oil filter YAMAHA YZ450F 2015 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: YZ450F, Model: YAMAHA YZ450F 2015Pages: 360, PDF Size: 10.82 MB

Page 18 of 360

DESCRIPTION

1-4

EAS1SL5009

DESCRIPTION

TIP

Designs and specifications of the vehicle are subject to change without notice. Therefore, please

note that the descriptions in this manual may be different from those for the vehicle you have pur-

chased.1. Clutch lever 10. Coolant drain bolt

2. Front brake lever 11. Rear brake pedal

3. Throttle grip 12. Air filter

4. Radiator cap 13. Drive chain

5. Fuel tank cap 14. Shift pedal

6. Engine stop switch 15. Oil level check window

7. Fuel tank 16. Starter knob/idle screw

8. Kickstarter lever 17. Front fork

9. Radiator

2 1

6

78 954 3

11 10 17 16 15 14 1312

Page 37 of 360

STARTING AND BREAK-IN

1-23

7. To stop the engine, push the engine stop

switch “1”.

TIP

Continue pushing the engine stop switch till the

engine comes to a full stop.

EAS1SL5045STARTING A WARM ENGINE

When the engine is warm, give a kick with the

throttle closed without using the starter knob/

idle screw.

TIP

If it fails to start, fully open the throttle grip and

give 10 to 20 slow kicks to clear the engine of

the rich air-fuel mixture retained in it.

EAS1SL5046BREAK-IN PROCEDURES

A break-in is important so that rotating portion,

sliding surfaces, and mounted areas may fit

one another, and that the rider may become ac-

customed to the machine.

ECA

NOTICE

Before running, do maintenance on the air

filter element.

Refer to “CLEANING THE AIR FILTER ELE-

MENT” on page 3-12.

1. After warming up the engine, drive it for

about 20 minutes at a throttle opening of 1/2

or less.

2. Make a pit stop, and check mounted areas

for looseness, oil leaks, or other problems.

3. Then, drive it for about 40 minutes at a throt-

tle opening of 3/4 or less.

4. Make a pit stop again, and thoroughly check

mounted areas for looseness, oil leaks, or

other problems. Thorough checks and ad-

justments are required in particular for

stretch of cables, free play of the brake,

stretch of the drive chain, looseness of the

spoke, and so on.

ECA

NOTICE

After a break-in or after each race, always

check the points shown in “TORQUE-

CHECK POINTS” for tightening torques and

retighten them. (Refer to “TORQUE-CHECK

POINTS” on page 1-25.)

Also when the following parts are replaced,

a break-in is required.

• Cylinder and Crankshaft: A break-in is re-

quired for about an hour.

• Piston, Piston ring, Valve, Camshaft, and

Gear: A break-in is required for about 30

minutes at a throttle opening of 1/2 or less.

Observe the condition of the engine careful-

ly during a break-in.

For checkpoints for a break-in, see “MAIN-

TENANCE AFTER BREAK-IN”. If any prob-

lem is found, immediately stop the engine

and make a checkup.

Page 45 of 360

ENGINE SPECIFICATIONS

2-2

EAS1SL5054

ENGINE SPECIFICATIONS

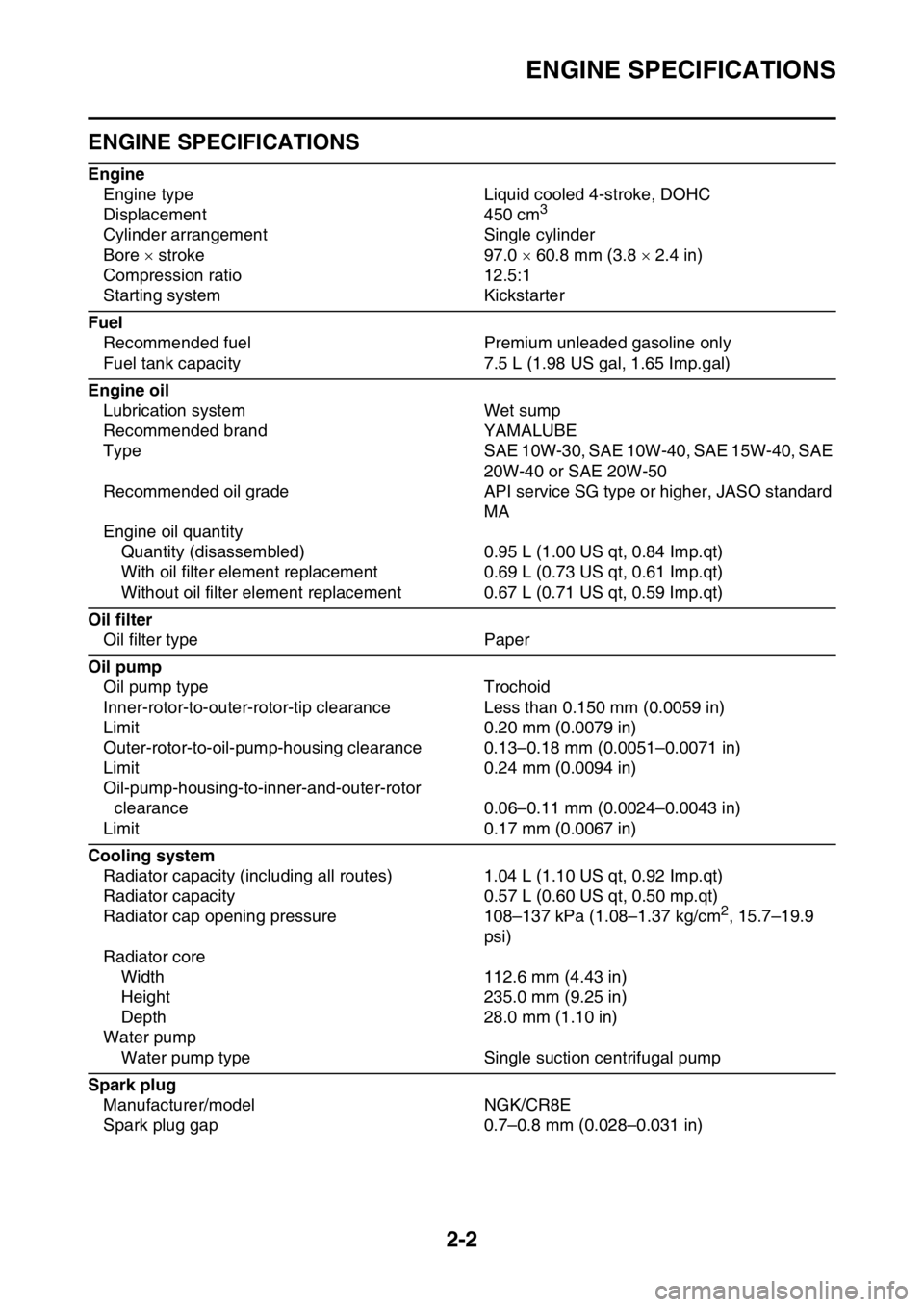

Engine

Engine type Liquid cooled 4-stroke, DOHC

Displacement 450 cm

3

Cylinder arrangement Single cylinder

Bore stroke 97.0 60.8 mm (3.8 2.4 in)

Compression ratio 12.5:1

Starting system Kickstarter

Fuel

Recommended fuel Premium unleaded gasoline only

Fuel tank capacity 7.5 L (1.98 US gal, 1.65 Imp.gal)

Engine oil

Lubrication system Wet sump

Recommended brand YAMALUBE

Type SAE 10W-30, SAE 10W-40, SAE 15W-40, SAE

20W-40 or SAE 20W-50

Recommended oil grade API service SG type or higher, JASO standard

MA

Engine oil quantity

Quantity (disassembled) 0.95 L (1.00 US qt, 0.84 Imp.qt)

With oil filter element replacement 0.69 L (0.73 US qt, 0.61 Imp.qt)

Without oil filter element replacement 0.67 L (0.71 US qt, 0.59 Imp.qt)

Oil filter

Oil filter type Paper

Oil pump

Oil pump type Trochoid

Inner-rotor-to-outer-rotor-tip clearance Less than 0.150 mm (0.0059 in)

Limit 0.20 mm (0.0079 in)

Outer-rotor-to-oil-pump-housing clearance 0.13–0.18 mm (0.0051–0.0071 in)

Limit 0.24 mm (0.0094 in)

Oil-pump-housing-to-inner-and-outer-rotor

clearance 0.06–0.11 mm (0.0024–0.0043 in)

Limit 0.17 mm (0.0067 in)

Cooling system

Radiator capacity (including all routes) 1.04 L (1.10 US qt, 0.92 Imp.qt)

Radiator capacity 0.57 L (0.60 US qt, 0.50 mp.qt)

Radiator cap opening pressure 108–137 kPa (1.08–1.37 kg/cm

2, 15.7–19.9

psi)

Radiator core

Width 112.6 mm (4.43 in)

Height 235.0 mm (9.25 in)

Depth 28.0 mm (1.10 in)

Water pump

Water pump type Single suction centrifugal pump

Spark plug

Manufacturer/model NGK/CR8E

Spark plug gap 0.7–0.8 mm (0.028–0.031 in)

Page 50 of 360

ENGINE SPECIFICATIONS

2-7

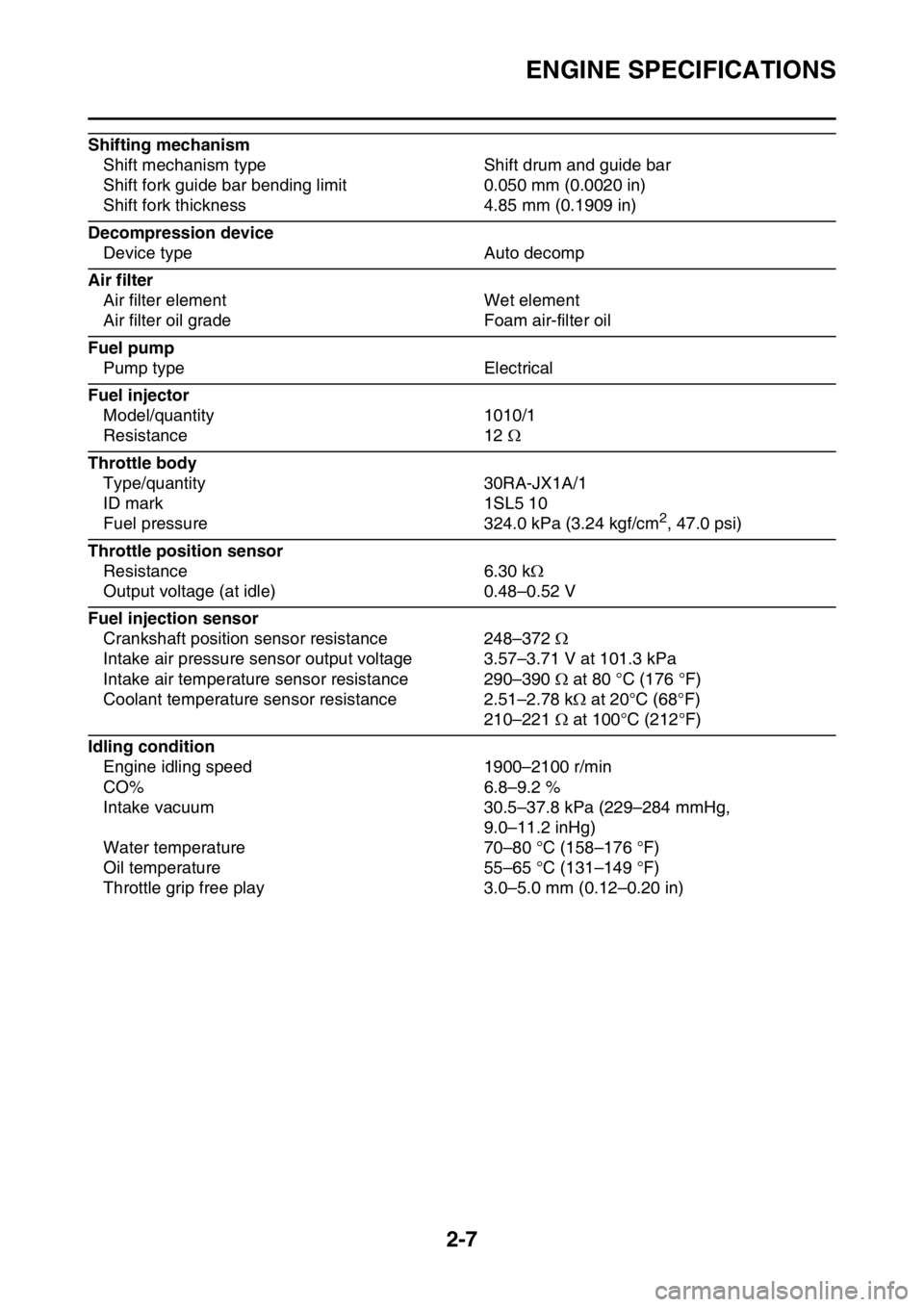

Shifting mechanism

Shift mechanism type Shift drum and guide bar

Shift fork guide bar bending limit 0.050 mm (0.0020 in)

Shift fork thickness 4.85 mm (0.1909 in)

Decompression device

Device type Auto decomp

Air filter

Air filter element Wet element

Air filter oil grade Foam air-filter oil

Fuel pump

Pump type Electrical

Fuel injector

Model/quantity 1010/1

Resistance 12

Throttle body

Type/quantity 30RA-JX1A/1

ID mark 1SL5 10

Fuel pressure 324.0 kPa (3.24 kgf/cm

2, 47.0 psi)

Throttle position sensor

Resistance 6.30 k

Output voltage (at idle) 0.48–0.52 V

Fuel injection sensor

Crankshaft position sensor resistance 248–372

Intake air pressure sensor output voltage 3.57–3.71 V at 101.3 kPa

Intake air temperature sensor resistance 290–390 at 80 °C (176 °F)

Coolant temperature sensor resistance 2.51–2.78 k at 20°C (68°F)

210–221 at 100°C (212°F)

Idling condition

Engine idling speed 1900–2100 r/min

CO% 6.8–9.2 %

Intake vacuum 30.5–37.8 kPa (229–284 mmHg,

9.0–11.2 inHg)

Water temperature 70–80 °C (158–176 °F)

Oil temperature 55–65 °C (131–149 °F)

Throttle grip free play 3.0–5.0 mm (0.12–0.20 in)

Page 58 of 360

TIGHTENING TORQUES

2-15

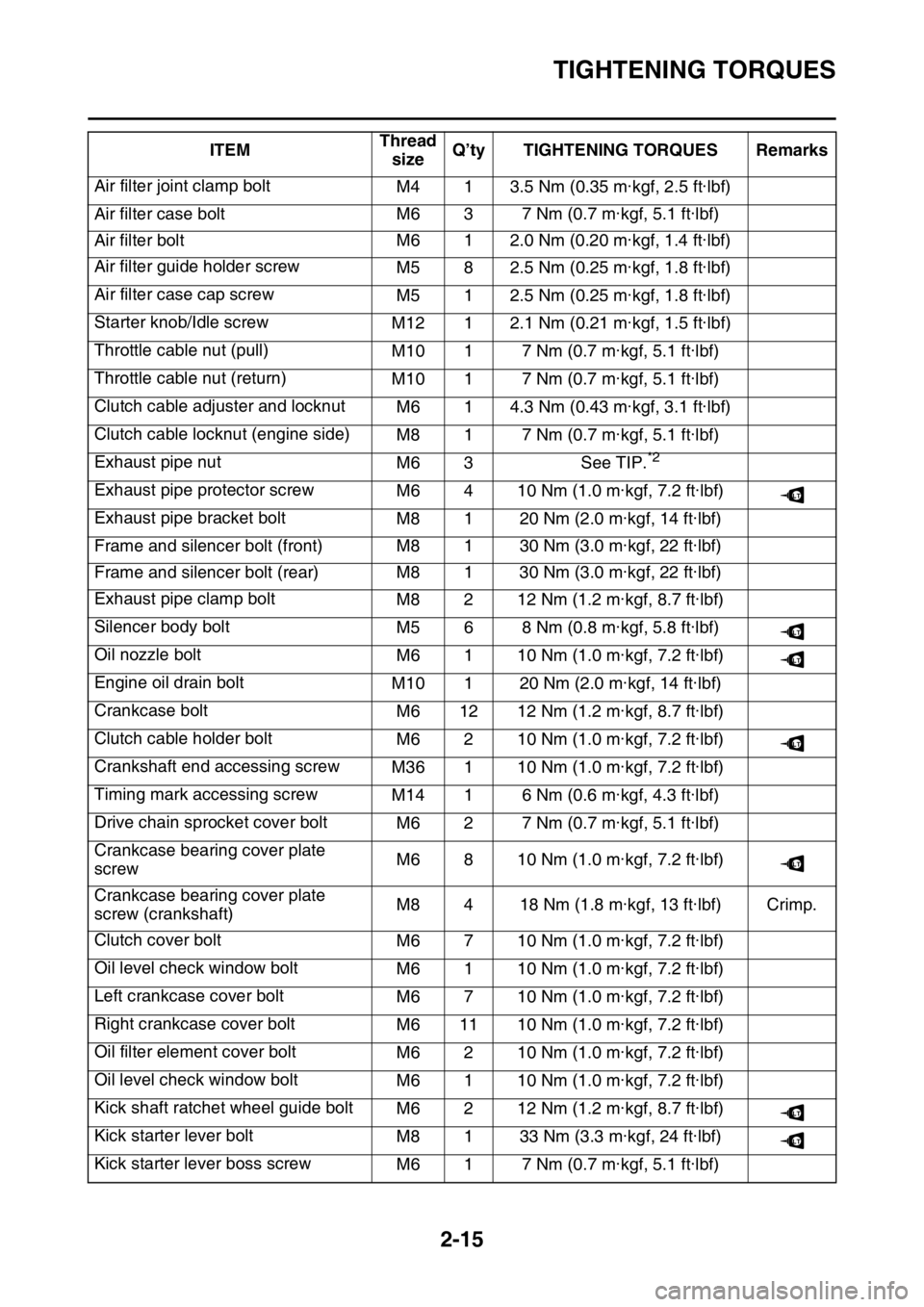

Air filter joint clamp bolt

M4 1 3.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

Air filter case bolt M6 3 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Air filter bolt M6 1 2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Air filter guide holder screw

M5 8 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Air filter case cap screw

M5 1 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Starter knob/Idle screw

M12 1 2.1 Nm (0.21 m·kgf, 1.5 ft·lbf)

Throttle cable nut (pull)

M10 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Throttle cable nut (return)

M10 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Clutch cable adjuster and locknut

M6 1 4.3 Nm (0.43 m·kgf, 3.1 ft·lbf)

Clutch cable locknut (engine side)

M8 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Exhaust pipe nut

M6 3 See TIP.

*2

Exhaust pipe protector screw

M6 4 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Exhaust pipe bracket bolt

M8 1 20 Nm (2.0 m·kgf, 14 ft·lbf)

Frame and silencer bolt (front) M8 1 30 Nm (3.0 m·kgf, 22 ft·lbf)

Frame and silencer bolt (rear) M8 1 30 Nm (3.0 m·kgf, 22 ft·lbf)

Exhaust pipe clamp bolt

M8 2 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Silencer body bolt

M5 6 8 Nm (0.8 m·kgf, 5.8 ft·lbf)

Oil nozzle bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Engine oil drain bolt

M10 1 20 Nm (2.0 m·kgf, 14 ft·lbf)

Crankcase bolt

M6 12 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Clutch cable holder bolt

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Crankshaft end accessing screw

M36 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Timing mark accessing screw

M14 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Drive chain sprocket cover bolt

M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Crankcase bearing cover plate

screwM6 8 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Crankcase bearing cover plate

screw (crankshaft)M8 4 18 Nm (1.8 m·kgf, 13 ft·lbf) Crimp.

Clutch cover bolt

M6 7 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil level check window bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Left crankcase cover bolt

M6 7 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Right crankcase cover bolt

M6 11 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil filter element cover bolt

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil level check window bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Kick shaft ratchet wheel guide bolt

M6 2 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Kick starter lever bolt

M8 1 33 Nm (3.3 m·kgf, 24 ft·lbf)

Kick starter lever boss screw

M6 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf) ITEMThread

sizeQ’ty TIGHTENING TORQUES RemarksLT

LT

LT

LT

LT

LT

LT

Page 69 of 360

LUBRICATION SYSTEM CHART AND DIAGRAMS

2-26

1. Intake camshaft

2. Exhaust camshaft

3. Piston

4. Oil nozzle

5. Oil filter element

6. Oil pump

7. Oil strainer

8. Crankshaft

9. Drive axle

10. Main axle

Page 73 of 360

LUBRICATION SYSTEM CHART AND DIAGRAMS

2-30

1. Exhaust camshaft

2. Intake camshaft

3. Oil filter element

4. Relief valve

5. Oil pump

Page 75 of 360

LUBRICATION SYSTEM CHART AND DIAGRAMS

2-32

1. Camshaft

2. Oil pressure check bolt

3. Oil filter element

4. Oil pump

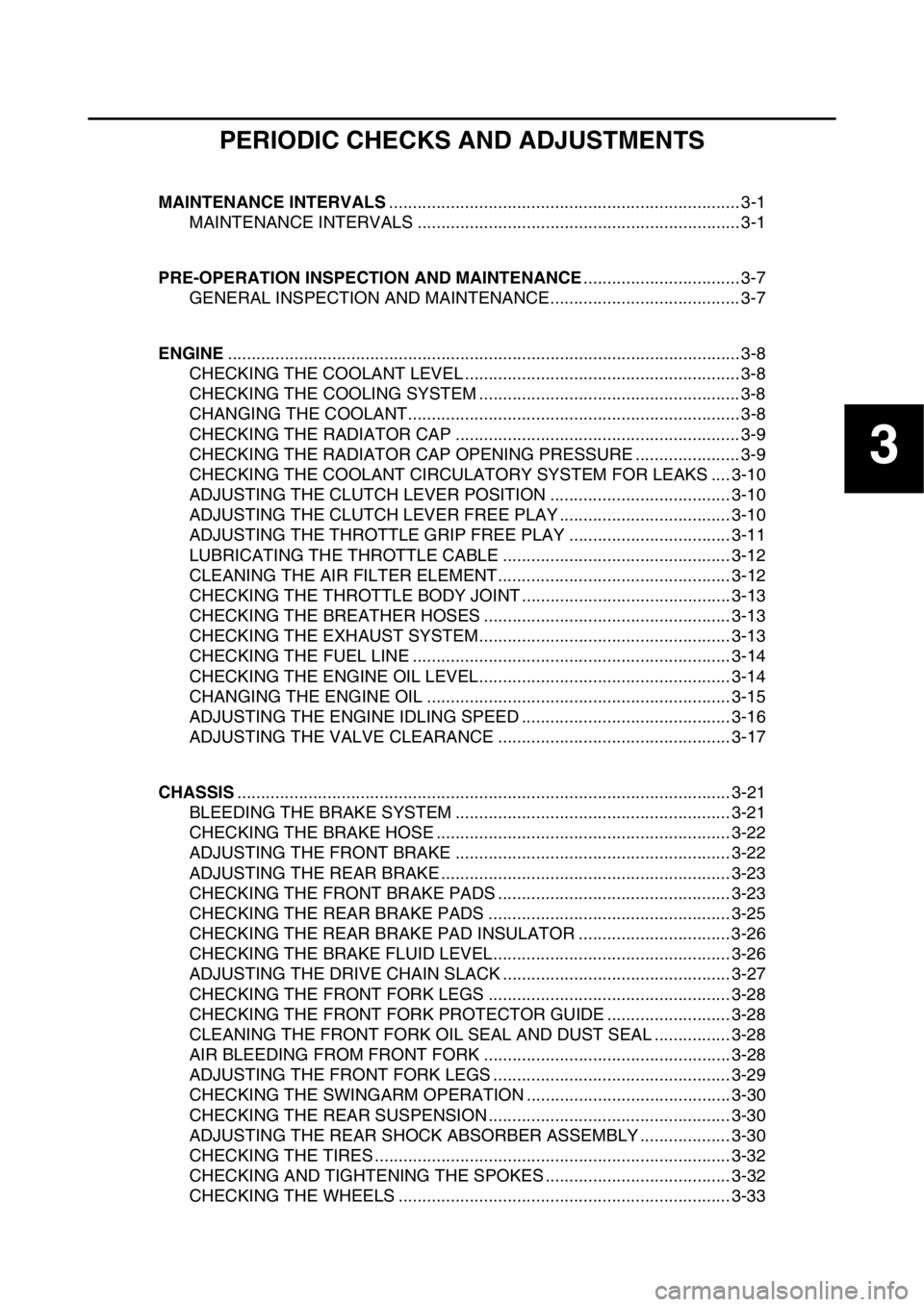

Page 87 of 360

3

PERIODIC CHECKS AND ADJUSTMENTS

MAINTENANCE INTERVALS.......................................................................... 3-1

MAINTENANCE INTERVALS .................................................................... 3-1

PRE-OPERATION INSPECTION AND MAINTENANCE................................. 3-7

GENERAL INSPECTION AND MAINTENANCE........................................ 3-7

ENGINE............................................................................................................ 3-8

CHECKING THE COOLANT LEVEL .......................................................... 3-8

CHECKING THE COOLING SYSTEM ....................................................... 3-8

CHANGING THE COOLANT...................................................................... 3-8

CHECKING THE RADIATOR CAP ............................................................ 3-9

CHECKING THE RADIATOR CAP OPENING PRESSURE ...................... 3-9

CHECKING THE COOLANT CIRCULATORY SYSTEM FOR LEAKS .... 3-10

ADJUSTING THE CLUTCH LEVER POSITION ...................................... 3-10

ADJUSTING THE CLUTCH LEVER FREE PLAY .................................... 3-10

ADJUSTING THE THROTTLE GRIP FREE PLAY .................................. 3-11

LUBRICATING THE THROTTLE CABLE ................................................ 3-12

CLEANING THE AIR FILTER ELEMENT................................................. 3-12

CHECKING THE THROTTLE BODY JOINT ............................................ 3-13

CHECKING THE BREATHER HOSES .................................................... 3-13

CHECKING THE EXHAUST SYSTEM..................................................... 3-13

CHECKING THE FUEL LINE ................................................................... 3-14

CHECKING THE ENGINE OIL LEVEL..................................................... 3-14

CHANGING THE ENGINE OIL ................................................................ 3-15

ADJUSTING THE ENGINE IDLING SPEED ............................................ 3-16

ADJUSTING THE VALVE CLEARANCE ................................................. 3-17

CHASSIS........................................................................................................ 3-21

BLEEDING THE BRAKE SYSTEM .......................................................... 3-21

CHECKING THE BRAKE HOSE .............................................................. 3-22

ADJUSTING THE FRONT BRAKE .......................................................... 3-22

ADJUSTING THE REAR BRAKE ............................................................. 3-23

CHECKING THE FRONT BRAKE PADS ................................................. 3-23

CHECKING THE REAR BRAKE PADS ................................................... 3-25

CHECKING THE REAR BRAKE PAD INSULATOR ................................ 3-26

CHECKING THE BRAKE FLUID LEVEL.................................................. 3-26

ADJUSTING THE DRIVE CHAIN SLACK ................................................ 3-27

CHECKING THE FRONT FORK LEGS ................................................... 3-28

CHECKING THE FRONT FORK PROTECTOR GUIDE .......................... 3-28

CLEANING THE FRONT FORK OIL SEAL AND DUST SEAL ................ 3-28

AIR BLEEDING FROM FRONT FORK .................................................... 3-28

ADJUSTING THE FRONT FORK LEGS .................................................. 3-29

CHECKING THE SWINGARM OPERATION ........................................... 3-30

CHECKING THE REAR SUSPENSION ................................................... 3-30

ADJUSTING THE REAR SHOCK ABSORBER ASSEMBLY ................... 3-30

CHECKING THE TIRES ........................................................................... 3-32

CHECKING AND TIGHTENING THE SPOKES ....................................... 3-32

CHECKING THE WHEELS ...................................................................... 3-33

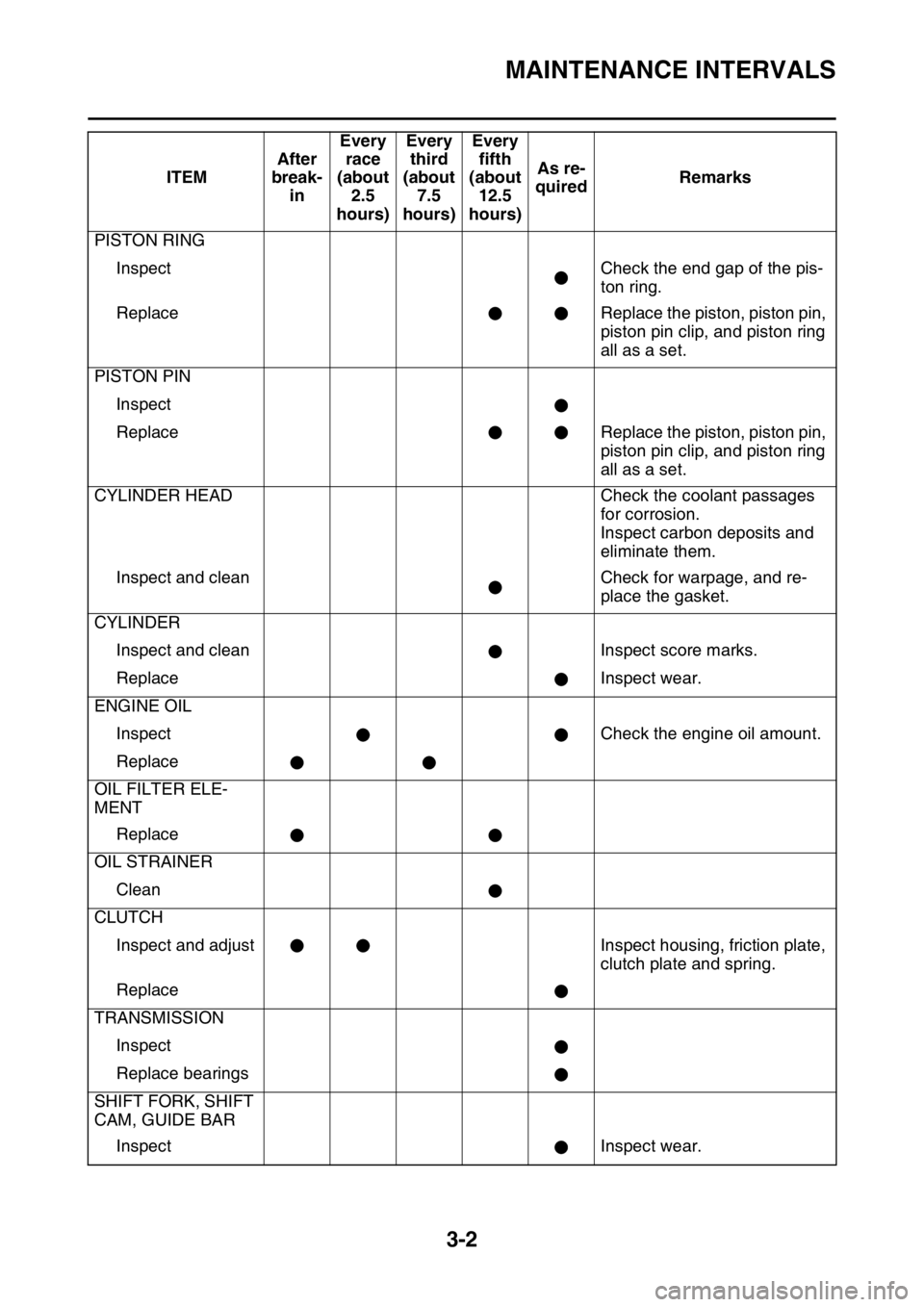

Page 90 of 360

MAINTENANCE INTERVALS

3-2

PISTON RING

Inspect Check the end gap of the pis-

ton ring.

Replace Replace the piston, piston pin,

piston pin clip, and piston ring

all as a set.

PISTON PIN

Inspect

Replace Replace the piston, piston pin,

piston pin clip, and piston ring

all as a set.

CYLINDER HEAD Check the coolant passages

for corrosion.

Inspect carbon deposits and

eliminate them.

Inspect and clean Check for warpage, and re-

place the gasket.

CYLINDER

Inspect and clean Inspect score marks.

Replace Inspect wear.

ENGINE OIL

Inspect Check the engine oil amount.

Replace

OIL FILTER ELE-

MENT

Replace

OIL STRAINER

Clean

CLUTCH

Inspect and adjust Inspect housing, friction plate,

clutch plate and spring.

Replace

TRANSMISSION

Inspect

Replace bearings

SHIFT FORK, SHIFT

CAM, GUIDE BAR

Inspect Inspect wear.ITEMAfter

break-

inEvery

race

(about

2.5

hours)Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)As re-

quiredRemarks