warning YAMAHA YZ85 2002 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: YZ85, Model: YAMAHA YZ85 2002Pages: 504, PDF Size: 40.45 MB

Page 156 of 504

3 - 18

INSP

ADJREAR BRAKE ADJUSTMENT/

FRONT BRAKE PAD INSPECTION AND REPLACEMENT

EC364002

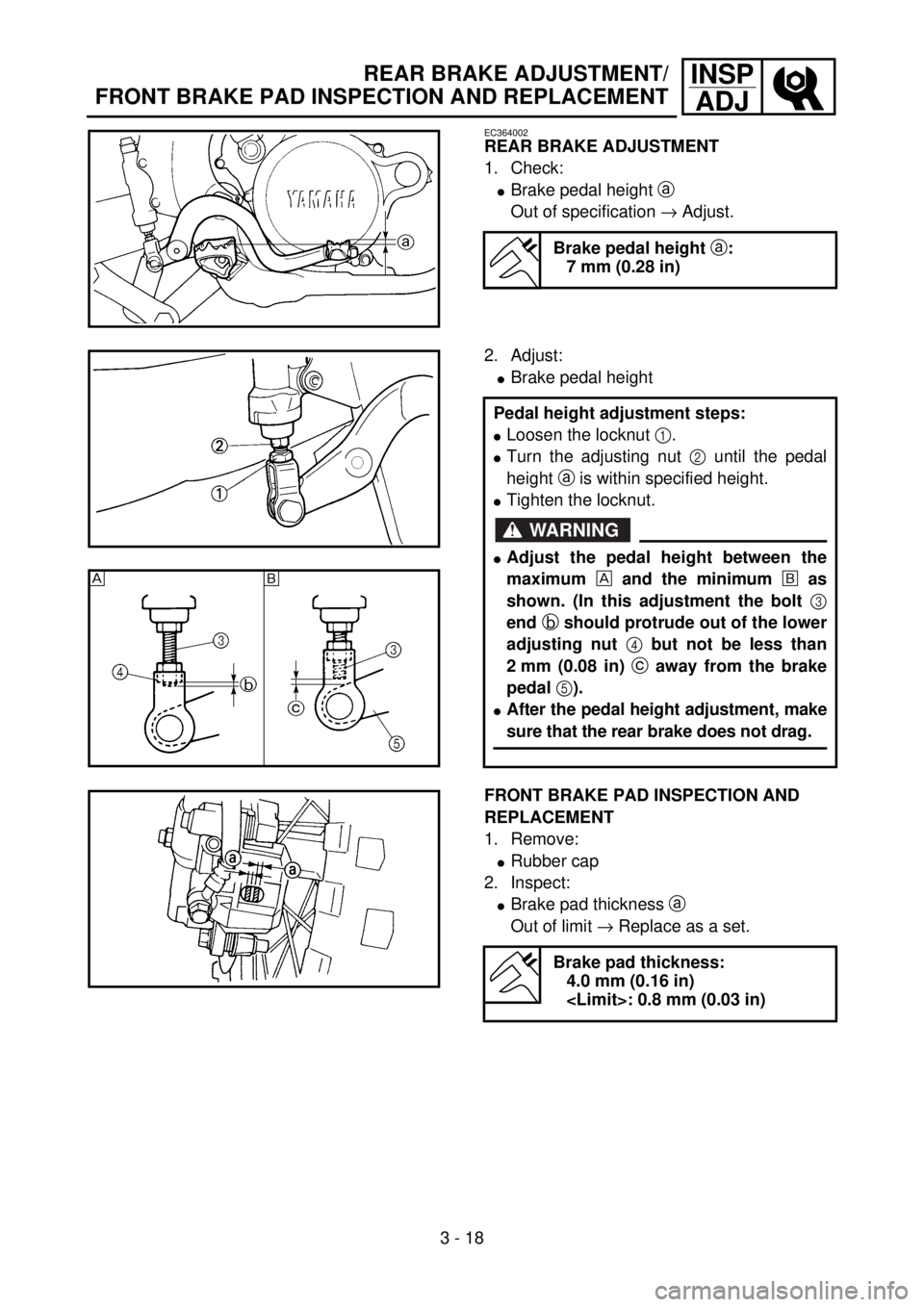

REAR BRAKE ADJUSTMENT

1. Check:

lBrake pedal height a

Out of specification ® Adjust.

Brake pedal height

a:

7 mm (0.28 in)

5PA30330

2. Adjust:

lBrake pedal height

Pedal height adjustment steps:

lLoosen the locknut 1.

lTurn the adjusting nut 2 until the pedal

height a is within specified height.

lTighten the locknut.

WARNING

lAdjust the pedal height between the

maximum

È and the minimum

É as

shown. (In this adjustment the bolt

3

end

b should protrude out of the lower

adjusting nut

4 but not be less than

2 mm (0.08 in)

c away from the brake

pedal

5).

lAfter the pedal height adjustment, make

sure that the rear brake does not drag.

5PA30340

ÈÉ

5PA30350

FRONT BRAKE PAD INSPECTION AND

REPLACEMENT

1. Remove:

lRubber cap

2. Inspect:

lBrake pad thickness a

Out of limit ® Replace as a set.

Brake pad thickness:

4.0 mm (0.16 in)

Page 162 of 504

3 - 21

INSP

ADJ

BRAKE FLUID LEVEL INSPECTION

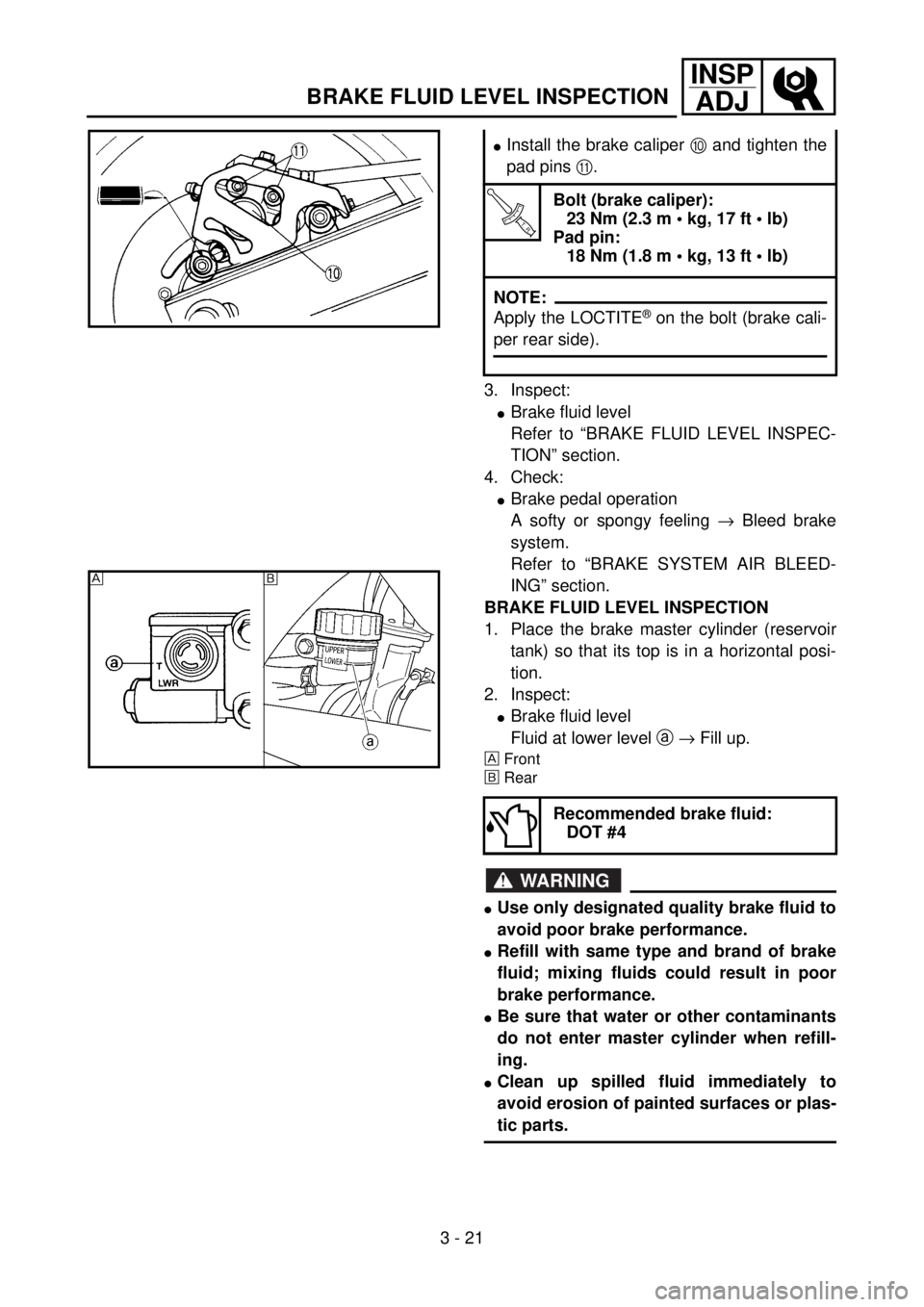

3. Inspect:

lBrake fluid level

Refer to “BRAKE FLUID LEVEL INSPEC-

TION” section.

4. Check:

lBrake pedal operation

A softy or spongy feeling ® Bleed brake

system.

Refer to “BRAKE SYSTEM AIR BLEED-

ING” section.

BRAKE FLUID LEVEL INSPECTION

1. Place the brake master cylinder (reservoir

tank) so that its top is in a horizontal posi-

tion.

2. Inspect:

lBrake fluid level

Fluid at lower level a ® Fill up.

ÈFront

ÉRear

WARNING

lUse only designated quality brake fluid to

avoid poor brake performance.

lRefill with same type and brand of brake

fluid; mixing fluids could result in poor

brake performance.

lBe sure that water or other contaminants

do not enter master cylinder when refill-

ing.

lClean up spilled fluid immediately to

avoid erosion of painted surfaces or plas-

tic parts.

lInstall the brake caliper 0 and tighten the

pad pins A.

T R..

Bolt (brake caliper):

23 Nm (2.3 m • kg, 17 ft • lb)

Pad pin:

18 Nm (1.8 m • kg, 13 ft • lb)

NOTE:

Apply the LOCTITE® on the bolt (brake cali-

per rear side).

Recommended brake fluid:

DOT #4

5PA30460

È

5PA30470

É

Page 172 of 504

3 - 26

INSP

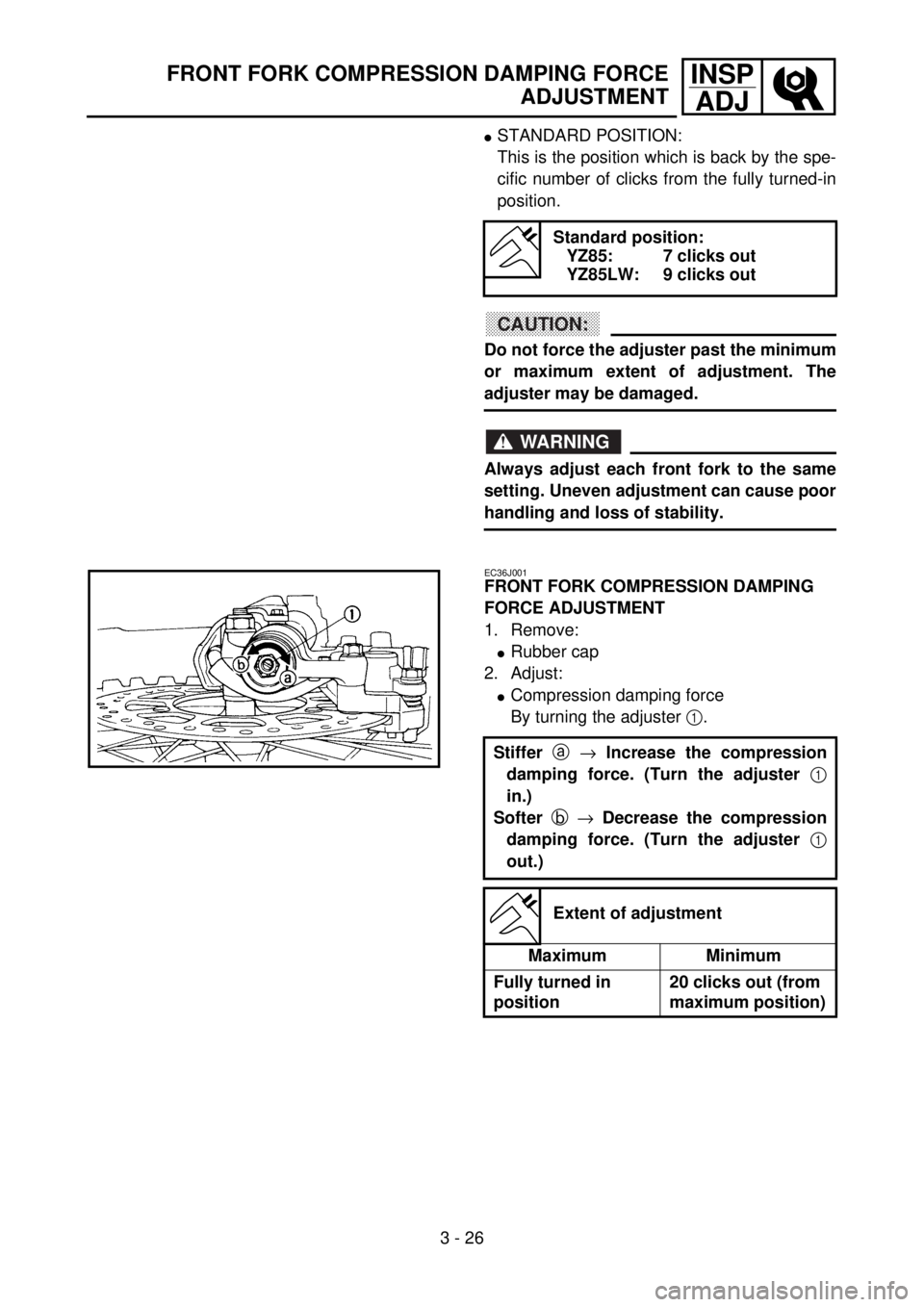

ADJFRONT FORK COMPRESSION DAMPING FORCE

ADJUSTMENT

lSTANDARD POSITION:

This is the position which is back by the spe-

cific number of clicks from the fully turned-in

position.

CAUTION:

Do not force the adjuster past the minimum

or maximum extent of adjustment. The

adjuster may be damaged.

WARNING

Always adjust each front fork to the same

setting. Uneven adjustment can cause poor

handling and loss of stability.

Standard position:

YZ85: 7 clicks out

YZ85LW: 9 clicks out

EC36J001

FRONT FORK COMPRESSION DAMPING

FORCE ADJUSTMENT

1. Remove:

lRubber cap

2. Adjust:

lCompression damping force

By turning the adjuster 1.

Stiffer

a

® Increase the compression

damping force. (Turn the adjuster

1

in.)

Softer

b

® Decrease the compression

damping force. (Turn the adjuster

1

out.)

Extent of adjustment

Maximum Minimum

Fully turned in

position20 clicks out (from

maximum position)

5PA30610

Page 174 of 504

3 - 27

INSP

ADJ

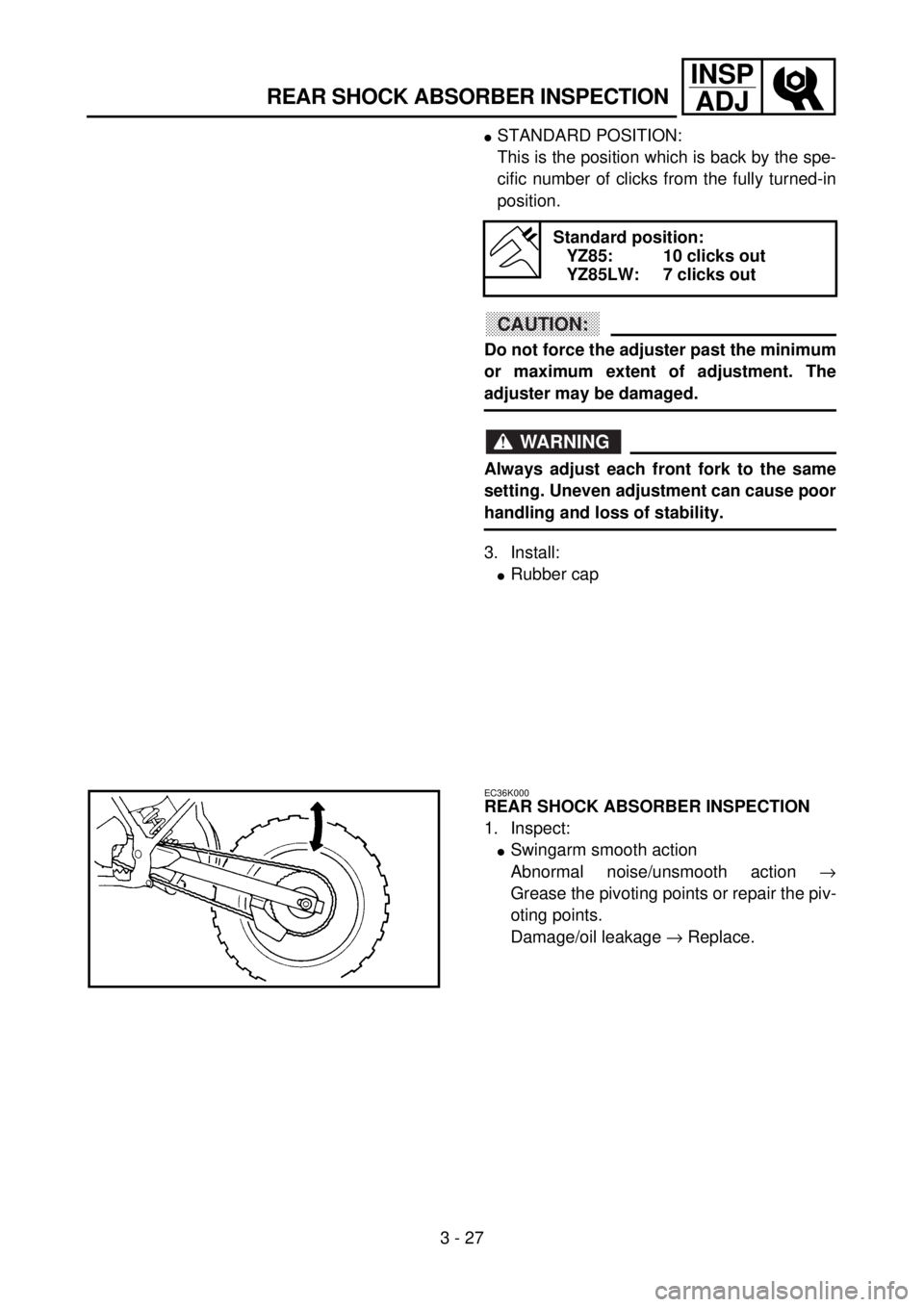

REAR SHOCK ABSORBER INSPECTION

lSTANDARD POSITION:

This is the position which is back by the spe-

cific number of clicks from the fully turned-in

position.

CAUTION:

Do not force the adjuster past the minimum

or maximum extent of adjustment. The

adjuster may be damaged.

WARNING

Always adjust each front fork to the same

setting. Uneven adjustment can cause poor

handling and loss of stability.

3. Install:

lRubber cap

Standard position:

YZ85: 10 clicks out

YZ85LW: 7 clicks out

EC36K000

REAR SHOCK ABSORBER INSPECTION

1. Inspect:

lSwingarm smooth action

Abnormal noise/unsmooth action ®

Grease the pivoting points or repair the piv-

oting points.

Damage/oil leakage ® Replace.

5PA30620

Page 186 of 504

3 - 33

INSP

ADJ

STEERING HEAD INSPECTION AND ADJUSTMENT

lTighten the steering ring nut 3 using

steering nut wrench 4.

NOTE:

Set the torque wrench to the steering nut

wrench so that they form a right angle.

Steering nut wrench:

YU-33975/90890-01403

T R..

Steering ring nut (initial tighten-

ing):

38 Nm (3.8 m • kg, 27 ft • lb)

lLoosen the steering ring nut one turn.

lRetighten the steering ring nut using the

steering nut wrench.

WARNING

Avoid over-tightening.

T R..

Steering ring nut (final tighten-

ing):

4 Nm (0.4 m • kg, 2.9 ft • lb)

lCheck the steering stem by turning it lock

to lock. If there is any binding, remove the

steering stem assembly and inspect the

steering bearings.

lInstall the upper bracket 5, steering stem

nut 6, handlebar 7, handlebar upper

holder 8 and number plate 9.

NOTE:

lThe upper handlebar holder should be

installed with the punched mark a for-

ward.

lInsert the end of fuel breather hose 0 into

the hole of the steering stem.

CAUTION:

First tighten the bolts on the front side of

the handlebar holder, and then tighten

the bolts on the rear side.

T R..

Steering stem nut:

115 Nm (11.5 m • kg, 85 ft • lb)

Handlebar upper holder:

27 Nm (2.7 m • kg, 19 ft • lb)

Pinch bolt (upper bracket):

22 Nm (2.2 m • kg, 16 ft • lb)

Number plate:

7 Nm (0.7 m • kg, 5.1 ft • lb)

5PA30750

5PA30760

Page 202 of 504

4 - 4

ENGRADIATOR

EC456000

HANDLING NOTE

WARNING

Do not remove the radiator cap when the

engine and radiator are hot. Scalding hot

fluid and steam may be blown out under

pressure, which could cause serious

injury.

When the engine has cooled, open the radi-

ator cap by the following procedure:

Place a thick rag, like a towel, over the radi-

ator cap, slowly rotate the cap counter-

clockwise to the detent. This procedure

allows any residual pressure to escape.

When the hissing sound has stopped,

press down on the cap while turning coun-

terclockwise and remove it.

EC454000

INSPECTION

Radiator

1. Inspect:

lRadiator core 1

Obstruction ® Blow out with compressed

air through rear of the radiator.

Bent fin ® Repair or replace.

5PA40040

EC455000

ASSEMBLY AND INSTALLATION

Radiator

1. Install:

lRadiator breather hose 1

To radiator 2.

5PA40050

2. Install:

lRadiator 1

lBolt (radiator) 2

5PA40060

Page 292 of 504

4 - 49

ENG

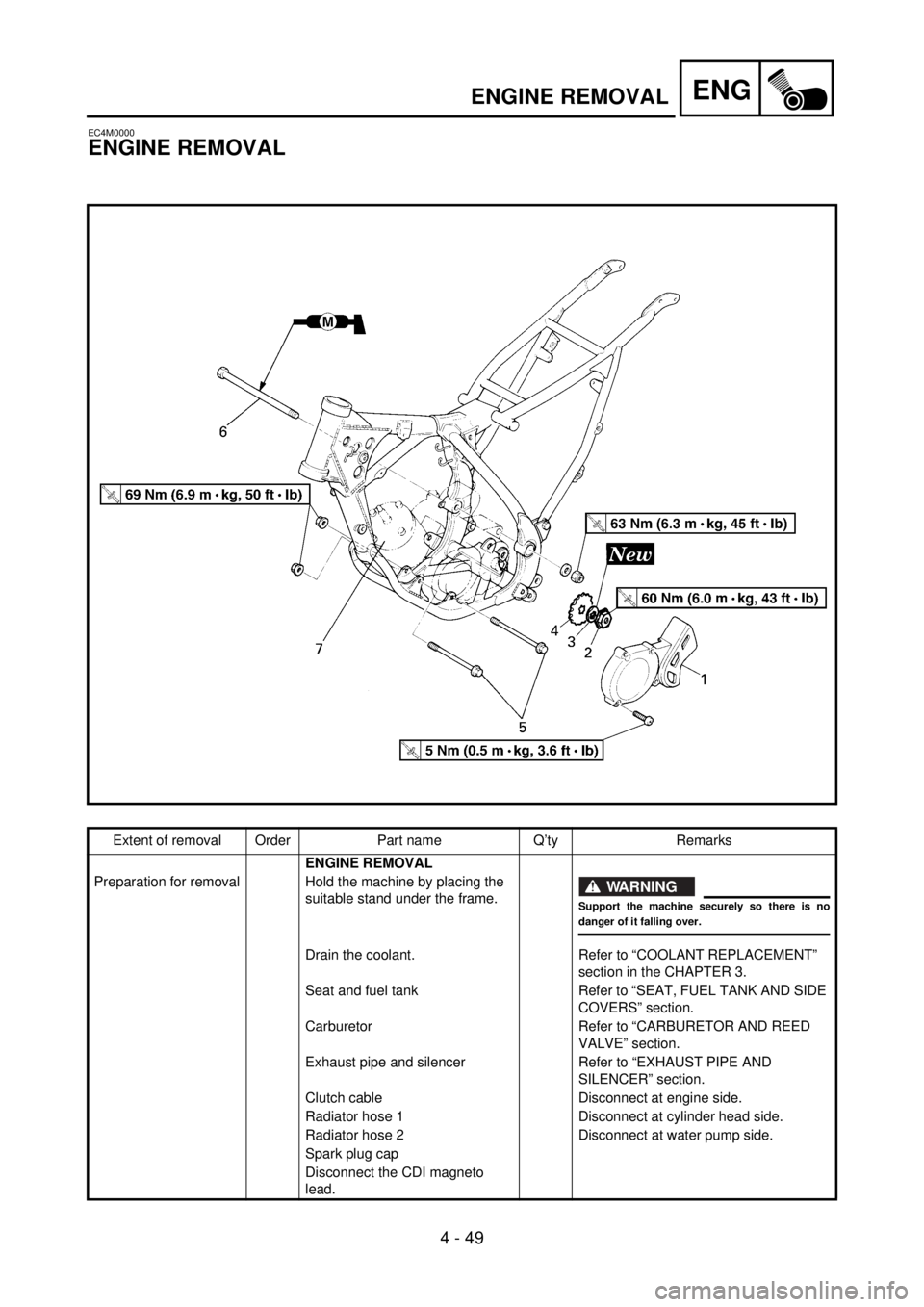

EC4M0000

ENGINE REMOVAL

5PA41490

Extent of removal Order Part name Q’ty Remarks

ENGINE REMOVAL

Preparation for removal Hold the machine by placing the

suitable stand under the frame.

WARNING

Support the machine securely so there is no

danger of it falling over.

Drain the coolant. Refer to “COOLANT REPLACEMENT”

section in the CHAPTER 3.

Seat and fuel tank Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

Carburetor Refer to “CARBURETOR AND REED

VALVE” section.

Exhaust pipe and silencer Refer to “EXHAUST PIPE AND

SILENCER” section.

Clutch cable Disconnect at engine side.

Radiator hose 1 Disconnect at cylinder head side.

Radiator hose 2 Disconnect at water pump side.

Spark plug cap

Disconnect the CDI magneto

lead.

ENGINE REMOVAL

Page 324 of 504

5 - 1

CHAS

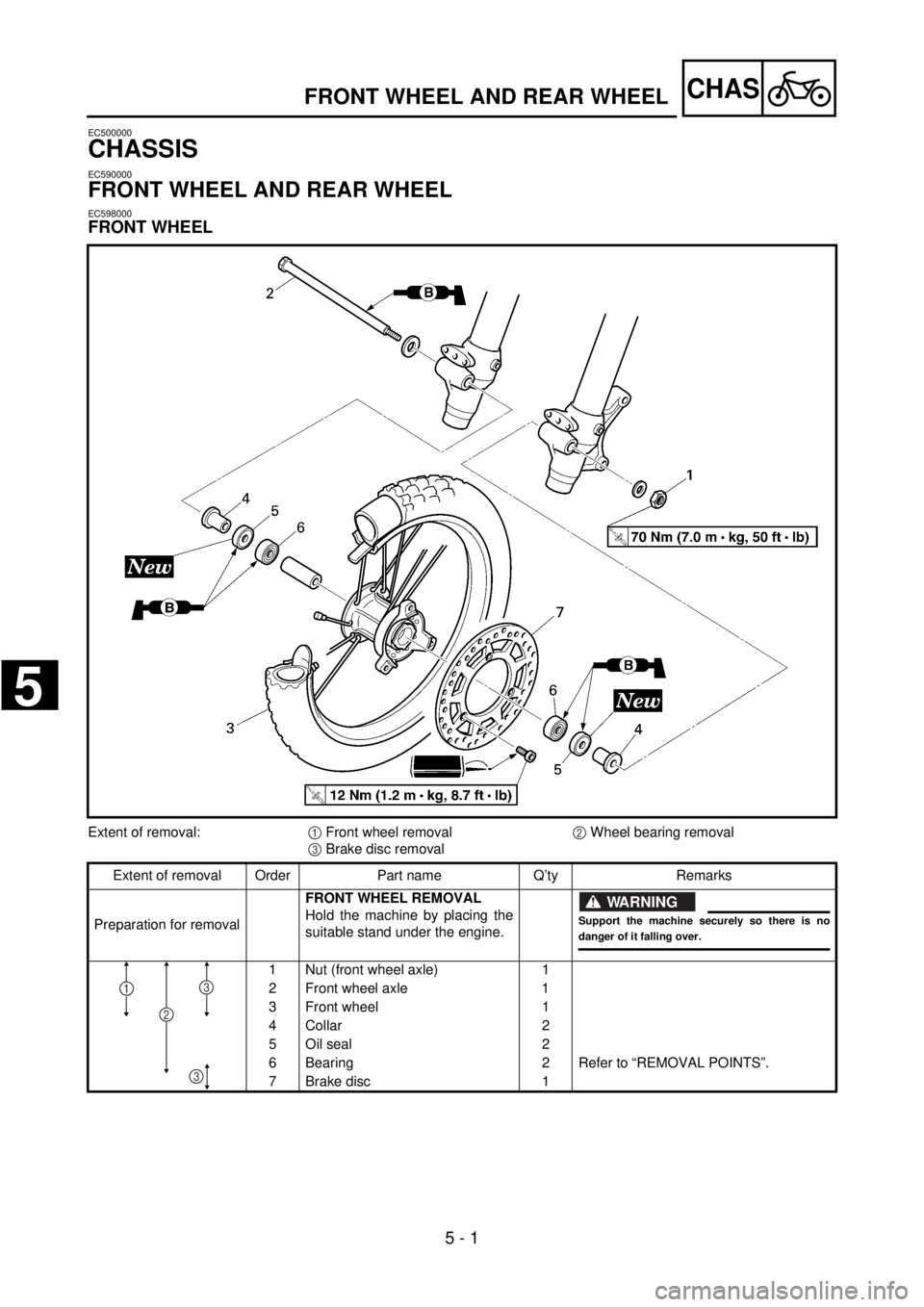

EC500000

CHASSIS

EC590000

FRONT WHEEL AND REAR WHEEL

EC598000

FRONT WHEEL

FRONT WHEEL AND REAR WHEEL

Extent of removal:

1 Front wheel removal

2 Wheel bearing removal

3 Brake disc removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalFRONT WHEEL REMOVAL

Hold the machine by placing the

suitable stand under the engine.

WARNING

Support the machine securely so there is no

danger of it falling over.

1 Nut (front wheel axle) 1

2 Front wheel axle 1

3 Front wheel 1

4 Collar 2

5 Oil seal 2

6 Bearing 2 Refer to “REMOVAL POINTS”.

7 Brake disc 1

2

31

3

5PA50010

5

Page 326 of 504

5 - 2

CHAS

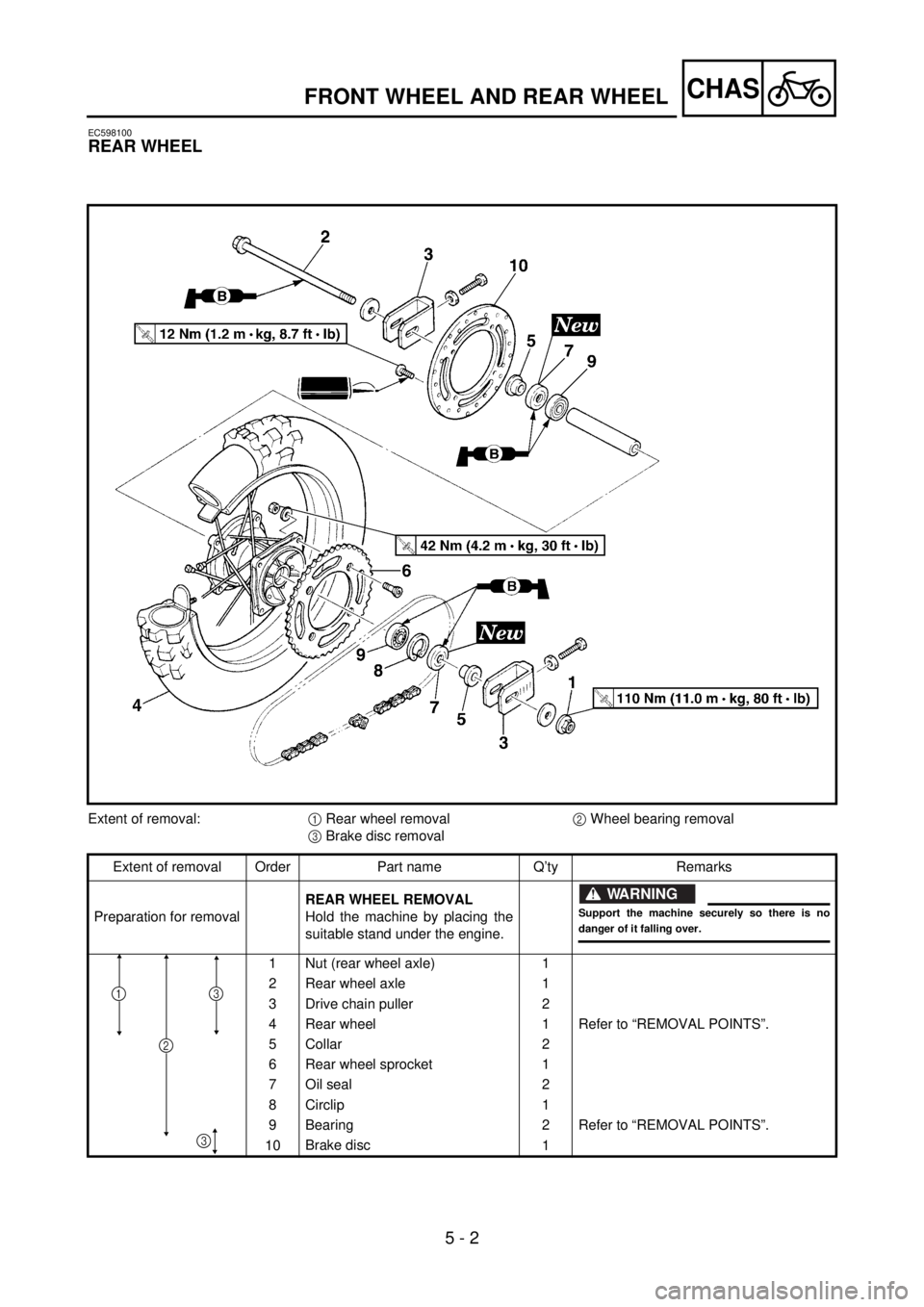

EC598100

REAR WHEEL

5PA50020

Extent of removal:

1 Rear wheel removal

2 Wheel bearing removal

3 Brake disc removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalREAR WHEEL REMOVAL

Hold the machine by placing the

suitable stand under the engine.

WARNING

Support the machine securely so there is no

danger of it falling over.

1 Nut (rear wheel axle) 1

2 Rear wheel axle 1

3 Drive chain puller 2

4 Rear wheel 1 Refer to “REMOVAL POINTS”.

5 Collar 2

6 Rear wheel sprocket 1

7 Oil seal 2

8 Circlip 1

9 Bearing 2 Refer to “REMOVAL POINTS”.

10Brake disc

1

2

31

3

FRONT WHEEL AND REAR WHEEL

Page 330 of 504

5 - 4

CHAS

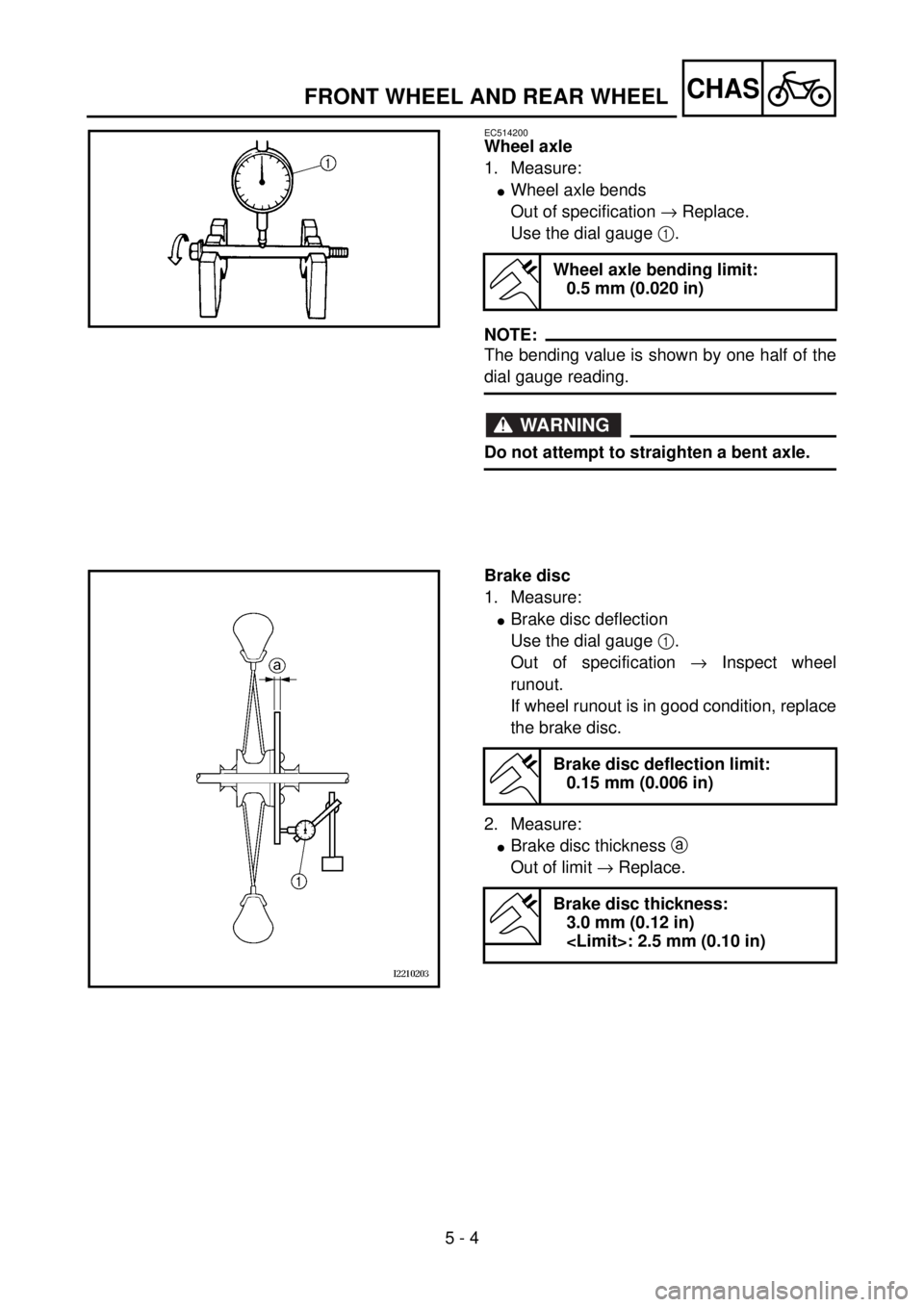

EC514200

Wheel axle

1. Measure:

lWheel axle bends

Out of specification ® Replace.

Use the dial gauge 1.

NOTE:

The bending value is shown by one half of the

dial gauge reading.

WARNING

Do not attempt to straighten a bent axle.

Wheel axle bending limit:

0.5 mm (0.020 in)

5PA50070

Brake disc

1. Measure:

lBrake disc deflection

Use the dial gauge 1.

Out of specification ® Inspect wheel

runout.

If wheel runout is in good condition, replace

the brake disc.

2. Measure:

lBrake disc thickness a

Out of limit ® Replace.

Brake disc deflection limit:

0.15 mm (0.006 in)

Brake disc thickness:

3.0 mm (0.12 in)

5PA50080

FRONT WHEEL AND REAR WHEEL