Oul YAMAHA YZ85 2017 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: YZ85, Model: YAMAHA YZ85 2017Pages: 88, PDF Size: 2.12 MB

Page 26 of 88

Instrument and control functions

4-1

4

EAU40661

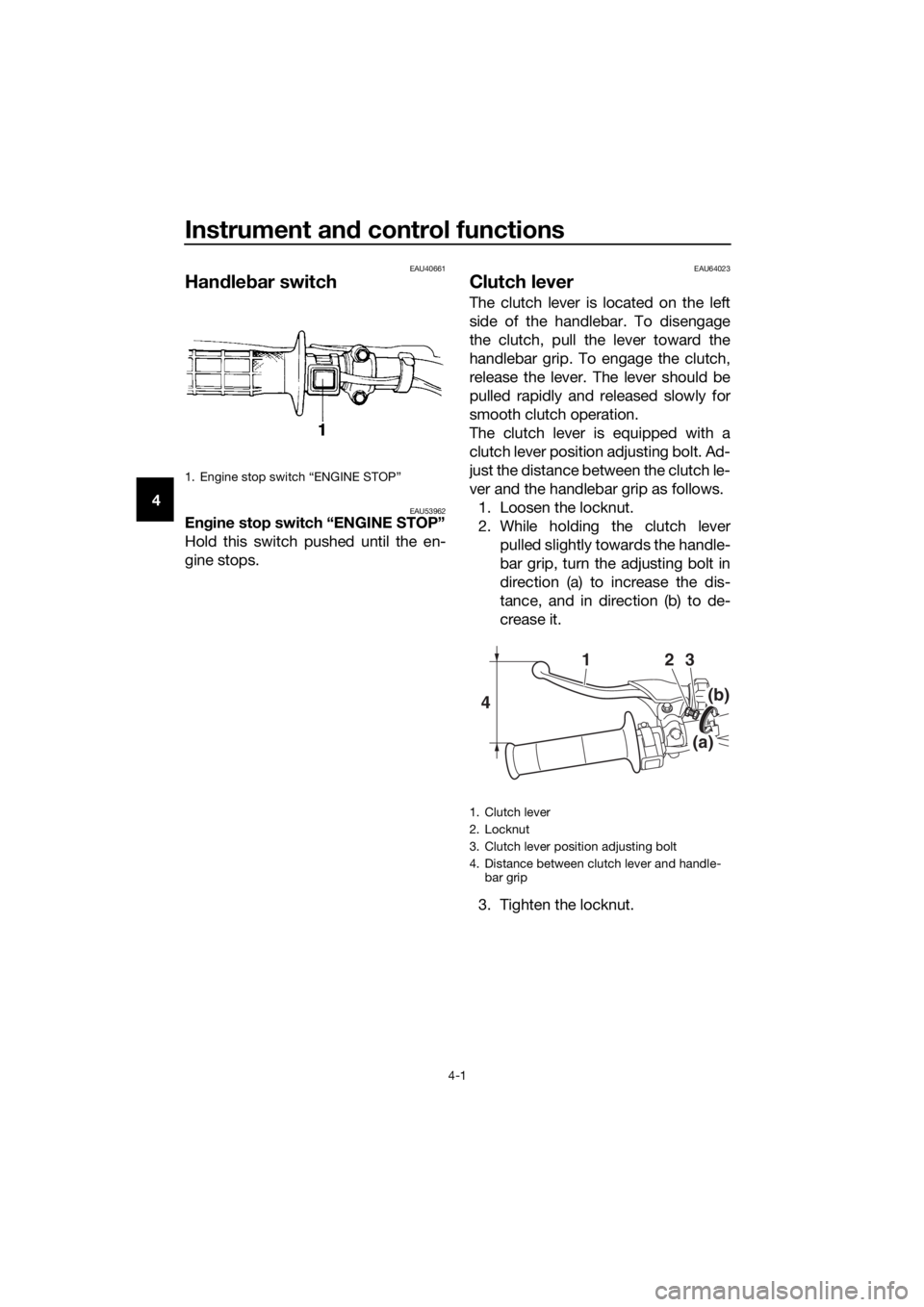

Han dle bar switch

EAU53962En gine stop switch “ENGINE STOP”

Hold this switch pushed until the en-

gine stops.

EAU64023

Clutch lever

The clutch lever is located on the left

side of the handlebar. To disengage

the clutch, pull the lever toward the

handlebar grip. To engage the clutch,

release the lever. The lever should be

pulled rapidly and released slowly for

smooth clutch operation.

The clutch lever is equipped with a

clutch lever position adjusting bolt. Ad-

just the distance between the clutch le-

ver and the handlebar grip as follows. 1. Loosen the locknut.

2. While holding the clutch lever pulled slightly towards the handle-

bar grip, turn the adjusting bolt in

direction (a) to increase the dis-

tance, and in direction (b) to de-

crease it.

3. Tighten the locknut.

1. Engine stop switch “ENGINE STOP”

1. Clutch lever

2. Locknut

3. Clutch lever position adjusting bolt

4. Distance between clutch lever and handle- bar grip

4

213

(b)

(a)

U1SN85E0.book Page 1 Friday, June 10, 2016 1:20 PM

Page 29 of 88

Instrument and control functions

4-4

4

EAU41836

Fuel

This motorcycle has been designed to

use a premixed fuel of gasoline and 2-

stroke engine oil. Always mix the gaso-

line and oil in a clean container before

filling the fuel tank.

NOTICE

ECA15602

Always use fresh g asoline, and fill

the fuel tank with a fresh mix just be-

fore ri din g. Do not use premixe d fuel

that is more than a few hours ol d.

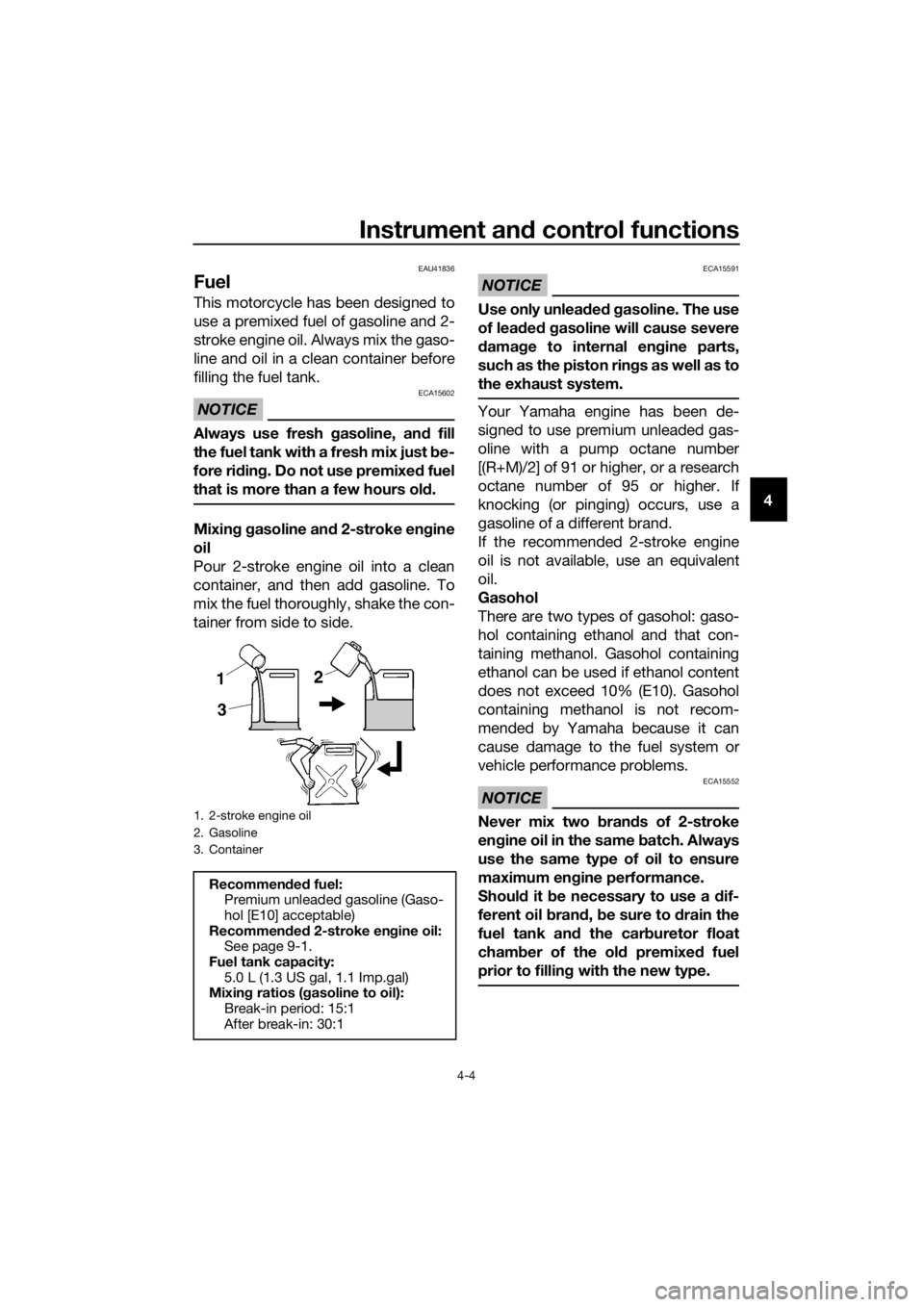

Mixin g g asoline an d 2-stroke en gine

oil

Pour 2-stroke engine oil into a clean

container, and then add gasoline. To

mix the fuel thoroughly, shake the con-

tainer from side to side.

NOTICE

ECA15591

Use only unlea ded g asoline. The use

of lead ed g asoline will cause severe

d amag e to internal en gine parts,

such as the piston rin gs as well as to

the exhaust system.

Your Yamaha engine has been de-

signed to use premium unleaded gas-

oline with a pump octane number

[(R+M)/2] of 91 or higher, or a research

octane number of 95 or higher. If

knocking (or pinging) occurs, use a

gasoline of a different brand.

If the recommended 2-stroke engine

oil is not available, use an equivalent

oil.

Gasohol

There are two types of gasohol: gaso-

hol containing ethanol and that con-

taining methanol. Gasohol containing

ethanol can be used if ethanol content

does not exceed 10% (E10). Gasohol

containing methanol is not recom-

mended by Yamaha because it can

cause damage to the fuel system or

vehicle performance problems.

NOTICE

ECA15552

Never mix two b rands of 2-stroke

en gine oil in the same b atch. Always

use the same type of oil to ensure

maximum en gine performance.

Shoul d it b e necessary to use a dif-

ferent oil bran d, b e sure to drain the

fuel tank an d the car buretor float

cham ber of the ol d premixe d fuel

prior to fillin g with the new type.1. 2-stroke engine oil

2. Gasoline

3. Container

Recommen ded fuel:

Premium unleaded gasoline (Gaso-

hol [E10] acceptable)

Recommen ded 2-stroke en gine oil:

See page 9-1.

Fuel tank capacity: 5.0 L (1.3 US gal, 1.1 Imp.gal)

Mixin g ratios ( gasoline to oil):

Break-in period: 15:1

After break-in: 30:1

U1SN85E0.book Page 4 Friday, June 10, 2016 1:20 PM

Page 30 of 88

Instrument and control functions

4-5

4 Fillin

g the fuel tank

WARNING

EWA10882

Gasoline an d g asoline vapors are

extremely flamma ble. To avoi d fires

an d explosions an d to re duce the

risk of injury when refuelin g, follow

these instructions.

1. Before refueling, turn off the en- gine and be sure that no one is sit-

ting on the vehicle. Never refuel

while smoking, or while in the vi-

cinity of sparks, open flames, or

other sources of ignition such as

the pilot lights of water heaters

and clothes dryers.

2. Do not overfill the fuel tank. Stop filling when the fuel reaches the

bottom of the filler tube. Because

fuel expands when it heats up,

heat from the engine or the sun

can cause fuel to spill out of the

fuel tank.

3. Wipe up any spilled fuel immedi- ately. NOTICE: Immediately

wipe off spille d fuel with a clean,

d ry, soft cloth, since fuel may

d eteriorate painted surfaces or

plastic parts.

[ECA10072]

4. Be sure to securely close the fuel tank cap.

WARNING

EWA15152

Gasoline is poisonous an d can cau-

se injury or death. Han dle gasoline

with care. Never siphon gasoline by

mouth. If you shoul d swallow some

g asoline or inhale a lot of gasoline

vapor, or get some g asoline in your

eyes, see your doctor imme diately. If

g asoline spills on your skin, wash

with soap an d water. If gasoline

spills on your clothin g, chan ge your

clothes.

1. Maximum fuel level

2. Fuel tank filler tube

U1SN85E0.book Page 5 Friday, June 10, 2016 1:20 PM

Page 34 of 88

Instrument and control functions

4-9

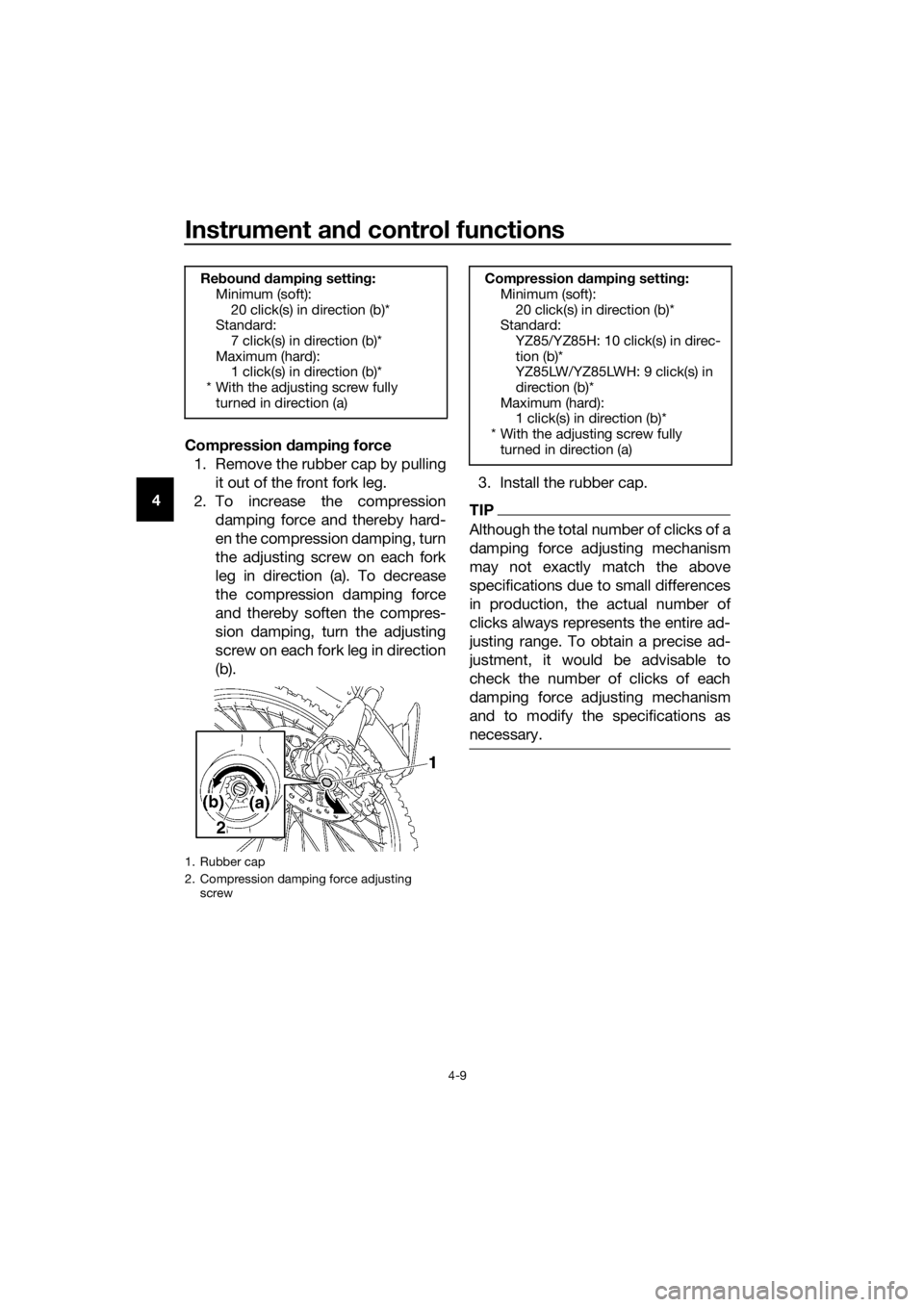

4 Compression

dampin g force

1. Remove the rubber cap by pulling it out of the front fork leg.

2. To increase the compression damping force and thereby hard-

en the compression damping, turn

the adjusting screw on each fork

leg in direction (a). To decrease

the compression damping force

and thereby soften the compres-

sion damping, turn the adjusting

screw on each fork leg in direction

(b). 3. Install the rubber cap.TIP

Although the total number of clicks of a

damping force adjusting mechanism

may not exactly match the above

specifications due to small differences

in production, the actual number of

clicks always represents the entire ad-

justing range. To obtain a precise ad-

justment, it would be advisable to

check the number of clicks of each

damping force adjusting mechanism

and to modify the specifications as

necessary.

Re

boun d d ampin g setting :

Minimum (soft): 20 click(s) in direction (b)*

Standard:

7 click(s) in direction (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

1. Rubber cap

2. Compression damping force adjusting

screw

Compression dampin g settin g:

Minimum (soft): 20 click(s) in direction (b)*

Standard:

YZ85/YZ85H: 10 click(s) in direc-

tion (b)*

YZ85LW/YZ85LWH: 9 click(s) in

direction (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

U1SN85E0.book Page 9 Friday, June 10, 2016 1:20 PM

Page 35 of 88

Instrument and control functions

4-10

4

EAU51651

Front fork blee din g

WARNING

EWA10201

Always blee d b oth fork le gs, other-

wise poor han dlin g an d loss of sta-

b ility may result.

When riding in extremely rough condi-

tions, the air temperature and pressure

in the front fork will rise. This will in-

crease the spring preload and harden

the front suspension. If this occurs,

bleed the front fork as follows.

1. Lift the front wheel off the ground according to the procedure on

page 7-28.

TIP

When bleeding the front fork, there

should be no weight on the front end of

the vehicle.

2. Remove the bleed screws and al-low all of the air to escape from

each fork leg.

3. Install the bleed screws.

4. Lower the front wheel so that it is on the ground, install the remov-

able sidestand, and then rest the

motorcycle on it.

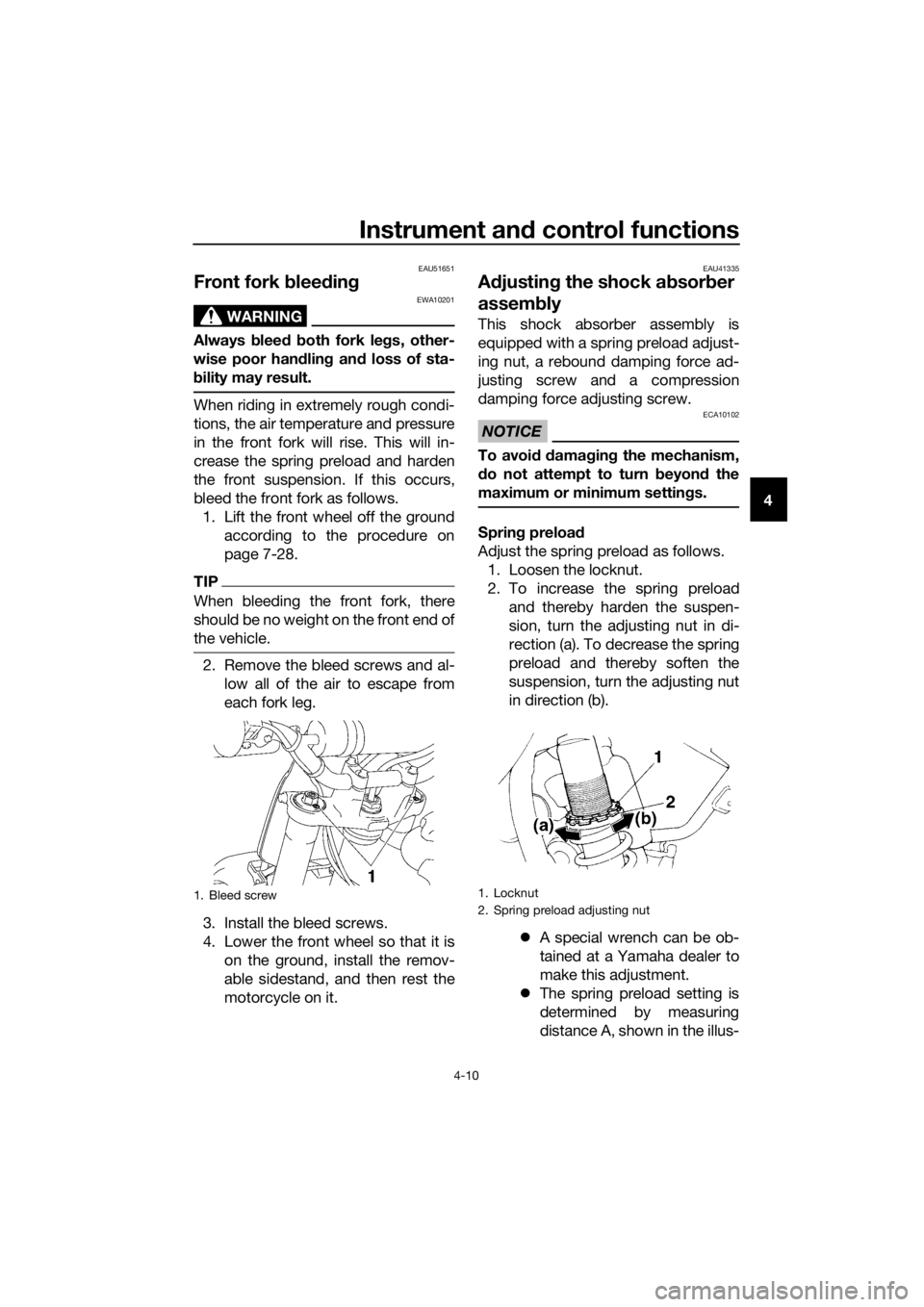

EAU41335

Adjustin g the shock a bsor ber

assem bly

This shock absorber assembly is

equipped with a spring preload adjust-

ing nut, a rebound damping force ad-

justing screw and a compression

damping force adjusting screw.

NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn b eyond the

maximum or minimum settin gs.

Sprin g preloa d

Adjust the spring preload as follows. 1. Loosen the locknut.

2. To increase the spring preload and thereby harden the suspen-

sion, turn the adjusting nut in di-

rection (a). To decrease the spring

preload and thereby soften the

suspension, turn the adjusting nut

in direction (b).

A special wrench can be ob-

tained at a Yamaha dealer to

make this adjustment.

The spring preload setting is

determined by measuring

distance A, shown in the illus-

1. Bleed screw1. Locknut

2. Spring preload adjusting nut

U1SN85E0.book Page 10 Friday, June 10, 2016 1:20 PM

Page 41 of 88

Operation and important ri din g points

6-1

6

EAU15952

Read the Owner’s Manual carefully to

become familiar with all controls. If

there is a control or function you do not

understand, ask your Yamaha dealer.

WARNING

EWA10272

Failure to familiarize yourself with

the controls can lead to loss of con-

trol, which coul d cause an acci dent

or injury.

EAU41308

Startin g an d warmin g up a

col d en gine

1. Turn the fuel cock lever to “ON”.

2. Shift the transmission into the

neutral position.

3. Turn the starter (choke) on and completely close the throttle. (See

page 4-7.)

4. Start the engine by pushing the kickstarter lever down.

5. When the engine is warm, turn the starter (choke) off.

TIP

The engine is warm when it responds

quickly to the throttle with the starter

(choke) turned off.

NOTICE

ECA11043

For maximum en gine life, never ac-

celerate har d when the en gine is

col d!

U1SN85E0.book Page 1 Friday, June 10, 2016 1:20 PM

Page 44 of 88

Operation and important rid ing points

6-4

6 be used, but sustained full-throttle

operation should be avoided.

Stop the engine and check the

spark plug again.

6. Allow the engine to cool, remove the cylinder head and cylinder,

and inspect the piston and cylin-

der. Remove any high spots on

the piston with #600-grit wet

sandpaper. Clean all components

and carefully reassemble the cyl-

inder head and cylinder.

7. Drain the break-in oil-fuel mixture from the fuel tank and refill with

the specified mix. (See page 4-4.)

8. Start the engine and check the op- eration of the motorcycle through-

out its entire operating range.

Stop the engine and check the

spark plug condition. Restart the

motorcycle and ride it for about 10

to 15 more minutes. The motorcy-

cle will now be ready to ride nor-

mally.

After the engine break-in period, thor-

oughly check the motorcycle for loose

parts, oil leakage and any other prob-

lems. Be sure to inspect and make ad-

justments thoroughly, especially cable

and drive chain slack and loose

spokes. In addition, check all fittings

and fasteners for looseness, and tight-

en if necessary.

NOTICE

ECA15561

When any of the following parts

have been replaced , they must

b e broken in.

Cylin der or crankshaft:

A bout one hour of b reak-in op-

eration is necessary. Piston, rin

gs or transmission

g ears:

These parts require a bout 30

minutes of b reak-in operation at

half-throttle or less. O bserve the

con dition of the en gine carefully

d urin g operation.

If any en gine trou ble shoul d oc-

cur durin g the en gine break-in

perio d, imme diately have a

Yamaha dealer check the vehi-

cle.

U1SN85E0.book Page 4 Friday, June 10, 2016 1:20 PM

Page 46 of 88

Periodic maintenance an d a djustment

7-1

7

EAU42074

Periodic inspection, adjustment, and

lubrication will keep your vehicle in the

safest and most efficient condition

possible. Safety is an obligation of the

vehicle owner/operator. The most im-

portant points of vehicle inspection,

adjustment, and lubrication are ex-

plained on the following pages.

The intervals given in the periodic

maintenance and lubrication chart

should be simply considered as a gen-

eral guide under normal riding condi-

tions. However, depending on the

weather, terrain, geographical location,

and individual use, the maintenance in-

tervals may need to be shortened.

WARNING

EWA10322

Failure to properly maintain the vehi-

cle or performin g maintenance ac-

tivities incorrectly may increase

your risk of injury or d eath durin g

service or while usin g the vehicle. If

you are not familiar with vehicle ser-

vice, have a Yamaha d ealer perform

service.

WARNING

EWA15123

Turn off the en gine when performin g

maintenance unless otherwise

specified .

A runnin g en gine has movin g

parts that can catch on body

parts or clothin g an d electrical

parts that can cause shocks or

fires.

Runnin g the en gine while ser-

vicin g can lead to eye injury,

b urns, fire, or car bon monoxi de

poisonin g – possi bly lea din g to d

eath. See pag e 2-2 for more in-

formation a bout car bon monox-

i d e.

WARNING

EWA15461

Brake discs, calipers, drums, an d

linin gs can b ecome very hot during

use. To avoi d possi ble burns, let

b rake components cool before

touchin g them.

U1SN85E0.book Page 1 Friday, June 10, 2016 1:20 PM

Page 47 of 88

Periodic maintenance an d a djustment

7-2

7

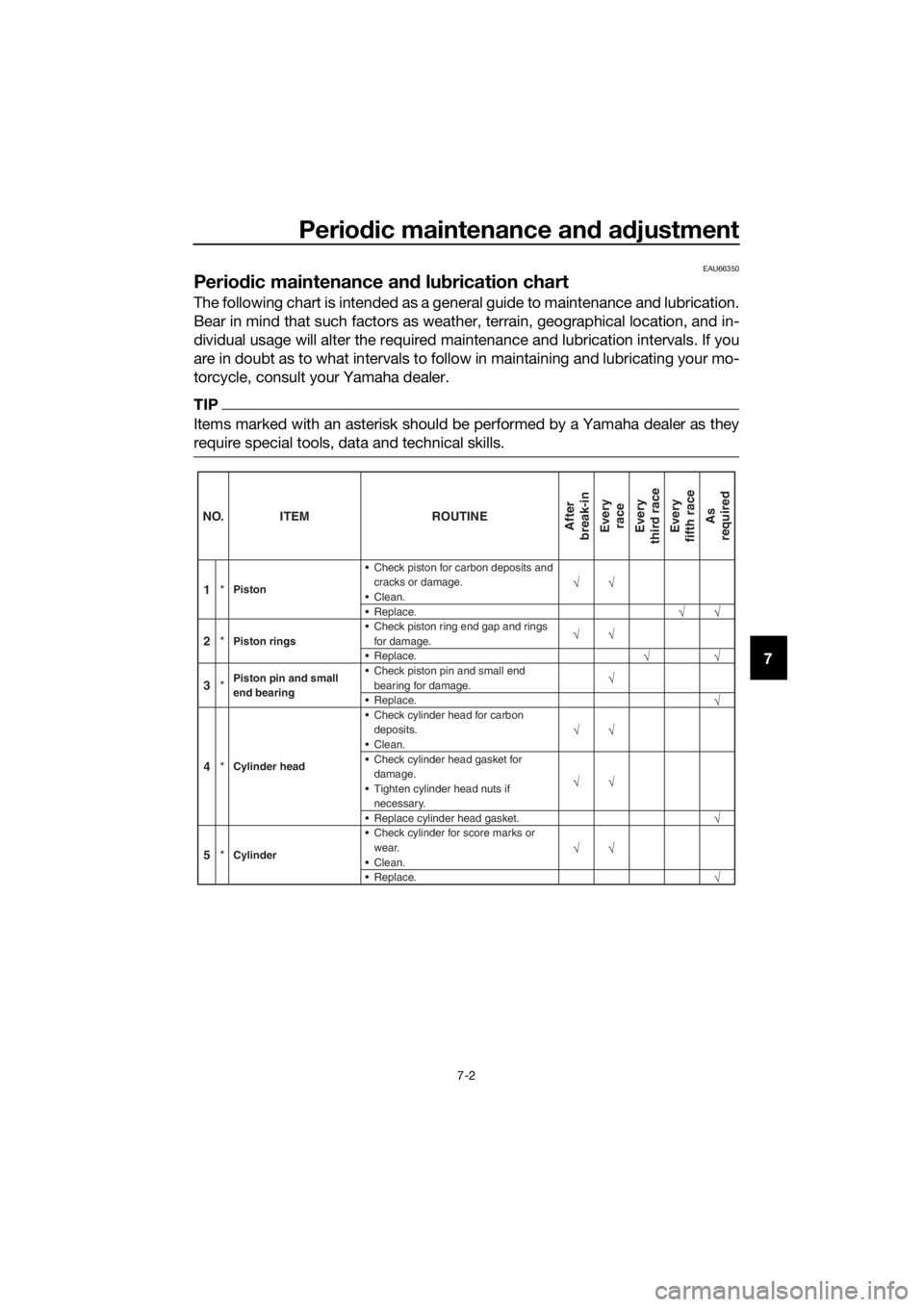

EAU66350

Perio dic maintenance an d lu brication chart

The following chart is intended as a general guide to maintenance and lubrication.

Bear in mind that such factors as weather, terrain, geographical location, and in-

dividual usage will alter the required maintenance and lubrication intervals. If you

are in doubt as to what intervals to follow in maintaining and lubricating your mo-

torcycle, consult your Yamaha dealer.

TIP

Items marked with an asterisk should be performed by a Yamaha dealer as they

require special tools, data and technical skills.

NO. ITEM ROUTINEAfter

break-in

Everyrace

Every

third race

Every

fifth race

As

required

1 *Piston Check piston for carbon deposits and

cracks or damage.√√ Clean.

Replace.

√√

2 *

Piston rings Check piston ring end gap and rings

for damage.√√

Replace.√√

3 *

Piston pin and small

end bearing Check piston pin and small end

bearing for damage.√

Replace.√

4 *

Cylinder head Check cylinder head for carbon

deposits.

√√ Clean.

Check cylinder head gasket for damage.

√√ Tighten cylinder head nuts if necessary.

Replace cylinder head gasket.

√

5 *

Cylinder Check cylinder for score marks or

wear.√√ Clean.

Replace.

√

U1SN85E0.book Page 2 Friday, June 10, 2016 1:20 PM

Page 51 of 88

Periodic maintenance an d a djustment

7-6

7

EAU19614

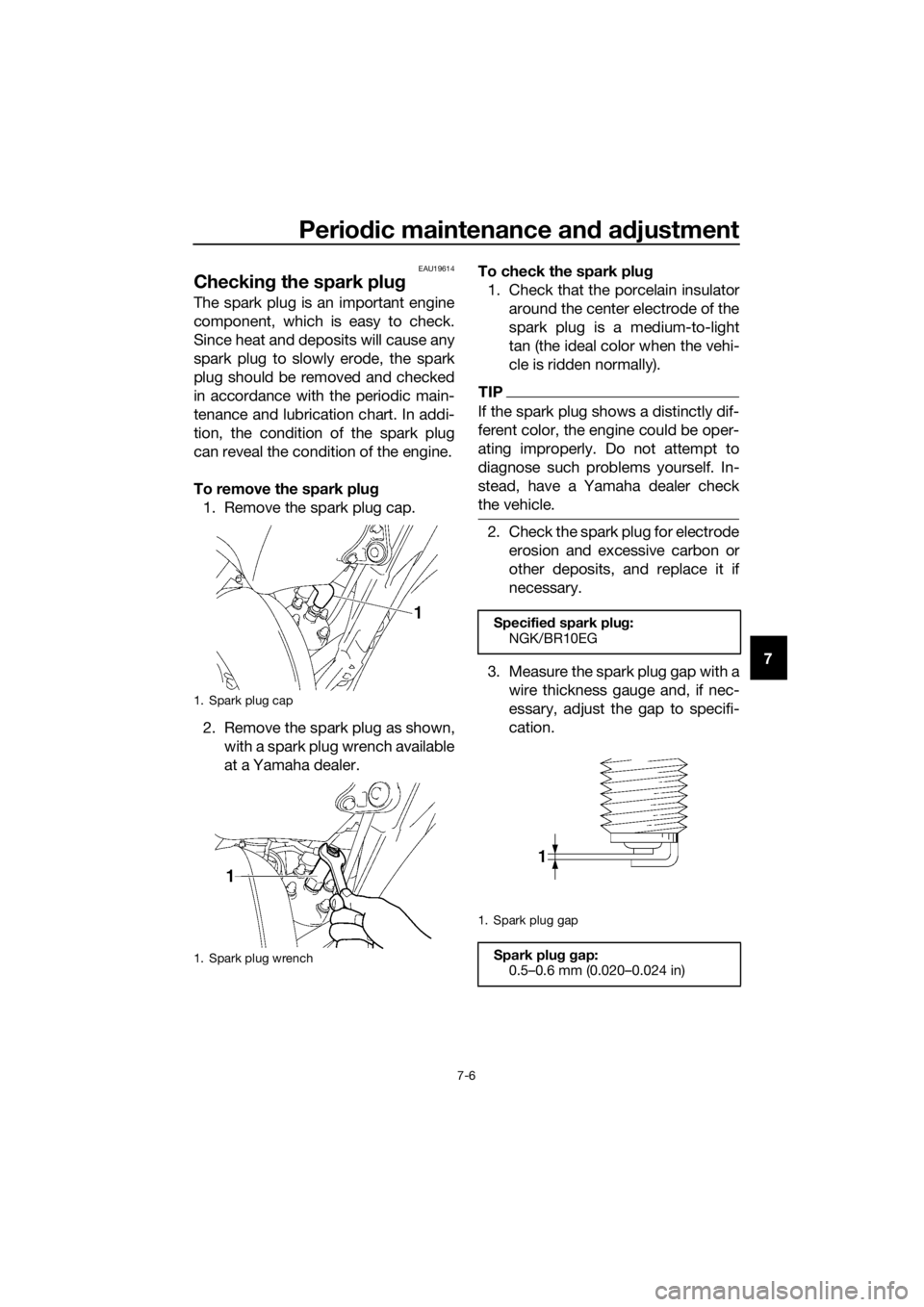

Checkin g the spark plu g

The spark plug is an important engine

component, which is easy to check.

Since heat and deposits will cause any

spark plug to slowly erode, the spark

plug should be removed and checked

in accordance with the periodic main-

tenance and lubrication chart. In addi-

tion, the condition of the spark plug

can reveal the condition of the engine.

To remove the spark plu g

1. Remove the spark plug cap.

2. Remove the spark plug as shown, with a spark plug wrench available

at a Yamaha dealer. To check the spark plu

g

1. Check that the porcelain insulator around the center electrode of the

spark plug is a medium-to-light

tan (the ideal color when the vehi-

cle is ridden normally).

TIP

If the spark plug shows a distinctly dif-

ferent color, the engine could be oper-

ating improperly. Do not attempt to

diagnose such problems yourself. In-

stead, have a Yamaha dealer check

the vehicle.

2. Check the spark plug for electrodeerosion and excessive carbon or

other deposits, and replace it if

necessary.

3. Measure the spark plug gap with a wire thickness gauge and, if nec-

essary, adjust the gap to specifi-

cation.

1. Spark plug cap

1. Spark plug wrench

Specified spark plu g:

NGK/BR10EG

1. Spark plug gap

Spark plu g g ap:

0.5–0.6 mm (0.020–0.024 in)

U1SN85E0.book Page 6 Friday, June 10, 2016 1:20 PM