fuel YAMAHA YZ85 2002 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: YZ85, Model: YAMAHA YZ85 2002Pages: 504, PDF Size: 40.45 MB

Page 196 of 504

4 - 1

ENG

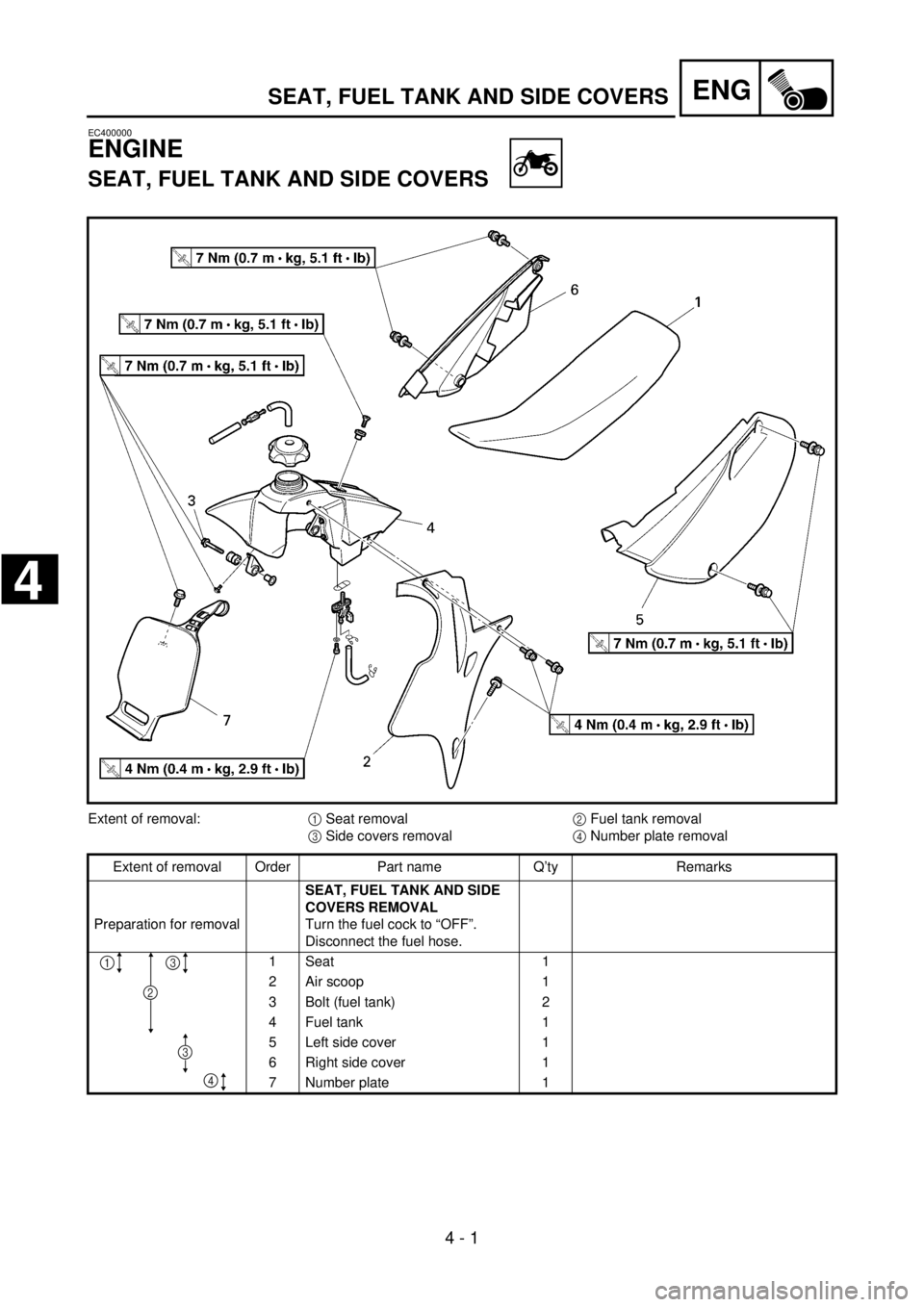

EC400000

ENGINE

SEAT, FUEL TANK AND SIDE COVERS

5PA40010

Extent of removal:

1 Seat removal

2 Fuel tank removal

3 Side covers removal

4 Number plate removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalSEAT, FUEL TANK AND SIDE

COVERS REMOVAL

Turn the fuel cock to “OFF”.

Disconnect the fuel hose.

1Seat 1

2 Air scoop 1

3 Bolt (fuel tank) 2

4 Fuel tank 1

5 Left side cover 1

6 Right side cover 1

7 Number plate 1

13

4

2

3

SEAT, FUEL TANK AND SIDE COVERS

4

4

Page 198 of 504

4 - 2

ENGEXHAUST PIPE AND SILENCER

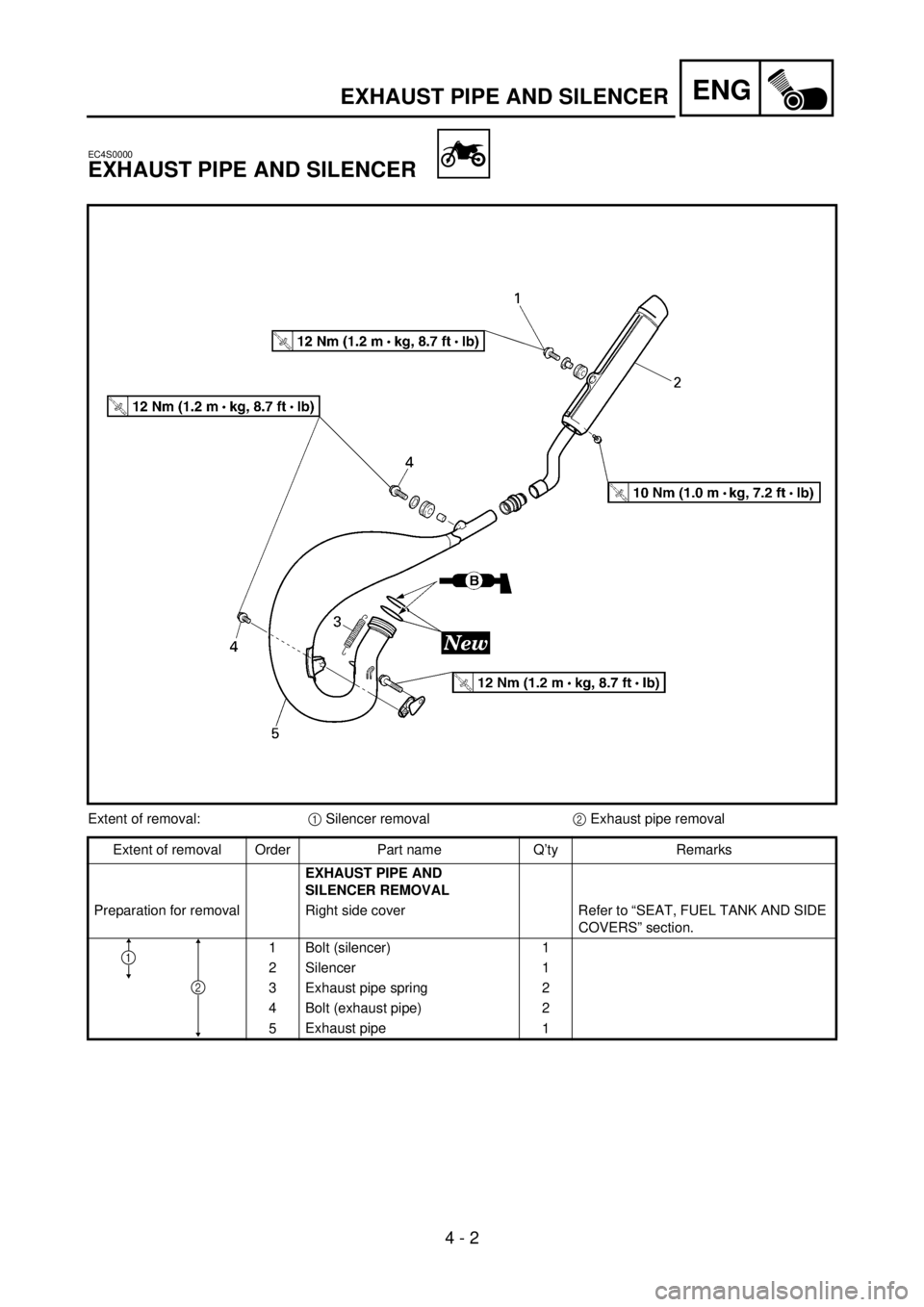

EC4S0000

EXHAUST PIPE AND SILENCER

5PA40020

Extent of removal:

1 Silencer removal

2 Exhaust pipe removal

Extent of removal Order Part name Q’ty Remarks

EXHAUST PIPE AND

SILENCER REMOVAL

Preparation for removal Right side cover Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

1 Bolt (silencer) 1

2 Silencer 1

3 Exhaust pipe spring 2

4 Bolt (exhaust pipe) 2

5Exhaust pipe

1

1

2

Page 200 of 504

4 - 3

ENGRADIATOR

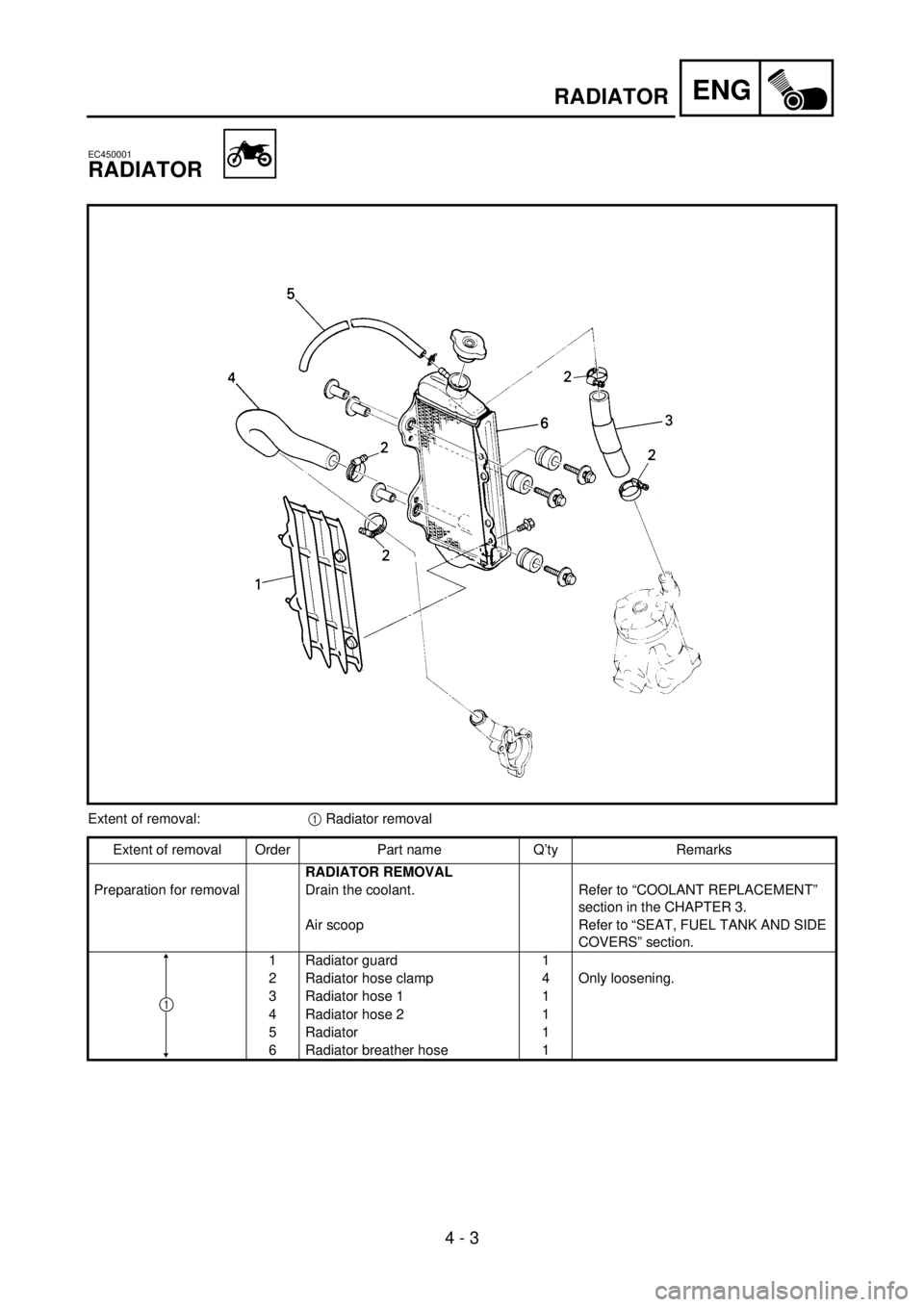

EC450001

RADIATOR

5PA40030

Extent of removal:

1 Radiator removal

Extent of removal Order Part name Q’ty Remarks

RADIATOR REMOVAL

Preparation for removal Drain the coolant. Refer to “COOLANT REPLACEMENT”

section in the CHAPTER 3.

Air scoop Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

1 Radiator guard 1

2 Radiator hose clamp 4 Only loosening.

3 Radiator hose 1 1

4 Radiator hose 2 1

5Radiator 1

6 Radiator breather hose 1

1

Page 210 of 504

4 - 8

ENGCARBURETOR AND REED VALVE

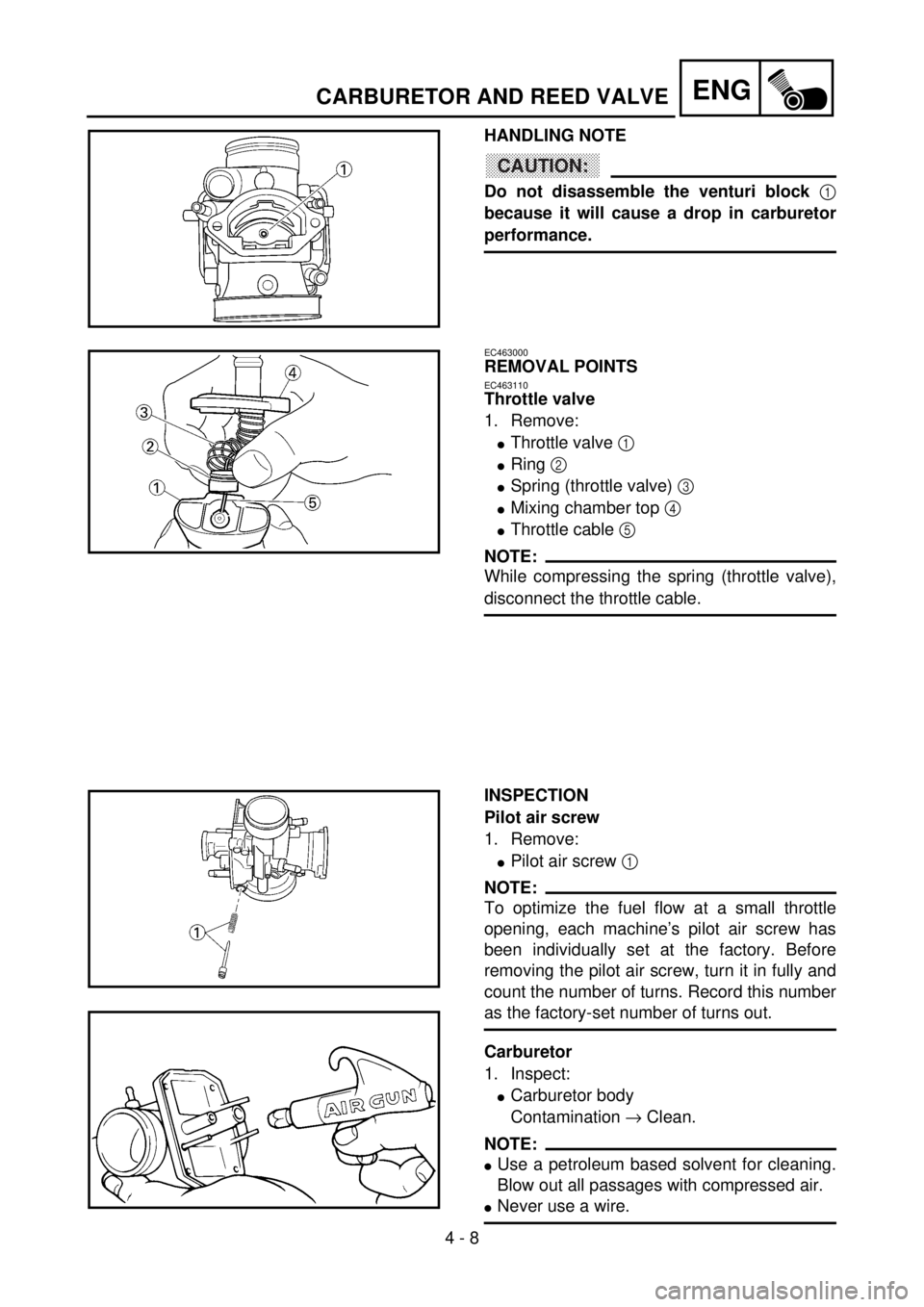

HANDLING NOTE

CAUTION:

Do not disassemble the venturi block

1

because it will cause a drop in carburetor

performance.

5PA40110

EC463000

REMOVAL POINTS

EC463110

Throttle valve

1. Remove:

lThrottle valve 1

lRing 2

lSpring (throttle valve) 3

lMixing chamber top 4

lThrottle cable 5

NOTE:

While compressing the spring (throttle valve),

disconnect the throttle cable.

5PA40120

INSPECTION

Pilot air screw

1. Remove:

lPilot air screw 1

NOTE:

To optimize the fuel flow at a small throttle

opening, each machine’s pilot air screw has

been individually set at the factory. Before

removing the pilot air screw, turn it in fully and

count the number of turns. Record this number

as the factory-set number of turns out.

Carburetor

1. Inspect:

lCarburetor body

Contamination ® Clean.

NOTE:

lUse a petroleum based solvent for cleaning.

Blow out all passages with compressed air.

lNever use a wire.

5PA40130

5PA40130

Page 224 of 504

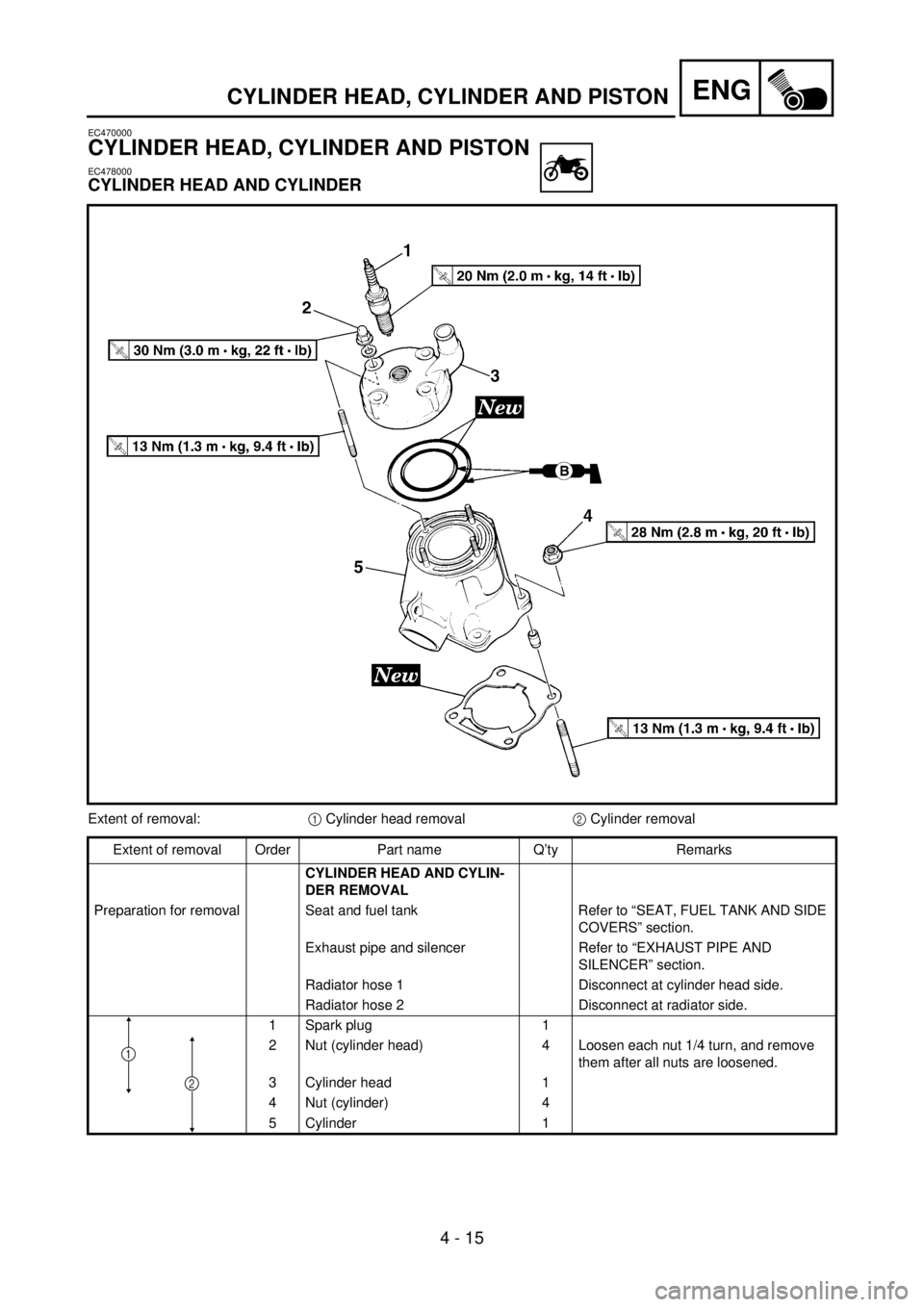

4 - 15

ENGCYLINDER HEAD, CYLINDER AND PISTON

EC470000

CYLINDER HEAD, CYLINDER AND PISTON

EC478000

CYLINDER HEAD AND CYLINDER

5PA40390

Extent of removal:

1 Cylinder head removal

2 Cylinder removal

Extent of removal Order Part name Q’ty Remarks

CYLINDER HEAD AND CYLIN-

DER REMOVAL

Preparation for removal Seat and fuel tank Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

Exhaust pipe and silencer Refer to “EXHAUST PIPE AND

SILENCER” section.

Radiator hose 1 Disconnect at cylinder head side.

Radiator hose 2 Disconnect at radiator side.

1 Spark plug 1

2 Nut (cylinder head) 4 Loosen each nut 1/4 turn, and remove

them after all nuts are loosened.

3 Cylinder head 1

4 Nut (cylinder) 4

5 Cylinder 1

1

2

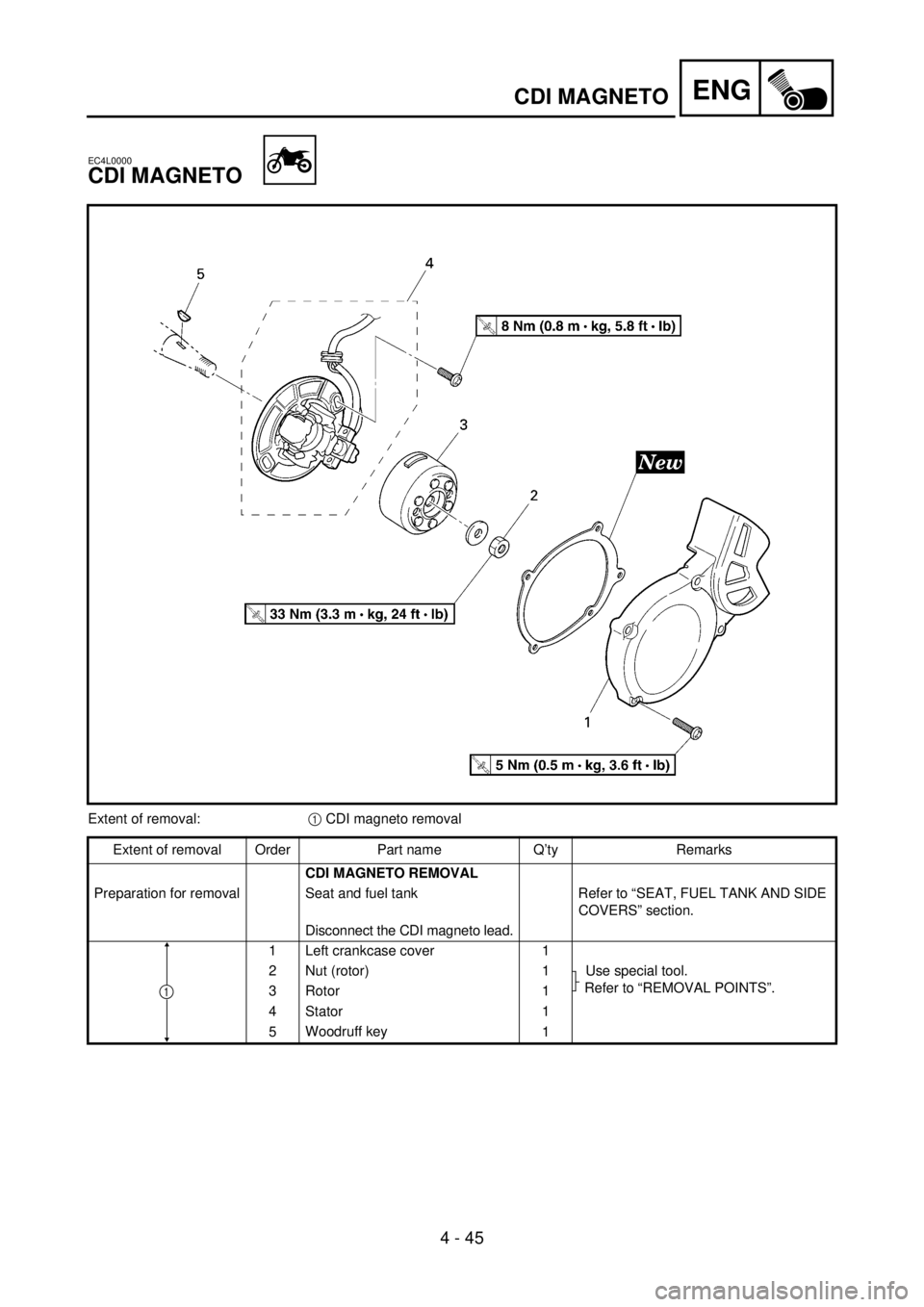

Page 284 of 504

4 - 45

ENG

EC4L0000

CDI MAGNETO

5PA41380

Extent of removal:

1 CDI magneto removal

Extent of removal Order Part name Q’ty Remarks

CDI MAGNETO REMOVAL

Preparation for removal Seat and fuel tank Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

Disconnect the CDI magneto lead.

1 Left crankcase cover 1

2 Nut (rotor) 1 Use special tool.

Refer to “REMOVAL POINTS”.

3 Rotor 1

4 Stator 1

5Woodruff key

1

1

CDI MAGNETO

Page 292 of 504

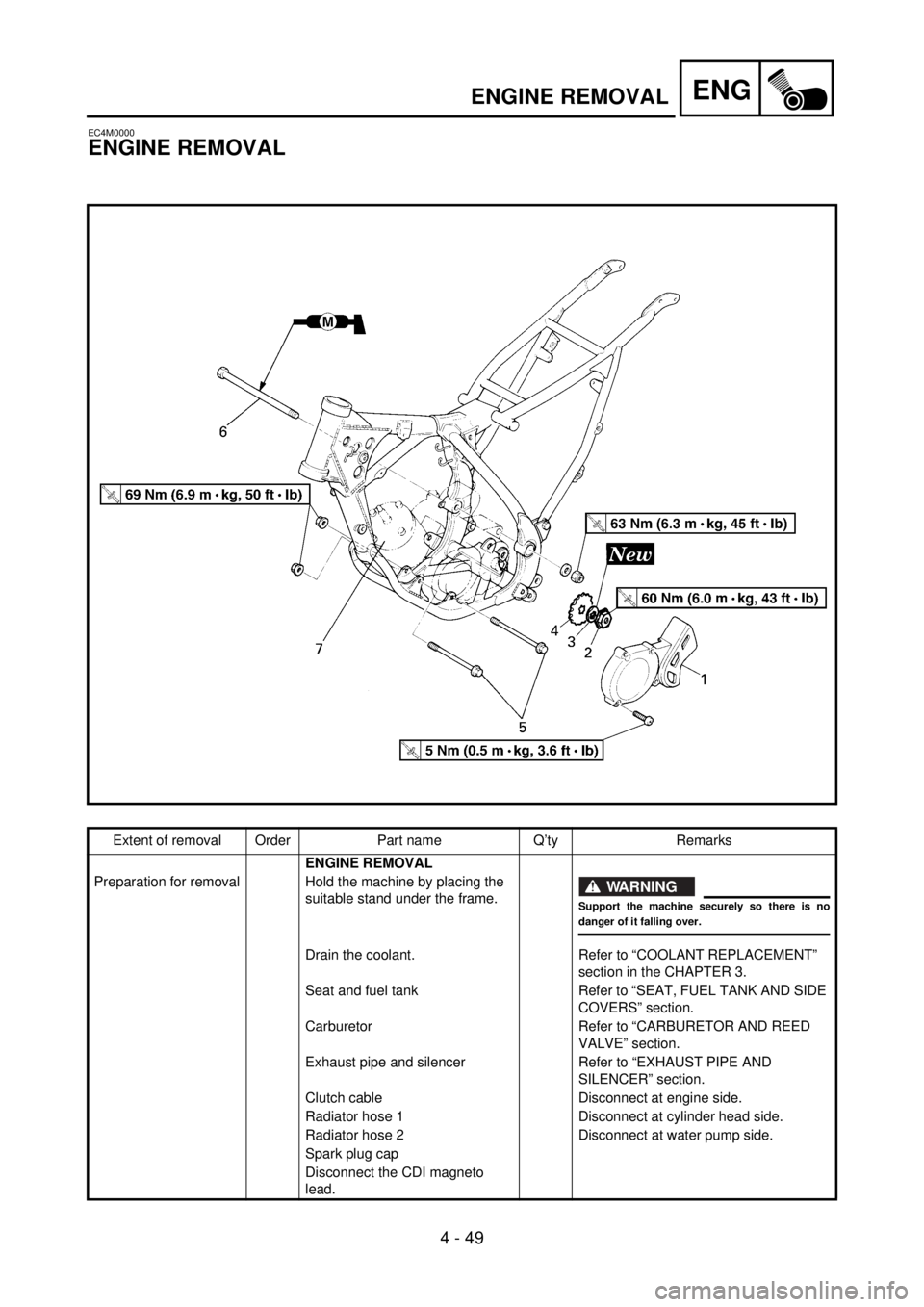

4 - 49

ENG

EC4M0000

ENGINE REMOVAL

5PA41490

Extent of removal Order Part name Q’ty Remarks

ENGINE REMOVAL

Preparation for removal Hold the machine by placing the

suitable stand under the frame.

WARNING

Support the machine securely so there is no

danger of it falling over.

Drain the coolant. Refer to “COOLANT REPLACEMENT”

section in the CHAPTER 3.

Seat and fuel tank Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

Carburetor Refer to “CARBURETOR AND REED

VALVE” section.

Exhaust pipe and silencer Refer to “EXHAUST PIPE AND

SILENCER” section.

Clutch cable Disconnect at engine side.

Radiator hose 1 Disconnect at cylinder head side.

Radiator hose 2 Disconnect at water pump side.

Spark plug cap

Disconnect the CDI magneto

lead.

ENGINE REMOVAL

Page 412 of 504

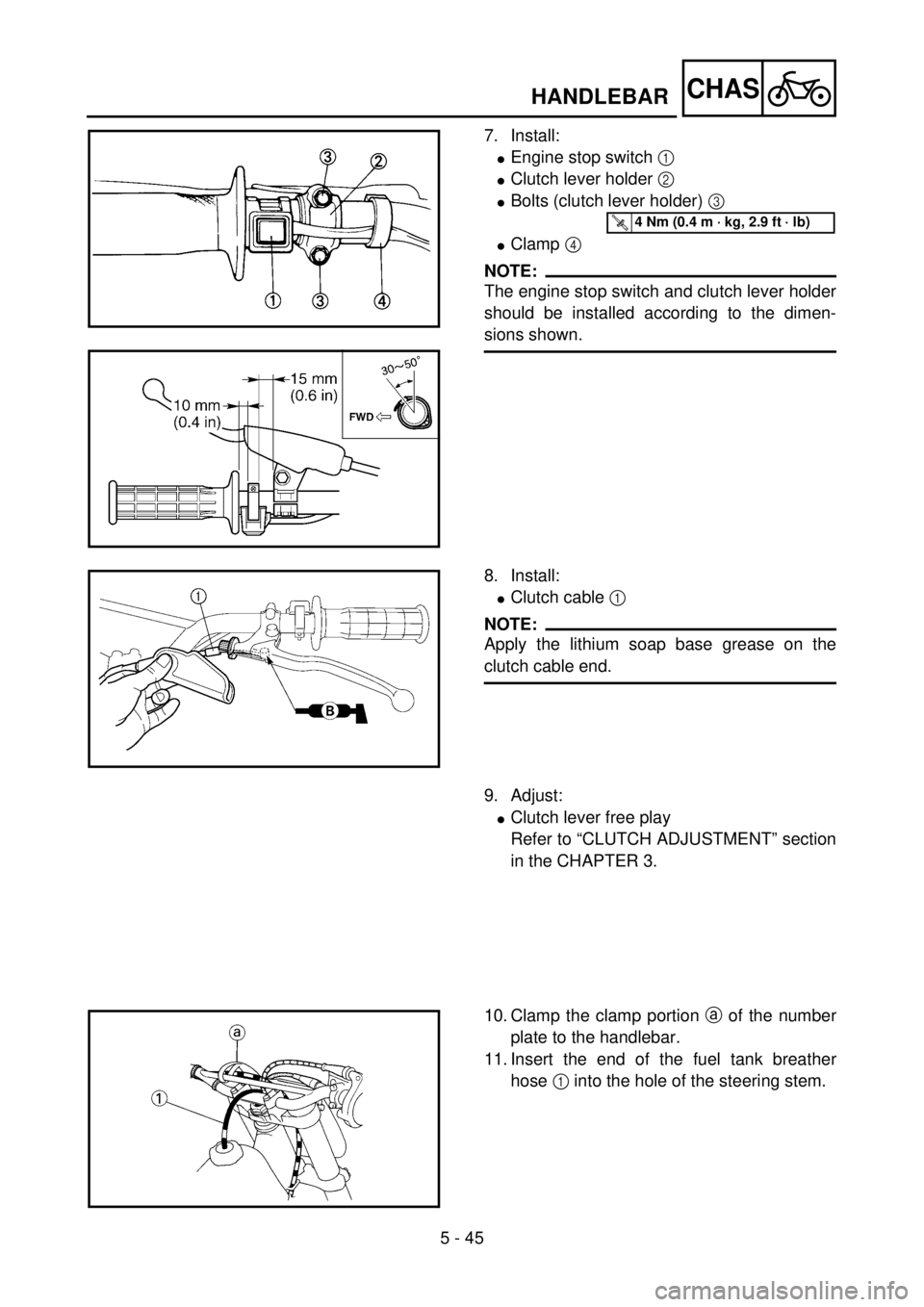

5 - 45

CHAS

7. Install:

lEngine stop switch 1

lClutch lever holder 2

lBolts (clutch lever holder) 3

lClamp 4

NOTE:

The engine stop switch and clutch lever holder

should be installed according to the dimen-

sions shown.

5PA51420

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

5PA51430

8. Install:

lClutch cable 1

NOTE:

Apply the lithium soap base grease on the

clutch cable end.

5PA51440

9. Adjust:

lClutch lever free play

Refer to “CLUTCH ADJUSTMENT” section

in the CHAPTER 3.

10. Clamp the clamp portion a of the number

plate to the handlebar.

11. Insert the end of the fuel tank breather

hose 1 into the hole of the steering stem.

5PA51450

HANDLEBAR

Page 440 of 504

5 - 59

CHASREAR SHOCK ABSORBER

EC580000

REAR SHOCK ABSORBER

5PA51870

Extent of removal:

1 Rear shock absorber removal

2 Rear shock absorber disassembly

Extent of removal Order Part name Q’ty Remarks

Preparation for removalREAR SHOCK ABSORBER

REMOVAL

Hold the machine by placing the

suitable stand under the engine.

WARNING

Support the machine securely so there is no

danger of it falling over.

Seat Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section in the CHAPTER 4.

Silencer Refer to “EXHAUST PIPE AND

SILENCER” section in the CHAPTER 4.

1 Clamp (air cleaner joint) 1 Only loosening.

2Rear frame 1

3 Bolt (rear shock absorber-relay

arm)1 Hold the swingarm.

4 Bolt (rear shock absorber-frame) 1

5 Rear shock absorber 1

6 Locknut 1 Only loosening.

7 Adjuster 1 Only loosening.

8 Spring guide 1

9 Spring (rear shock absorber) 1

1

2

Page 452 of 504

6 - 2

–+ELECIGNITION SYSTEM

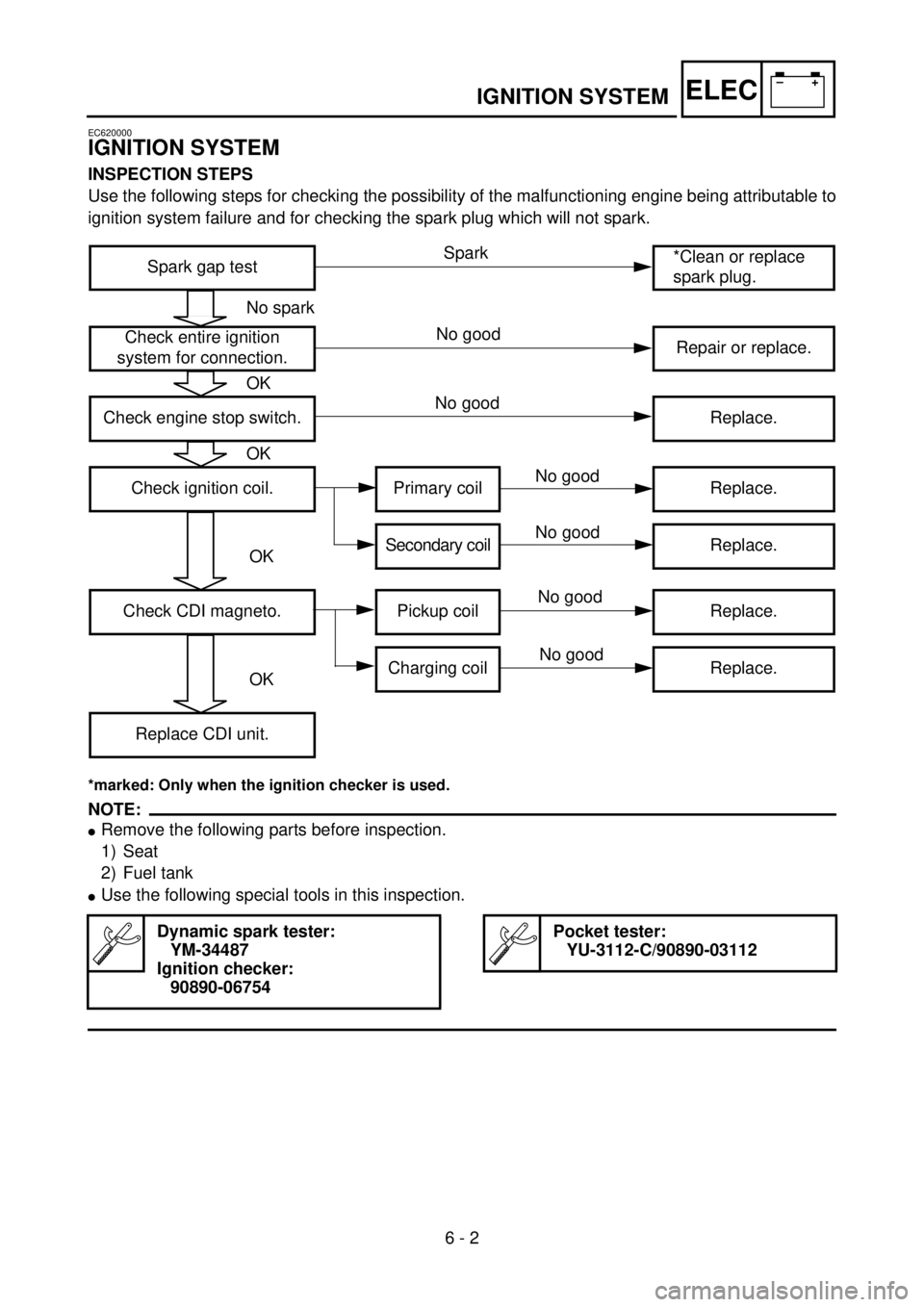

EC620000

IGNITION SYSTEM

INSPECTION STEPS

Use the following steps for checking the possibility of the malfunctioning engine being attributable to

ignition system failure and for checking the spark plug which will not spark.

*marked: Only when the ignition checker is used.

NOTE:

lRemove the following parts before inspection.

1) Seat

2) Fuel tank

lUse the following special tools in this inspection.

Dynamic spark tester:

YM-34487

Ignition checker:

90890-06754Pocket tester:

YU-3112-C/90890-03112

Spark gap test*Clean or replace

spark plug.

Check entire ignition

system for connection.Repair or replace.

Check engine stop switch. Replace.

Check ignition coil. Primary coil Replace.

Secondary coil Replace.

Check CDI magneto. Pickup coil Replace.

Charging coil Replace.

Replace CDI unit.

No spark

OK

OK

OK

OK

Spark

No good

No good

No good

No good

No good

No good