steering YAMAHA YZ85 2002 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: YZ85, Model: YAMAHA YZ85 2002Pages: 504, PDF Size: 40.45 MB

Page 24 of 504

CHAPTER 5

CHASSIS

FRONT WHEEL AND REAR WHEEL....... 5-1

FRONT BRAKE AND REAR BRAKE....... 5-9

FRONT FORK.......................................... 5-27

HANDLEBAR........................................... 5-41

STEERING............................................... 5-46

SWINGARM............................................. 5-51

REAR SHOCK ABSORBER.................... 5-59

CHAPTER 6

ELECTRICAL

ELECTRICAL COMPONENTS

AND WIRING DIAGRAM........................... 6-1

IGNITION SYSTEM.................................... 6-2

CHAPTER 7

TUNING

ENGINE...................................................... 7-1

CHASSIS................................................. 7-10

Page 28 of 504

1 - 2

GEN

INFO

MACHINE IDENTIFICATION

EC120001

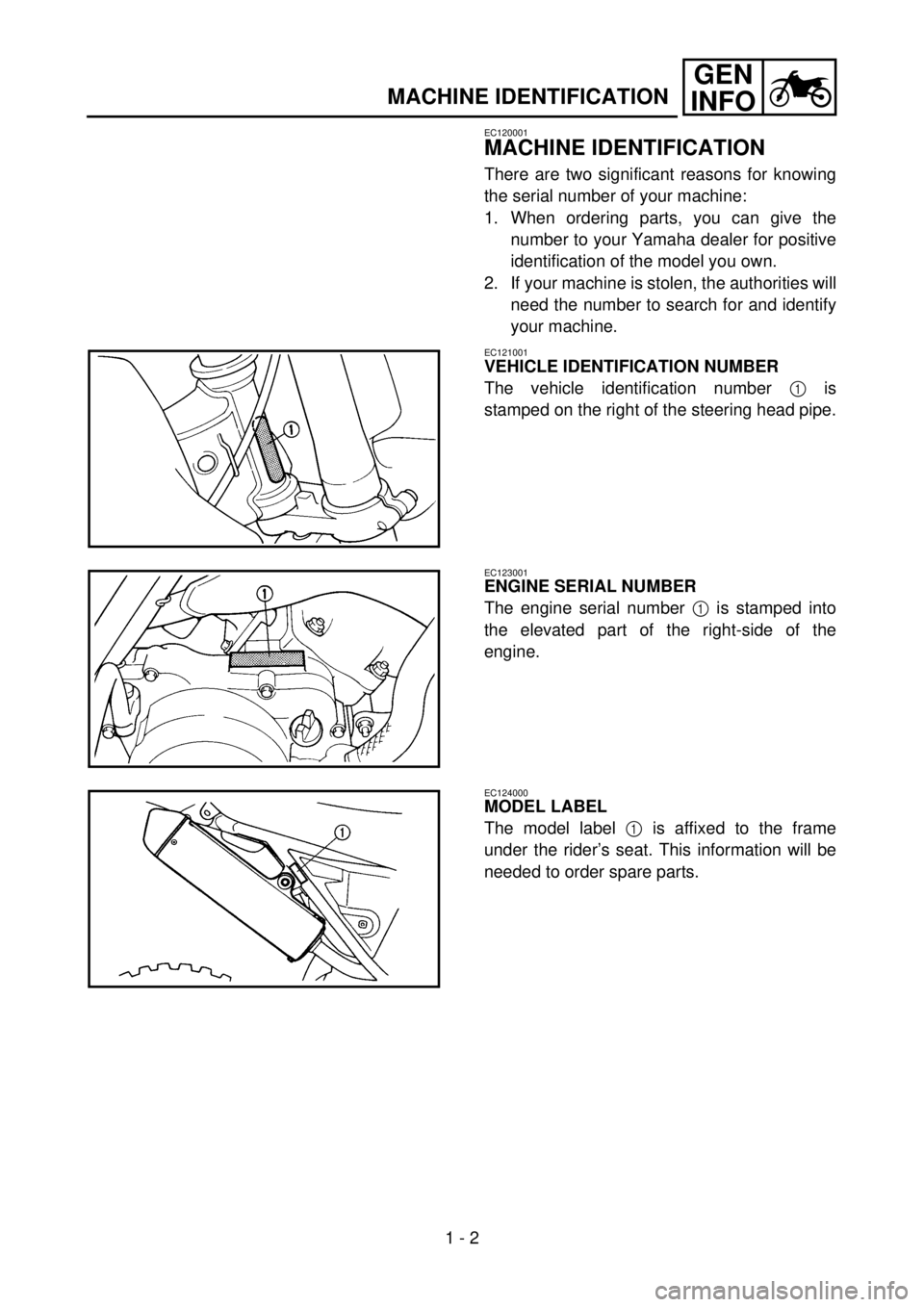

MACHINE IDENTIFICATION

There are two significant reasons for knowing

the serial number of your machine:

1. When ordering parts, you can give the

number to your Yamaha dealer for positive

identification of the model you own.

2. If your machine is stolen, the authorities will

need the number to search for and identify

your machine.

EC121001

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number 1 is

stamped on the right of the steering head pipe.

5PA10040

EC123001

ENGINE SERIAL NUMBER

The engine serial number 1 is stamped into

the elevated part of the right-side of the

engine.

5PA10050

EC124000

MODEL LABEL

The model label 1 is affixed to the frame

under the rider’s seat. This information will be

needed to order spare parts.

5PA10060

Page 39 of 504

GEN

INFO

1 - 8

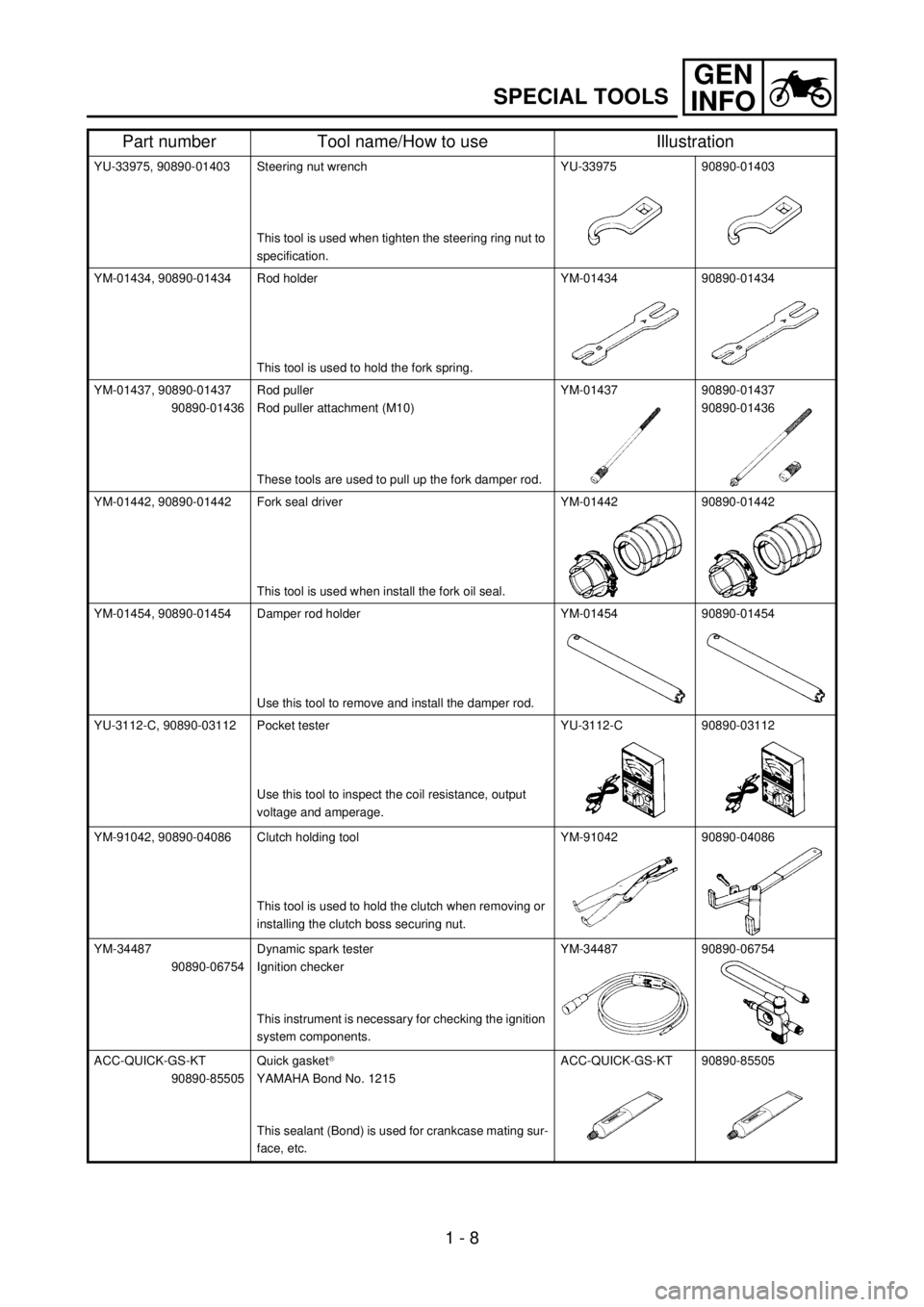

SPECIAL TOOLS

YU-33975, 90890-01403 Steering nut wrench

This tool is used when tighten the steering ring nut to

specification.YU-33975 90890-01403

YM-01434, 90890-01434 Rod holder

This tool is used to hold the fork spring.YM-01434 90890-01434

YM-01437, 90890-01437

90890-01436Rod puller

Rod puller attachment (M10)

These tools are used to pull up the fork damper rod.YM-01437 90890-01437

90890-01436

YM-01442, 90890-01442 Fork seal driver

This tool is used when install the fork oil seal.YM-01442 90890-01442

YM-01454, 90890-01454 Damper rod holder

Use this tool to remove and install the damper rod.YM-01454 90890-01454

YU-3112-C, 90890-03112 Pocket tester

Use this tool to inspect the coil resistance, output

voltage and amperage.YU-3112-C 90890-03112

YM-91042, 90890-04086 Clutch holding tool

This tool is used to hold the clutch when removing or

installing the clutch boss securing nut.YM-91042 90890-04086

YM-34487

90890-06754Dynamic spark tester

Ignition checker

This instrument is necessary for checking the ignition

system components.YM-34487 90890-06754

ACC-QUICK-GS-KT

90890-85505Quick gasket

â

YAMAHA Bond No. 1215

This sealant (Bond) is used for crankcase mating sur-

face, etc.ACC-QUICK-GS-KT 90890-85505

Part number Tool name/How to use Illustration

5PA103005PA10300

5PA103105PA10310

5PA10320

5PA103405PA10340

5PA103505PA10350

5PA103605PA10360

5PA103705PA10380

5PA103905PA10400

5PA104105PA10410

Page 58 of 504

GEN

INFO

1 - 16

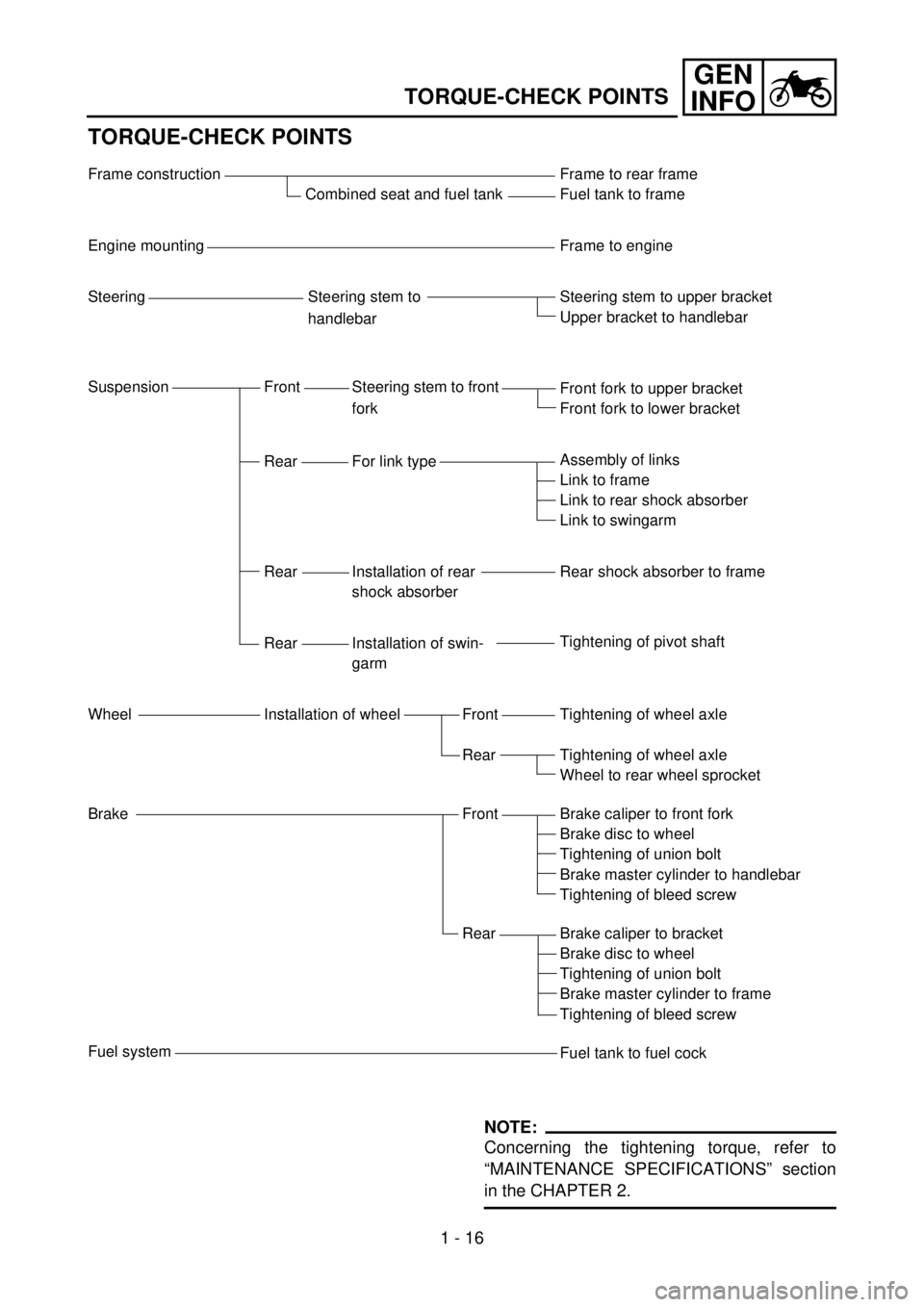

TORQUE-CHECK POINTS

TORQUE-CHECK POINTS

Frame construction

Combined seat and fuel tank

Engine mounting

Steering Steering stem to

handlebar

Suspension Front Steering stem to front

fork

Rear For link type

Rear Installation of rear

shock absorber

Rear Installation of swin-

garm

Wheel Installation of wheel Front

Rear

Brake Front

Rear

Fuel systemFrame to rear frame

Fuel tank to frame

Frame to engine

Steering stem to upper bracket

Upper bracket to handlebar

Front fork to upper bracket

Front fork to lower bracket

Assembly of links

Link to frame

Link to rear shock absorber

Link to swingarm

Rear shock absorber to frame

Tightening of pivot shaft

Tightening of wheel axle

Tightening of wheel axle

Wheel to rear wheel sprocket

Brake caliper to front fork

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handlebar

Tightening of bleed screw

Brake caliper to bracket

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Fuel tank to fuel cock

NOTE:

Concerning the tightening torque, refer to

“MAINTENANCE SPECIFICATIONS” section

in the CHAPTER 2.

Page 73 of 504

SPEC

2 - 8

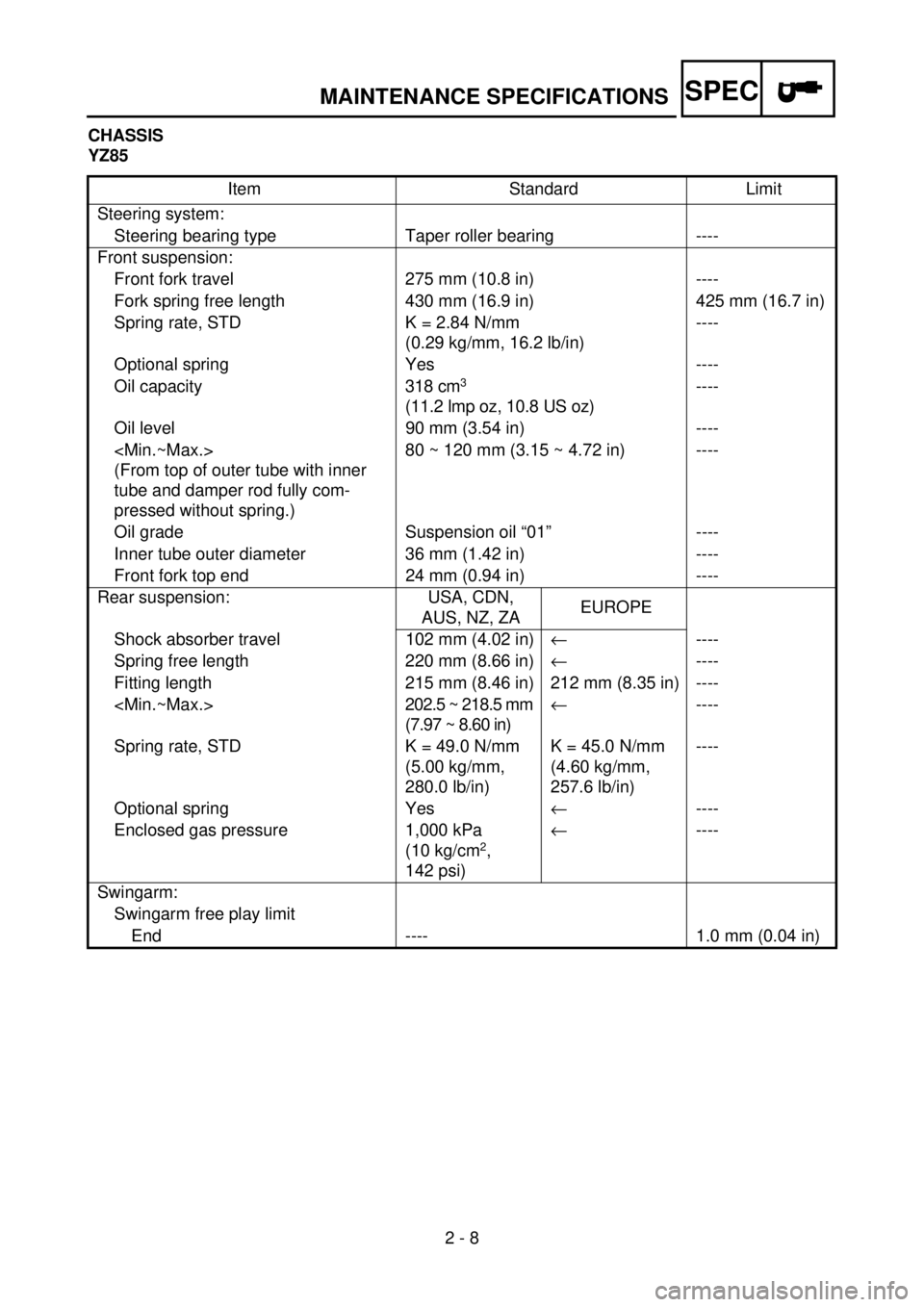

MAINTENANCE SPECIFICATIONS

CHASSIS

YZ85

Item Standard Limit

Steering system:

Steering bearing type Taper roller bearing ----

Front suspension:

Front fork travel 275 mm (10.8 in) ----

Fork spring free length 430 mm (16.9 in) 425 mm (16.7 in)

Spring rate, STD K = 2.84 N/mm

(0.29 kg/mm, 16.2 lb/in)----

Optional spring Yes ----

Oil capacity318 cm

3

(11.2 lmp oz, 10.8 US oz) ----

Oil level 90 mm (3.54 in) ----

(From top of outer tube with inner

tube and damper rod fully com-

pressed without spring.)80 ~ 120 mm (3.15 ~ 4.72 in) ----

Oil grade Suspension oil “01” ----

Inner tube outer diameter 36 mm (1.42 in) ----

Front fork top end 24 mm (0.94 in) ----

Rear suspension: USA, CDN,

AUS, NZ, ZAEUROPE

Shock absorber travel 102 mm (4.02 in)¬----

Spring free length 220 mm (8.66 in)¬----

Fitting length 215 mm (8.46 in) 212 mm (8.35 in) ----

(7.97 ~ 8.60 in)¬----

Spring rate, STD K = 49.0 N/mm

(5.00 kg/mm,

280.0 lb/in)K = 45.0 N/mm

(4.60 kg/mm,

257.6 lb/in)----

Optional spring Yes¬----

Enclosed gas pressure 1,000 kPa

(10 kg/cm

2,

142 psi)¬----

Swingarm:

Swingarm free play limit

End ---- 1.0 mm (0.04 in)

Page 75 of 504

SPEC

2 - 10

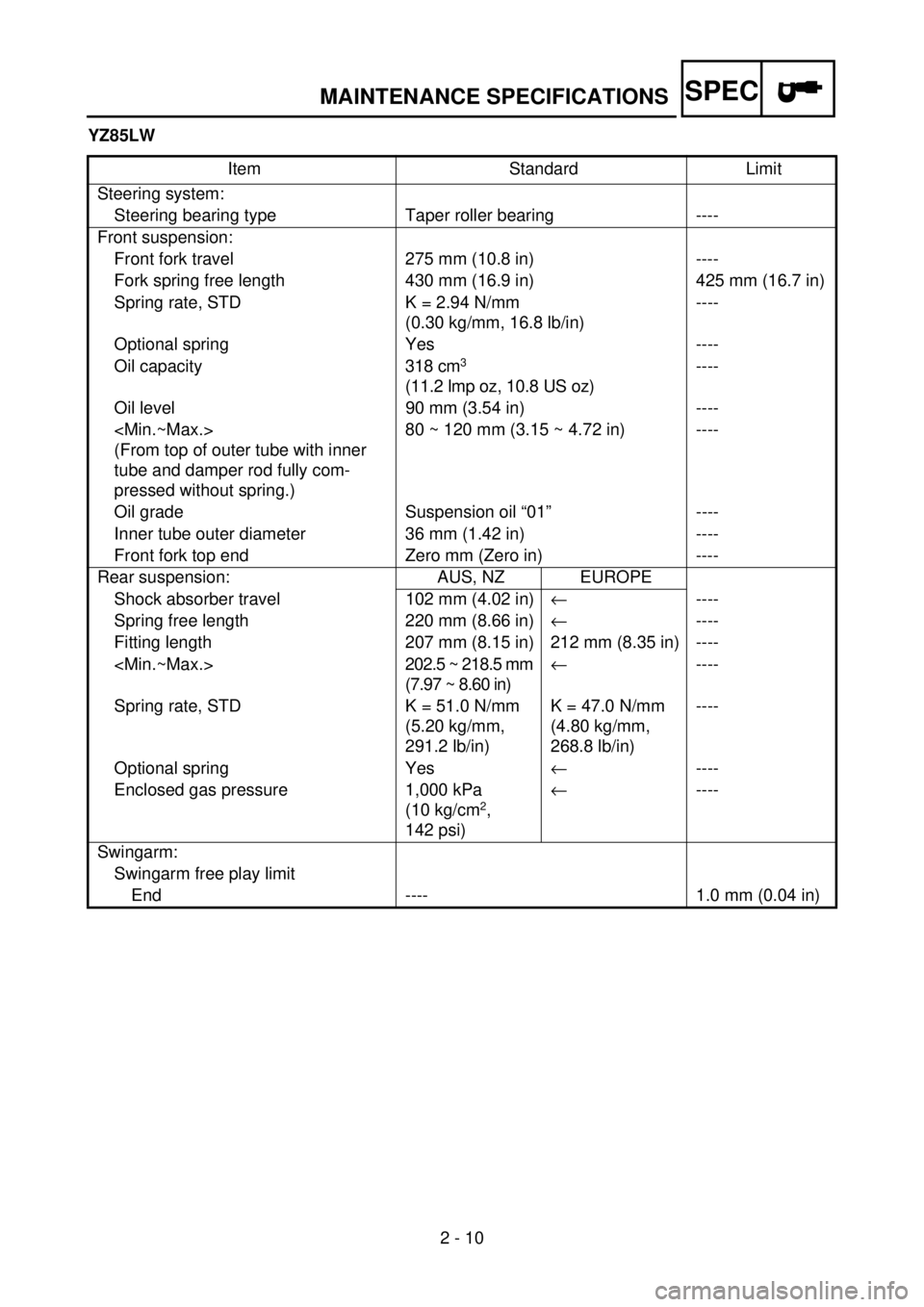

MAINTENANCE SPECIFICATIONS

YZ85LW

Item Standard Limit

Steering system:

Steering bearing type Taper roller bearing ----

Front suspension:

Front fork travel 275 mm (10.8 in) ----

Fork spring free length 430 mm (16.9 in) 425 mm (16.7 in)

Spring rate, STD K = 2.94 N/mm

(0.30 kg/mm, 16.8 lb/in)----

Optional spring Yes ----

Oil capacity318 cm

3

(11.2 lmp oz, 10.8 US oz) ----

Oil level 90 mm (3.54 in) ----

(From top of outer tube with inner

tube and damper rod fully com-

pressed without spring.)80 ~ 120 mm (3.15 ~ 4.72 in) ----

Oil grade Suspension oil “01” ----

Inner tube outer diameter 36 mm (1.42 in) ----

Front fork top end Zero mm (Zero in) ----

Rear suspension: AUS, NZ EUROPE

Shock absorber travel 102 mm (4.02 in)¬----

Spring free length 220 mm (8.66 in)¬----

Fitting length 207 mm (8.15 in) 212 mm (8.35 in) ----

(7.97 ~ 8.60 in)¬----

Spring rate, STD K = 51.0 N/mm

(5.20 kg/mm,

291.2 lb/in)K = 47.0 N/mm

(4.80 kg/mm,

268.8 lb/in)----

Optional spring Yes¬----

Enclosed gas pressure 1,000 kPa

(10 kg/cm

2,

142 psi)¬----

Swingarm:

Swingarm free play limit

End ---- 1.0 mm (0.04 in)

Page 77 of 504

SPEC

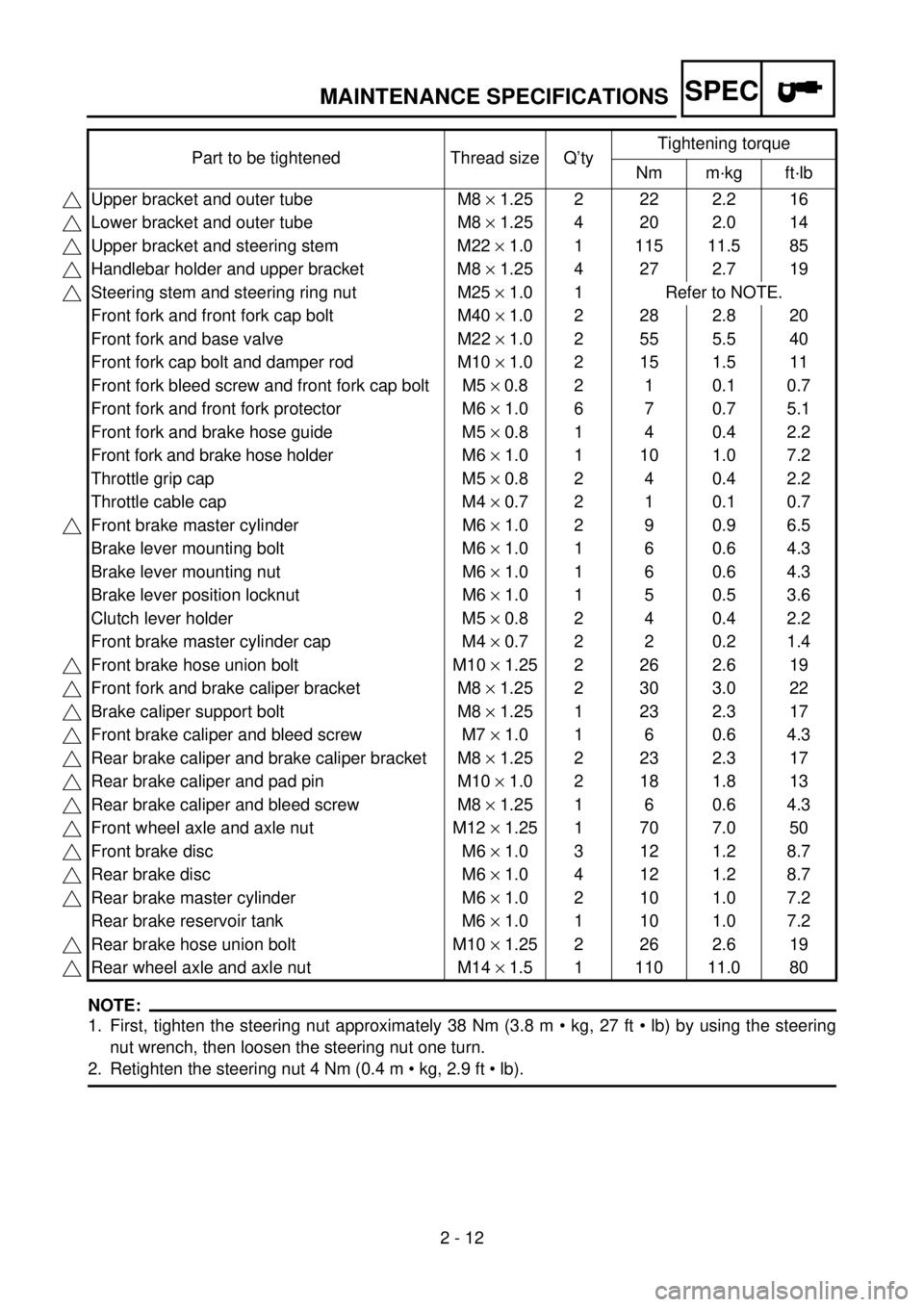

2 - 12

MAINTENANCE SPECIFICATIONS

NOTE:

1. First, tighten the steering nut approximately 38 Nm (3.8 m • kg, 27 ft • lb) by using the steering

nut wrench, then loosen the steering nut one turn.

2. Retighten the steering nut 4 Nm (0.4 m • kg, 2.9 ft • lb).Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Upper bracket and outer tube M8 ´ 1.25 2 22 2.2 16

Lower bracket and outer tube M8 ´ 1.25 4 20 2.0 14

Upper bracket and steering stem M22 ´ 1.0 1 115 11.5 85

Handlebar holder and upper bracket M8 ´ 1.25 4 27 2.7 19

Steering stem and steering ring nut M25 ´ 1.0 1 Refer to NOTE.

Front fork and front fork cap bolt M40 ´ 1.0 2 28 2.8 20

Front fork and base valve M22 ´ 1.0 2 55 5.5 40

Front fork cap bolt and damper rod M10 ´ 1.0 2 15 1.5 11

Front fork bleed screw and front fork cap bolt M5 ´ 0.8 2 1 0.1 0.7

Front fork and front fork protector M6 ´ 1.0 6 7 0.7 5.1

Front fork and brake hose guide M5 ´ 0.8 1 4 0.4 2.2

Front fork and brake hose holder M6 ´ 1.0 1 10 1.0 7.2

Throttle grip cap M5 ´ 0.8 2 4 0.4 2.2

Throttle cable cap M4 ´ 0.7 2 1 0.1 0.7

Front brake master cylinder M6 ´ 1.0 2 9 0.9 6.5

Brake lever mounting bolt M6 ´ 1.0 1 6 0.6 4.3

Brake lever mounting nut M6 ´ 1.0 1 6 0.6 4.3

Brake lever position locknut M6 ´ 1.0 1 5 0.5 3.6

Clutch lever holder M5 ´ 0.8 2 4 0.4 2.2

Front brake master cylinder cap M4 ´ 0.7 2 2 0.2 1.4

Front brake hose union bolt M10 ´ 1.25 2 26 2.6 19

Front fork and brake caliper bracket M8 ´ 1.25 2 30 3.0 22

Brake caliper support bolt M8 ´ 1.25 1 23 2.3 17

Front brake caliper and bleed screw M7 ´ 1.0 1 6 0.6 4.3

Rear brake caliper and brake caliper bracket M8 ´ 1.25 2 23 2.3 17

Rear brake caliper and pad pin M10 ´ 1.0 2 18 1.8 13

Rear brake caliper and bleed screw M8 ´ 1.25 1 6 0.6 4.3

Front wheel axle and axle nut M12 ´ 1.25 1 70 7.0 50

Front brake disc M6 ´ 1.0 3 12 1.2 8.7

Rear brake disc M6 ´ 1.0 4 12 1.2 8.7

Rear brake master cylinder M6 ´ 1.0 2 10 1.0 7.2

Rear brake reservoir tank M6 ´ 1.0 1 10 1.0 7.2

Rear brake hose union bolt M10 ´ 1.25 2 26 2.6 19

Rear wheel axle and axle nut M14 ´ 1.5 1 110 11.0 80

Page 112 of 504

2 - 16

SPEC

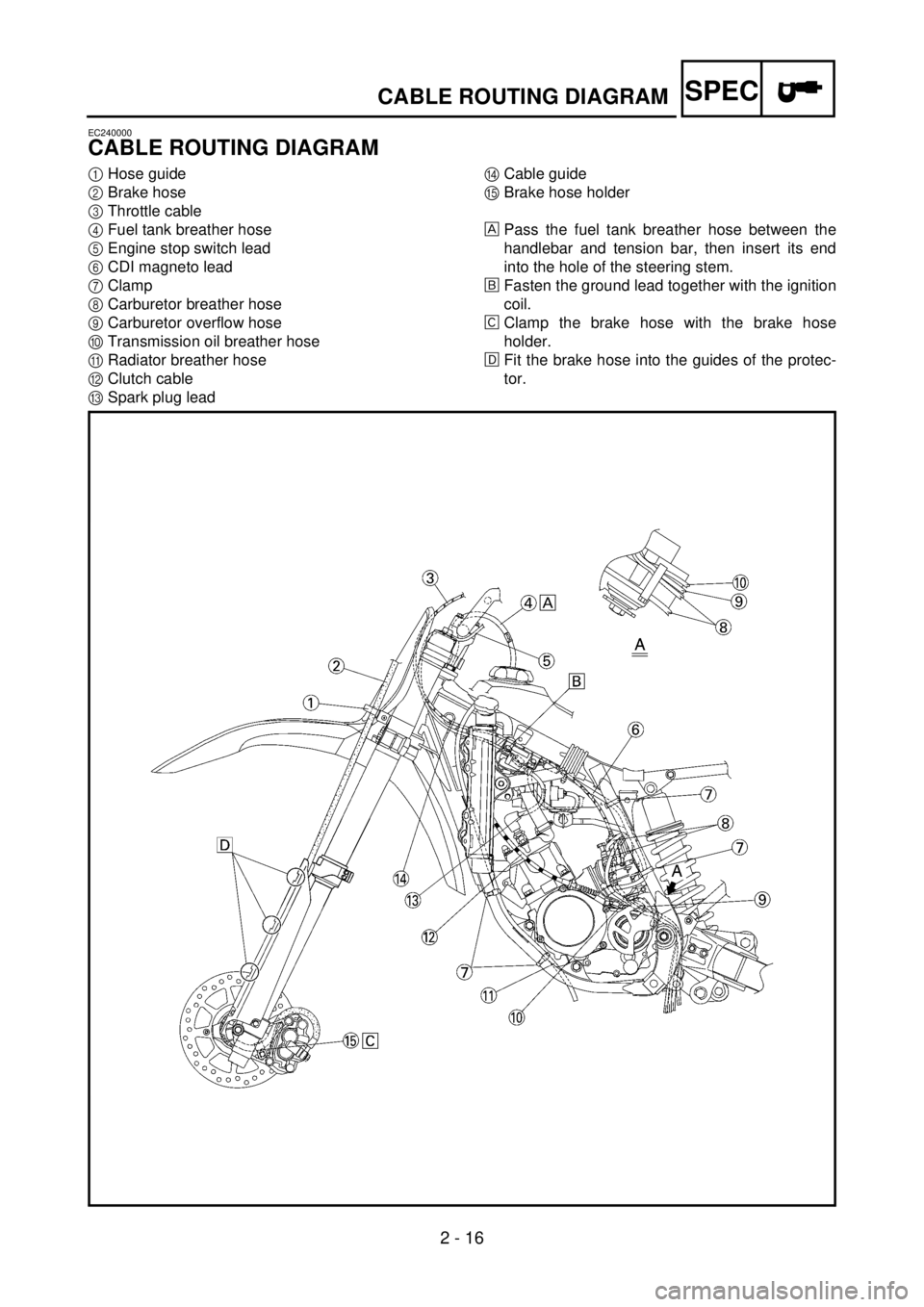

EC240000

CABLE ROUTING DIAGRAM

1Hose guide

2Brake hose

3Throttle cable

4Fuel tank breather hose

5Engine stop switch lead

6CDI magneto lead

7Clamp

8Carburetor breather hose

9Carburetor overflow hose

0Transmission oil breather hose

ARadiator breather hose

BClutch cable

CSpark plug leadDCable guide

EBrake hose holder

ÈPass the fuel tank breather hose between the

handlebar and tension bar, then insert its end

into the hole of the steering stem.

ÉFasten the ground lead together with the ignition

coil.

ÊClamp the brake hose with the brake hose

holder.

ËFit the brake hose into the guides of the protec-

tor.

CABLE ROUTING DIAGRAM

Page 119 of 504

3 - 2

INSP

ADJ

MAINTENANCE INTERVALS

COOLING SYSTEM

Check coolant level and leakage

Check radiator cap operation

Replace coolant

Inspect hoses

ll

ll

l

Every two years

OUTSIDE NUTS AND BOLTS

Retighten

ll

AIR FILTER

Clean and lubricate

Replace

ll

lUse foam air-filter oil

FRAME

Clean and inspect

ll

FUEL TANK, COCK

Clean and inspect

ll

BRAKES

Adjust lever position and pedal height

Lubricate pivot point

Check brake disc surface

Check fluid level and leakage

Retighten brake disc bolts, caliper

bolts, master cylinder bolts and union

bolts

Replace pads

Replace brake fluid

l

l

l

l

ll

l

l

l

l

l

l

Every one year

FRONT FORKS

Inspect and adjust

Replace oil

Replace oil seal

l

ll

l

l

Suspension oil “01”

FRONT FORK OIL SEAL AND DUST

SEAL

Clean and lube

llLithium base grease

REAR SHOCK ABSORBER

Inspect and adjust

Lube

Retighten

l

ll

ll(After

rain ride)

l

Molybdenum disulfide

grease

CHAIN GUARD AND ROLLERS

Inspect

l

SWINGARM

Inspect and retighten

Lube

l

ll

l

Molybdenum disulfide

grease

RELAY ARM, CONNECTING ROD

Inspect and retighten

Lube

l

ll

l

Molybdenum disulfide

grease

STEERING HEAD

Inspect free play and retighten

Clean and lube

Replace bearing

ll

l

l

Lithium base grease ItemAfter

break-inEvery

raceEvery

third

raceEvery

fifth

raceAs re-

quiredRemarks

3

Page 127 of 504

3 - 4

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.P.3-5 ~ 9

FuelCheck that a fresh mixture of oil and gasoline is filled in the fuel

tank. Check the fuel line for leakage.P.1-12

Transmission oilCheck that the oil level is correct. Check the crankcase for leak-

age.P.3-12 ~ 13

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-9

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-10

Brakes Check the play of front brake and effect of front and rear brake. P.3-16 ~ 21

Drive chainCheck drive chain slack and alignment. Check that the drive

chain is lubricated properly.P.3-22 ~ 24

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-31 ~ 32

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-32 ~ 33

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-24 ~ 30

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or

when the front forks travel up and down.—

Exhaust pipe and silencerCheck that the exhaust pipe is tightly mounted and has no

cracks.P.4-2

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-22

Lubrication Check for smooth operation. Lubricate if necessary. P.3-34

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-16

Lead connectorsCheck that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-6

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 19