service YAMAHA YZ85 2014 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ85, Model: YAMAHA YZ85 2014Pages: 88, PDF Size: 1.8 MB

Page 6 of 88

INTRODUCTIONAN IMPORTANT NOTE TO PARENTS:

This motorcycle is not a toy. Before you let your child ride this motorcycle, you should understand the instructions and warn-

ings in this Owner’s Manual. Then be sure your child understands and will follow them. Children differ in skills, physical abil-

ities, and judgment. Some children may not be able to operate a motorcycle safely. Parents should supervise their child’s

use of the motorcycle at all times. Parents should permit continued use only if they determine that the child has the ability

to operate the motorcycle safely.

Motorcycles are sin gle track vehicles. Their safe use an d operation are d ependent upon the use of proper ri din g

techniques as well as the expertise of the operator. Every operator shoul d know the followin g requirements b efore

ri din g this motorcycle.

He or she should: Obtain thorough instructions from a competent source on all aspects of motorcycle operation.

Observe the warnings and maintenance requirements in this Owner’s Manual.

Obtain qualified training in safe and proper riding techniques.

Obtain professional technical service as indicated in this Owner’s Manual and/or when made necessary by mechanical

conditions.U1SN82E0.book Page 2 Friday, June 7, 2013 3:51 PM

Page 37 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-11

4

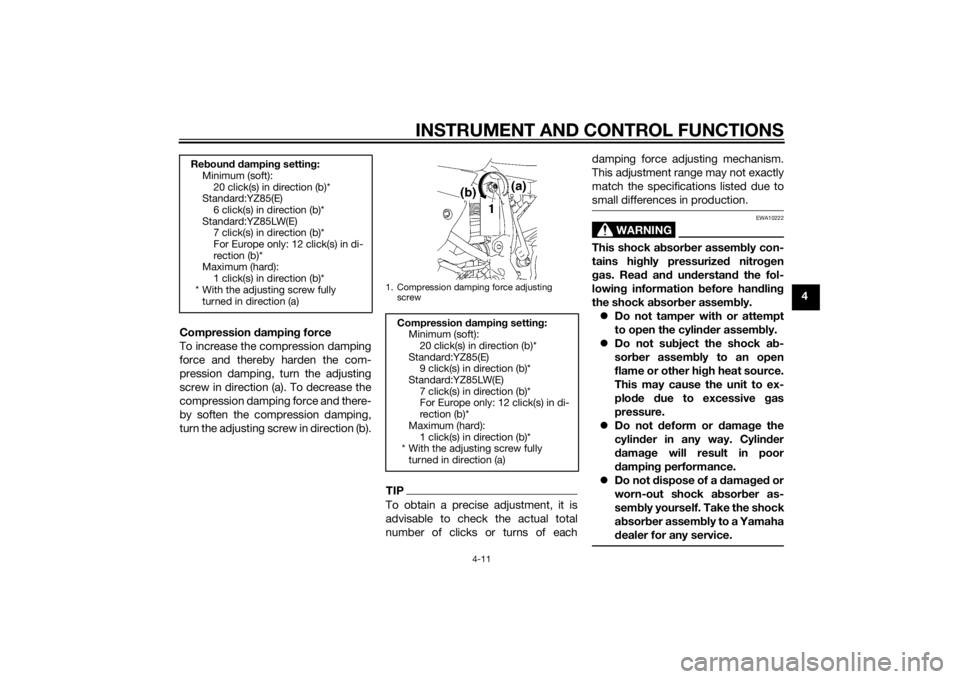

Compression dampin g force

To increase the compression damping

force and thereby harden the com-

pression damping, turn the adjusting

screw in direction (a). To decrease the

compression damping force and there-

by soften the compression damping,

turn the adjusting screw in direction (b).

TIPTo obtain a precise adjustment, it is

advisable to check the actual total

number of clicks or turns of each damping force adjusting mechanism.

This adjustment range may not exactly

match the specifications listed due to

small differences in production.

WARNING

EWA10222

This shock a

bsor ber assem bly con-

tains hig hly pressurize d nitro gen

g as. Rea d an d un derstan d the fol-

lowin g information before han dlin g

the shock a bsor ber assem bly.

Do not tamper with or attempt

to open the cylind er assembly.

Do not su bject the shock a b-

sor ber assem bly to an open

flame or other hi gh heat source.

This may cause the unit to ex-

plo de due to excessive gas

pressure.

Do not deform or damag e the

cylin der in any way. Cylin der

d ama ge will result in poor

d ampin g performance.

Do not dispose of a damag ed or

worn-out shock a bsor ber as-

sem bly

yourself. Take the shock

a b sor ber assem bly to a Yamaha

d ealer for any service.

Re boun d d ampin g settin g:

Minimum (soft):

20 click(s) in direction (b)*

Standard:YZ85(E)

6 click(s) in direction (b)*

Standard:YZ85LW(E) 7 click(s) in direction (b)*

For Europe only: 12 click(s) in di-

rection (b)*

Maximum (hard):

1 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

1. Compression damping force adjusting

screw

Compression dampin g setting :

Minimum (soft): 20 click(s) in direction (b)*

Standard:YZ85(E) 9 click(s) in direction (b)*

Standard:YZ85LW(E)

7 click(s) in direction (b)*

For Europe only: 12 click(s) in di-

rection (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully

turned in direction (a)

U1SN82E0.book Page 11 Friday, June 7, 2013 3:51 PM

Page 44 of 88

OPERATION AND IMPORTANT RIDING POINTS

6-3

6

EAU41504

Engine break-in

WARNING

EWA10322

Failure to properly maintain the vehi-

cle or performin g maintenance ac-

tivities incorrectly may increase

your risk of injury or death durin g

service or while usin g the vehicle. If

you are not familiar with vehicle ser-

vice, have a Yamaha d ealer perform

service.1. Before starting the engine, fill the fuel tank with a break-in oil-fuel

mixture as follows.

2. Start and warm up the engine. Check the operation of the con-

trols and the engine stop button.

(See page 4-1.)

3. Operate the motorcycle in the lower gears at moderate throttle

openings for five to eight minutes.

Stop the engine and check the spark plug condition (see page

7-8); it will show a rich condition

during break-in.

4. Allow the engine to cool. Restart the engine and operate the motor-

cycle as in the step above for five

minutes. Then, very briefly shift to

the higher gears and check the

full-throttle response. Stop the en-

gine and check the spark plug.

5. After again allowing the engine to cool, restart and run the motorcy-

cle for five more minutes. Full

throttle and the higher gears may

be used, but sustained full-throttle

operation should be avoided.

Stop the engine and check the

spark plug again.

6. Allow the engine to cool, remove the cylinder head and cylinder,

and inspect the piston and cylin-

der. Remove any high spots on

the piston with #600-grit wet

sandpaper. Clean all components

and carefully reassemble the cyl-

inder head and cylinder.

7. Drain the break-in oil-fuel mixture from the fuel tank and refill with

the specified mix. (See page 4-3.) 8. Start the engine and check the op-

eration of the motorcycle through-

out its entire operating range.

Stop the engine and check the

spark plug condition. Restart the

motorcycle and ride it for about 10

to 15 more minutes. The motorcy-

cle will now be ready to ride nor-

mally.

After the engine break-in period, thor-

oughly check the motorcycle for loose

parts, oil leakage and any other prob-

lems. Be sure to inspect and make ad-

justments thoroughly, especially cable

and drive chain slack and loose

spokes. In addition, check all fittings

and fasteners for looseness, and tight-

en if necessary.

NOTICE

ECA15561

When any of the followin g parts

have been replaced , they must

b e broken in.

Cylin der or crankshaft:

A bout one hour of b reak-in op-

eration is necessary.

Piston, rin gs or transmission

g ears:

Recommen ded 2-stroke en gine oil:

See page 9-1.

Mixin g ratio ( gasoline to oil):

15:1

U1SN82E0.book Page 3 Friday, June 7, 2013 3:51 PM

Page 46 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-1

7

EAU42074

Periodic inspection, adjustment, and

lubrication will keep your vehicle in the

safest and most efficient condition

possible. Safety is an obligation of the

vehicle owner/operator. The most im-

portant points of vehicle inspection,

adjustment, and lubrication are ex-

plained on the following pages.

The intervals given in the periodic

maintenance and lubrication chart

should be simply considered as a gen-

eral guide under normal riding condi-

tions. However, depending on the

weather, terrain, geographical location,

and individual use, the maintenance in-

tervals may need to be shortened.

WARNING

EWA10322

Failure to properly maintain the vehi-

cle or performing maintenance ac-

tivities incorrectly may increase

your risk of injury or death durin g

service or while usin g the vehicle. If

you are not familiar with vehicle ser-

vice, have a Yamaha d ealer perform

service.

WARNING

EWA15123

Turn off the en gine when performin g

maintenance unless otherwise

specified .

A runnin g en gine has movin g

parts that can catch on body

parts or clothin g an d electrical

parts that can cause shocks or

fires.

Runnin g the en gine while ser-

vicin g can lead to eye injury,

b urns, fire, or car bon monoxi de

poisonin g – possi bly lea din g to

d eath. See pag e 2-2 for more in-

formation a bout car bon monox-

i d e.

WARNING

EWA15461

Brake discs, calipers, drums, and

linin gs can b ecome very hot d uring

use. To avoi d possi ble burns, let

b rake components cool before

touchin g them.

U1SN82E0.book Page 1 Friday, June 7, 2013 3:51 PM

Page 51 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-6

7

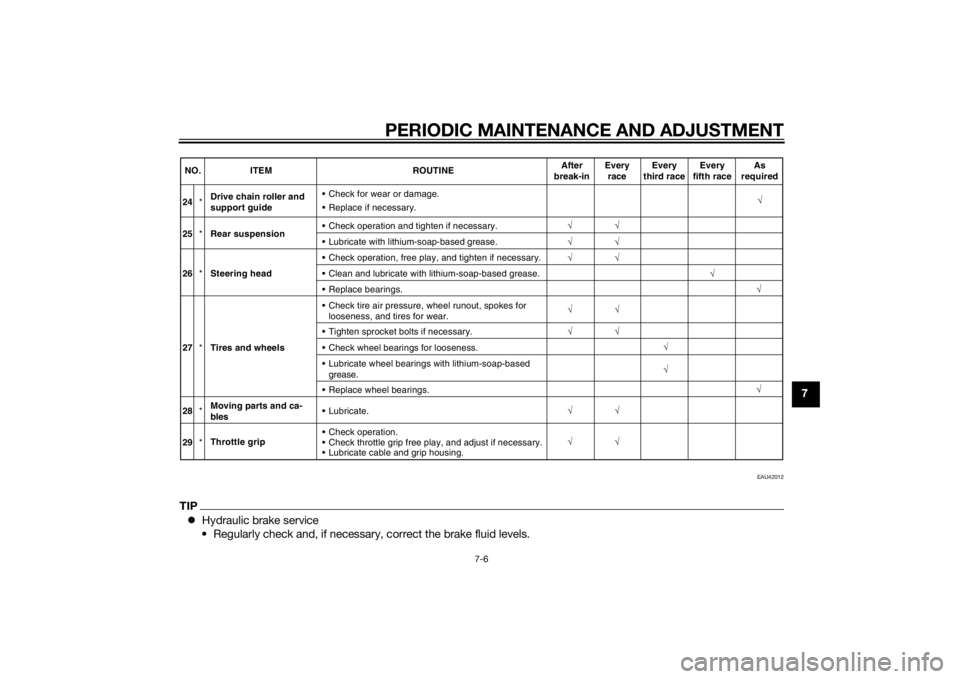

EAU42012

TIPHydraulic brake service

• Regularly check and, if necessary, correct the brake fluid levels.

√

√√

√

24

*Drive chain roller and

support guide

Replace if necessary. Check for wear or damage.

√

25 *Rear suspension Check operation and tighten if necessary.

Lubricate with

lithium-soap-based grease

.

NO.

ITEM ROUTINEAfter

break-in Every

race Every

third race Every

fifth race As

required

√ √√

√

√ √

√

√ √

√

√

√ √

√

√

26

*Steering head Check operation, free play, and tighten if necessary.

Clean and lubricate with lithium-soap-based grease.

Replace bearings.

27 *Tires and wheels Check tire air pressure, wheel runout, spokes for

looseness, and tires for wear.

Tighten sprocket bolts if necessary.

Check wheel bearings for looseness.

Lubricate wheel bearings with lithium-soap-based grease.

Replace wheel bearings.

28 *Moving parts and ca-

bles Lubricate.

29 *Throttle grip Check operation.

Check throttle grip free play, and adjust if necessary.

Lubricate cable and grip housing.

U1SN82E0.book Page 6 Friday, June 7, 2013 3:51 PM

Page 59 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-14

7

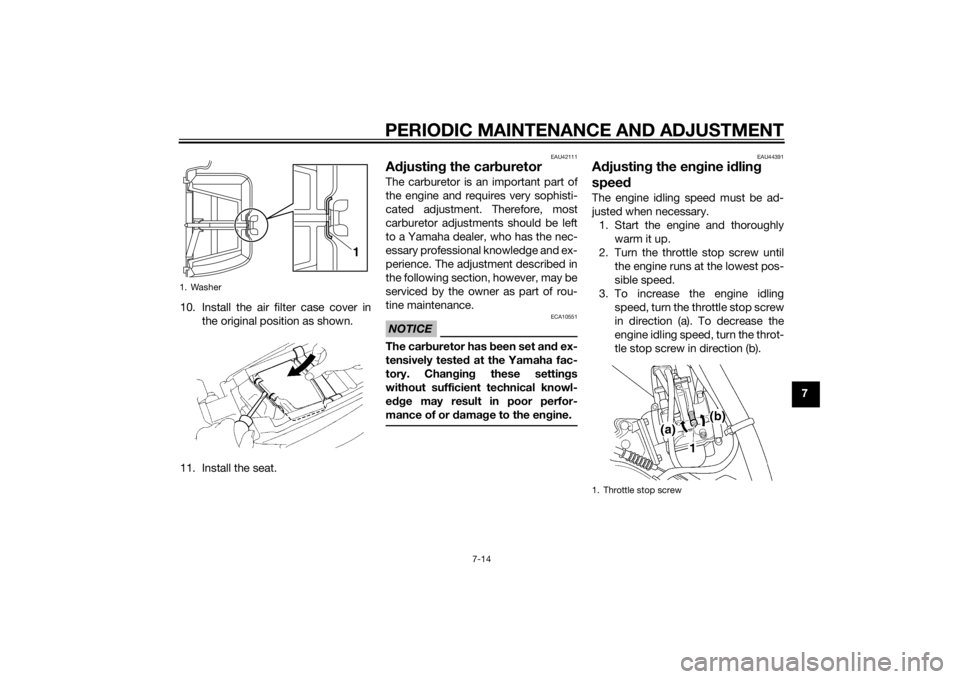

10. Install the air filter case cover in

the original position as shown.

11. Install the seat.

EAU42111

A djustin g the car buretorThe carburetor is an important part of

the engine and requires very sophisti-

cated adjustment. Therefore, most

carburetor adjustments should be left

to a Yamaha dealer, who has the nec-

essary professional knowledge and ex-

perience. The adjustment described in

the following section, however, may be

serviced by the owner as part of rou-

tine maintenance.NOTICE

ECA10551

The car buretor has b een set and ex-

tensively teste d at the Yamaha fac-

tory. Chan gin g these settin gs

without sufficient technical knowl-

e dge may result in poor perfor-

mance of or damag e to the en gine.

EAU44391

A djustin g the en gine i dlin g

spee dThe engine idling speed must be ad-

justed when necessary.

1. Start the engine and thoroughly warm it up.

2. Turn the throttle stop screw until the engine runs at the lowest pos-

sible speed.

3. To increase the engine idling speed, turn the throttle stop screw

in direction (a). To decrease the

engine idling speed, turn the throt-

tle stop screw in direction (b).

1. Washer

1

1. Throttle stop screw

U1SN82E0.book Page 14 Friday, June 7, 2013 3:51 PM

Page 68 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-23

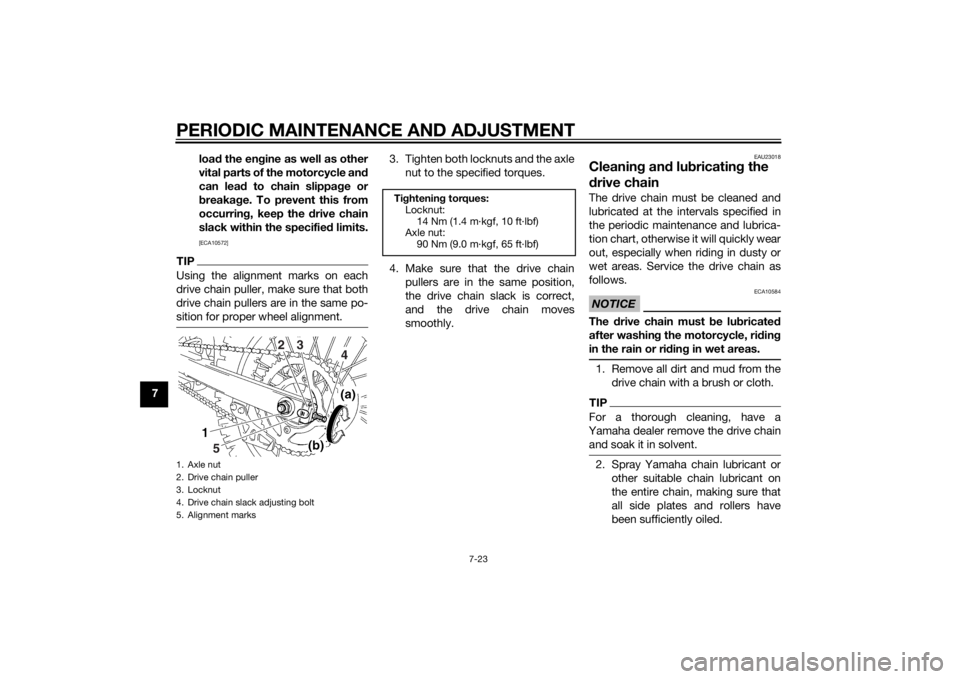

7loa

d the en gine as well as other

vital parts of the motorcycle an d

can lead to chain slippa ge or

b reakag e. To prevent this from

occurrin g, keep the drive chain

slack within the specifie d limits.

[ECA10572]

TIPUsing the alignment marks on each

drive chain puller, make sure that both

drive chain pullers are in the same po-

sition for proper wheel alignment.

3. Tighten both locknuts and the axle

nut to the specified torques.

4. Make sure that the drive chain pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23018

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must be lu bricated

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Remove all dirt and mud from the

drive chain with a brush or cloth.TIPFor a thorough cleaning, have a

Yamaha dealer remove the drive chain and soak it in solvent.2. Spray Yamaha chain lubricant or other suitable chain lubricant on

the entire chain, making sure that

all side plates and rollers have

been sufficiently oiled.

1. Axle nut

2. Drive chain puller

3. Locknut

4. Drive chain slack adjusting bolt

5. Alignment marks

5 4

32

Ti

ghtenin g torques:

Locknut: 14 Nm (1.4 m·kgf, 10 ft·lbf)

Axle nut:

90 Nm (9.0 m·kgf, 65 ft·lbf)

U1SN82E0.book Page 23 Friday, June 7, 2013 3:51 PM

Page 73 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-28

7

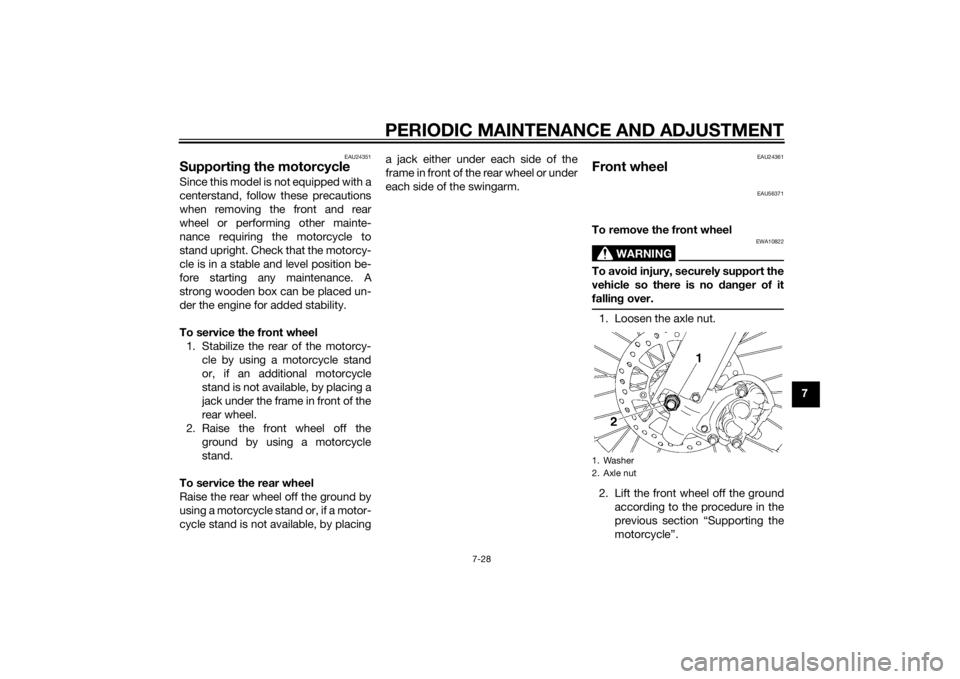

EAU24351

Supporting the motorcycleSince this model is not equipped with a

centerstand, follow these precautions

when removing the front and rear

wheel or performing other mainte-

nance requiring the motorcycle to

stand upright. Check that the motorcy-

cle is in a stable and level position be-

fore starting any maintenance. A

strong wooden box can be placed un-

der the engine for added stability.

To service the front wheel

1. Stabilize the rear of the motorcy- cle by using a motorcycle stand

or, if an additional motorcycle

stand is not available, by placing a

jack under the frame in front of the

rear wheel.

2. Raise the front wheel off the ground by using a motorcycle

stand.

To service the rear wheel

Raise the rear wheel off the ground by

using a motorcycle stand or, if a motor-

cycle stand is not available, by placing a jack either under each side of the

frame in front of the rear wheel or under

each side of the swingarm.

EAU24361

Front wheel

EAU56371

To remove the front wheel

WARNING

EWA10822

To avoi

d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Loosen the axle nut.

2. Lift the front wheel off the ground

according to the procedure in the

previous section “Supporting the

motorcycle”.1. Washer

2. Axle nut

U1SN82E0.book Page 28 Friday, June 7, 2013 3:51 PM

Page 76 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-31

75. Adjust the drive chain slack. (See

page 7-22.)

6. Tighten the locknuts and the axle nut to their specified torques.

EAU25872

Trou bleshootin gAlthough Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition systems,

for example, can cause poor starting

and loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWA15142

When checkin g the fuel system, do

not smoke, an d make sure there are

no open flames or sparks in the ar-

ea, inclu din g pilot lig hts from water heaters or furnaces. Gasoline or

g

asoline vapors can i gnite or ex-

plod e, causin g severe injury or prop-

erty damag e.

Tightenin g torque:

Locknut: 14 Nm (1.4 m·kgf, 10 ft·lbf)

Axle nut:

90 Nm (9.0 m·kgf, 65 ft·lbf)

U1SN82E0.book Page 31 Friday, June 7, 2013 3:51 PM