width YAMAHA YZ450F 2015 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: YZ450F, Model: YAMAHA YZ450F 2015Pages: 360, PDF Size: 10.82 MB

Page 44 of 360

GENERAL SPECIFICATIONS

2-1

EAS1SL5053

GENERAL SPECIFICATIONS

Model

Model 1SL5 (USA) (CAN)

1SL6 (EUR)

1SL7 (JPN)

1SL8 (AUS) (NZL) (ZAF)

Dimensions

Overall length 2175 mm (85.6 in) (USA) (CAN)

2180 mm (85.8 in) (EUR) (JPN) (AUS) (NZL)

(ZAF)

Overall width 825 mm (32.5 in)

Overall height 1290 mm (50.8 in) (USA) (CAN)

1280 mm (50.4 in) (EUR) (JPN) (AUS) (NZL)

(ZAF)

Seat height 975 mm (38.4 in) (USA) (CAN)

965 mm (38.0 in) (EUR) (JPN) (AUS) (NZL)

(ZAF)

Wheelbase 1480 mm (58.3 in)

Ground clearance 335 mm (13.2 in) (USA) (CAN) (EUR)

330 mm (13.0 in) (JPN) (AUS) (NZL) (ZAF)

Weight

Curb weight 112 kg (247 lb)

Page 45 of 360

ENGINE SPECIFICATIONS

2-2

EAS1SL5054

ENGINE SPECIFICATIONS

Engine

Engine type Liquid cooled 4-stroke, DOHC

Displacement 450 cm

3

Cylinder arrangement Single cylinder

Bore stroke 97.0 60.8 mm (3.8 2.4 in)

Compression ratio 12.5:1

Starting system Kickstarter

Fuel

Recommended fuel Premium unleaded gasoline only

Fuel tank capacity 7.5 L (1.98 US gal, 1.65 Imp.gal)

Engine oil

Lubrication system Wet sump

Recommended brand YAMALUBE

Type SAE 10W-30, SAE 10W-40, SAE 15W-40, SAE

20W-40 or SAE 20W-50

Recommended oil grade API service SG type or higher, JASO standard

MA

Engine oil quantity

Quantity (disassembled) 0.95 L (1.00 US qt, 0.84 Imp.qt)

With oil filter element replacement 0.69 L (0.73 US qt, 0.61 Imp.qt)

Without oil filter element replacement 0.67 L (0.71 US qt, 0.59 Imp.qt)

Oil filter

Oil filter type Paper

Oil pump

Oil pump type Trochoid

Inner-rotor-to-outer-rotor-tip clearance Less than 0.150 mm (0.0059 in)

Limit 0.20 mm (0.0079 in)

Outer-rotor-to-oil-pump-housing clearance 0.13–0.18 mm (0.0051–0.0071 in)

Limit 0.24 mm (0.0094 in)

Oil-pump-housing-to-inner-and-outer-rotor

clearance 0.06–0.11 mm (0.0024–0.0043 in)

Limit 0.17 mm (0.0067 in)

Cooling system

Radiator capacity (including all routes) 1.04 L (1.10 US qt, 0.92 Imp.qt)

Radiator capacity 0.57 L (0.60 US qt, 0.50 mp.qt)

Radiator cap opening pressure 108–137 kPa (1.08–1.37 kg/cm

2, 15.7–19.9

psi)

Radiator core

Width 112.6 mm (4.43 in)

Height 235.0 mm (9.25 in)

Depth 28.0 mm (1.10 in)

Water pump

Water pump type Single suction centrifugal pump

Spark plug

Manufacturer/model NGK/CR8E

Spark plug gap 0.7–0.8 mm (0.028–0.031 in)

Page 46 of 360

ENGINE SPECIFICATIONS

2-3

Cylinder head

Volume 25.98–26.78 cm3 (1.59–1.63 cu.in)

Warpage limit 0.05 mm (0.0020 in)

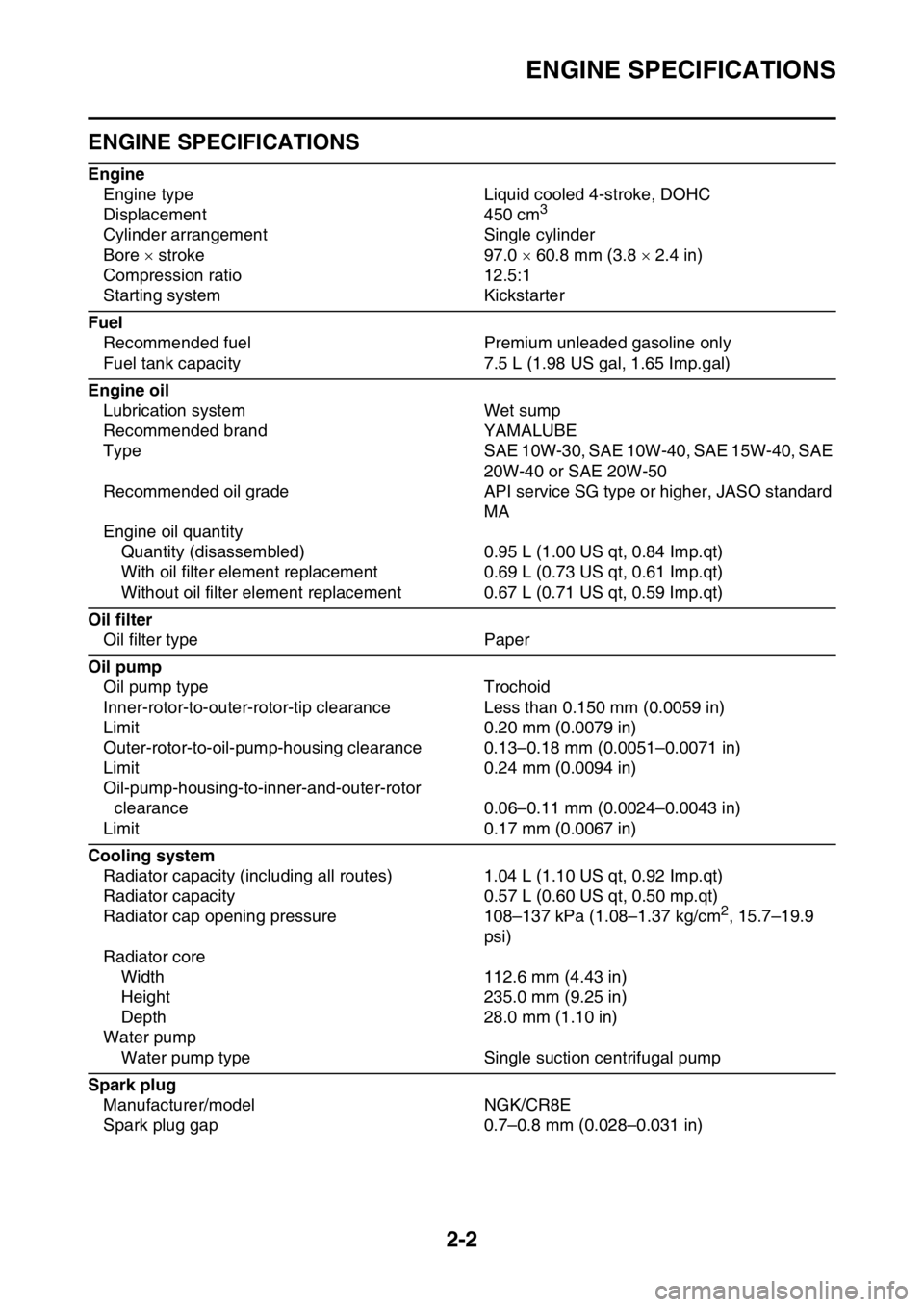

Camshaft

Drive system Chain drive (left)

Camshaft cap inside diameter 22.000–22.021 mm (0.8661–0.8670 in)

Camshaft journal diameter 21.959–21.972 mm (0.8645–0.8650 in)

Camshaft-journal-to-camshaft-cap clearance 0.028–0.062 mm (0.0011–0.0024 in)

Camshaft lobe dimensions

Intake A 37.730–37.830 mm (1.4854–1.4894 in)

Limit 37.630 mm (1.4815 in)

Intake B 27.950–28.050 mm (1.1004–1.1043 in)

Limit 27.850 mm (1.0965 in)

Exhaust A 33.540–33.640 mm (1.3205–1.3244 in)

Limit 33.440 mm (1.3165 in)

Exhaust B 24.769–24.869 mm (0.9752–0.9791 in)

Limit 24.669 mm (0.9712 in)

Camshaft runout limit 0.030 mm (0.0012 in)

Timing chain

Tensioning system Automatic

Valve, valve seat, valve guide

Valve clearance (cold)

Intake 0.13–0.20 mm (0.0051–0.0079 in)

Exhaust 0.20–0.25 mm (0.0079–0.0098 in)

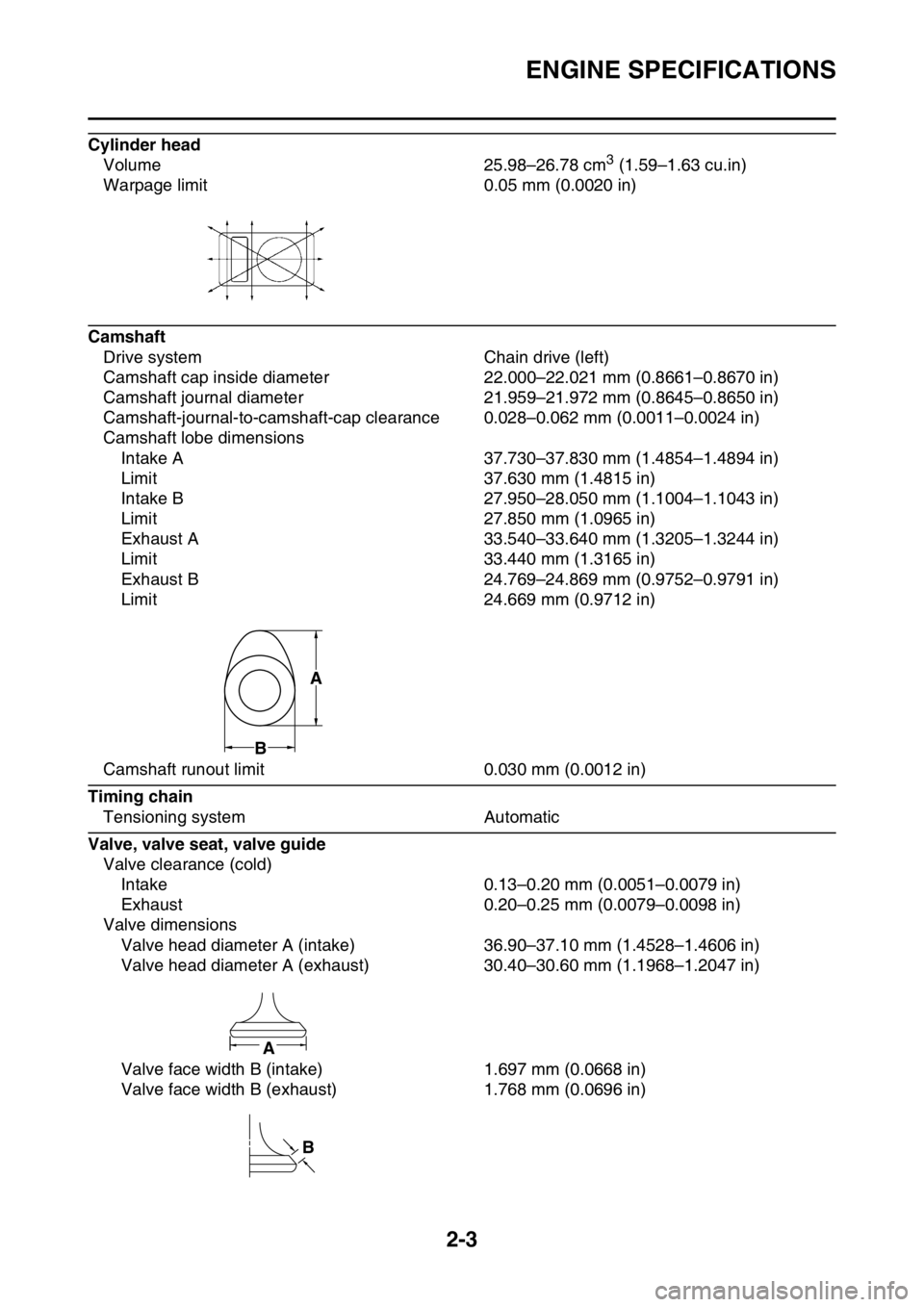

Valve dimensions

Valve head diameter A (intake) 36.90–37.10 mm (1.4528–1.4606 in)

Valve head diameter A (exhaust) 30.40–30.60 mm (1.1968–1.2047 in)

Valve face width B (intake) 1.697 mm (0.0668 in)

Valve face width B (exhaust) 1.768 mm (0.0696 in)

A

B

A

B

Page 47 of 360

ENGINE SPECIFICATIONS

2-4

Valve seat width C (intake) 0.90–1.10 mm (0.0354–0.0433 in)

Valve seat width C (exhaust) 0.90–1.10 mm (0.0354–0.0433 in)

Valve margin thickness D (intake) 1.20 mm (0.0472 in)

Valve margin thickness D (exhaust) 0.85 mm (0.0335 in)

Valve stem diameter (intake) 5.475–5.490 mm (0.2156–0.2161 in)

Limit 5.445 mm (0.2144 in)

Valve stem diameter (exhaust) 5.465–5.480 mm (0.2152–0.2157 in)

Limit 5.435 mm (0.2140 in)

Valve guide inside diameter (intake) 5.500–5.512 mm (0.2165–0.2170 in)

Limit 5.550 mm (0.2185 in)

Valve guide inside diameter (exhaust) 5.500–5.512 mm (0.2165–0.2170 in)

Limit 5.550 mm (0.2185 in)

Valve-stem-to-valve-guide clearance (intake) 0.010–0.037 mm (0.0004–0.0015 in)

Limit 0.080 mm (0.0032 in)

Valve-stem-to-valve-guide clearance (exhaust) 0.020–0.047 mm (0.0008–0.0019 in)

Limit 0.100 mm (0.0039 in)

Valve stem runout 0.010 mm (0.0004 in)

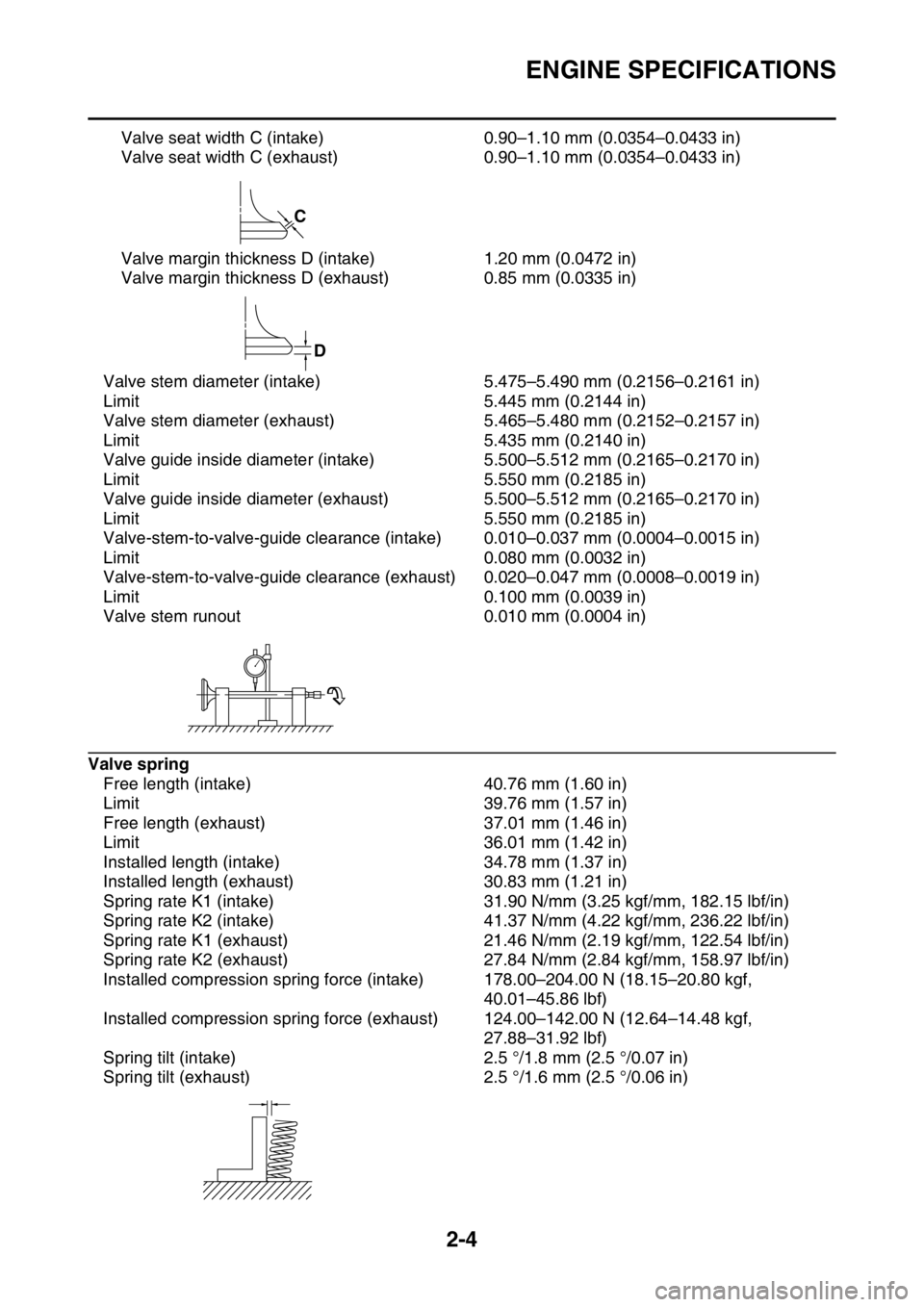

Valve spring

Free length (intake) 40.76 mm (1.60 in)

Limit 39.76 mm (1.57 in)

Free length (exhaust) 37.01 mm (1.46 in)

Limit 36.01 mm (1.42 in)

Installed length (intake) 34.78 mm (1.37 in)

Installed length (exhaust) 30.83 mm (1.21 in)

Spring rate K1 (intake) 31.90 N/mm (3.25 kgf/mm, 182.15 lbf/in)

Spring rate K2 (intake) 41.37 N/mm (4.22 kgf/mm, 236.22 lbf/in)

Spring rate K1 (exhaust) 21.46 N/mm (2.19 kgf/mm, 122.54 lbf/in)

Spring rate K2 (exhaust) 27.84 N/mm (2.84 kgf/mm, 158.97 lbf/in)

Installed compression spring force (intake) 178.00–204.00 N (18.15–20.80 kgf,

40.01–45.86 lbf)

Installed compression spring force (exhaust) 124.00–142.00 N (12.64–14.48 kgf,

27.88–31.92 lbf)

Spring tilt (intake) 2.5 °/1.8 mm (2.5 °/0.07 in)

Spring tilt (exhaust) 2.5 °/1.6 mm (2.5 °/0.06 in)

C

D

Page 49 of 360

ENGINE SPECIFICATIONS

2-6

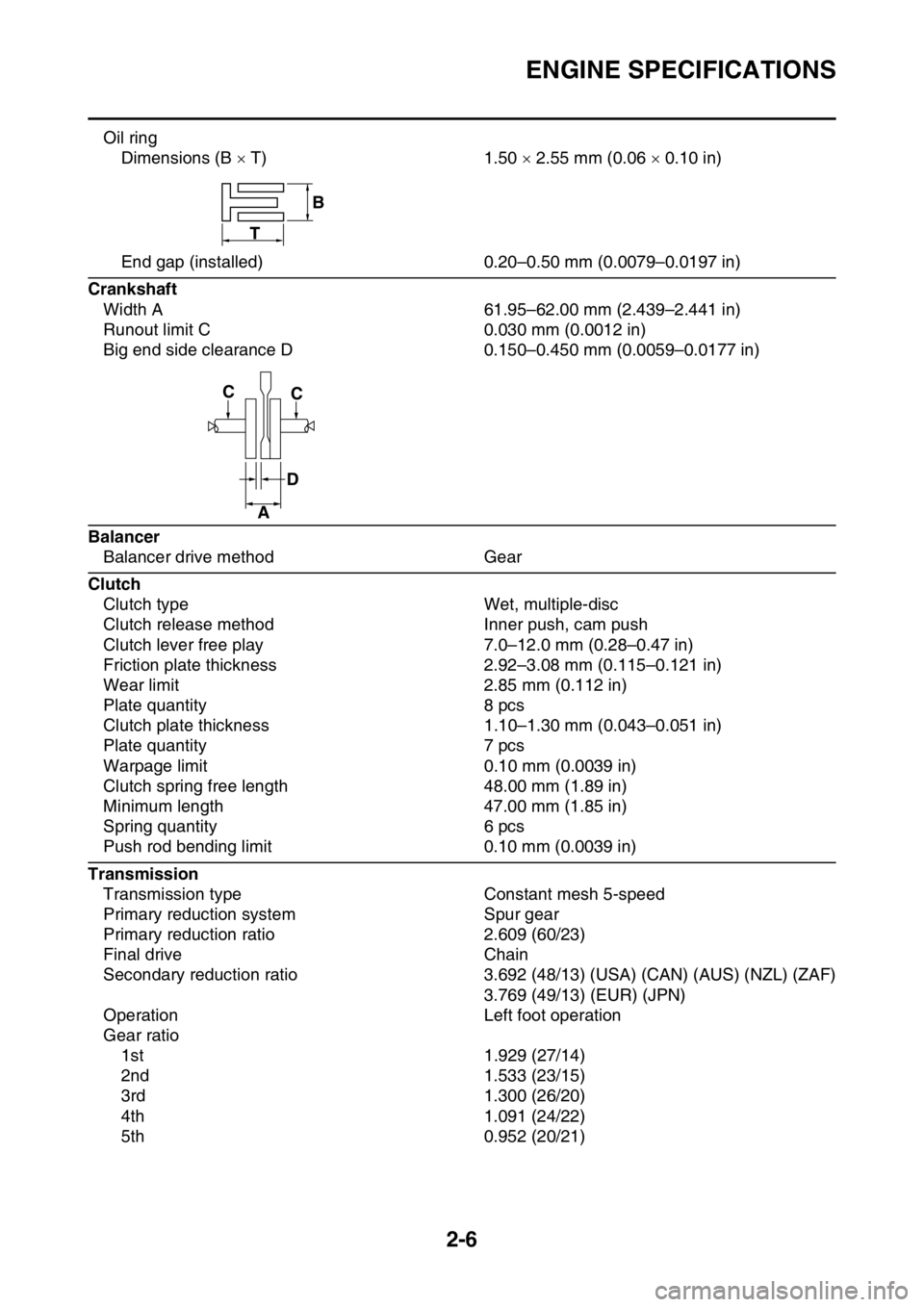

Oil ring

Dimensions (B T) 1.50 2.55 mm (0.06 0.10 in)

End gap (installed) 0.20–0.50 mm (0.0079–0.0197 in)

Crankshaft

Width A 61.95–62.00 mm (2.439–2.441 in)

Runout limit C 0.030 mm (0.0012 in)

Big end side clearance D 0.150–0.450 mm (0.0059–0.0177 in)

Balancer

Balancer drive method Gear

Clutch

Clutch type Wet, multiple-disc

Clutch release method Inner push, cam push

Clutch lever free play 7.0–12.0 mm (0.28–0.47 in)

Friction plate thickness 2.92–3.08 mm (0.115–0.121 in)

Wear limit 2.85 mm (0.112 in)

Plate quantity 8 pcs

Clutch plate thickness 1.10–1.30 mm (0.043–0.051 in)

Plate quantity 7 pcs

Warpage limit 0.10 mm (0.0039 in)

Clutch spring free length 48.00 mm (1.89 in)

Minimum length 47.00 mm (1.85 in)

Spring quantity 6 pcs

Push rod bending limit 0.10 mm (0.0039 in)

Transmission

Transmission type Constant mesh 5-speed

Primary reduction system Spur gear

Primary reduction ratio 2.609 (60/23)

Final drive Chain

Secondary reduction ratio 3.692 (48/13) (USA) (CAN) (AUS) (NZL) (ZAF)

3.769 (49/13) (EUR) (JPN)

Operation Left foot operation

Gear ratio

1st 1.929 (27/14)

2nd 1.533 (23/15)

3rd 1.300 (26/20)

4th 1.091 (24/22)

5th 0.952 (20/21)

B

T

CC

D

A

Page 210 of 360

CAMSHAFT

5-15

c. Install the dowel pins and the camshaft

caps.

TIP

• Tighten the camshaft cap bolts in a crisscross

pattern from innermost to outer caps.

• Do not turn the camshaft when measuring the

camshaft journal-to-camshaft cap clearance.

d. Remove the camshaft caps and then mea-

sure the width of the Plastigauge® “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Measure:

• Camshaft journal diameter “a”

Out of specification Replace the cam-

shaft.

Within specification Replace the cylinder

head and the camshaft caps as a set.

EAS1SL5211CHECKING THE TIMING CHAIN AND CAM-

SHAFT SPROCKET

1. Check:

• Timing chain “1”

Damage/stiffness Replace the timing

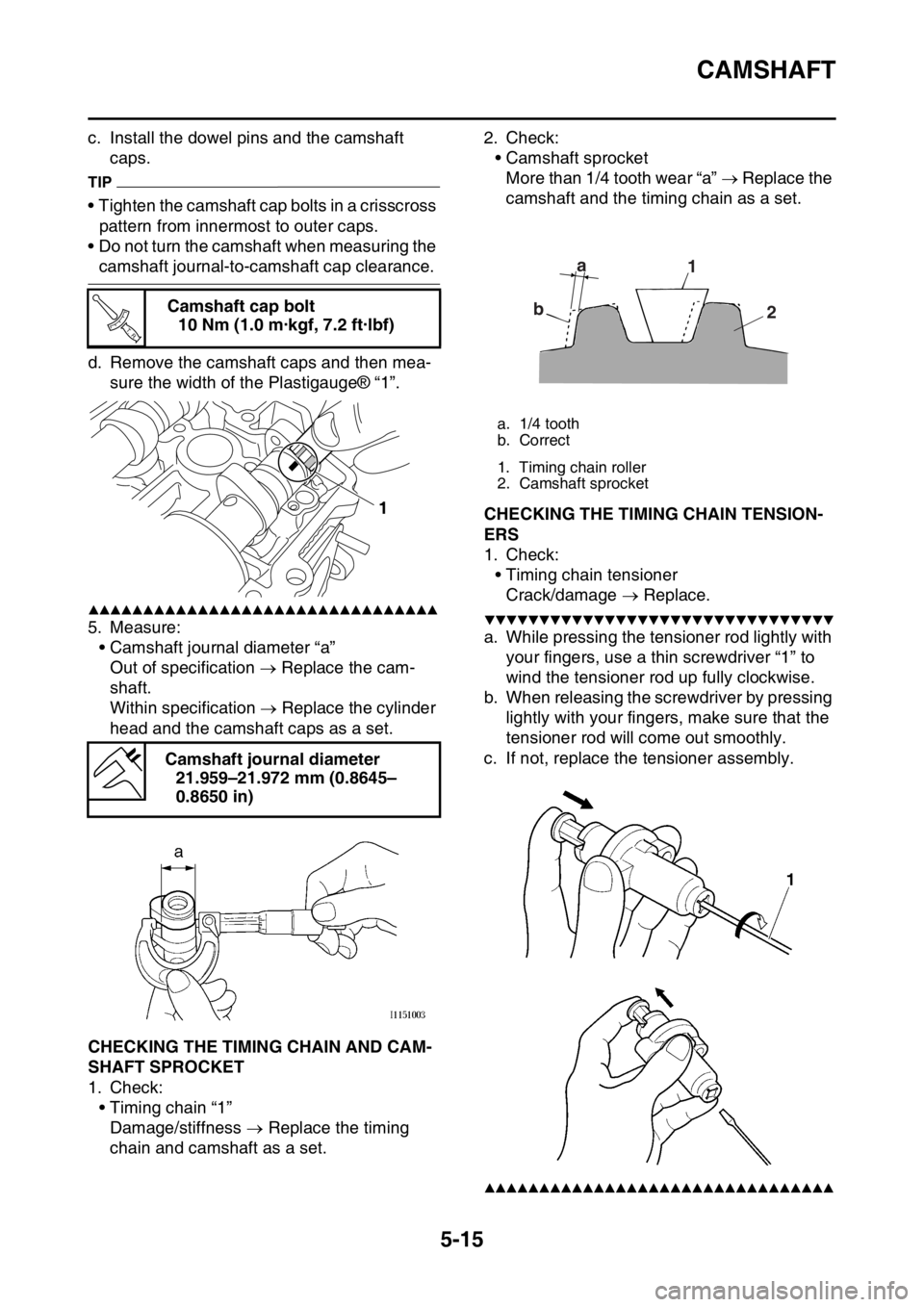

chain and camshaft as a set.2. Check:

• Camshaft sprocket

More than 1/4 tooth wear “a” Replace the

camshaft and the timing chain as a set.

EAS1SL5212CHECKING THE TIMING CHAIN TENSION-

ERS

1. Check:

• Timing chain tensioner

Crack/damage Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. While pressing the tensioner rod lightly with

your fingers, use a thin screwdriver “1” to

wind the tensioner rod up fully clockwise.

b. When releasing the screwdriver by pressing

lightly with your fingers, make sure that the

tensioner rod will come out smoothly.

c. If not, replace the tensioner assembly.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Camshaft cap bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Camshaft journal diameter

21.959–21.972 mm (0.8645–

0.8650 in)

T R..

1

a. 1/4 tooth

b. Correct

1. Timing chain roller

2. Camshaft sprocket

a

b1

2

Page 220 of 360

VALVES AND VALVE SPRINGS

5-25

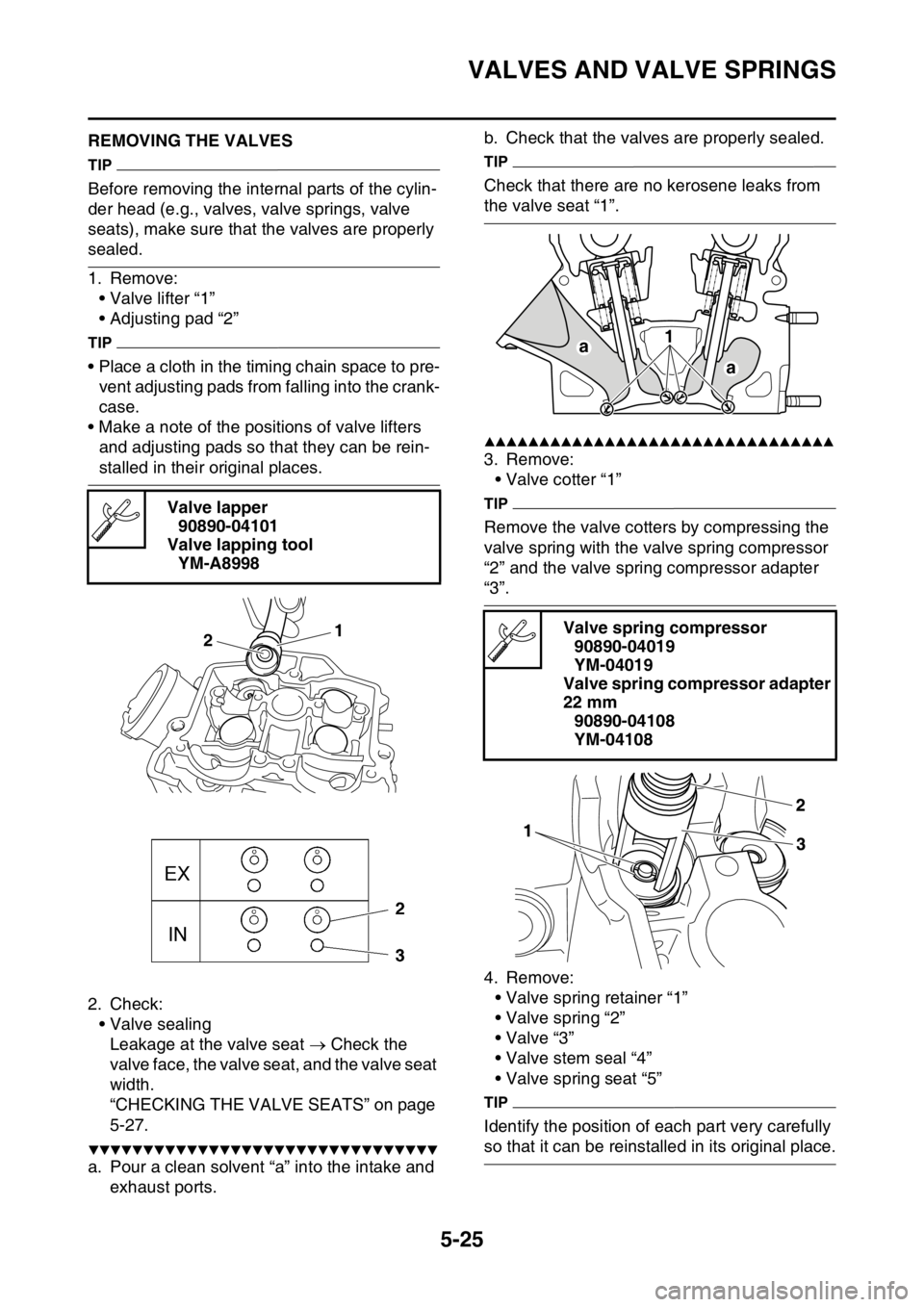

EAS1SL5221REMOVING THE VALVES

TIP

Before removing the internal parts of the cylin-

der head (e.g., valves, valve springs, valve

seats), make sure that the valves are properly

sealed.

1. Remove:

• Valve lifter “1”

• Adjusting pad “2”

TIP

• Place a cloth in the timing chain space to pre-

vent adjusting pads from falling into the crank-

case.

• Make a note of the positions of valve lifters

and adjusting pads so that they can be rein-

stalled in their original places.

2. Check:

• Valve sealing

Leakage at the valve seat Check the

valve face, the valve seat, and the valve seat

width.

“CHECKING THE VALVE SEATS” on page

5-27.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Pour a clean solvent “a” into the intake and

exhaust ports.b. Check that the valves are properly sealed.

TIP

Check that there are no kerosene leaks from

the valve seat “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Remove:

• Valve cotter “1”

TIP

Remove the valve cotters by compressing the

valve spring with the valve spring compressor

“2” and the valve spring compressor adapter

“3”.

4. Remove:

• Valve spring retainer “1”

• Valve spring “2”

•Valve “3”

• Valve stem seal “4”

• Valve spring seat “5”

TIP

Identify the position of each part very carefully

so that it can be reinstalled in its original place. Valve lapper

90890-04101

Valve lapping tool

YM-A8998

1

2Valve spring compressor

90890-04019

YM-04019

Valve spring compressor adapter

22 mm

90890-04108

YM-04108

a1

a

Page 222 of 360

VALVES AND VALVE SPRINGS

5-27

TIP

After replacing the valve guide, reface the valve

seat.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

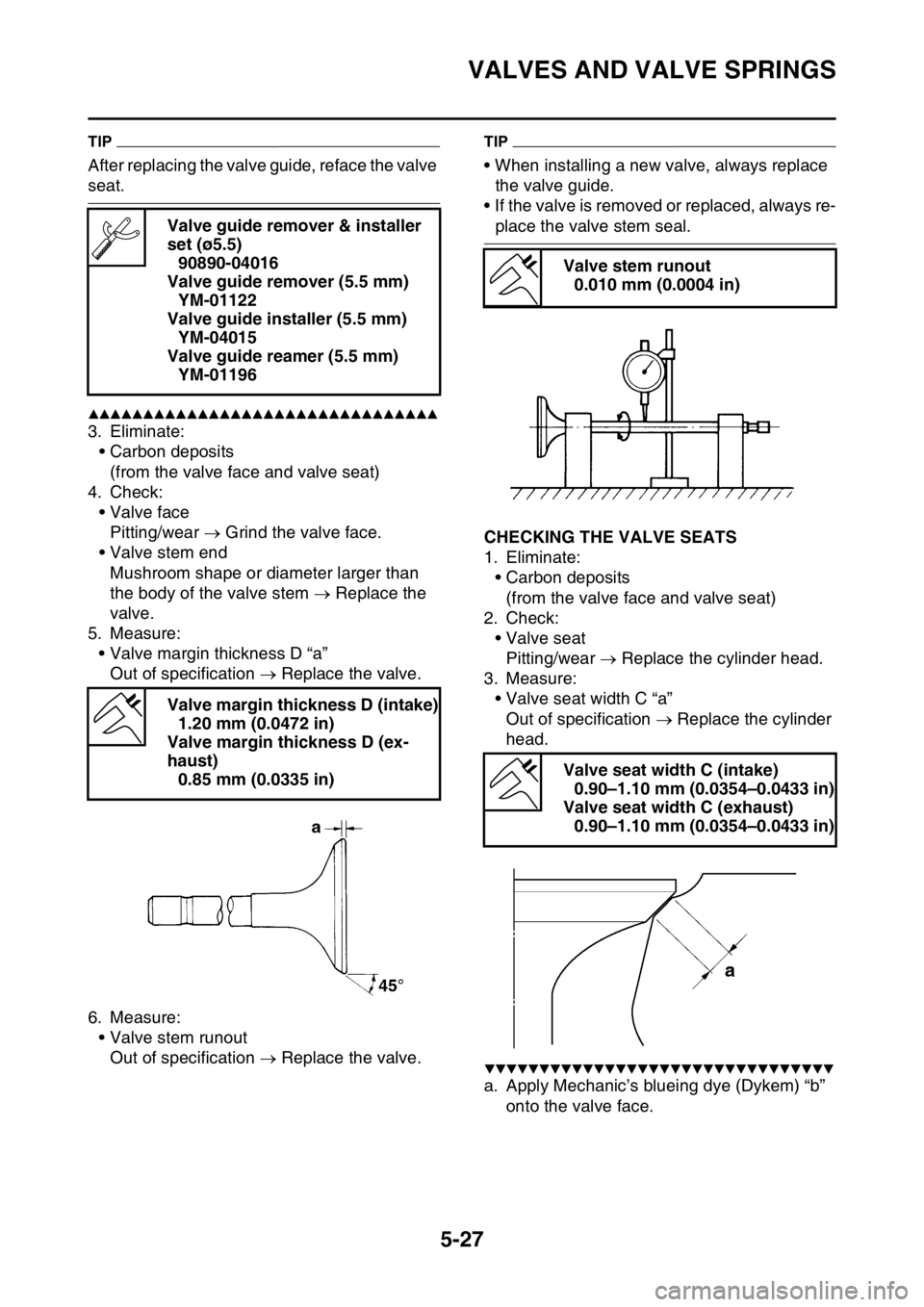

3. Eliminate:

• Carbon deposits

(from the valve face and valve seat)

4. Check:

• Valve face

Pitting/wear Grind the valve face.

• Valve stem end

Mushroom shape or diameter larger than

the body of the valve stem Replace the

valve.

5. Measure:

• Valve margin thickness D “a”

Out of specification Replace the valve.

6. Measure:

• Valve stem runout

Out of specification Replace the valve.

TIP

• When installing a new valve, always replace

the valve guide.

• If the valve is removed or replaced, always re-

place the valve stem seal.

EAS1SL5223CHECKING THE VALVE SEATS

1. Eliminate:

• Carbon deposits

(from the valve face and valve seat)

2. Check:

• Valve seat

Pitting/wear Replace the cylinder head.

3. Measure:

• Valve seat width C “a”

Out of specification Replace the cylinder

head.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Apply Mechanic’s blueing dye (Dykem) “b”

onto the valve face. Valve guide remover & installer

set (ø5.5)

90890-04016

Valve guide remover (5.5 mm)

YM-01122

Valve guide installer (5.5 mm)

YM-04015

Valve guide reamer (5.5 mm)

YM-01196

Valve margin thickness D (intake)

1.20 mm (0.0472 in)

Valve margin thickness D (ex-

haust)

0.85 mm (0.0335 in)

Valve stem runout

0.010 mm (0.0004 in)

Valve seat width C (intake)

0.90–1.10 mm (0.0354–0.0433 in)

Valve seat width C (exhaust)

0.90–1.10 mm (0.0354–0.0433 in)

Page 223 of 360

VALVES AND VALVE SPRINGS

5-28

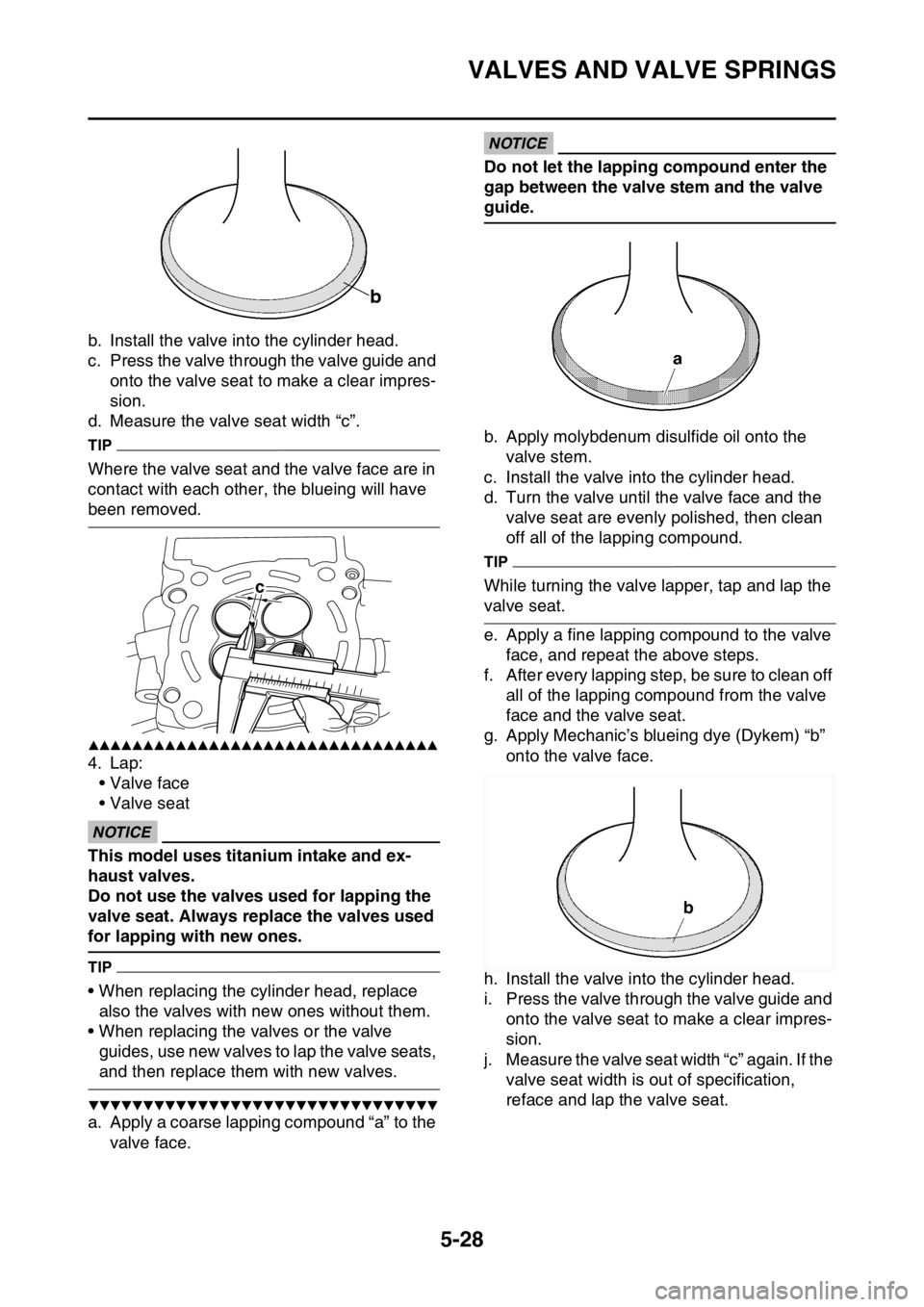

b. Install the valve into the cylinder head.

c. Press the valve through the valve guide and

onto the valve seat to make a clear impres-

sion.

d. Measure the valve seat width “c”.

TIP

Where the valve seat and the valve face are in

contact with each other, the blueing will have

been removed.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

4. Lap:

• Valve face

• Valve seat

ECA1DX1018

NOTICE

This model uses titanium intake and ex-

haust valves.

Do not use the valves used for lapping the

valve seat. Always replace the valves used

for lapping with new ones.

TIP

• When replacing the cylinder head, replace

also the valves with new ones without them.

• When replacing the valves or the valve

guides, use new valves to lap the valve seats,

and then replace them with new valves.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Apply a coarse lapping compound “a” to the

valve face.

ECA13790

NOTICE

Do not let the lapping compound enter the

gap between the valve stem and the valve

guide.

b. Apply molybdenum disulfide oil onto the

valve stem.

c. Install the valve into the cylinder head.

d. Turn the valve until the valve face and the

valve seat are evenly polished, then clean

off all of the lapping compound.

TIP

While turning the valve lapper, tap and lap the

valve seat.

e. Apply a fine lapping compound to the valve

face, and repeat the above steps.

f. After every lapping step, be sure to clean off

all of the lapping compound from the valve

face and the valve seat.

g. Apply Mechanic’s blueing dye (Dykem) “b”

onto the valve face.

h. Install the valve into the cylinder head.

i. Press the valve through the valve guide and

onto the valve seat to make a clear impres-

sion.

j. Measure the valve seat width “c” again. If the

valve seat width is out of specification,

reface and lap the valve seat.

c

Page 263 of 360

CRANKSHAFT ASSEMBLY AND BALANCER SHAFT

5-68

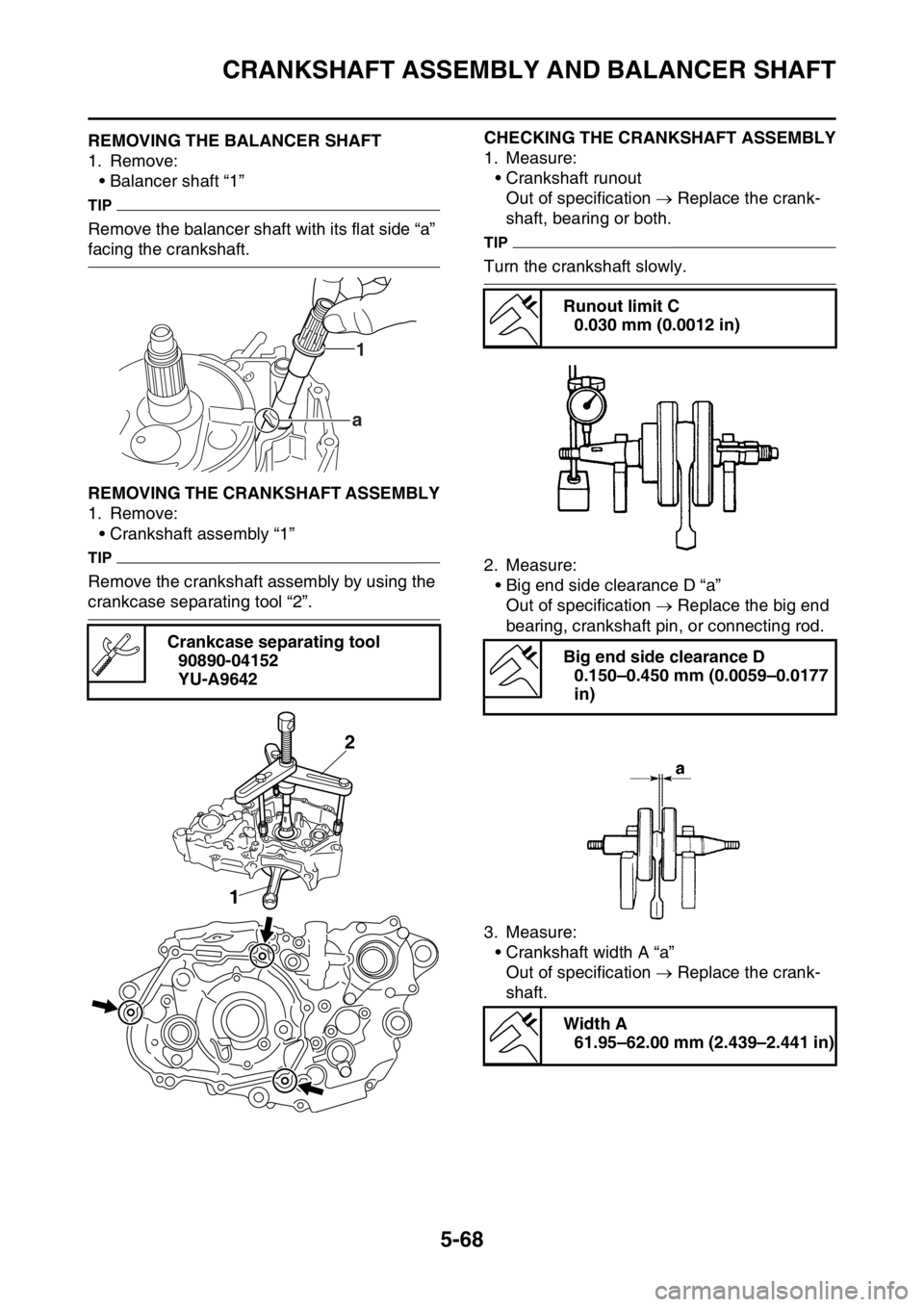

EAS1SL5285REMOVING THE BALANCER SHAFT

1. Remove:

• Balancer shaft “1”

TIP

Remove the balancer shaft with its flat side “a”

facing the crankshaft.

EAS1SL5286REMOVING THE CRANKSHAFT ASSEMBLY

1. Remove:

• Crankshaft assembly “1”

TIP

Remove the crankshaft assembly by using the

crankcase separating tool “2”.

EAS1SL5287

CHECKING THE CRANKSHAFT ASSEMBLY

1. Measure:

• Crankshaft runout

Out of specification Replace the crank-

shaft, bearing or both.

TIP

Turn the crankshaft slowly.

2. Measure:

• Big end side clearance D “a”

Out of specification Replace the big end

bearing, crankshaft pin, or connecting rod.

3. Measure:

• Crankshaft width A “a”

Out of specification Replace the crank-

shaft. Crankcase separating tool

90890-04152

YU-A9642

1

a

2

1

Runout limit C

0.030 mm (0.0012 in)

Big end side clearance D

0.150–0.450 mm (0.0059–0.0177

in)

Width A

61.95–62.00 mm (2.439–2.441 in)