YAMAHA YZ85 2015 Owner's Guide

Manufacturer: YAMAHA, Model Year: 2015, Model line: YZ85, Model: YAMAHA YZ85 2015Pages: 88, PDF Size: 2.07 MB

Page 31 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-5

4

other sources of ignition such as

the pilot lights of water heaters

and clothes dryers.

2. Do not overfill the fuel tank. Stop filling when the fuel reaches the

bottom of the filler tube. Because

fuel expands when it heats up,

heat from the engine or the sun

can cause fuel to spill out of the

fuel tank.

3. Wipe up any spilled fuel immedi- ately. NOTICE: Immediately

wipe off spille d fuel with a clean,

d ry, soft cloth, since fuel may

d eteriorate painte d surfaces or

plastic parts.

[ECA10072]

4. Be sure to securely close the fuel tank cap.

WARNING

EWA15152

Gasoline is poisonous an d can

cause injury or d eath. Handle gaso-

line with care. Never siphon gasoline

b y mouth. If you shoul d swallow

some gasoline or inhale a lot of gas-

oline vapor, or get some g asoline in

your eyes, see your doctor imme di-

ately. If g asoline spills on your skin, wash with soap an

d water. If gaso-

line spills on your clothin g, chan ge

your clothes.

EAU41362

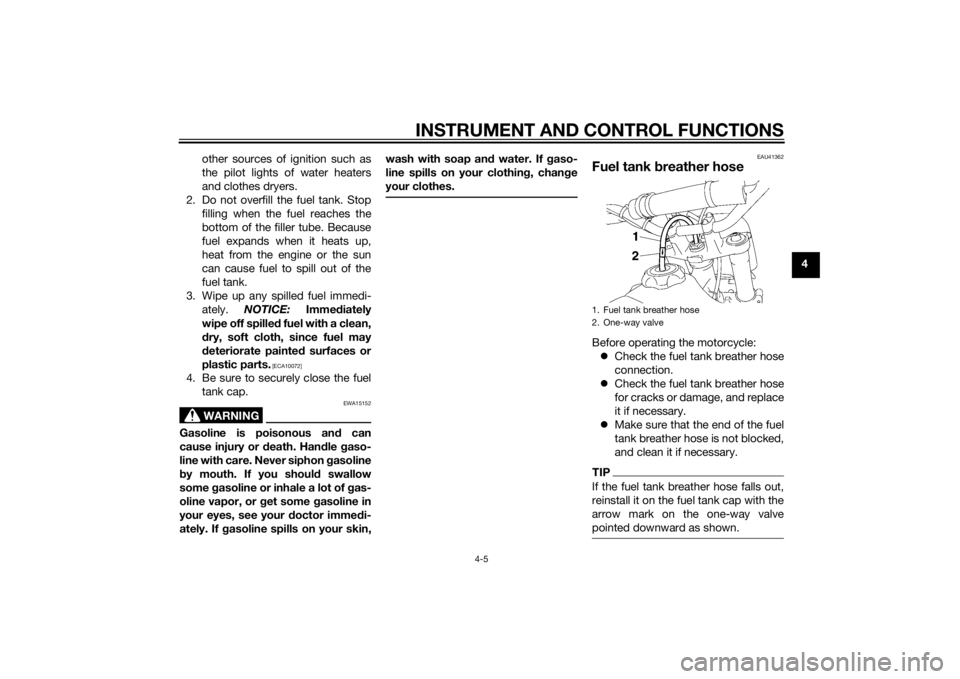

Fuel tank breather hoseBefore operating the motorcycle:

Check the fuel tank breather hose

connection.

Check the fuel tank breather hose

for cracks or damage, and replace

it if necessary.

Make sure that the end of the fuel

tank breather hose is not blocked,

and clean it if necessary.TIPIf the fuel tank breather hose falls out,

reinstall it on the fuel tank cap with the

arrow mark on the one-way valve

pointed downward as shown.1. Fuel tank breather hose

2. One-way valve

U1SN83E0.book Page 5 Monday, September 8, 2014 2:36 PM

Page 32 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-6

4

EAU41281

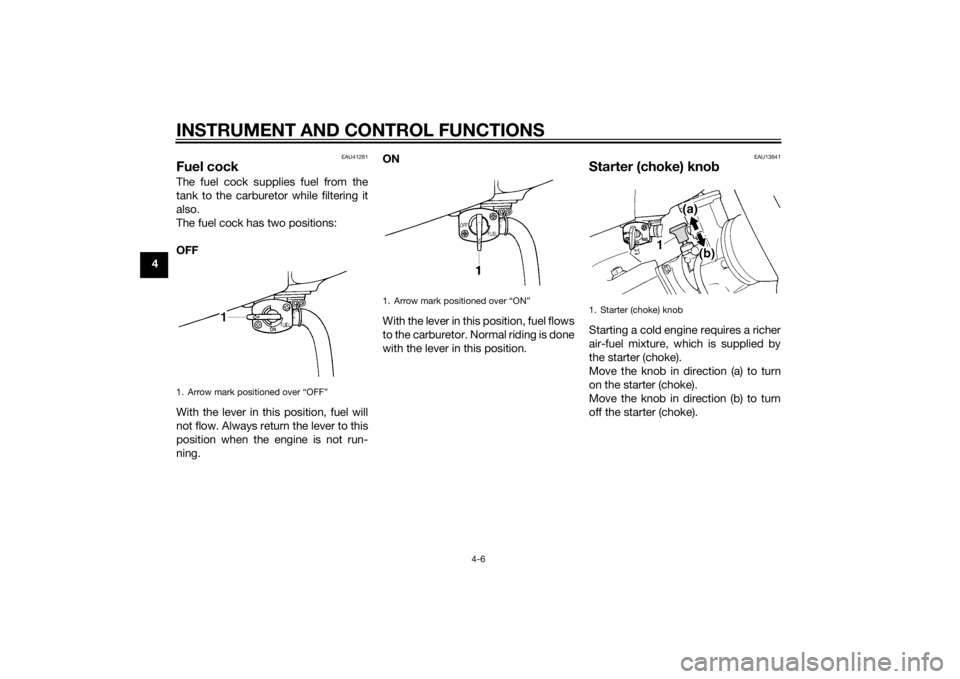

Fuel cockThe fuel cock supplies fuel from the

tank to the carburetor while filtering it

also.

The fuel cock has two positions:

OFF

With the lever in this position, fuel will

not flow. Always return the lever to this

position when the engine is not run-

ning.ON

With the lever in this position, fuel flows

to the carburetor. Normal riding is done

with the lever in this position.

EAU13641

Starter (choke) kno

bStarting a cold engine requires a richer

air-fuel mixture, which is supplied by

the starter (choke).

Move the knob in direction (a) to turn

on the starter (choke).

Move the knob in direction (b) to turn

off the starter (choke).

1. Arrow mark positioned over “OFF”

1. Arrow mark positioned over “ON”

1. Starter (choke) knob

U1SN83E0.book Page 6 Monday, September 8, 2014 2:36 PM

Page 33 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-7

4

EAU13651

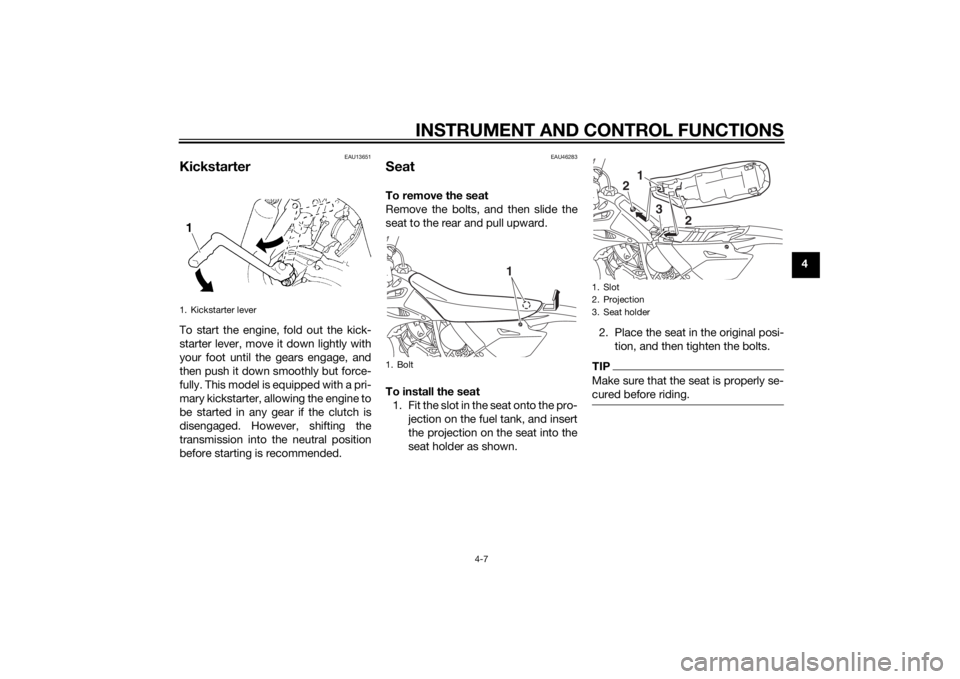

KickstarterTo start the engine, fold out the kick-

starter lever, move it down lightly with

your foot until the gears engage, and

then push it down smoothly but force-

fully. This model is equipped with a pri-

mary kickstarter, allowing the engine to

be started in any gear if the clutch is

disengaged. However, shifting the

transmission into the neutral position

before starting is recommended.

EAU46283

SeatTo remove the seat

Remove the bolts, and then slide the

seat to the rear and pull upward.

To install the seat1. Fit the slot in the seat onto the pro- jection on the fuel tank, and insert

the projection on the seat into the

seat holder as shown. 2. Place the seat in the original posi-

tion, and then tighten the bolts.

TIPMake sure that the seat is properly se-

cured before riding.

1. Kickstarter lever

1. Bolt

1

1. Slot

2. Projection

3. Seat holder

1

2

3

2

U1SN83E0.book Page 7 Monday, September 8, 2014 2:36 PM

Page 34 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-8

4

EAU41473

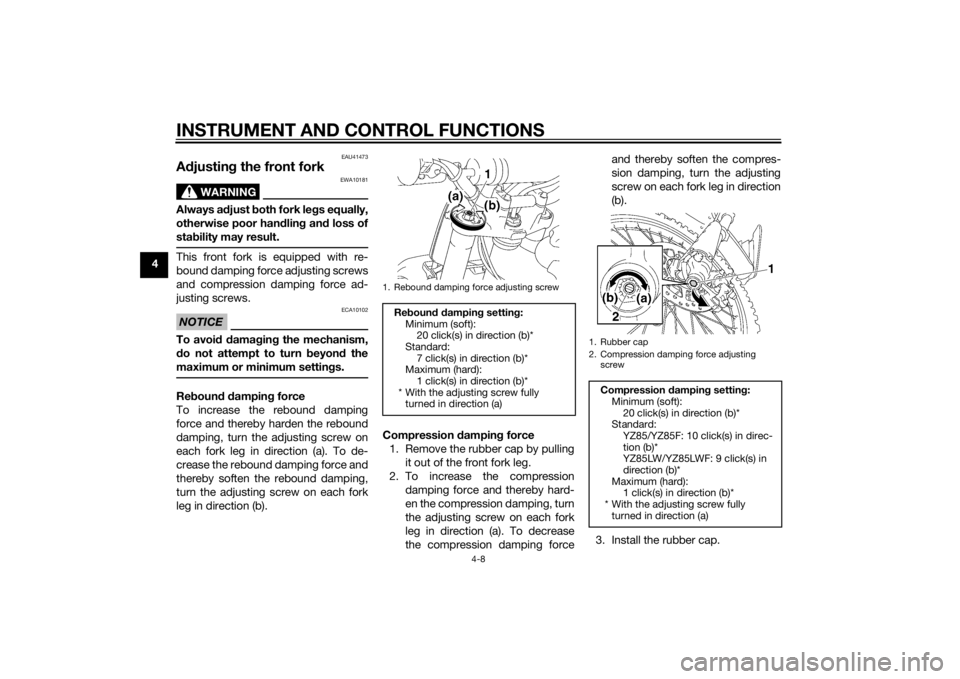

Adjustin g the front fork

WARNING

EWA10181

Always a djust both fork le gs equally,

otherwise poor han dlin g an d loss of

sta bility may result.This front fork is equipped with re-

bound damping force adjusting screws

and compression damping force ad-

justing screws.NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn b eyond the

maximum or minimum setting s.Reboun d d ampin g force

To increase the rebound damping

force and thereby harden the rebound

damping, turn the adjusting screw on

each fork leg in direction (a). To de-

crease the rebound damping force and

thereby soften the rebound damping,

turn the adjusting screw on each fork

leg in direction (b). Compression

dampin g force

1. Remove the rubber cap by pulling it out of the front fork leg.

2. To increase the compression damping force and thereby hard-

en the compression damping, turn

the adjusting screw on each fork

leg in direction (a). To decrease

the compression damping force and thereby soften the compres-

sion damping, turn the adjusting

screw on each fork leg in direction

(b).

3. Install the rubber cap.

1. Rebound damping force adjusting screwRe boun d d ampin g setting :

Minimum (soft): 20 click(s) in direction (b)*

Standard: 7 click(s) in direction (b)*

Maximum (hard):

1 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

1. Rubber cap

2. Compression damping force adjusting

screwCompression dampin g settin g:

Minimum (soft): 20 click(s) in direction (b)*

Standard:

YZ85/YZ85F: 10 click(s) in direc-

tion (b)*

YZ85LW/YZ85LWF: 9 click(s) in

direction (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

U1SN83E0.book Page 8 Monday, September 8, 2014 2:36 PM

Page 35 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-9

4

TIPAlthough the total number of clicks of a

damping force adjusting mechanism

may not exactly match the above

specifications due to small differences

in production, the actual number of

clicks always represents the entire ad-

justing range. To obtain a precise ad-

justment, it would be advisable to

check the number of clicks of each

damping force adjusting mechanism

and to modify the specifications as

necessary.

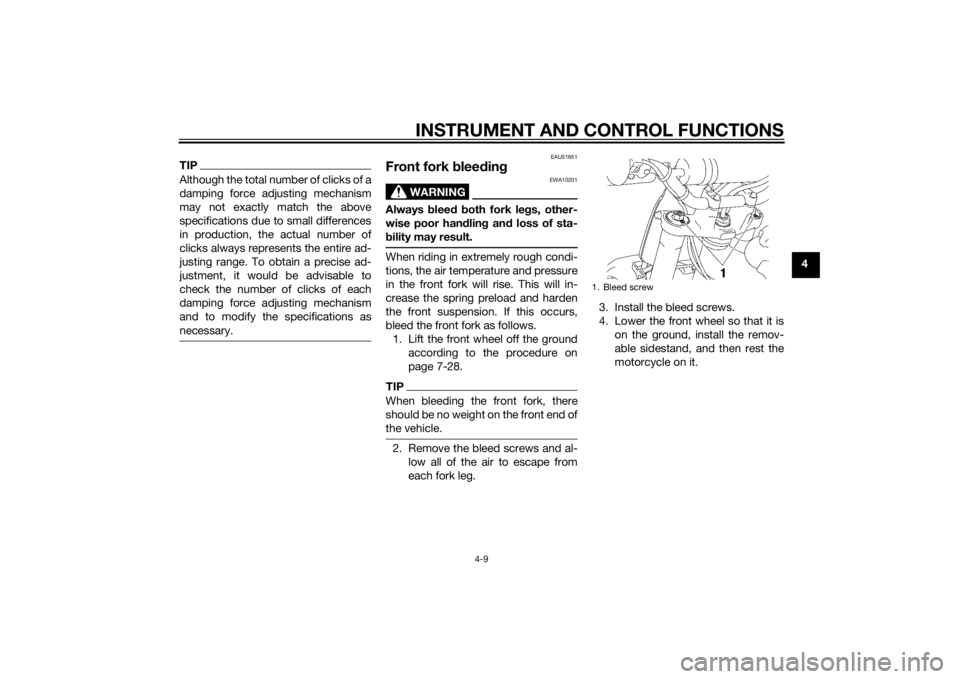

EAU51651

Front fork bleedin g

WARNING

EWA10201

Always blee d b oth fork le gs, other-

wise poor han dlin g an d loss of sta-

b ility may result.When riding in extremely rough condi-

tions, the air temperature and pressure

in the front fork will rise. This will in-

crease the spring preload and harden

the front suspension. If this occurs,

bleed the front fork as follows.

1. Lift the front wheel off the ground according to the procedure on

page 7-28.TIPWhen bleeding the front fork, there

should be no weight on the front end of

the vehicle.2. Remove the bleed screws and al-low all of the air to escape from

each fork leg. 3. Install the bleed screws.

4. Lower the front wheel so that it is

on the ground, install the remov-

able sidestand, and then rest the

motorcycle on it.

1. Bleed screw

U1SN83E0.book Page 9 Monday, September 8, 2014 2:36 PM

Page 36 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-10

4

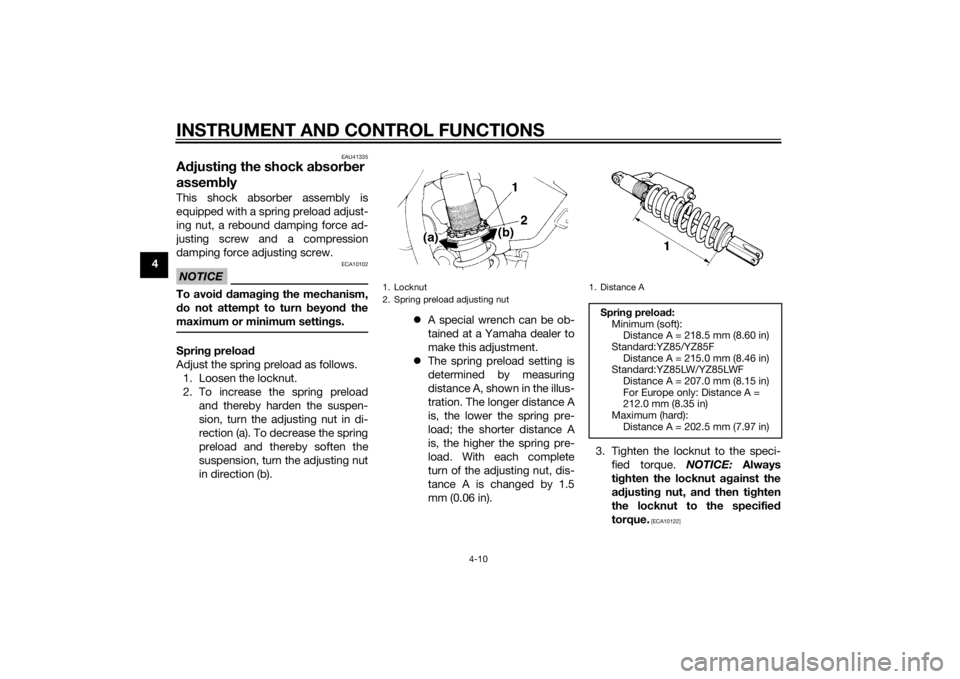

EAU41335

Adjustin g the shock a bsorb er

assem blyThis shock absorber assembly is

equipped with a spring preload adjust-

ing nut, a rebound damping force ad-

justing screw and a compression

damping force adjusting screw.NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn b eyond the

maximum or minimum setting s.Spring preloa d

Adjust the spring preload as follows. 1. Loosen the locknut.

2. To increase the spring preload and thereby harden the suspen-

sion, turn the adjusting nut in di-

rection (a). To decrease the spring

preload and thereby soften the

suspension, turn the adjusting nut

in direction (b).

A special wrench can be ob-

tained at a Yamaha dealer to

make this adjustment.

The spring preload setting is

determined by measuring

distance A, shown in the illus-

tration. The longer distance A

is, the lower the spring pre-

load; the shorter distance A

is, the higher the spring pre-

load. With each complete

turn of the adjusting nut, dis-

tance A is changed by 1.5

mm (0.06 in). 3. Tighten the locknut to the speci-

fied torque. NOTICE: Always

ti g hten the locknut ag ainst the

a d justin g nut, an d then ti ghten

the locknut to the specified

torque.

[ECA10122]

1. Locknut

2. Spring preload adjusting nut

1. Distance ASprin g preloa d:

Minimum (soft): Distance A = 218.5 mm (8.60 in)

Standard:YZ85/YZ85F Distance A = 215.0 mm (8.46 in)

Standard:YZ85LW/YZ85LWF

Distance A = 207.0 mm (8.15 in)

For Europe only: Distance A =

212.0 mm (8.35 in)

Maximum (hard): Distance A = 202.5 mm (7.97 in)

U1SN83E0.book Page 10 Monday, September 8, 2014 2:36 PM

Page 37 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-11

4

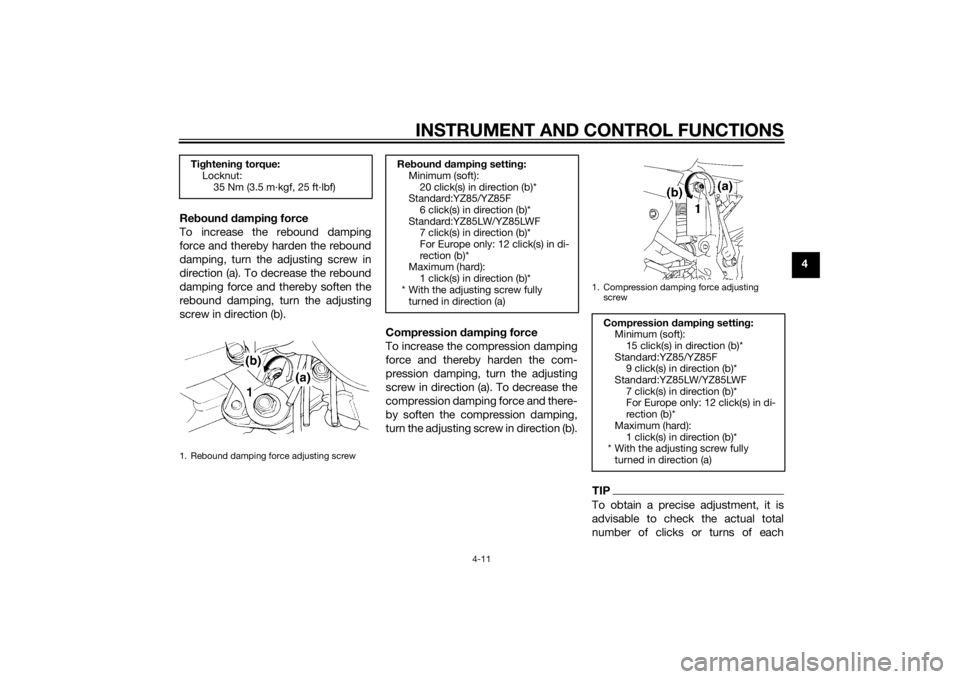

Re

boun d d ampin g force

To increase the rebound damping

force and thereby harden the rebound

damping, turn the adjusting screw in

direction (a). To decrease the rebound

damping force and thereby soften the

rebound damping, turn the adjusting

screw in direction (b).

Compression dampin g force

To increase the compression damping

force and thereby harden the com-

pression damping, turn the adjusting

screw in direction (a). To decrease the

compression damping force and there-

by soften the compression damping,

turn the adjusting screw in direction (b).

TIPTo obtain a precise adjustment, it is

advisable to check the actual total

number of clicks or turns of each

Ti ghtenin g torque:

Locknut:

35 Nm (3.5 m·kgf, 25 ft·lbf)1. Rebound damping force adjusting screw

Re boun d d ampin g settin g:

Minimum (soft):

20 click(s) in direction (b)*

Standard:YZ85/YZ85F

6 click(s) in direction (b)*

Standard:YZ85LW/YZ85LWF 7 click(s) in direction (b)*

For Europe only: 12 click(s) in di-

rection (b)*

Maximum (hard):

1 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

1. Compression damping force adjusting

screw

Compression dampin g settin g:

Minimum (soft): 15 click(s) in direction (b)*

Standard:YZ85/YZ85F 9 click(s) in direction (b)*

Standard:YZ85LW/YZ85LWF

7 click(s) in direction (b)*

For Europe only: 12 click(s) in di-

rection (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully

turned in direction (a)

U1SN83E0.book Page 11 Monday, September 8, 2014 2:36 PM

Page 38 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-12

4damping force adjusting mechanism.

This adjustment range may not exactly

match the specifications listed due to

small differences in production.

WARNING

EWA10222

This shock a

bsor ber assem bly con-

tains hi ghly pressurize d nitro gen

g as. Rea d an d un derstan d the fol-

lowin g information before han dlin g

the shock a bsor ber assem bly.

Do not tamper with or attempt

to open the cylind er assembly.

Do not su bject the shock a b-

sor ber assem bly to an open

flame or other hi gh heat source.

This may cause the unit to ex-

plo de due to excessive gas

pressure.

Do not d eform or d amage the

cylin der in any way. Cylin der

d amag e will result in poor

d ampin g performance.

Do not dispose of a damag ed or

worn-out shock a bsor ber as-

sem bl

y yourself. Take the shock

a b sor ber assem bly to a Yamaha

d ealer for any service.

EAU41382

Remova ble sid estan dThis motorcycle is equipped with a re-

movable sidestand.TIPMake sure that the sidestand is proper-

ly secured when the motorcycle is be-

ing supported or is being transported.

WARNING

EWA14602

Never apply force on the motor-

cycle while it is on the si de-

stan d.

Always remove the si destan d

b efore startin g out.1. Sidestand

1

U1SN83E0.book Page 12 Monday, September 8, 2014 2:36 PM

Page 39 of 88

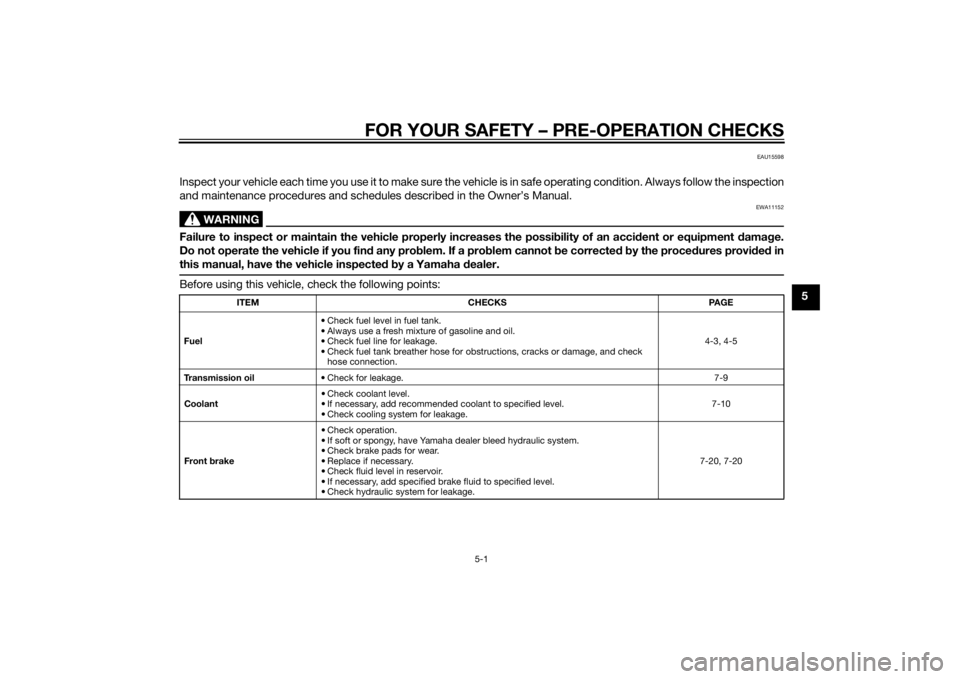

FOR YOUR SAFETY – PRE-OPERATION CHECKS

5-1

5

EAU15598

Inspect your vehicle each time you use it to make sure the vehicle is in safe operating condition. Always follow the inspection

and maintenance procedures and schedules described in the Owner’s Manual.

WARNING

EWA11152

Failure to inspect or maintain the vehicle properly increases the possibility of an acci dent or equipment damag e.

Do not operate the vehicle if you fin d any pro blem. If a pro blem cannot be corrected b y the proce dures provi ded in

this manual, have the vehicle inspecte d b y a Yamaha dealer.Before using this vehicle, check the following points:

ITEM CHECKS PAGE

Fuel • Check fuel level in fuel tank.

• Always use a fresh mixture of gasoline and oil.

• Check fuel line for leakage.

• Check fuel tank breather hose for obstructions, cracks or damage, and check

hose connection. 4-3, 4-5

Transmission oil • Check for leakage. 7-9

Coolant • Check coolant level.

• If necessary, add recommended coolant to specified level.

• Check cooling system for leakage. 7-10

Front brake • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage. 7-20, 7-20

U1SN83E0.book Page 1 Monday, September 8, 2014 2:36 PM

Page 40 of 88

FOR YOUR SAFETY – PRE-OPERATION CHECKS

5-2

5

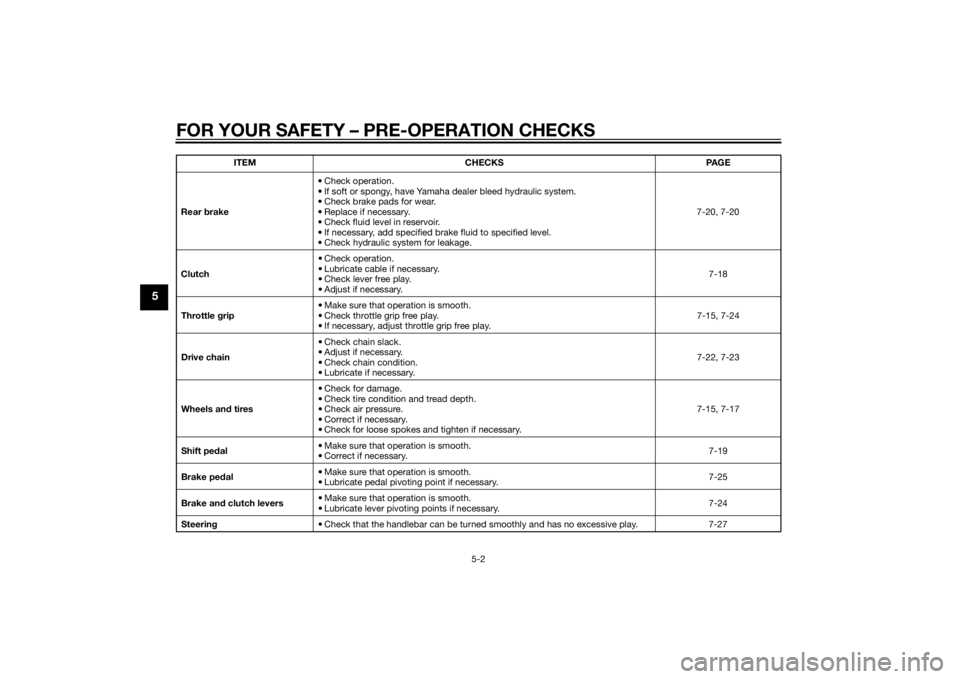

Rear brake • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage. 7-20, 7-20

Clutch • Check operation.

• Lubricate cable if necessary.

• Check lever free play.

• Adjust if necessary.

7-18

Throttle g rip • Make sure that operation is smooth.

• Check throttle grip free play.

• If necessary, adjust throttle grip free play. 7-15, 7-24

Drive chain • Check chain slack.

• Adjust if necessary.

• Check chain condition.

• Lubricate if necessary. 7-22, 7-23

Wheels an d tires •Check for damage.

• Check tire condition and tread depth.

• Check air pressure.

• Correct if necessary.

• Check for loose spokes and tighten if necessary. 7-15, 7-17

Shift pe dal • Make sure that operation is smooth.

• Correct if necessary.

7-19

Brake ped al • Make sure that operation is smooth.

• Lubricate pedal pivoting point if necessary. 7-25

Brake an d clutch levers • Make sure that operation is smooth.

• Lubricate lever pivoting points if necessary.

7-24

Steerin g • Check that the handlebar can be turned smoothly and has no excessive play. 7-27

ITEM CHECKS PAGE

U1SN83E0.book Page 2 Monday, September 8, 2014 2:36 PM