lock YAMAHA YZ85 2014 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ85, Model: YAMAHA YZ85 2014Pages: 88, PDF Size: 1.8 MB

Page 28 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-2

4

EAU41265

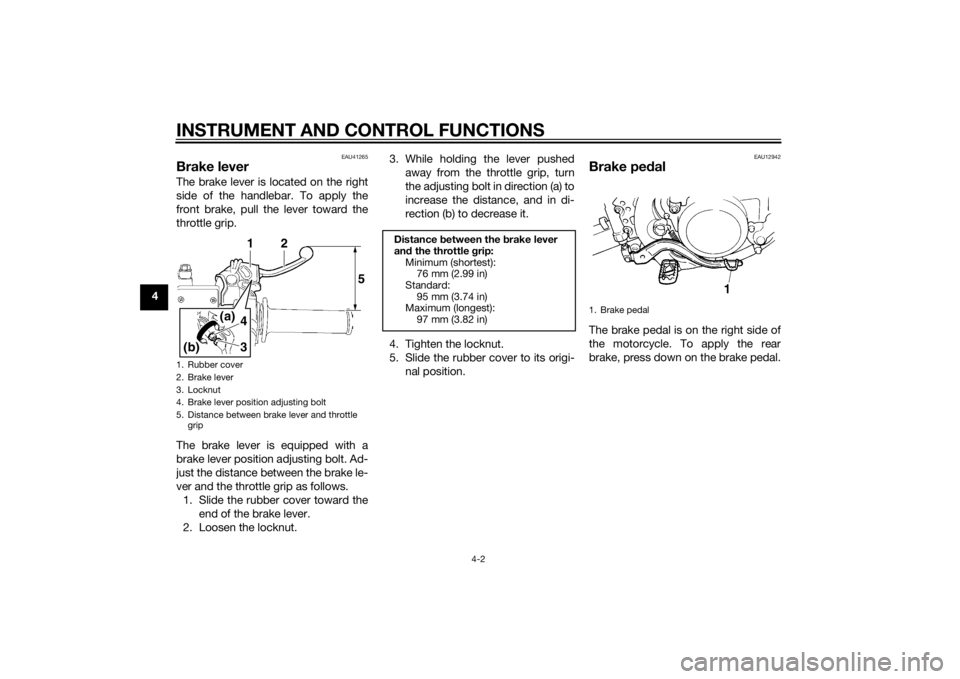

Brake leverThe brake lever is located on the right

side of the handlebar. To apply the

front brake, pull the lever toward the

throttle grip.

The brake lever is equipped with a

brake lever position adjusting bolt. Ad-

just the distance between the brake le-

ver and the throttle grip as follows.1. Slide the rubber cover toward the end of the brake lever.

2. Loosen the locknut. 3. While holding the lever pushed

away from the throttle grip, turn

the adjusting bolt in direction (a) to

increase the distance, and in di-

rection (b) to decrease it.

4. Tighten the locknut.

5. Slide the rubber cover to its origi- nal position.

EAU12942

Brake ped alThe brake pedal is on the right side of

the motorcycle. To apply the rear

brake, press down on the brake pedal.

1. Rubber cover

2. Brake lever

3. Locknut

4. Brake lever position adjusting bolt

5. Distance between brake lever and throttle

grip

143

(a)

(b)

2

5

Distance between the brake lever

an d the throttle g rip:

Minimum (shortest): 76 mm (2.99 in)

Standard: 95 mm (3.74 in)

Maximum (longest):

97 mm (3.82 in)

1. Brake pedal

U1SN82E0.book Page 2 Friday, June 7, 2013 3:51 PM

Page 29 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-3

4

EAU13183

Fuel tank capTo remove the fuel tank cap, turn it

counterclockwise, and then pull it off.

To install the fuel tank cap, insert it into

the tank opening, and then turn it

clockwise.

WARNING

EWA11092

Make sure that the fuel tank cap is

properly closed after filling fuel.

Leakin g fuel is a fire hazar d.

EAU41834

FuelThis motorcycle has been designed to

use a premixed fuel of gasoline and 2-

stroke engine oil. Always mix the gaso-

line and oil in a clean container before

filling the fuel tank.NOTICE

ECA15602

Always use fresh gasoline, an d fill

the fuel tank with a fresh mix just be-

fore ri din g. Do not use premixed fuel

that is more than a few hours ol d.Mixin g g asoline an d 2-stroke en gine

oil

Pour 2-stroke engine oil into a clean

container, and then add gasoline. To

mix the fuel thoroughly, shake the con-

tainer from side to side.

NOTICE

ECA15591

Use only unlea ded g asoline. The use

of lead ed g asoline will cause severe

d amag e to internal en gine parts,

such as the piston rin gs as well as to

the exhaust system.

1. Fuel tank cap

1. 2-stroke engine oil

2. Gasoline

3. Container

Recommen ded fuel:

Premium unleaded gasoline only

Recommen ded 2-stroke en gine oil:

See page 9-1.

Fuel tank capacity:

5.0 L (1.32 US gal, 1.10 Imp.gal)

Mixin g ratios ( gasoline to oil):

Break-in period: 15:1

After break-in: 30:1

U1SN82E0.book Page 3 Friday, June 7, 2013 3:51 PM

Page 31 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-5

4

wash with soap an

d water. If gaso-

line spills on your clothin g, chan ge

your clothes.

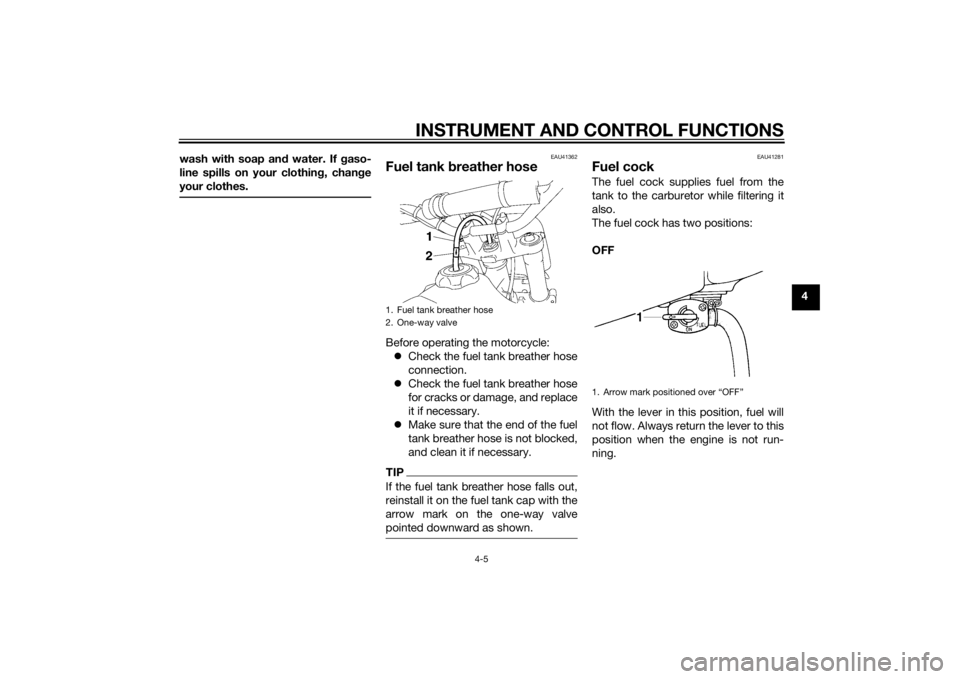

EAU41362

Fuel tank breather hoseBefore operating the motorcycle:

Check the fuel tank breather hose

connection.

Check the fuel tank breather hose

for cracks or damage, and replace

it if necessary.

Make sure that the end of the fuel

tank breather hose is not blocked,

and clean it if necessary.TIPIf the fuel tank breather hose falls out,

reinstall it on the fuel tank cap with the

arrow mark on the one-way valve

pointed downward as shown.

EAU41281

Fuel cockThe fuel cock supplies fuel from the

tank to the carburetor while filtering it

also.

The fuel cock has two positions:

OFF

With the lever in this position, fuel will

not flow. Always return the lever to this

position when the engine is not run-

ning.

1. Fuel tank breather hose

2. One-way valve

1. Arrow mark positioned over “OFF”

U1SN82E0.book Page 5 Friday, June 7, 2013 3:51 PM

Page 35 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-9

4

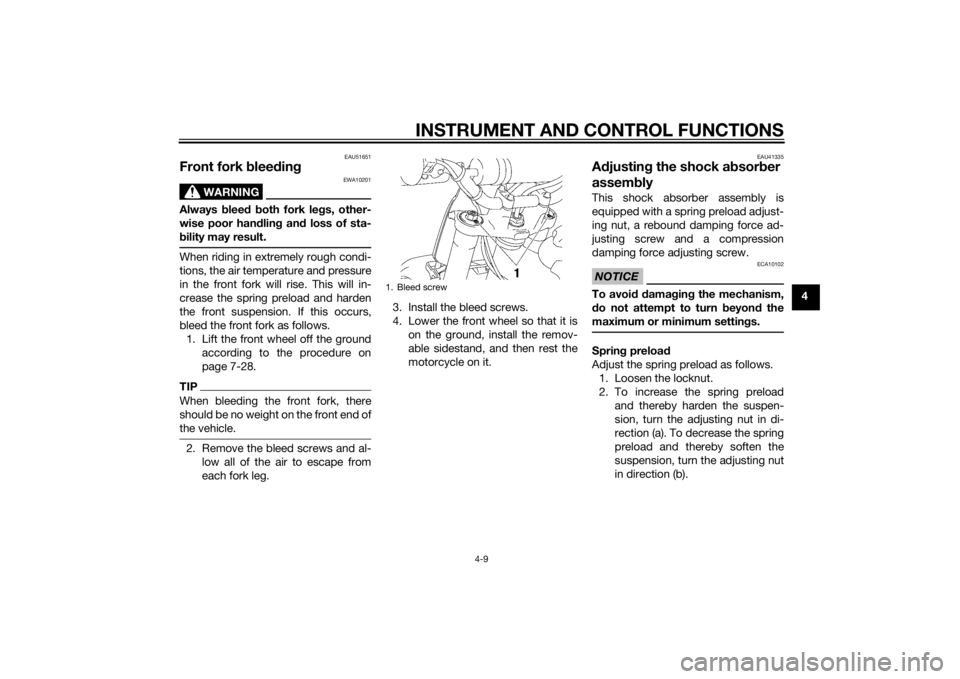

EAU51651

Front fork bleedin g

WARNING

EWA10201

Always blee d b oth fork le gs, other-

wise poor han dlin g an d loss of sta-

b ility may result.When riding in extremely rough condi-

tions, the air temperature and pressure

in the front fork will rise. This will in-

crease the spring preload and harden

the front suspension. If this occurs,

bleed the front fork as follows.

1. Lift the front wheel off the ground according to the procedure on

page 7-28.TIPWhen bleeding the front fork, there

should be no weight on the front end of

the vehicle.2. Remove the bleed screws and al-low all of the air to escape from

each fork leg. 3. Install the bleed screws.

4. Lower the front wheel so that it is

on the ground, install the remov-

able sidestand, and then rest the

motorcycle on it.

EAU41335

Adjustin g the shock a bsor ber

assem blyThis shock absorber assembly is

equipped with a spring preload adjust-

ing nut, a rebound damping force ad-

justing screw and a compression

damping force adjusting screw.NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn beyon d the

maximum or minimum settin gs.Sprin g preloa d

Adjust the spring preload as follows. 1. Loosen the locknut.

2. To increase the spring preload and thereby harden the suspen-

sion, turn the adjusting nut in di-

rection (a). To decrease the spring

preload and thereby soften the

suspension, turn the adjusting nut

in direction (b).

1. Bleed screw

U1SN82E0.book Page 9 Friday, June 7, 2013 3:51 PM

Page 36 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-10

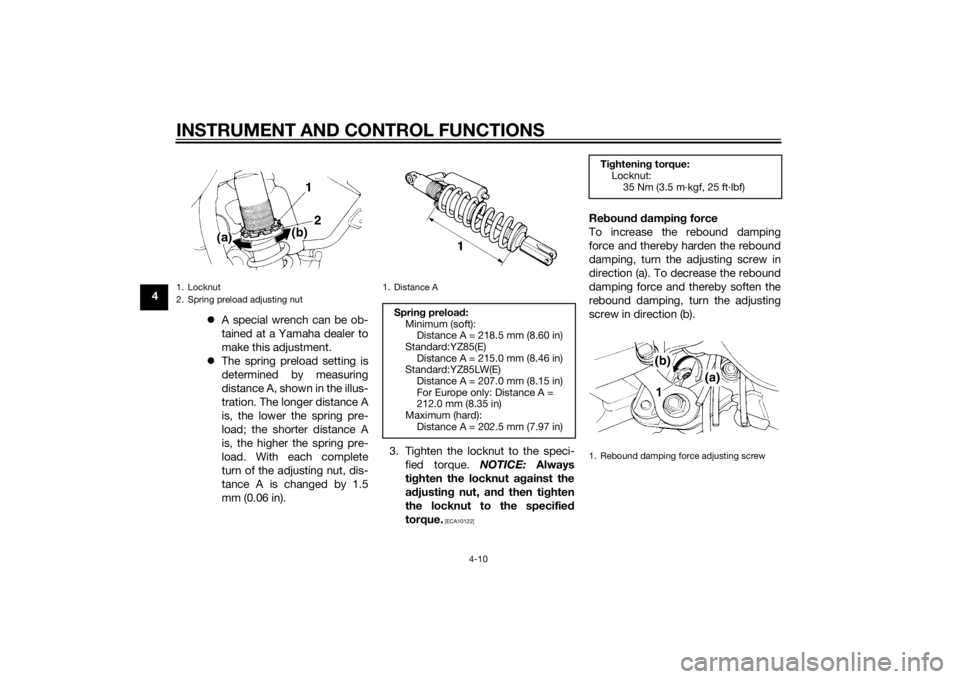

4A special wrench can be ob-

tained at a Yamaha dealer to

make this adjustment.

The spring preload setting is

determined by measuring

distance A, shown in the illus-

tration. The longer distance A

is, the lower the spring pre-

load; the shorter distance A

is, the higher the spring pre-

load. With each complete

turn of the adjusting nut, dis-

tance A is changed by 1.5

mm (0.06 in). 3. Tighten the locknut to the speci-

fied torque. NOTICE: Always

ti g hten the locknut ag ainst the

a d justin g nut, and then tighten

the locknut to the specified

torque.

[ECA10122]

Re boun d d ampin g force

To increase the rebound damping

force and thereby harden the rebound

damping, turn the adjusting screw in

direction (a). To decrease the rebound

damping force and thereby soften the

rebound damping, turn the adjusting

screw in direction (b).

1. Locknut

2. Spring preload adjusting nut

1. Distance ASprin g preloa d:

Minimum (soft): Distance A = 218.5 mm (8.60 in)

Standard:YZ85(E) Distance A = 215.0 mm (8.46 in)

Standard:YZ85LW(E)

Distance A = 207.0 mm (8.15 in)

For Europe only: Distance A =

212.0 mm (8.35 in)

Maximum (hard): Distance A = 202.5 mm (7.97 in)

Tightenin g torque:

Locknut:

35 Nm (3.5 m·kgf, 25 ft·lbf)1. Rebound damping force adjusting screw

U1SN82E0.book Page 10 Friday, June 7, 2013 3:51 PM

Page 60 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-15

7

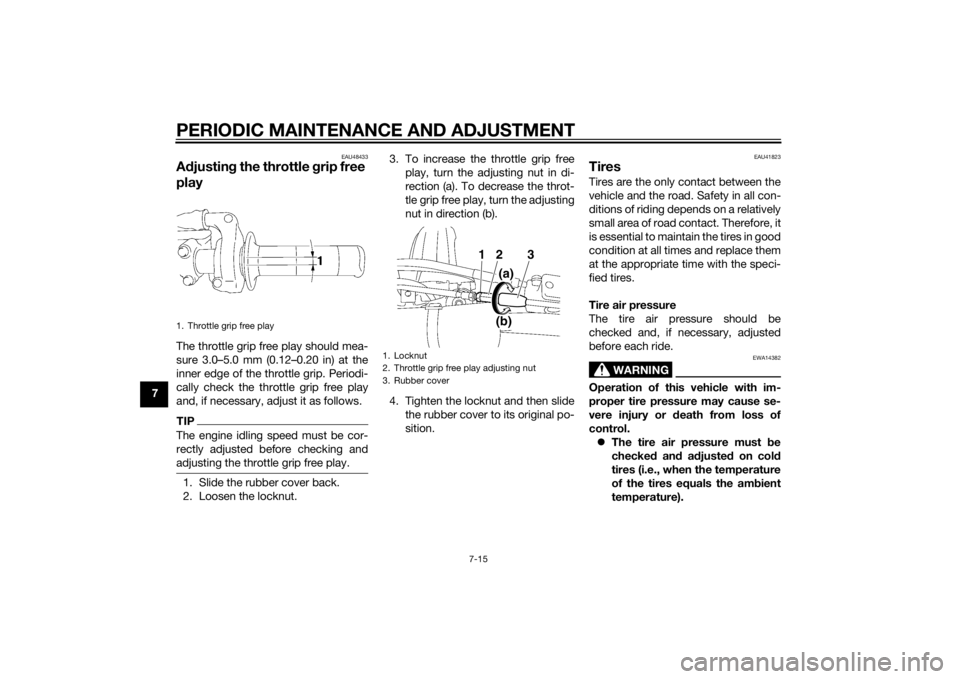

EAU48433

Adjustin g the throttle grip free

playThe throttle grip free play should mea-

sure 3.0–5.0 mm (0.12–0.20 in) at the

inner edge of the throttle grip. Periodi-

cally check the throttle grip free play

and, if necessary, adjust it as follows.TIPThe engine idling speed must be cor-

rectly adjusted before checking and

adjusting the throttle grip free play.1. Slide the rubber cover back.

2. Loosen the locknut. 3. To increase the throttle grip free

play, turn the adjusting nut in di-

rection (a). To decrease the throt-

tle grip free play, turn the adjusting

nut in direction (b).

4. Tighten the locknut and then slide the rubber cover to its original po-

sition.

EAU41823

TiresTires are the only contact between the

vehicle and the road. Safety in all con-

ditions of riding depends on a relatively

small area of road contact. Therefore, it

is essential to maintain the tires in good

condition at all times and replace them

at the appropriate time with the speci-

fied tires.

Tire air pressure

The tire air pressure should be

checked and, if necessary, adjusted

before each ride.

WARNING

EWA14382

Operation of this vehicle with im-

proper tire pressure may cause se-

vere injury or death from loss of

control. The tire air pressure must be

checked and a djuste d on col d

tires (i.e., when the temperature

of the tires equals the am bient

temperature).

1. Throttle grip free play

1. Locknut

2. Throttle grip free play adjusting nut

3. Rubber cover

2

3

(a)

(b)

1

U1SN82E0.book Page 15 Friday, June 7, 2013 3:51 PM

Page 63 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-18

7

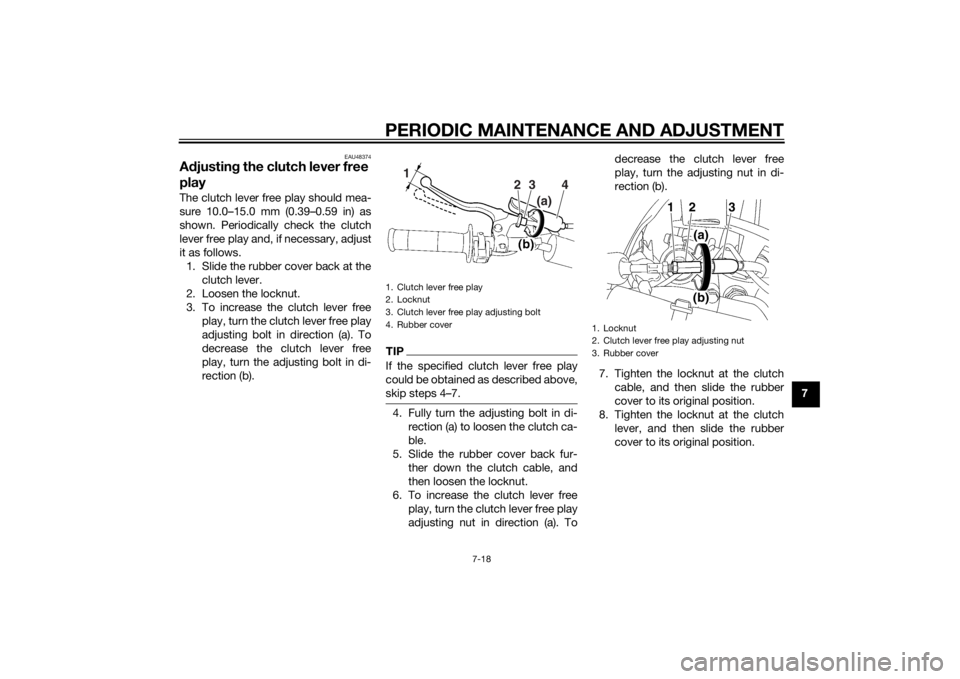

EAU48374

Adjustin g the clutch lever free

playThe clutch lever free play should mea-

sure 10.0–15.0 mm (0.39–0.59 in) as

shown. Periodically check the clutch

lever free play and, if necessary, adjust

it as follows.

1. Slide the rubber cover back at the clutch lever.

2. Loosen the locknut.

3. To increase the clutch lever free play, turn the clutch lever free play

adjusting bolt in direction (a). To

decrease the clutch lever free

play, turn the adjusting bolt in di-

rection (b).

TIPIf the specified clutch lever free play

could be obtained as described above,

skip steps 4–7.4. Fully turn the adjusting bolt in di-rection (a) to loosen the clutch ca-

ble.

5. Slide the rubber cover back fur- ther down the clutch cable, and

then loosen the locknut.

6. To increase the clutch lever free play, turn the clutch lever free play

adjusting nut in direction (a). To decrease the clutch lever free

play, turn the adjusting nut in di-

rection (b).

7. Tighten the locknut at the clutch cable, and then slide the rubber

cover to its original position.

8. Tighten the locknut at the clutch lever, and then slide the rubber

cover to its original position.1. Clutch lever free play

2. Locknut

3. Clutch lever free play adjusting bolt

4. Rubber cover

1

(a)

23

4

1. Locknut

2. Clutch lever free play adjusting nut

3. Rubber cover

1

2

3

(a)(b)

U1SN82E0.book Page 18 Friday, June 7, 2013 3:51 PM

Page 66 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-21

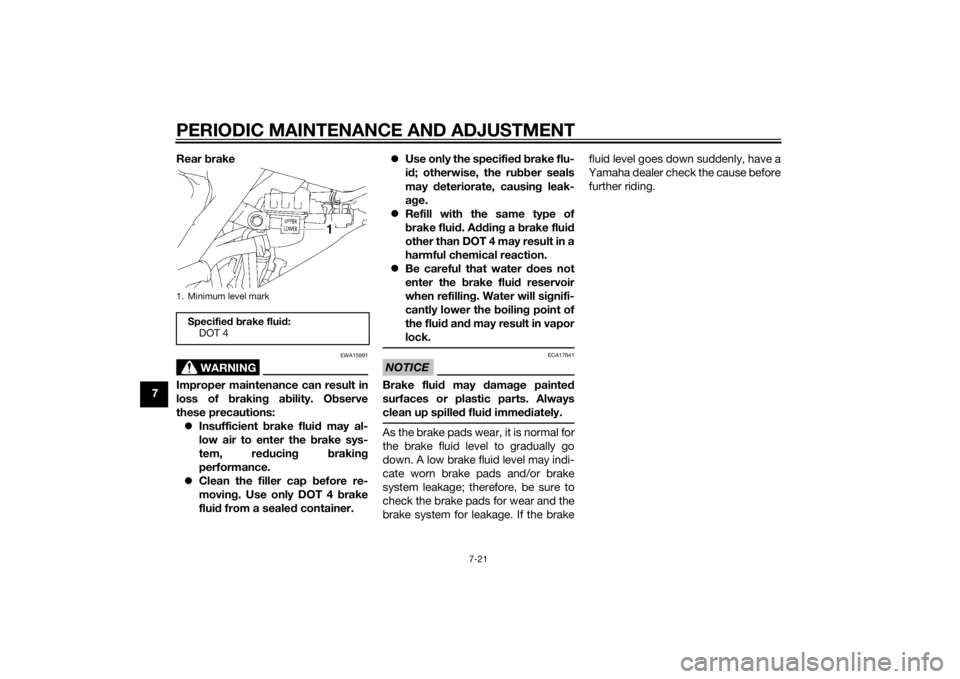

7Rear

brake

WARNING

EWA15991

Improper maintenance can result in

loss of brakin g a bility. O bserve

these precautions: Insufficient brake flui d may al-

low air to enter the b rake sys-

tem, re ducin g brakin g

performance.

Clean the filler cap before re-

moving . Use only DOT 4 b rake

flui d from a seale d container.

Use only the specified b rake flu-

i d ; otherwise, the ru bber seals

may deteriorate, causin g leak-

a g e.

Refill with the same type of

brake flui d. A ddin g a brake flui d

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water does not

enter the brake flui d reservoir

when refillin g. Water will si gnifi-

cantly lower the boilin g point of

the flui d an d may result in vapor

lock.

NOTICE

ECA17641

Brake flui d may damag e painted

surfaces or plastic parts. Always

clean up spille d flui d imme diately.As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake

system leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brake fluid level goes down suddenly, have a

Yamaha dealer check the cause before further riding.

1. Minimum level markSpecifie d b rake flui d:

DOT 4

U1SN82E0.book Page 21 Friday, June 7, 2013 3:51 PM

Page 67 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-22

7

EAU51721

Changin g the brake flui dHave a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the master cylinders and calipers as

well as the brake hoses replaced at the

intervals listed below or whenever they

are damaged or leaking.

Oil seals: Replace every two

years.

Brake hoses: Replace every four

years.

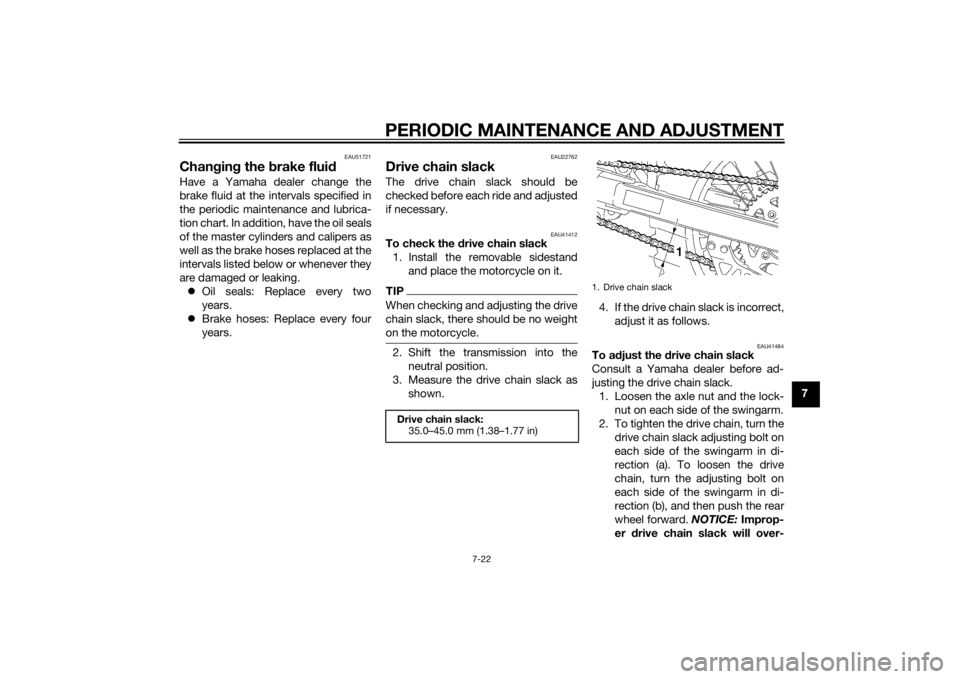

EAU22762

Drive chain slackThe drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU41412

To check the drive chain slack

1. Install the removable sidestand and place the motorcycle on it.TIPWhen checking and adjusting the drive

chain slack, there should be no weight

on the motorcycle.2. Shift the transmission into theneutral position.

3. Measure the drive chain slack as shown. 4. If the drive chain slack is incorrect,

adjust it as follows.

EAU41484

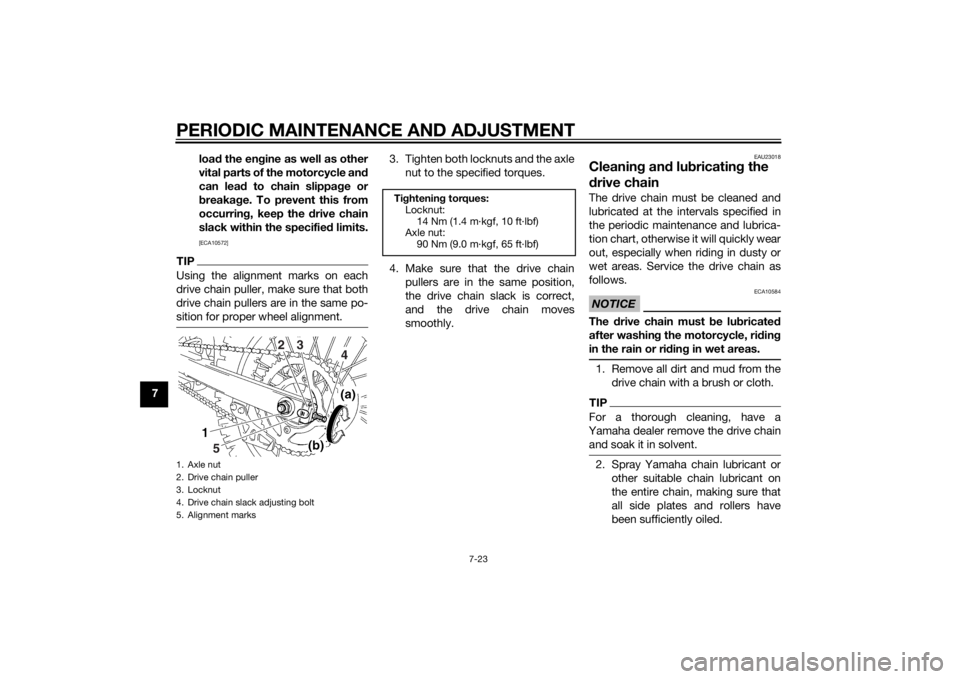

To a djust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Loosen the axle nut and the lock- nut on each side of the swingarm.

2. To tighten the drive chain, turn the drive chain slack adjusting bolt on

each side of the swingarm in di-

rection (a). To loosen the drive

chain, turn the adjusting bolt on

each side of the swingarm in di-

rection (b), and then push the rear

wheel forward. NOTICE: Improp-

er drive chain slack will over-

Drive chain slack:

35.0–45.0 mm (1.38–1.77 in)

1. Drive chain slack

U1SN82E0.book Page 22 Friday, June 7, 2013 3:51 PM

Page 68 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-23

7loa

d the en gine as well as other

vital parts of the motorcycle an d

can lead to chain slippa ge or

b reakag e. To prevent this from

occurrin g, keep the drive chain

slack within the specifie d limits.

[ECA10572]

TIPUsing the alignment marks on each

drive chain puller, make sure that both

drive chain pullers are in the same po-

sition for proper wheel alignment.

3. Tighten both locknuts and the axle

nut to the specified torques.

4. Make sure that the drive chain pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23018

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must be lu bricated

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Remove all dirt and mud from the

drive chain with a brush or cloth.TIPFor a thorough cleaning, have a

Yamaha dealer remove the drive chain and soak it in solvent.2. Spray Yamaha chain lubricant or other suitable chain lubricant on

the entire chain, making sure that

all side plates and rollers have

been sufficiently oiled.

1. Axle nut

2. Drive chain puller

3. Locknut

4. Drive chain slack adjusting bolt

5. Alignment marks

5 4

32

Ti

ghtenin g torques:

Locknut: 14 Nm (1.4 m·kgf, 10 ft·lbf)

Axle nut:

90 Nm (9.0 m·kgf, 65 ft·lbf)

U1SN82E0.book Page 23 Friday, June 7, 2013 3:51 PM