engine oil YAMAHA YZ85 2005 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: YZ85, Model: YAMAHA YZ85 2005Pages: 508, PDF Size: 10.47 MB

Page 8 of 508

6. GASOLINE CAN CAUSE INJURY.

If you should swallow some gasoline,

inhale excess gasoline vapors, or

allow any gasoline to get into your

eyes, contact a doctor immediately. If

any gasoline spills onto your skin or

clothing, immediately wash skin areas

with soap and water, and change your

clothes.

7. ONLY OPERATE THE MACHINE IN AN

AREA WITH ADEQUATE VENTILA-

TION.

Never start the engine or let it run for

any length of time in an enclosed area.

Exhaust fumes are poisonous. These

fumes contain carbon monoxide,

which by itself is odorless and color-

less. Carbon monoxide is a dangerous

gas which can cause unconscious-

ness or can be lethal.

8. PARK THE MACHINE CAREFULLY;

TURN OFF THE ENGINE.

Always turn off the engine if you are

going to leave the machine. Do not

park the machine on a slope or soft

ground as it may fall over.

9. THE ENGINE, EXHAUST PIPE, MUF-

FLER, AND OIL TANK WILL BE VERY

HOT AFTER THE ENGINE HAS BEEN

RUN.

Be careful not to touch them or to

allow any clothing item to contact

them during inspection or repair.

10. PROPERLY SECURE THE MACHINE

BEFORE TRANSPORTING IT.

When transporting the machine in

another vehicle, always be sure it is

properly secured and in an upright

position and that the fuel cock is in

the “OFF” position. Otherwise, fuel

may leak out of the carburetor or fuel

tank.

Page 16 of 508

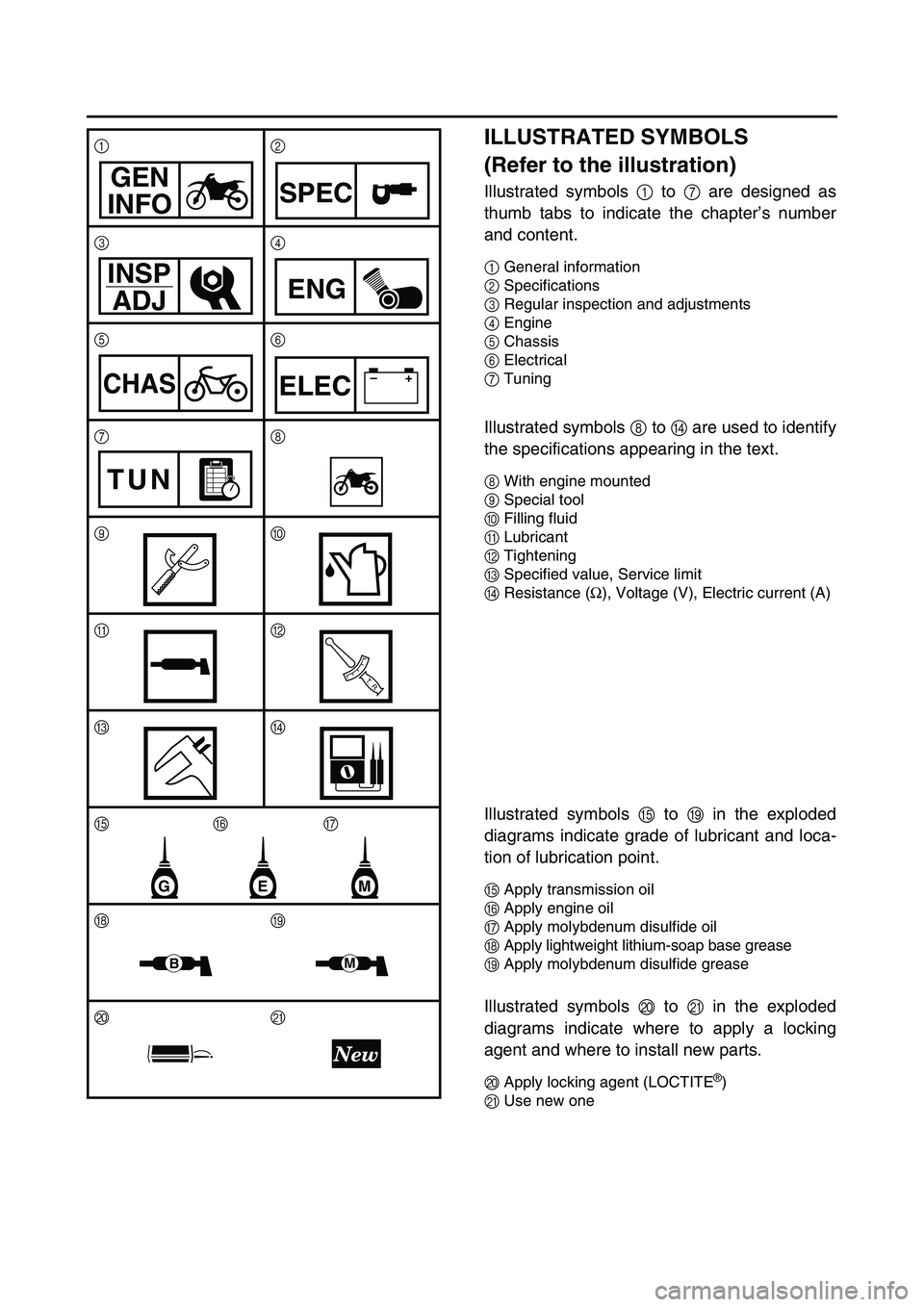

ILLUSTRATED SYMBOLS

(Refer to the illustration)

Illustrated symbols 1 to 7 are designed as

thumb tabs to indicate the chapter’s number

and content.

1General information

2Specifications

3Regular inspection and adjustments

4Engine

5Chassis

6Electrical

7Tuning

Illustrated symbols 8 to D are used to identify

the specifications appearing in the text.

8With engine mounted

9Special tool

0Filling fluid

ALubricant

BTightening

CSpecified value, Service limit

DResistance (

Ω), Voltage (V), Electric current (A)

Illustrated symbols E to I in the exploded

diagrams indicate grade of lubricant and loca-

tion of lubrication point.

EApply transmission oil

FApply engine oil

GApply molybdenum disulfide oil

HApply lightweight lithium-soap base grease

IApply molybdenum disulfide grease

Illustrated symbols J to K in the exploded

diagrams indicate where to apply a locking

agent and where to install new parts.

JApply locking agent (LOCTITE®)

KUse new one 12

34

56

78

90

AB

CD

EFG

HI

JK

GEN

INFO

SPEC

INSP

ADJ

ENG

CHAS–+ELEC

TUN

T R..

EMG

BM

Page 20 of 508

EC0A0000

CONTENTS

CHAPTER 1

GENERAL INFORMATION

DESCRIPTION

........................................... 1-1

MACHINE IDENTIFICATION

..................... 1-2

IMPORTANT INFORMATION

.................... 1-3

CHECKING OF CONNECTION

................. 1-6

SPECIAL TOOLS

...................................... 1-7

CONTROL FUNCTIONS

............................ 1-9

FUEL AND ENGINE MIXING OIL

............ 1-13

STARTING AND BREAK-IN

.................... 1-14

TORQUE-CHECK POINTS

...................... 1-17

CLEANING AND STORAGE

................... 1-18

CHAPTER 2

SPECIFICATIONS

GENERAL SPECIFICATIONS

................... 2-1

MAINTENANCE SPECIFICATIONS

.......... 2-4

ENGINE

................................................... 2-4

CHASSIS

................................................. 2-8

YZ85

..................................................... 2-8

YZ85LW

.............................................. 2-10

ELECTRICAL

........................................ 2-14

GENERAL TORQUE

SPECIFICATIONS

................................... 2-15

DEFINITION OF UNITS

........................... 2-15

CABLE ROUTING DIAGRAM

................. 2-16

Page 32 of 508

1 - 4

GEN

INFO

IMPORTANT INFORMATION

EC132000

ALL REPLACEMENT PARTS

1. We recommend to use Yamaha genuine

parts for all replacements. Use oil and/or

grease recommended by Yamaha for

assembly and adjustment.

EC133000

GASKETS, OIL SEALS AND O-RINGS

1. All gaskets, oil seals, and O-rings should

be replaced when an engine is overhauled.

All gasket surfaces, oil seal lips, and O-

rings must be cleaned.

2. Properly oil all mating parts and bearings

during reassembly. Apply grease to the oil

seal lips.

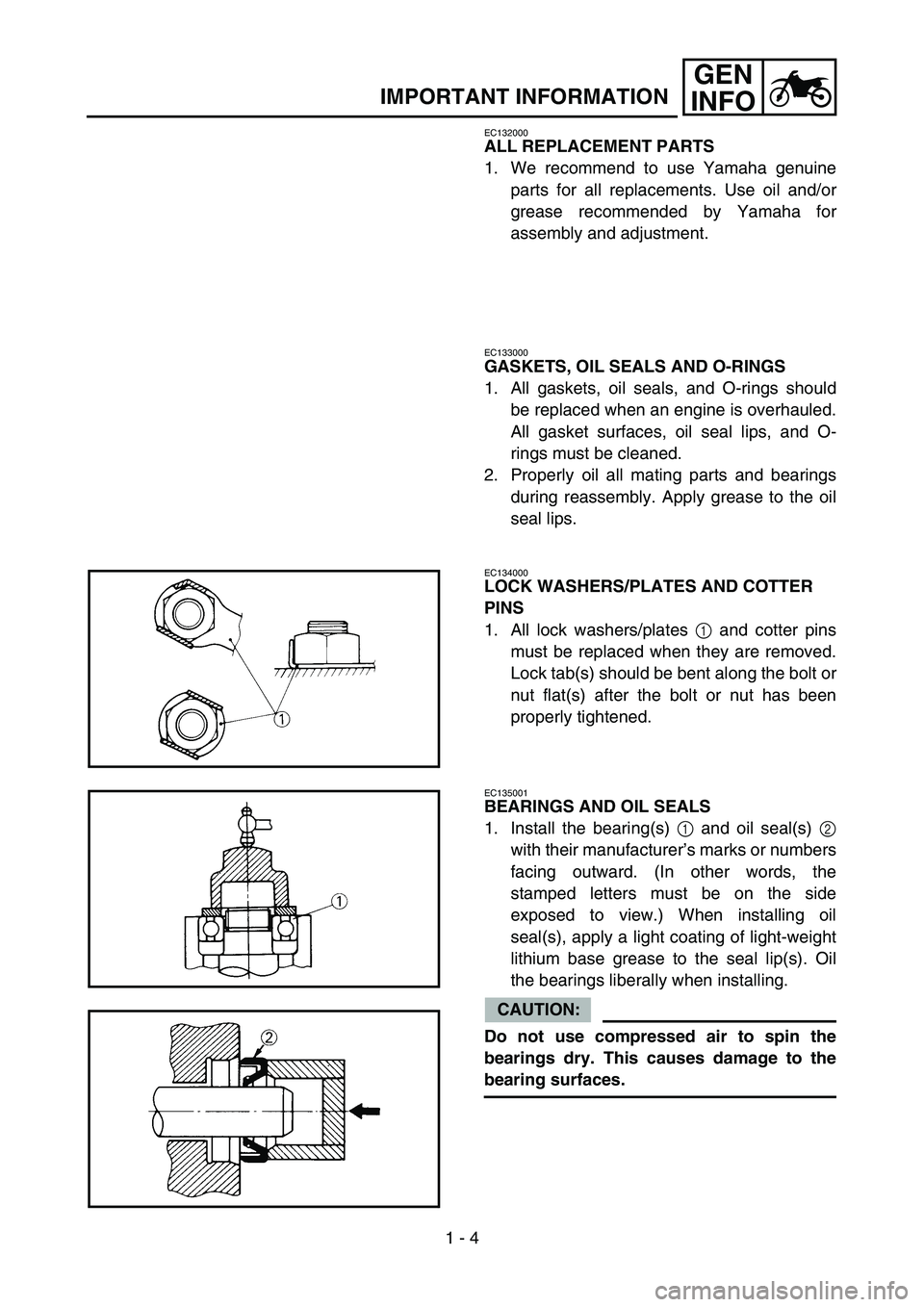

EC134000

LOCK WASHERS/PLATES AND COTTER

PINS

1. All lock washers/plates 1 and cotter pins

must be replaced when they are removed.

Lock tab(s) should be bent along the bolt or

nut flat(s) after the bolt or nut has been

properly tightened.

5PA10120

EC135001

BEARINGS AND OIL SEALS

1. Install the bearing(s) 1 and oil seal(s) 2

with their manufacturer’s marks or numbers

facing outward. (In other words, the

stamped letters must be on the side

exposed to view.) When installing oil

seal(s), apply a light coating of light-weight

lithium base grease to the seal lip(s). Oil

the bearings liberally when installing.

CAUTION:

Do not use compressed air to spin the

bearings dry. This causes damage to the

bearing surfaces.

5PA10130

5PA10140

Page 52 of 508

1 - 13

GEN

INFO

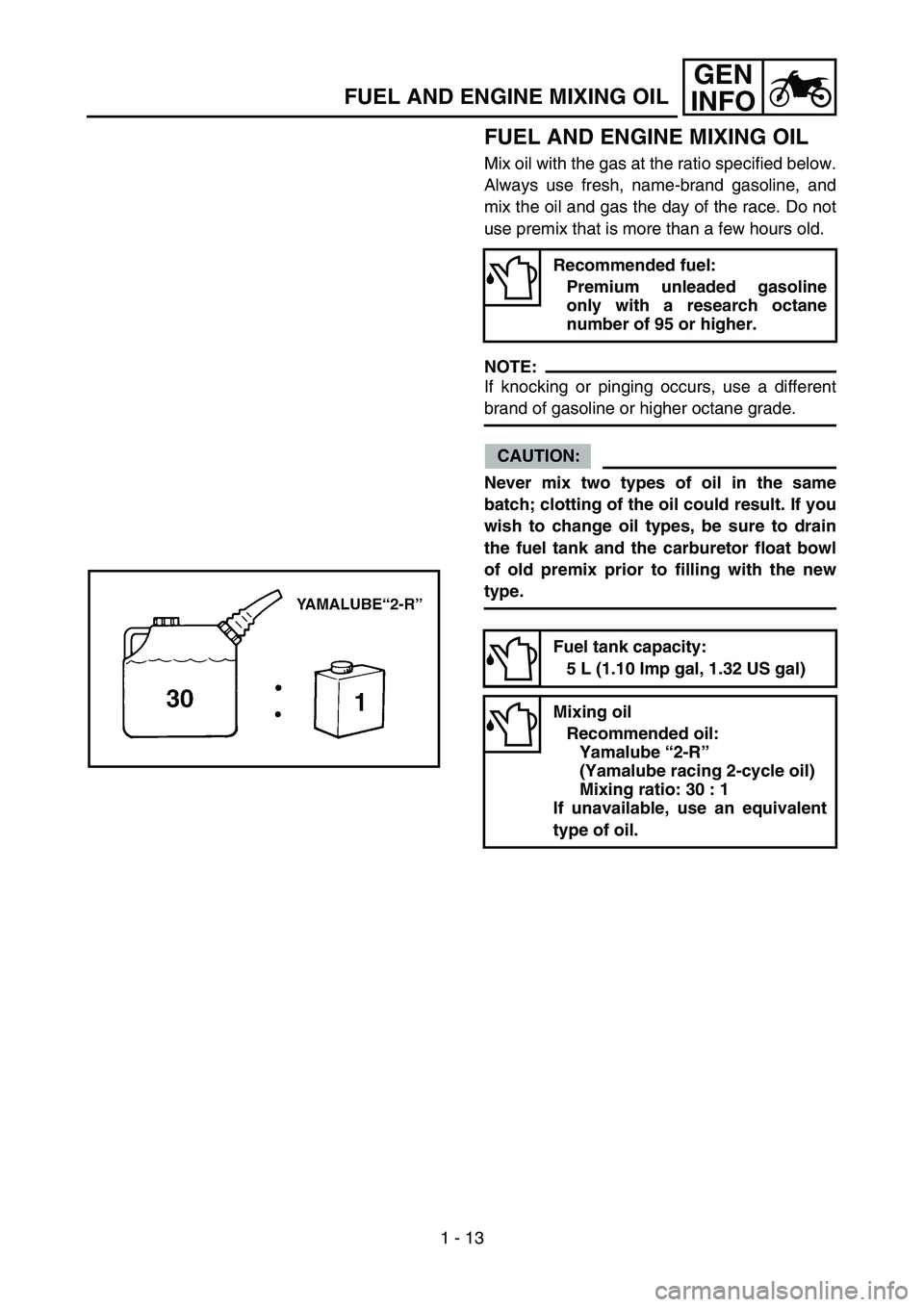

FUEL AND ENGINE MIXING OIL

FUEL AND ENGINE MIXING OIL

Mix oil with the gas at the ratio specified below.

Always use fresh, name-brand gasoline, and

mix the oil and gas the day of the race. Do not

use premix that is more than a few hours old.

NOTE:

If knocking or pinging occurs, use a different

brand of gasoline or higher octane grade.

CAUTION:

Never mix two types of oil in the same

batch; clotting of the oil could result. If you

wish to change oil types, be sure to drain

the fuel tank and the carburetor float bowl

of old premix prior to filling with the new

type.

Recommended fuel:

Premium unleaded gasoline

only with a research octane

number of 95 or higher.

Fuel tank capacity:

5 L (1.10 Imp gal, 1.32 US gal)

Mixing oil

Recommended oil:

Yamalube “2-R”

(Yamalube racing 2-cycle oil)

Mixing ratio: 30 : 1

If unavailable, use an equivalent

type of oil.

5PA10540

Page 56 of 508

1 - 15

GEN

INFO

STARTING AND BREAK-IN

BREAK-IN PROCEDURES

1. Before starting the engine, fill the fuel tank

with a break-in oil-fuel mixture as follows.

2. Perform the pre-operation checks on the

machine.

3. Start and warm up the engine. Check the

idle speed, and check the operation of the

controls and the engine stop switch.

4. Operate the machine in the lower gears at

moderate throttle openings for five to eight

minutes. Stop and check the spark plug

condition; it will show a rich condition dur-

ing break-in.

5. Allow the engine to cool. Restart the

engine and operate the machine as in the

step above for five minutes. Then, very

briefly shift to the higher gears and check

full-throttle response. Stop and check the

spark plug.

6. After again allowing the engine to cool,

restart and run the machine for five more

minutes. Full throttle and the higher gears

may be used, but sustained full-throttle

operation should be avoided. Check the

spark plug condition.

7. Allow the engine to cool, remove the top

end, and inspect the piston and cylinder.

Remove any high spots on the piston with

#600 grit wet sandpaper. Clean all compo-

nents and carefully reassemble the top

end.

8. Drain the break-in oil-fuel mixture from the

fuel tank and refill with the specified mix.

9. Restart the engine and check the operation

of the machine throughout its entire operat-

ing range. Stop and check the spark plug

condition. Restart the machine and operate

it for about 10 to 15 more minutes. The

machine will now be ready to race.

Mixing oil:

Yamalube “2-R”

Mixing ratio:

15 : 1

Page 66 of 508

1 - 19

GEN

INFO

CLEANING AND STORAGE

EC1B2001

STORAGE

If your machine is to be stored for 60 days or

more, some preventive measures must be

taken to avoid deterioration. After cleaning the

machine thoroughly, prepare it for storage as

follows:

1. Drain the fuel tank, fuel lines, and the car-

buretor float bowl.

2. Remove the spark plug, pour a tablespoon

of SAE 10W-30 motor oil in the spark plug

hole, and reinstall the plug. With the engine

stop switch pushed in, kick the engine over

several times to coat the cylinder walls with

oil.

3. Remove the drive chain, clean it thoroughly

with solvent, and lubricate it. Reinstall the

chain or store it in a plastic bag tied to the

frame.

4. Lubricate all control cables.

5. Block the frame up to raise the wheels off

the ground.

6. Tie a plastic bag over the exhaust pipe out-

let to prevent moisture from entering.

7. If the machine is to be stored in a humid or

salt-air environment, coat all exposed

metal surfaces with a film of light oil. Do not

apply oil to rubber parts or the seat cover.

NOTE:

Make any necessary repairs before the

machine is stored.

Page 68 of 508

SPEC

2 - 1

GENERAL SPECIFICATIONS

EC200000

SPECIFICATIONS

EC211000

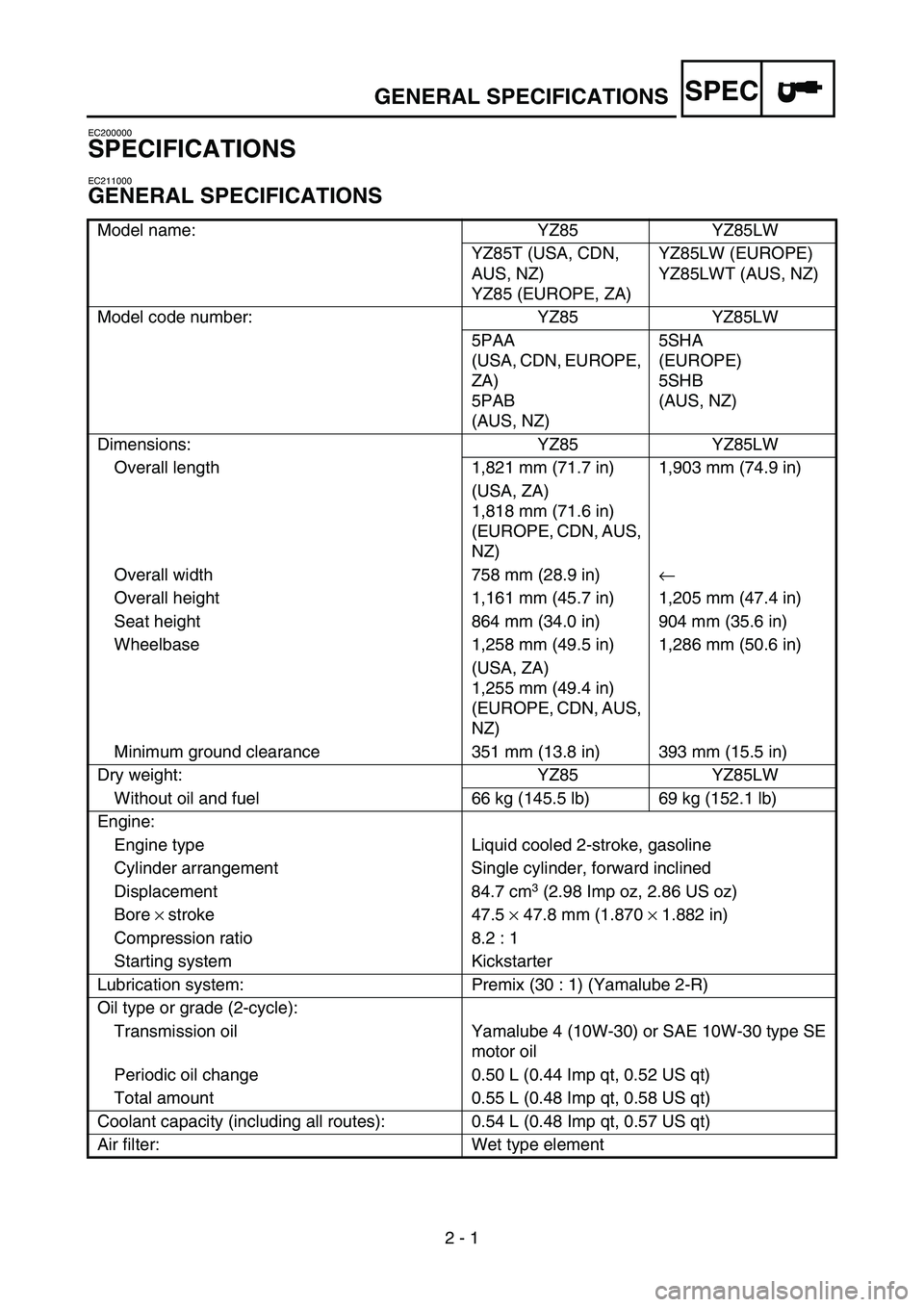

GENERAL SPECIFICATIONS

Model name: YZ85 YZ85LW

YZ85T (USA, CDN,

AUS, NZ)

YZ85 (EUROPE, ZA)YZ85LW (EUROPE)

YZ85LWT (AUS, NZ)

Model code number: YZ85 YZ85LW

5PAA

(USA, CDN, EUROPE,

ZA)

5PAB

(AUS, NZ)5SHA

(EUROPE)

5SHB

(AUS, NZ)

Dimensions: YZ85 YZ85LW

Overall length 1,821 mm (71.7 in) 1,903 mm (74.9 in)

(USA, ZA)

1,818 mm (71.6 in)

(EUROPE, CDN, AUS,

NZ)

Overall width 758 mm (28.9 in)←

Overall height 1,161 mm (45.7 in) 1,205 mm (47.4 in)

Seat height 864 mm (34.0 in) 904 mm (35.6 in)

Wheelbase 1,258 mm (49.5 in) 1,286 mm (50.6 in)

(USA, ZA)

1,255 mm (49.4 in)

(EUROPE, CDN, AUS,

NZ)

Minimum ground clearance 351 mm (13.8 in) 393 mm (15.5 in)

Dry weight: YZ85 YZ85LW

Without oil and fuel 66 kg (145.5 lb) 69 kg (152.1 lb)

Engine:

Engine type Liquid cooled 2-stroke, gasoline

Cylinder arrangement Single cylinder, forward inclined

Displacement 84.7 cm

3 (2.98 Imp oz, 2.86 US oz)

Bore × stroke 47.5 × 47.8 mm (1.870 × 1.882 in)

Compression ratio 8.2 : 1

Starting system Kickstarter

Lubrication system: Premix (30 : 1) (Yamalube 2-R)

Oil type or grade (2-cycle):

Transmission oil Yamalube 4 (10W-30) or SAE 10W-30 type SE

motor oil

Periodic oil change 0.50 L (0.44 Imp qt, 0.52 US qt)

Total amount 0.55 L (0.48 Imp qt, 0.58 US qt)

Coolant capacity (including all routes): 0.54 L (0.48 Imp qt, 0.57 US qt)

Air filter: Wet type element

2

Page 114 of 508

2 - 16

SPEC

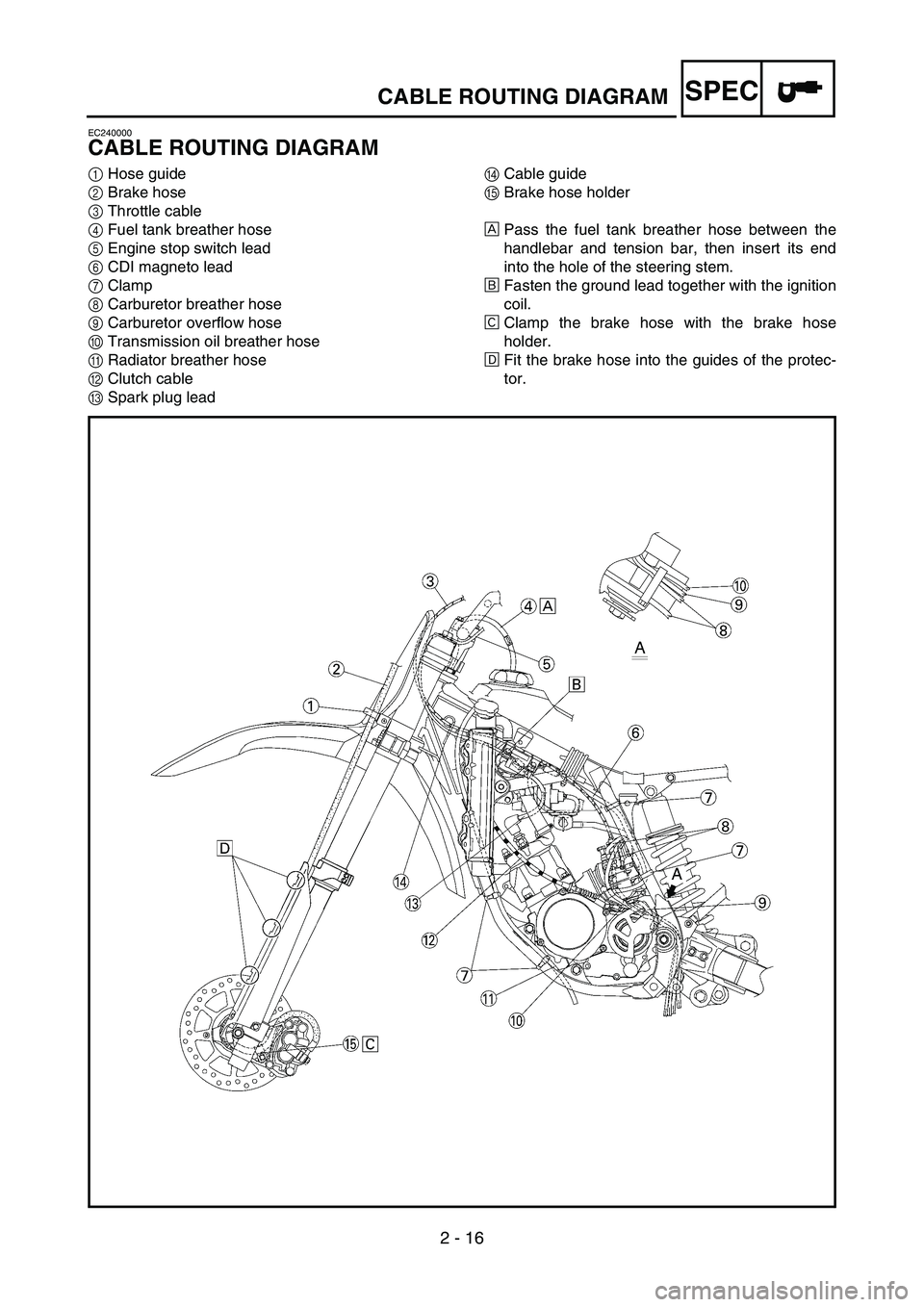

EC240000

CABLE ROUTING DIAGRAM

1Hose guide

2Brake hose

3Throttle cable

4Fuel tank breather hose

5Engine stop switch lead

6CDI magneto lead

7Clamp

8Carburetor breather hose

9Carburetor overflow hose

0Transmission oil breather hose

ARadiator breather hose

BClutch cable

CSpark plug leadDCable guide

EBrake hose holder

ÈPass the fuel tank breather hose between the

handlebar and tension bar, then insert its end

into the hole of the steering stem.

ÉFasten the ground lead together with the ignition

coil.

ÊClamp the brake hose with the brake hose

holder.

ËFit the brake hose into the guides of the protec-

tor.

CABLE ROUTING DIAGRAM

Page 129 of 508

3 - 4

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.P.3-5 ~ 9

FuelCheck that a fresh mixture of oil and gasoline is filled in the fuel

tank. Check the fuel line for leakage.P.1-13

Transmission oilCheck that the oil level is correct. Check the crankcase for leak-

age.P.3-12 ~ 13

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-9

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-10

Brakes Check the play of front brake and effect of front and rear brake. P.3-16 ~ 21

Drive chainCheck drive chain slack and alignment. Check that the drive

chain is lubricated properly.P.3-22 ~ 24

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-31 ~ 32

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-32 ~ 34

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-24 ~ 30

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or

when the front forks travel up and down.—

Exhaust pipe and silencerCheck that the exhaust pipe is tightly mounted and has no

cracks.P.4-2

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-22

Lubrication Check for smooth operation. Lubricate if necessary. P.3-35

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-17

Lead connectorsCheck that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-6

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 19