turned in finger tight

Minimum 20 click (s) out*

Standard 8 click (s) out*

Maximum (hard) Fully turned in

Rear suspension

Type Swingarm (link suspension)

Spring/shock absorber type Coil spring/gas-oil damper

Rear shock absorber assembly travel 132.0 mm (5.20 in)

Spring free length 275.0 mm (10.83 in)

Spring rate K1 58.00 N/mm (5.91 kgf/mm, 331.18 lbf/in) (USA)

(CAN)

56.00 N/mm (5.71 kgf/mm, 319.76 lbf/in) (EUR)

(JPN) (AUS) (NZL) (ZAF)

Spring stroke K1 0.0–150.0 mm (0.00–5.91 in)

Optional spring available Yes

Enclosed gas/air pressure (STD) 980 kPa (9.8 kgf/cm

2, 139.4 psi)

Spring installed length

Minimum Position in which the spring is turned in 1.5 mm

(0.06 in) from its free length.

Standard Position in which the spring is turned in 10 mm

(0.39 in) from its free length.

Maximum Position in which the spring is turned in 18 mm

(0.71 in) from its free length.

Rebound damping adjusting positions

* Position in which the adjuster is turned in finger tight

Minimum 30 click (s) out*

Standard 14 click (s) out* (USA) (CAN)

12 click (s) out* (EUR) (JPN) (AUS) (NZL)

(ZAF)

Maximum Fully turned in

Compression damping adjusting positions

(for fast compression damping)

* Position in which the adjuster is turned in finger tight

Minimum 2 turn (s) out*

Standard 1-1/2 turn (s) out* (USA) (CAN)

1-1/8 turn (s) out* (EUR) (JPN) (AUS) (NZL)

(ZAF)

Maximum Fully turned in

Compression damping adjusting positions

(for slow compression damping)

* Position in which the adjuster is turned in finger tight

Minimum 20 click (s) out*

Standard 12 click (s) out* (USA) (CAN)

10 click (s) out* (EUR) (JPN) (AUS) (NZL)

(ZAF)

Maximum Fully turned in

Swingarm

Swingarm end free play limit (radial) 1.0 mm (0.04 in)

Swingarm end free play limit (axial) 0.2–0.9 mm (0.01–0.04 in)

Page 64 of 360

LUBRICATION POINTS AND LUBRICANT TYPES

2-21

EAS1SL5060

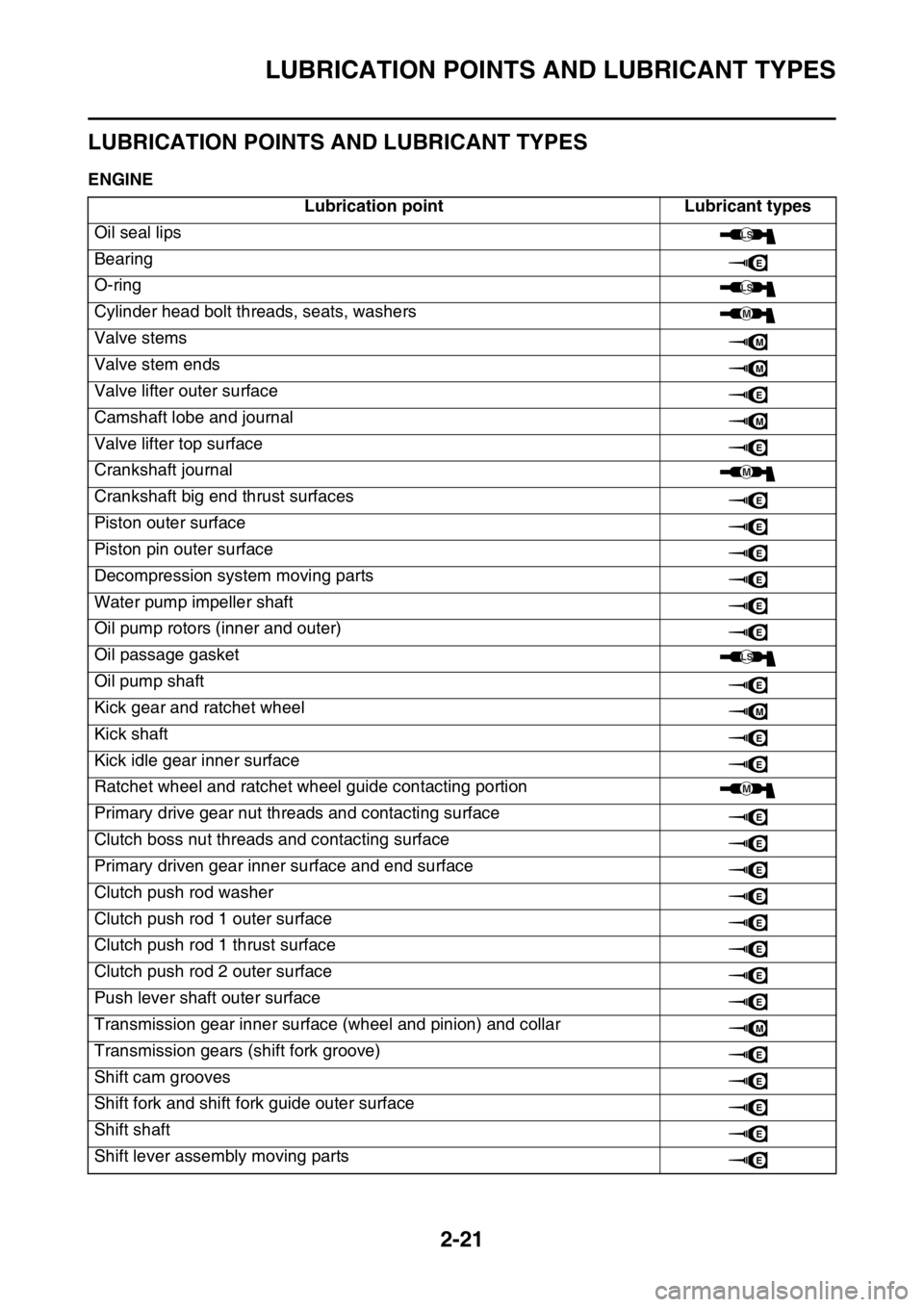

LUBRICATION POINTS AND LUBRICANT TYPES

EAS1SL5061ENGINE

Lubrication point Lubricant types

Oil seal lips

Bearing

O-ring

Cylinder head bolt threads, seats, washers

Valve stems

Valve stem ends

Valve lifter outer surface

Camshaft lobe and journal

Valve lifter top surface

Crankshaft journal

Crankshaft big end thrust surfaces

Piston outer surface

Piston pin outer surface

Decompression system moving parts

Water pump impeller shaft

Oil pump rotors (inner and outer)

Oil passage gasket

Oil pump shaft

Kick gear and ratchet wheel

Kick shaft

Kick idle gear inner surface

Ratchet wheel and ratchet wheel guide contacting portion

Primary drive gear nut threads and contacting surface

Clutch boss nut threads and contacting surface

Primary driven gear inner surface and end surface

Clutch push rod washer

Clutch push rod 1 outer surface

Clutch push rod 1 thrust surface

Clutch push rod 2 outer surface

Push lever shaft outer surface

Transmission gear inner surface (wheel and pinion) and collar

Transmission gears (shift fork groove)

Shift cam grooves

Shift fork and shift fork guide outer surface

Shift shaft

Shift lever assembly moving parts

LS

E

LS

M

M

M

E

M

E

M

E

E

E

E

E

E

LS

E

M

E

E

M

E

E

E

E

E

E

E

E

M

E

E

E

E

E

Page 65 of 360

LUBRICATION POINTS AND LUBRICANT TYPES

2-22

Cylinder head cover gasketThree Bond

No.1215®

Crankcase mating surfaceThree Bond

No.1215®

Stator assembly lead grommetThree Bond

No.1215® Lubrication point Lubricant types

Page 123 of 360

ELECTRICAL SYSTEM

3-35

EAS1SL5115

ELECTRICAL SYSTEM

EAS1SL5116CHECKING THE SPARK PLUG

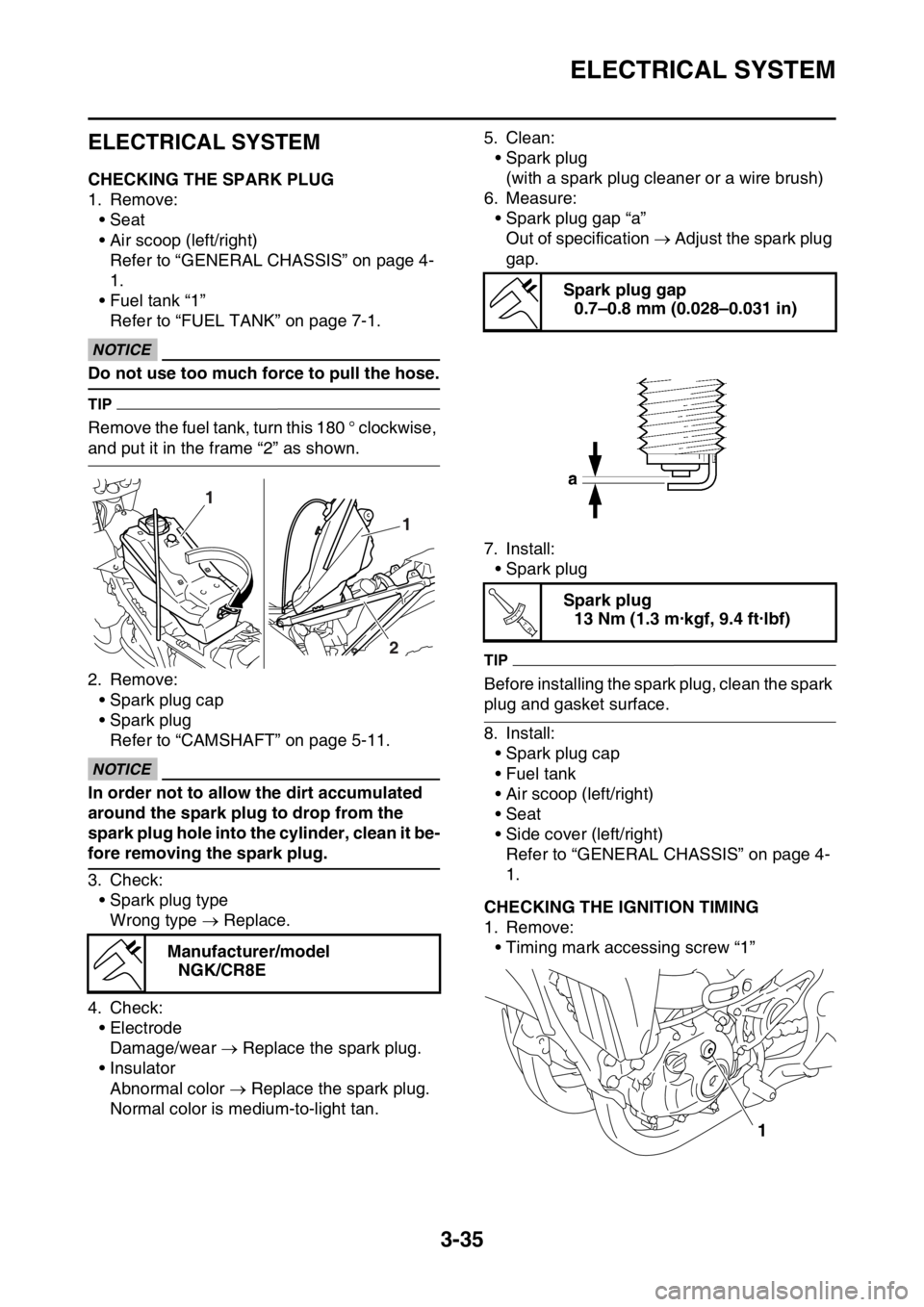

1. Remove:

• Seat

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

• Fuel tank “1”

Refer to “FUEL TANK” on page 7-1.

ECA1DX1001

NOTICE

Do not use too much force to pull the hose.

TIP

Remove the fuel tank, turn this 180 ° clockwise,

and put it in the frame “2” as shown.

2. Remove:

• Spark plug cap

• Spark plug

Refer to “CAMSHAFT” on page 5-11.

ECA13330

NOTICE

In order not to allow the dirt accumulated

around the spark plug to drop from the

spark plug hole into the cylinder, clean it be-

fore removing the spark plug.

3. Check:

• Spark plug type

Wrong type Replace.

4. Check:

• Electrode

Damage/wear Replace the spark plug.

• Insulator

Abnormal color Replace the spark plug.

Normal color is medium-to-light tan.5. Clean:

• Spark plug

(with a spark plug cleaner or a wire brush)

6. Measure:

• Spark plug gap “a”

Out of specification Adjust the spark plug

gap.

7. Install:

• Spark plug

TIP

Before installing the spark plug, clean the spark

plug and gasket surface.

8. Install:

• Spark plug cap

• Fuel tank

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

EAS1SL5117CHECKING THE IGNITION TIMING

1. Remove:

• Timing mark accessing screw “1”

Manufacturer/model

NGK/CR8E

1

1

2

Spark plug gap

0.7–0.8 mm (0.028–0.031 in)

Spark plug

13 Nm (1.3 m·kgf, 9.4 ft·lbf)

T R..

1