Oil YAMAHA YZ85 2017 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: YZ85, Model: YAMAHA YZ85 2017Pages: 88, PDF Size: 2.12 MB

Page 52 of 88

Periodic maintenance an d a djustment

7-7

7 To install the spark plu

g

1. Clean the surface of the spark plug gasket and its mating surfa-

ce, and then wipe off any grime

from the spark plug threads.

2. Install the spark plug with the spark plug wrench, and then tight-

en it to the specified torque.

TIP

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.

3. Install the spark plug cap.

EAU4144B

Transmission oil

The transmission must be checked for

oil leakage before each ride. If any

leakage is found, have a Yamaha deal-

er check and repair the motorcycle. In

addition, the transmission oil must be

changed at the intervals specified in

the periodic maintenance and lubrica-

tion chart.1. Start the engine, warm it up for several minutes, and then turn it

off.

2. Place the motorcycle on a level surface and hold it in an upright

position.

3. Place an oil pan under the trans- mission case to collect the used

oil.

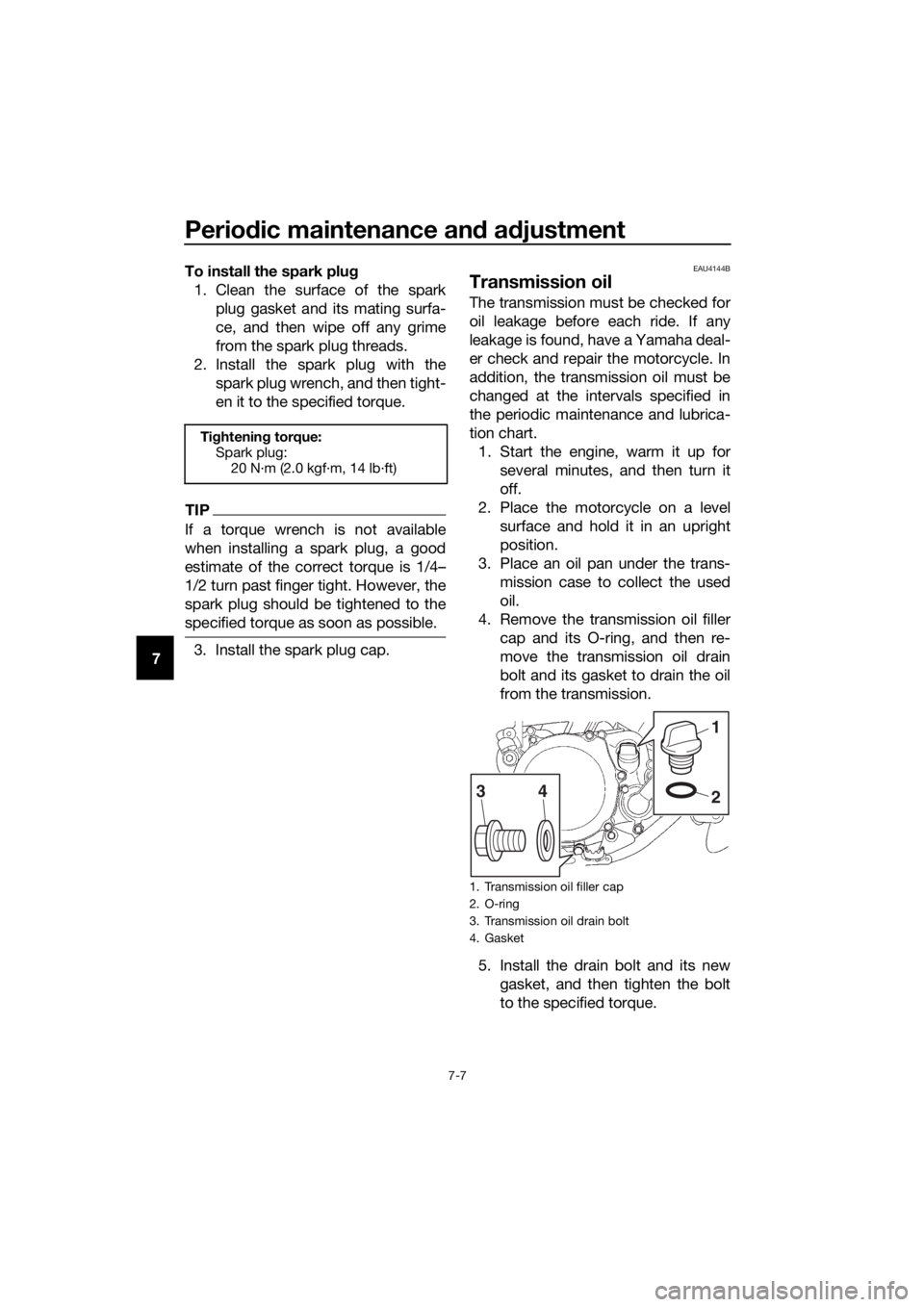

4. Remove the transmission oil filler cap and its O-ring, and then re-

move the transmission oil drain

bolt and its gasket to drain the oil

from the transmission.

5. Install the drain bolt and its new gasket, and then tighten the bolt

to the specified torque.

Tightenin g torque:

Spark plug: 20 N·m (2.0 kgf·m, 14 lb·ft)

1. Transmission oil filler cap

2. O-ring

3. Transmission oil drain bolt

4. Gasket

34

1

2

U1SN85E0.book Page 7 Friday, June 10, 2016 1:20 PM

Page 53 of 88

Periodic maintenance an d a djustment

7-8

7

6. Refill with the specified amount of

the recommended transmission

oil.

NOTICE

ECA10453

In or der to prevent clutch slip-

pa ge (since the transmission oil

also lu bricates the clutch), do

not mix any chemical additives.

Do not use oils with a diesel

specification of “CD” or oils of a

hi gher quality than specifie d. In

a ddition, do not use oils la bele d

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the transmission.

7. Check the O-ring for damage, and replace it if necessary.

8. Install and tighten the transmis- sion oil filler cap and its O-ring.

9. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

EAU20071

Coolant

The coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAUM1296To check the coolant level1. Place the vehicle on a level surfa- ce and hold it in an upright posi-

tion.

TIP

The coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.

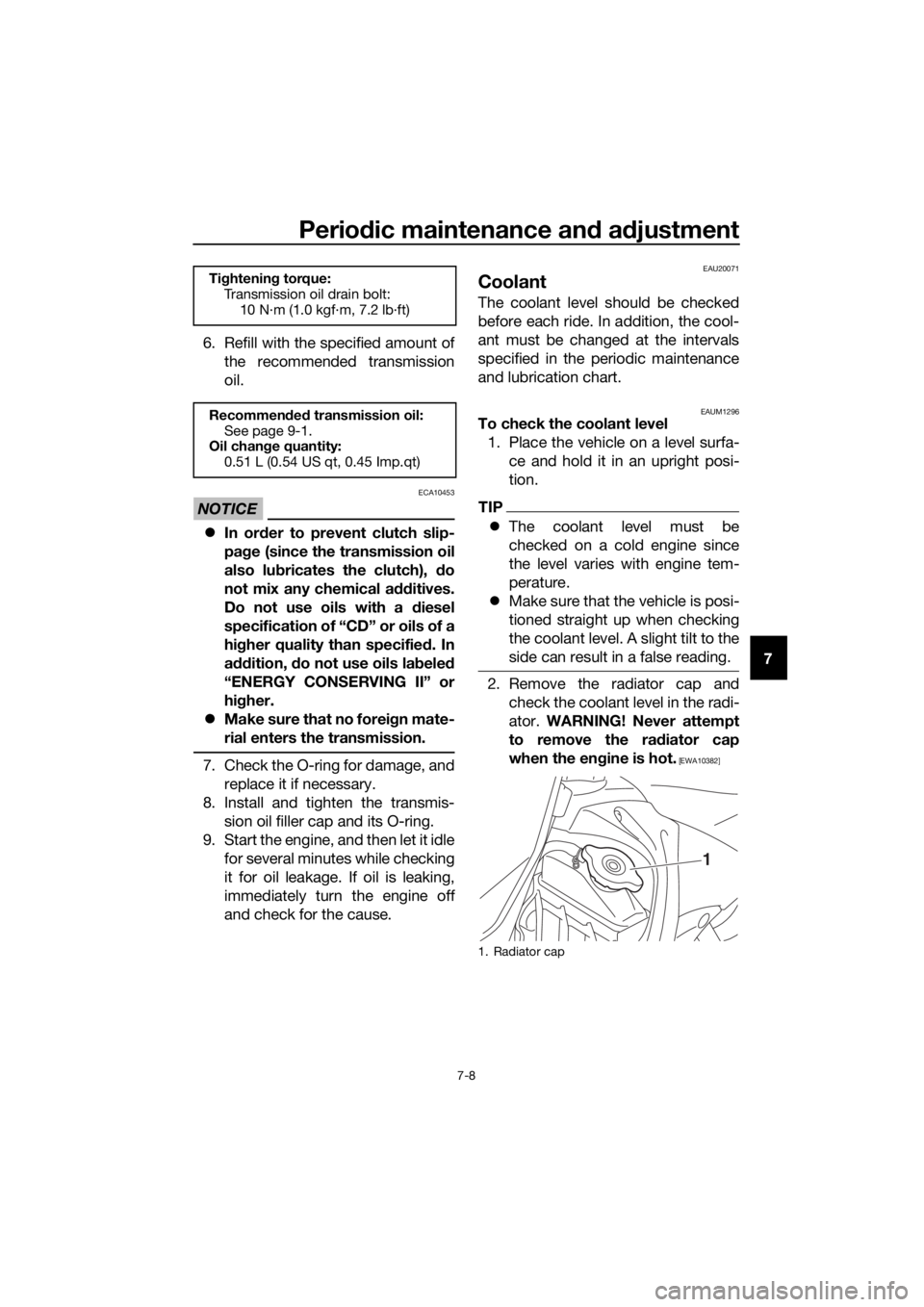

2. Remove the radiator cap and

check the coolant level in the radi-

ator. WARNING! Never attempt

to remove the ra diator cap

when the en gine is hot.

[EWA10382]

Ti ghtening torque:

Transmission oil drain bolt: 10 N·m (1.0 kgf·m, 7.2 lb·ft)

Recommen ded transmission oil:

See page 9-1.

Oil chan ge quantity:

0.51 L (0.54 US qt, 0.45 Imp.qt)

1. Radiator cap

1

U1SN85E0.book Page 8 Friday, June 10, 2016 1:20 PM

Page 56 of 88

Periodic maintenance an d a djustment

7-11

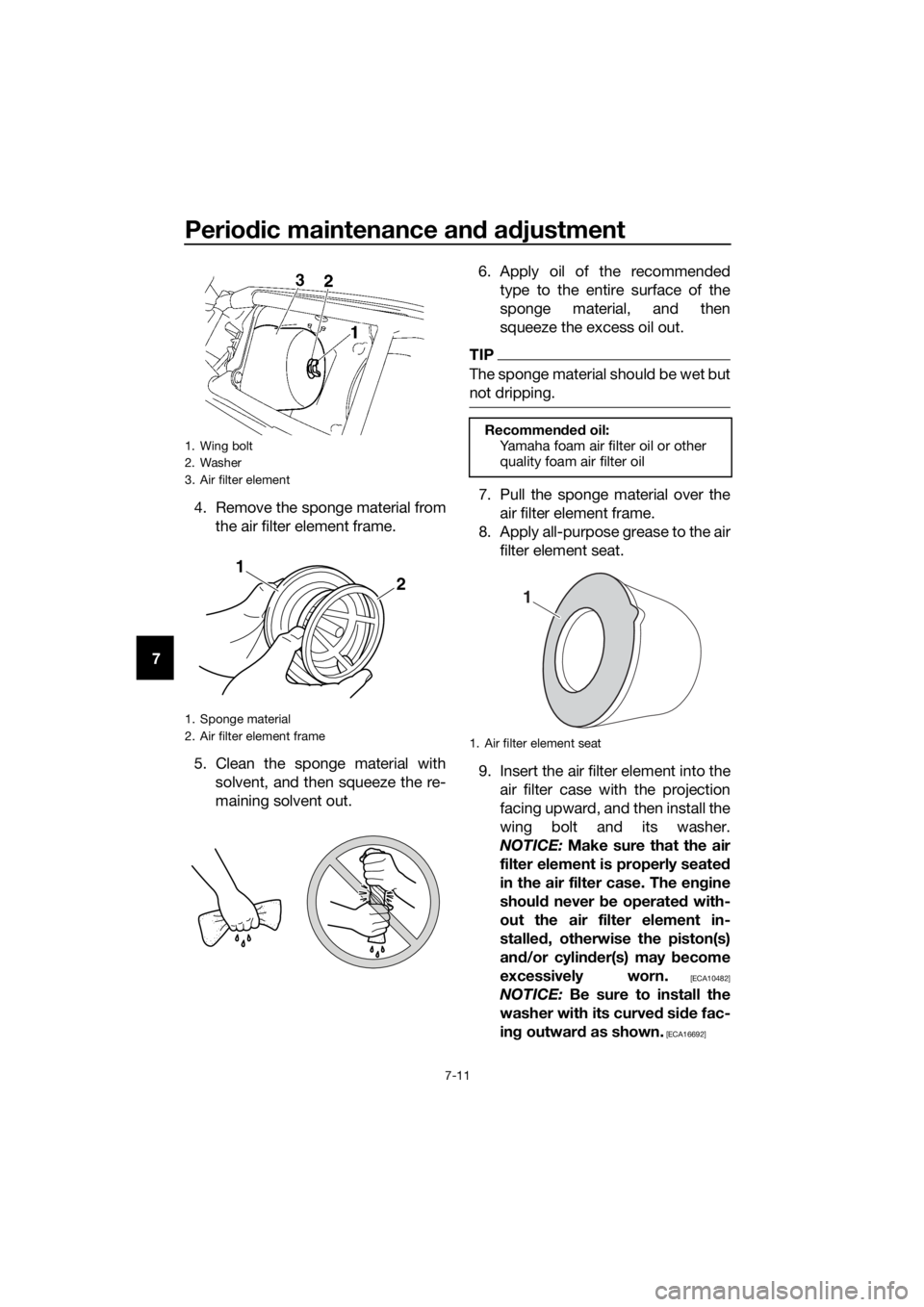

7 4. Remove the sponge material from

the air filter element frame.

5. Clean the sponge material with solvent, and then squeeze the re-

maining solvent out. 6. Apply oil of the recommended

type to the entire surface of the

sponge material, and then

squeeze the excess oil out.

TIP

The sponge material should be wet but

not dripping.

7. Pull the sponge material over theair filter element frame.

8. Apply all-purpose grease to the air filter element seat.

9. Insert the air filter element into the air filter case with the projection

facing upward, and then install the

wing bolt and its washer.

NOTICE: Make sure that the air

filter element is properly seate d

in the air filter case. The en gine

shoul d never b e operated with-

out the air filter element in-

stalle d, otherwise the piston(s)

an d/or cylin der(s) may become

excessively worn.

[ECA10482]

NOTICE: Be sure to install the

washer with its curve d si de fac-

in g outwar d as shown.

[ECA16692]

1. Wing bolt

2. Washer

3. Air filter element

1. Sponge material

2. Air filter element frame

1

2

Recommended oil:

Yamaha foam air filter oil or other

quality foam air filter oil

1. Air filter element seat

1

U1SN85E0.book Page 11 Friday, June 10, 2016 1:20 PM

Page 65 of 88

Periodic maintenance an d a djustment

7-20

7

EAU22582

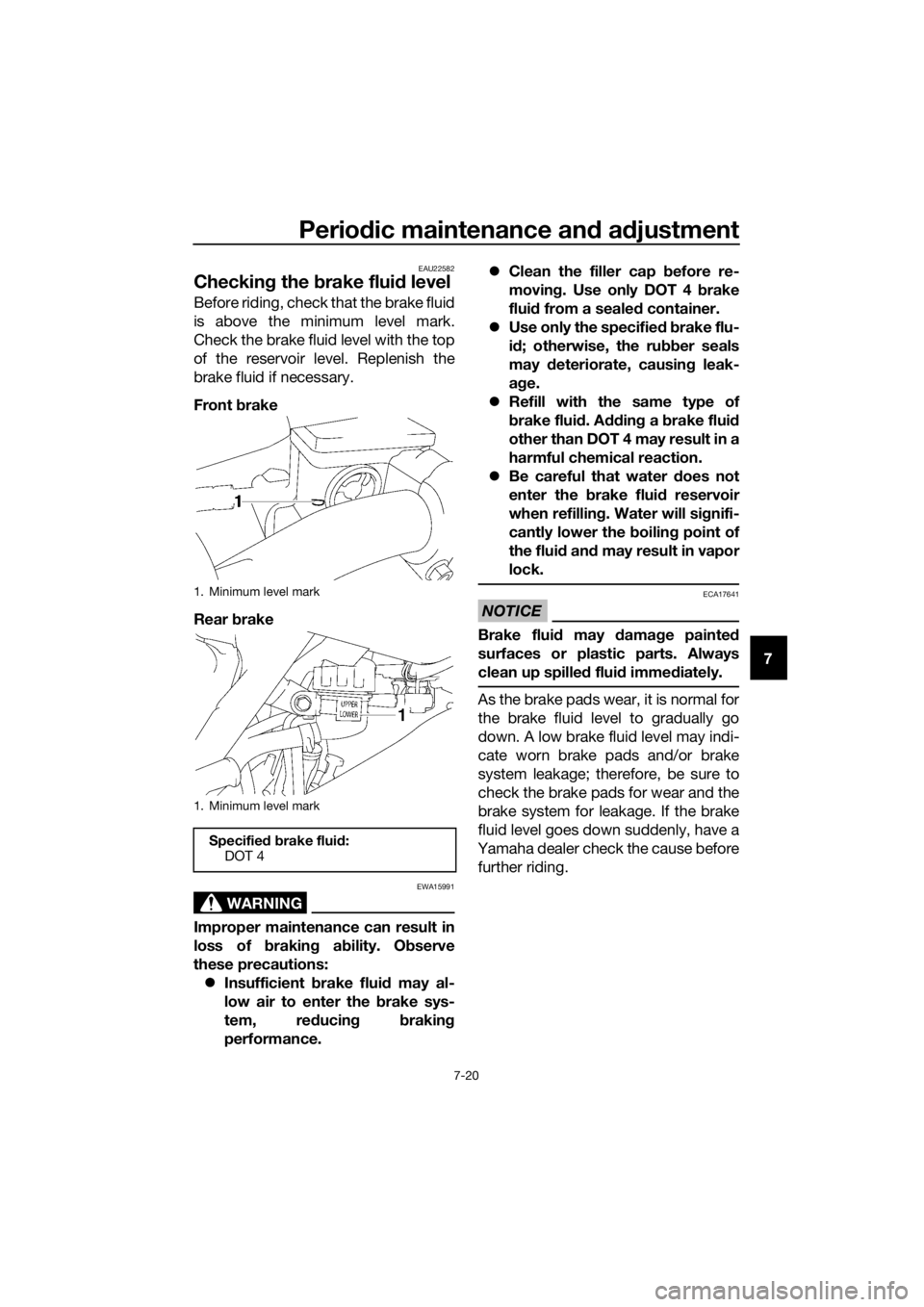

Checkin g the brake flui d level

Before riding, check that the brake fluid

is above the minimum level mark.

Check the brake fluid level with the top

of the reservoir level. Replenish the

brake fluid if necessary.

Front brake

Rear brake

WARNING

EWA15991

Improper maintenance can result in

loss of brakin g a bility. O bserve

these precautions: Insufficient brake flui d may al-

low air to enter the brake sys-

tem, re ducing brakin g

performance.

Clean the filler cap before re-

moving . Use only DOT 4 b rake

flui d from a seale d container.

Use only the specifie d b rake flu-

i d ; otherwise, the ru bber seals

may deteriorate, causin g leak-

a g e.

Refill with the same type of

brake flui d. A ddin g a brake flui d

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water d oes not

enter the brake flui d reservoir

when refillin g. Water will si gnifi-

cantly lower the b oiling point of

the flui d an d may result in vapor

lock.

NOTICE

ECA17641

Brake flui d may d amage painte d

surfaces or plastic parts. Always

clean up spille d flui d imme diately.

As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake

system leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brake

fluid level goes down suddenly, have a

Yamaha dealer check the cause before further riding.

1. Minimum level mark

1. Minimum level mark

Specified b rake flui d:

DOT 4

U1SN85E0.book Page 20 Friday, June 10, 2016 1:20 PM

Page 66 of 88

Periodic maintenance an d a djustment

7-21

7

EAU51721

Chan gin g the brake flui d

Have a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the master cylinders and calipers as

well as the brake hoses replaced at the

intervals listed below or whenever they

are damaged or leaking.

Oil seals: Replace every two

years.

Brake hoses: Replace every four

years.

EAU22762

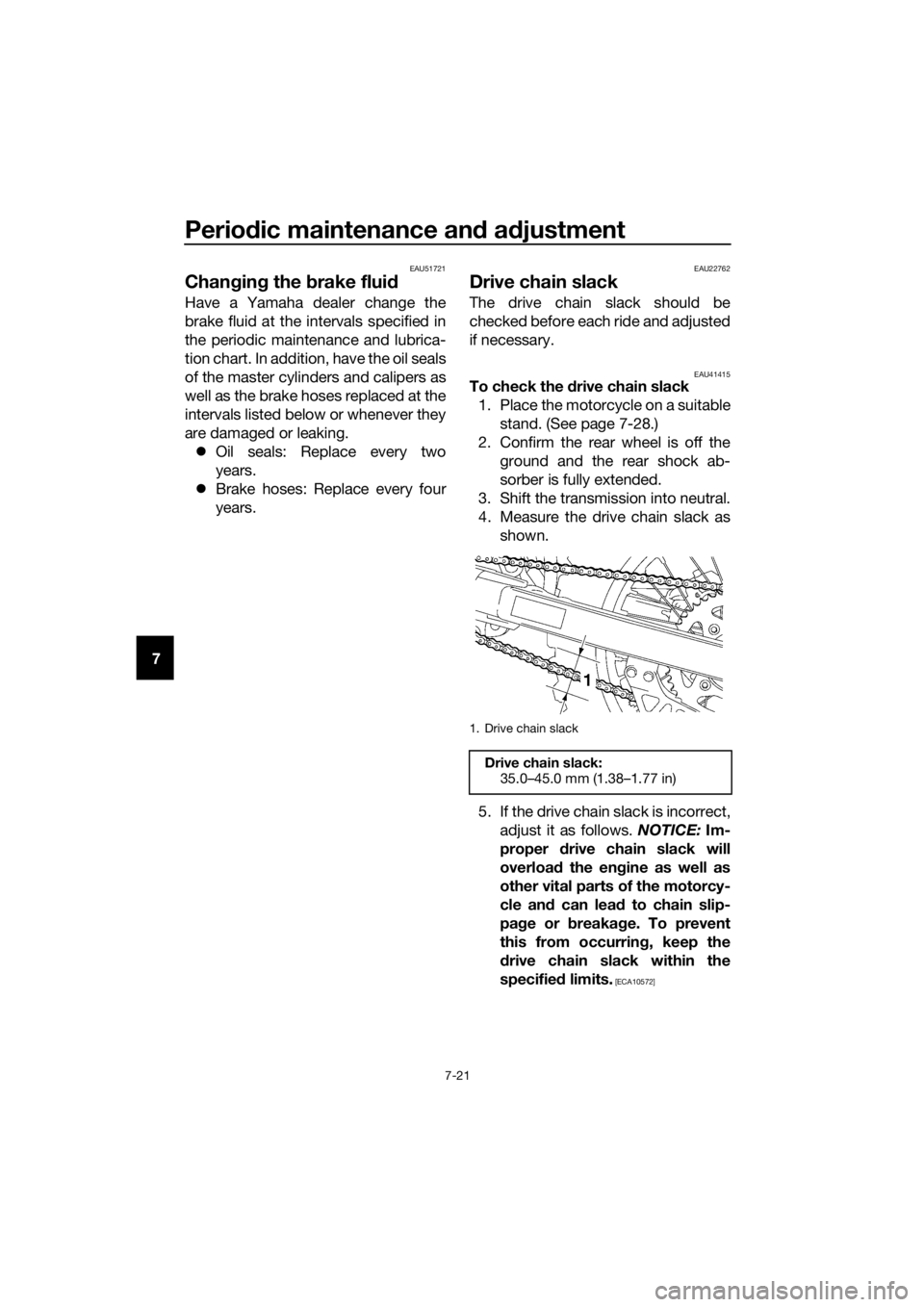

Drive chain slack

The drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU41415To check the drive chain slack

1. Place the motorcycle on a suitable stand. (See page 7-28.)

2. Confirm the rear wheel is off the ground and the rear shock ab-

sorber is fully extended.

3. Shift the transmission into neutral.

4. Measure the drive chain slack as shown.

5. If the drive chain slack is incorrect, adjust it as follows. NOTICE: Im-

proper drive chain slack will

overloa d the en gine as well as

other vital parts of the motorcy-

cle an d can lead to chain slip-

pa ge or b reakag e. To prevent

this from occurrin g, keep the

d rive chain slack within the

specified limits.

[ECA10572]

1. Drive chain slack

Drive chain slack:

35.0–45.0 mm (1.38–1.77 in)

U1SN85E0.book Page 21 Friday, June 10, 2016 1:20 PM

Page 68 of 88

Periodic maintenance an d a djustment

7-23

7

EAU23018

Cleanin g an d lu bricatin g the

d rive chain

The drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.

NOTICE

ECA10584

The drive chain must b e lubricated

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.

1. Remove all dirt and mud from the

drive chain with a brush or cloth.

TIP

For a thorough cleaning, have a

Yamaha dealer remove the drive chain and soak it in solvent.

2. Spray Yamaha chain lubricant or other suitable chain lubricant on

the entire chain, making sure that

all side plates and rollers have

been sufficiently oiled.

EAU23098

Checkin g an d lu bricatin g the

ca bles

The operation of all control cables and

the condition of the cables should be

checked before each ride, and the ca-

bles and cable ends should be lubri-

cated if necessary. If a cable is

damaged or does not move smoothly,

have a Yamaha dealer check or re-

place it. WARNING! Dama ge to the

outer housin g of cab les may result

in internal rustin g an d cause inter-

ference with cab le movement. Re-

place damag ed cab les as soon as

possi ble to prevent unsafe con di-

tions.

[EWA10712]

Recommen ded lu bricant:

Yamaha cable lubricant or other

suitable cable lubricant

U1SN85E0.book Page 23 Friday, June 10, 2016 1:20 PM

Page 71 of 88

Periodic maintenance an d a djustment

7-26

7

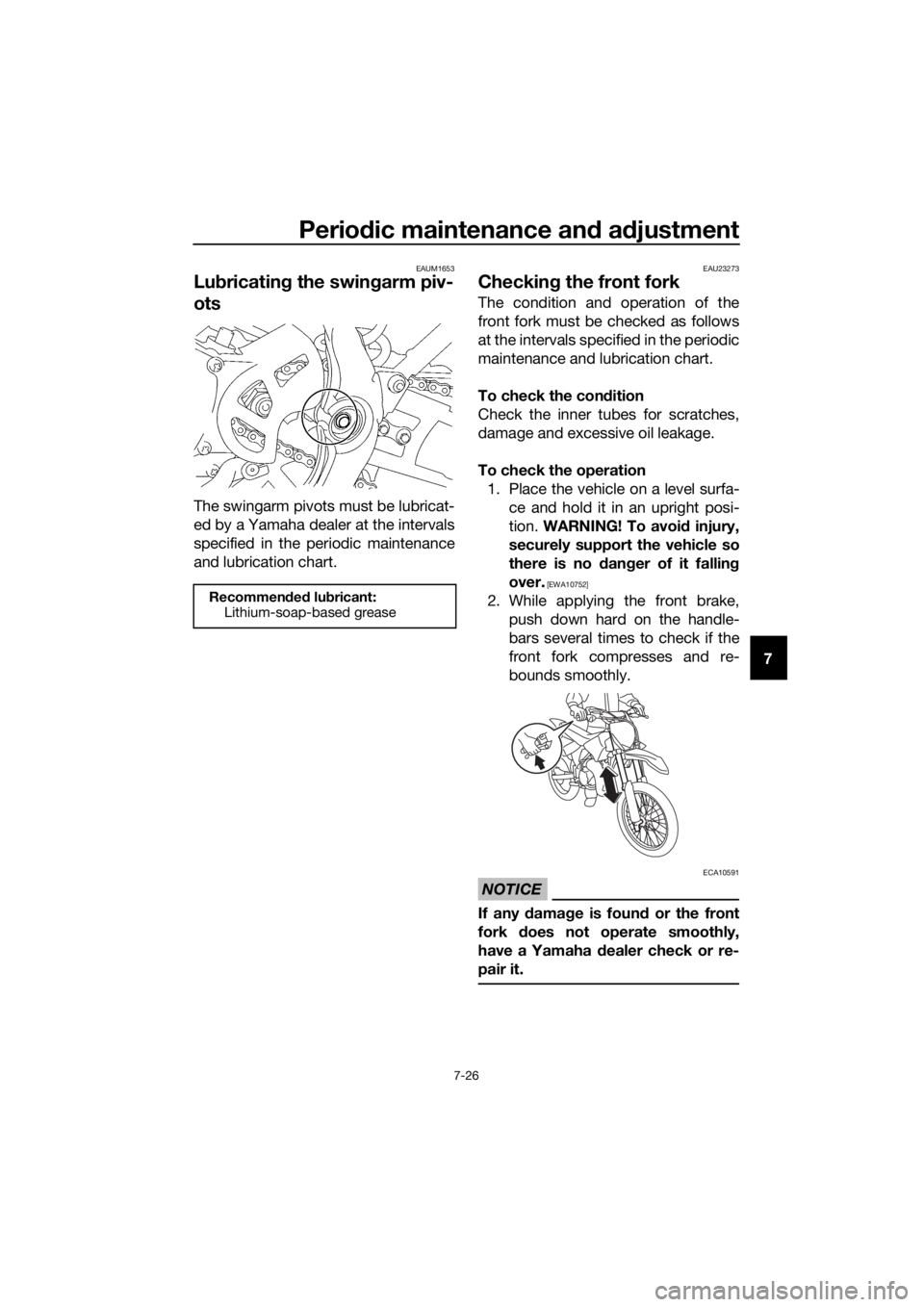

EAUM1653

Lub ricatin g the swin garm piv-

ots

The swingarm pivots must be lubricat-

ed by a Yamaha dealer at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU23273

Checkin g the front fork

The condition and operation of the

front fork must be checked as follows

at the intervals specified in the periodic

maintenance and lubrication chart.

To check the con dition

Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation 1. Place the vehicle on a level surfa- ce and hold it in an upright posi-

tion. WARNING! To avoi d injury,

securely support the vehicle so

there is no dan ger of it fallin g

over.

[EWA10752]

2. While applying the front brake, push down hard on the handle-

bars several times to check if the

front fork compresses and re-

bounds smoothly.

NOTICE

ECA10591

If any damag e is foun d or the front

fork does not operate smoothly,

have a Yamaha d ealer check or re-

pair it.

Recommen ded lu bricant:

Lithium-soap-based grease

U1SN85E0.book Page 26 Friday, June 10, 2016 1:20 PM

Page 79 of 88

Motorcycle care and stora ge

8-1

8

EAU37834

Matte color caution

NOTICE

ECA15193

Some mo dels are equipped with

matte colored finished parts. Be

sure to consult a Yamaha dealer for

a d vice on what pro ducts to use be-

fore cleanin g the vehicle. Usin g a

b rush, harsh chemical prod ucts or

cleanin g compoun ds when cleanin g

these parts will scratch or damag e

their surface. Wax also shoul d not

b e applie d to any matte colored fin-

ishe d parts.

EAU41359

Care

While the open design of a motorcycle

reveals the attractiveness of the tech-

nology, it also makes it more vulnera-

ble. Rust and corrosion can develop

even if high-quality components are

used. A rusty exhaust pipe may go un-

noticed on a car, however, it detracts

from the overall appearance of a mo-

torcycle. Frequent and proper care

does not only comply with the terms of

the warranty, but it will also keep your

motorcycle looking good, extend its

life and optimize its performance.

Before cleanin g

1. Cover the muffler outlet with a plastic bag after the engine has

cooled down.

2. Make sure that all caps and cov- ers as well as all electrical cou-

plers and connectors, including

the spark plug cap, are tightly in-

stalled.

3. Remove extremely stubborn dirt, like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such prod-

ucts onto seals, gaskets, sprock-

ets, the drive chain and wheel

axles. Always rinse the dirt and

degreaser off with water.

Cleanin g

NOTICE

ECA17692

Avoi d using strong aci dic wheel

cleaners, especially on spoked

wheels. If such pro ducts are

use d on har d-to-remove dirt, do

not leave the cleaner on the af-

U1SN85E0.book Page 1 Friday, June 10, 2016 1:20 PM

Page 80 of 88

Motorcycle care and stora ge

8-2

8 fected

area any lon ger than in-

structe d. Also, thorou ghly rinse

the area off with water, imme di-

ately dry it, an d then apply a cor-

rosion protection spray.

Improper cleanin g can d amage

plastic parts (such as cowlin gs,

panels, etc.) an d the mufflers.

Use only a soft, clean cloth or

spon ge with water to clean

plastic. However, if the plastic

parts cannot be thorou ghly

cleaned with water, dilute d mil d

d eter gent with water may b e

use d. Be sure to rinse off any

d eter gent resi due using plenty

of water, as it is harmful to plas-

tic parts.

Do not use any harsh chemical

prod ucts on plastic parts. Be

sure to avoi d using cloths or

spon ges which have been in

contact with stron g or a brasive

cleanin g prod ucts, solvent or

thinner, fuel (g asoline), rust re-

movers or inhi bitors, brake flui

d,

an

tifreeze or electrolyte.

Do not use hi gh-pressure wash-

ers or steam-jet cleaners since

they cause water seepa ge an d

d eterioration in the followin g ar-

eas: seals (of wheel an d swin g-

arm bearin gs, fork an d b rakes),

electric components (couplers,

connectors, an d switches),

b reather hoses an d vents.

After normal use

Remove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain or near the sea

Since sea salt is extremely corrosive,

carry out the following steps after each

ride in the rain or near the sea.

1. Clean the motorcycle with cold water and a mild detergent, after

the engine has cooled down.

NOTICE: Do not use warm wa-

ter since it increases the corro-

sive action of the salt.

[ECA10792]

2. Apply a corrosion protection spray on all metal, including chrome-

and nickel-plated, surfaces to pre-

vent corrosion.

After cleaning 1. Dry the motorcycle with a chamois or an absorbing cloth.

2. Immediately dry the drive chain and lubricate it to prevent it from

rusting.

3. Use a chrome polish to shine chrome, aluminum and stainless-

steel parts, including the exhaust

system.

4. To prevent corrosion, it is recom- mended to apply a corrosion pro-

tection spray on all metal,

including chrome- and nickel-plat-

ed, surfaces.

5. Use spray oil as a universal clean- er to remove any remaining dirt.

6. Touch up minor paint damage caused by stones, etc.

7. Wax all painted surfaces.

8. Let the motorcycle dry completely before storing or covering it.

U1SN85E0.book Page 2 Friday, June 10, 2016 1:20 PM

Page 81 of 88

Motorcycle care and stora ge

8-3

8

WARNING

EWA11132

Contaminants on the brakes or tires

can cause loss of control. Make sure that there is no oil or

wax on the brakes or tires.

If necessary, clean the brake

d iscs an d b rake linin gs with a

re gular brake disc cleaner or

acetone, an d wash the tires with

warm water an d a mil d d eter-

g ent. Before ri din g at hi gher

speed s, test the motorcycle’s

b rakin g performance an d cor-

nering b ehavior.

NOTICE

ECA10801

Apply spray oil an d wax spar-

in gly an d make sure to wipe off

any excess.

Never apply oil or wax to any

rubber an d plastic parts, but

treat them with a suitab le care

prod uct.

Avoi d using abrasive polishin g

compoun ds as they will wear

away the paint.

TIP

Consult a Yamaha dealer for advice on

what products to use.

EAU41515

Stora ge

Short-term

Always store your motorcycle in a cool,

dry place and, if necessary, protect it

against dust with a porous cover. Be

sure the engine and the exhaust sys-

tem are cool before covering the mo-

torcycle.

NOTICE

ECA10811

Storin g the motorcycle in a

poorly ventilate d room or cover-

in g it with a tarp, while it is still

wet, will allow water an d humi d-

ity to seep in an d cause rust.

To prevent corrosion, avoi d

d amp cellars, sta bles (b ecause

of the presence of ammonia)

an d areas where stron g chemi-

cals are stored .

Long-term

Before storing your motorcycle for sev-

eral months: 1. Follow all the instructions in the “Care” section of this chapter.

2. For motorcycles equipped with a fuel cock that has an “OFF” posi-

tion: Turn the fuel cock lever to

“OFF”.

3. Drain the fuel tank and fuel lines, and the carburetor float chamber

by loosening the drain bolt; this

will prevent fuel deposits from

building up.

4. Perform the following steps to protect the cylinder, piston rings,

etc. from corrosion.a. Remove the spark plug cap and spark plug.

U1SN85E0.book Page 3 Friday, June 10, 2016 1:20 PM