engine YAMAHA YZF-R125 2015 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: YZF-R125, Model: YAMAHA YZF-R125 2015Pages: 98, PDF Size: 6.92 MB

Page 40 of 98

OPERATION AND IMPORTANT RIDING POINTS

5-2

5

NOTICE

ECA11834

If a warning or indicator light does

not come on initially when the key is

turned to “ON”, or if a warning or in-

dicator light remains on, see page

3-2 for the corresponding warning

and indicator light circuit check.

For ABS models:The ABS warning light should

come on when the key is turned to

“ON”, and then go off after travel-

ing at a speed of 10 km/h (6 mi/h)

or higher.

NOTICE

ECA17682

If the ABS warning light does not

come on and then go off as ex-

plained above, see page 3-2 for the

warning light circuit check.2. Shift the transmission into the

neutral position. The neutral indi-

cator light should come on. If not,

ask a Yamaha dealer to check the

electrical circuit.

3. Start the engine by pushing the

start switch.If the engine fails to start, release

the start switch, wait a few sec-

onds, and then try again. Each

starting attempt should be as

short as possible to preserve the

battery. Do not crank the engine

more than 10 seconds on any one

attempt.

NOTICE

ECA11043

For maximum engine life, never ac-

celerate hard when the engine is

cold!

EAU16673

ShiftingShifting gears lets you control the

amount of engine power available for

starting off, accelerating, climbing hills,

etc.

The gear positions are shown in the il-

lustration.TIPTo shift the transmission into the neu-

tral position, press the shift pedal down

repeatedly until it reaches the end of its

travel, and then slightly raise it.1. Shift pedal

2. Neutral positionZAUM1167

1 N2 3 4 5

6

1

2

U5D7E5E0.book Page 2 Thursday, August 21, 2014 9:30 AM

Page 41 of 98

OPERATION AND IMPORTANT RIDING POINTS

5-3

5

NOTICE

ECA10261

Even with the transmission in

the neutral position, do not

coast for long periods of time

with the engine off, and do not

tow the motorcycle for long dis-

tances. The transmission is

properly lubricated only when

the engine is running. Inade-

quate lubrication may damage

the transmission.

Always use the clutch while

changing gears to avoid dam-

aging the engine, transmission,

and drive train, which are not

designed to withstand the

shock of forced shifting.

EAU16811

Tips for reducing fuel con-

sumptionFuel consumption depends largely on

your riding style. Consider the follow-

ing tips to reduce fuel consumption:

Shift up swiftly, and avoid high en-

gine speeds during acceleration.

Do not rev the engine while shift-

ing down, and avoid high engine

speeds with no load on the en-

gine.

Turn the engine off instead of let-

ting it idle for an extended length

of time (e.g., in traffic jams, at traf-

fic lights or at railroad crossings).

EAU16831

Engine break-inThere is never a more important period

in the life of your engine than the period

between 0 and 1000 km (600 mi). For

this reason, you should read the fol-

lowing material carefully.

Since the engine is brand new, do not

put an excessive load on it for the first

1000 km (600 mi). The various parts in

the engine wear and polish themselves

to the correct operating clearances.

During this period, prolonged full-throt-

tle operation or any condition that

might result in engine overheating

must be avoided.

EAU16983

0–500 km (0–300 mi)

Avoid prolonged operation above 6000

r/min.

After every hour of operation, stop the

engine, and then let it cool for five to

ten minutes.

Vary the engine speed from time to

time. Do not operate the engine at one

set throttle position.

U5D7E5E0.book Page 3 Thursday, August 21, 2014 9:30 AM

Page 42 of 98

OPERATION AND IMPORTANT RIDING POINTS

5-4

5500–1000 km (300–600 mi)

Avoid prolonged operation above 8000

r/min.

Rev the engine freely through the

gears, but do not use full throttle at any

time. NOTICE: After 1000 km (600 mi)

of operation, the engine oil must be

changed, the oil filter cartridge or el-

ement replaced, and the oil strainer

cleaned.

[ECA10322]

1000 km (600 mi) and beyond

The vehicle can now be operated nor-

mally.NOTICE

ECA10311

Keep the engine speed out of

the tachometer red zone.

If any engine trouble should oc-

cur during the engine break-in

period, immediately have a

Yamaha dealer check the vehi-

cle.

EAU17214

ParkingWhen parking, stop the engine, and

then remove the key from the main

switch.

WARNING

EWA10312

Since the engine and exhaust

system can become very hot,

park in a place where pedestri-

ans or children are not likely to

touch them and be burned.

Do not park on a slope or on soft

ground, otherwise the vehicle

may overturn, increasing the

risk of a fuel leak and fire.

Do not park near grass or other

flammable materials which

might catch fire.

U5D7E5E0.book Page 4 Thursday, August 21, 2014 9:30 AM

Page 43 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-1

6

EAU17245

Periodic inspection, adjustment, and

lubrication will keep your vehicle in the

safest and most efficient condition

possible. Safety is an obligation of the

vehicle owner/operator. The most im-

portant points of vehicle inspection,

adjustment, and lubrication are ex-

plained on the following pages.

The intervals given in the periodic

maintenance charts should be simply

considered as a general guide under

normal riding conditions. However, de-

pending on the weather, terrain, geo-

graphical location, and individual use,

the maintenance intervals may need to

be shortened.

WARNING

EWA10322

Failure to properly maintain the vehi-

cle or performing maintenance ac-

tivities incorrectly may increase

your risk of injury or death during

service or while using the vehicle. If

you are not familiar with vehicle ser-

vice, have a Yamaha dealer perform

service.

WARNING

EWA15123

Turn off the engine when performing

maintenance unless otherwise

specified.

A running engine has moving

parts that can catch on body

parts or clothing and electrical

parts that can cause shocks or

fires.

Running the engine while ser-

vicing can lead to eye injury,

burns, fire, or carbon monoxide

poisoning – possibly leading to

death. See page 1-3 for more in-

formation about carbon monox-

ide.

WARNING

EWA15461

Brake discs, calipers, drums, and

linings can become very hot during

use. To avoid possible burns, let

brake components cool before

touching them.

EAU17303

Emission controls not only function to

ensure cleaner air, but are also vital to

proper engine operation and maximum

performance. In the following periodic

maintenance charts, the services relat-

ed to emissions control are grouped

separately. These services require

specialized data, knowledge, and

equipment. Maintenance, replace-

ment, or repair of the emission control

devices and systems may be per-

formed by any repair establishment or

individual that is certified (if applicable).

Yamaha dealers are trained and

equipped to perform these particular

services.

U5D7E5E0.book Page 1 Thursday, August 21, 2014 9:30 AM

Page 45 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-3

6

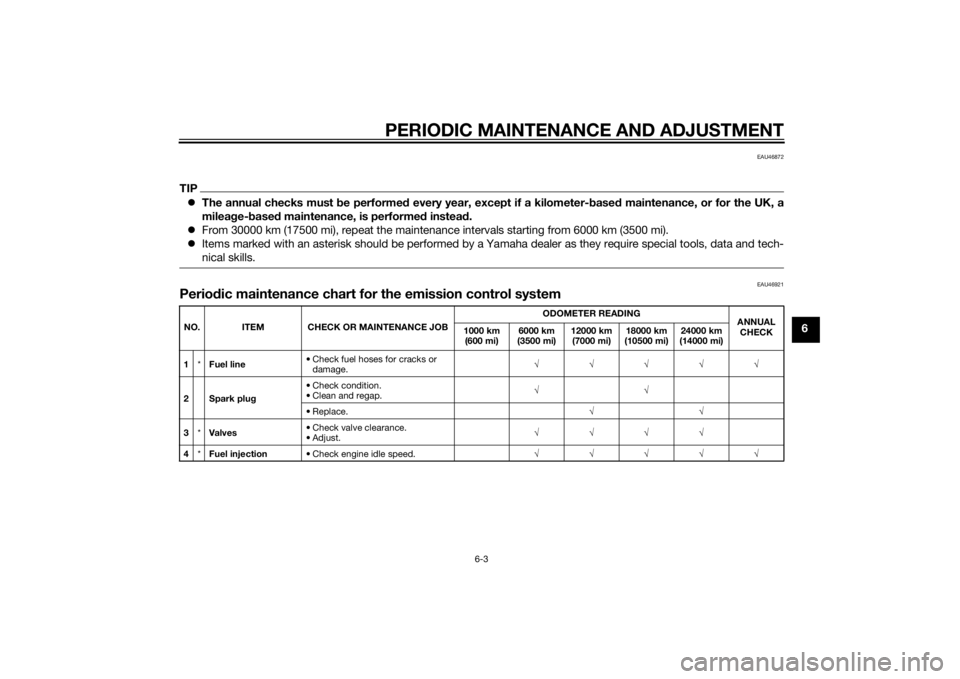

EAU46872

TIPThe annual checks must be performed every year, except if a kilometer-based maintenance, or for the UK, a

mileage-based maintenance, is performed instead.

From 30000 km (17500 mi), repeat the maintenance intervals starting from 6000 km (3500 mi).

Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and tech-

nical skills.

EAU46921

Periodic maintenance chart for the emission control systemNO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING

ANNUAL

CHECK 1000 km

(600 mi)6000 km

(3500 mi)12000 km

(7000 mi)18000 km

(10500 mi)24000 km

(14000 mi)

1*Fuel line• Check fuel hoses for cracks or

damage.√√√√√

2 Spark plug• Check condition.

• Clean and regap.√√

•Replace.√√

3*Valves• Check valve clearance.

•Adjust.√√√√

4*Fuel injection• Check engine idle speed.√√√√√

U5D7E5E0.book Page 3 Thursday, August 21, 2014 9:30 AM

Page 48 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-6

6

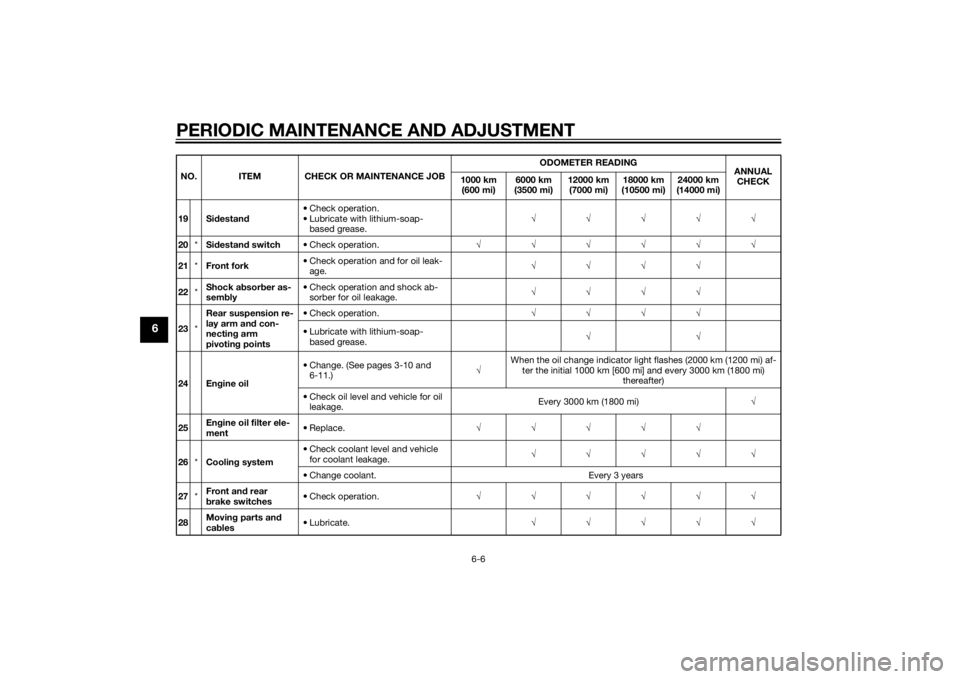

19 Sidestand• Check operation.

• Lubricate with lithium-soap-

based grease.√√√√√

20*Sidestand switch• Check operation.√√√√√√

21*Front fork• Check operation and for oil leak-

age.√√√√

22*Shock absorber as-

sembly• Check operation and shock ab-

sorber for oil leakage.√√√√

23*Rear suspension re-

lay arm and con-

necting arm

pivoting points• Check operation.√√√√

• Lubricate with lithium-soap-

based grease.√√

24 Engine oil• Change. (See pages 3-10 and

6-11.)√When the oil change indicator light flashes (2000 km (1200 mi) af-

ter the initial 1000 km [600 mi] and every 3000 km (1800 mi)

thereafter)

• Check oil level and vehicle for oil

leakage.Every 3000 km (1800 mi)√

25Engine oil filter ele-

ment• Replace.√√√√√

26*Cooling system• Check coolant level and vehicle

for coolant leakage.√√√√√

• Change coolant. Every 3 years

27*Front and rear

brake switches• Check operation.√√√√√√

28Moving parts and

cables

• Lubricate.√√√√√ NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING

ANNUAL

CHECK 1000 km

(600 mi)6000 km

(3500 mi)12000 km

(7000 mi)18000 km

(10500 mi)24000 km

(14000 mi)

U5D7E5E0.book Page 6 Thursday, August 21, 2014 9:30 AM

Page 52 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-10

6To install the panel

1. Place the panel in the original po-

sition, and then install the screws.

2. Install the rider seat.

EAU19633

Checking the spark plugThe spark plug is an important engine

component, which is easy to check.

Since heat and deposits will cause any

spark plug to slowly erode, the spark

plug should be removed and checked

in accordance with the periodic main-

tenance and lubrication chart. In addi-

tion, the condition of the spark plug

can reveal the condition of the engine.

To remove the spark plug

1. Remove cowling A. (See page

6-8.)

2. Remove the spark plug cap.3. Remove the spark plug as shown,

with the spark plug wrench includ-

ed in the owner’s tool kit.

To check the spark plug

1. Check that the porcelain insulator

around the center electrode of the

spark plug is a medium-to-light

tan (the ideal color when the vehi-

cle is ridden normally).

TIPIf the spark plug shows a distinctly dif-

ferent color, the engine could be oper-

ating improperly. Do not attempt to

diagnose such problems yourself. In-

stead, have a Yamaha dealer check

the vehicle.

1. Screw

2. Panel A

1. Spark plug cap

1. Spark plug wrench

U5D7E5E0.book Page 10 Thursday, August 21, 2014 9:30 AM

Page 53 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-11

6 2. Check the spark plug for electrode

erosion and excessive carbon or

other deposits, and replace it if

necessary.

To install the spark plug

1. Measure the spark plug gap with a

wire thickness gauge and, if nec-

essary, adjust the gap to specifi-

cation.2. Clean the surface of the spark

plug gasket and its mating sur-

face, and then wipe off any grime

from the spark plug threads.

3. Install the spark plug with the

spark plug wrench, and then tight-

en it to the specified torque.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4…

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.4. Install the spark plug cap.

5. Install the cowling.

EAUM3490

Engine oil and oil filter ele-

mentThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart.

To check the engine oil level

1. Place the vehicle on a level sur-

face and hold it in an upright posi-

tion. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Wait a few minutes until the oil set-

tles, remove the oil filler cap, wipe

the dipstick clean, insert it back

into the oil filler hole (without

screwing it in), and then remove it

again to check the oil level.

NOTICE: Do not operate the ve-

hicle until you know that the en-

gine oil level is sufficient.

[ECA10012]

Specified spark plug:

NGK/CR9E1. Spark plug gapSpark plug gap:

0.7–0.8 mm (0.028–0.031 in)

1

ZAUM0037

Tightening torque:

Spark plug:

12.5 Nm (1.25 m·kgf, 9.04 ft·lbf)

U5D7E5E0.book Page 11 Thursday, August 21, 2014 9:30 AM

Page 54 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-12

6

TIPThe engine oil should be between the

minimum and maximum level marks.

4. If the engine oil is below the mini-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Install the oil filler cap.

To change the engine oil (with or

without oil filter element replace-

ment)

1. Remove cowling D. (See page

6-8.)

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Install the engine oil drain attach-

ment, provided with the owner’s

tool kit, under the drain bolt of the

crankcase.4. Place an oil pan under the engine

to collect the used oil.

5. Remove the engine oil filler cap

and the drain bolt along with the

O-ring, compression spring, and

engine oil strainer, to drain the oil

from the crankcase. NOTICE:

When removing the engine oil

drain bolt, the O-ring, compres-

sion spring, and oil strainer will

fall out. Take care not to lose

these parts.

[ECA11002]

1. Engine oil filler cap

1. Dipstick

2. Maximum level mark

3. Minimum level mark

1

2

3

ZAUE1300

1. Engine oil drain bolt (crankcase)

2. Engine oil drain attachmentZAUM1229

2

U5D7E5E0.book Page 12 Thursday, August 21, 2014 9:30 AM

Page 55 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-13

6

6. Clean the engine oil strainer with

solvent.

TIPSkip steps 7…9 if the oil filter element is

not being replaced.7. Remove the oil filter element cover

by removing the bolts.8. Remove and replace the oil filter

element and O-ring.9. Install the oil filter element cover

by installing the bolts, then tight-

ening them to the specified

torque.

TIPMake sure that the O-ring is properly

seated.10. Install the engine oil strainer, com-

pression spring, O-ring and the

engine oil drain bolt, and then

tighten it to the specified torque.

NOTICE: Before installing the

engine oil drain bolt, do not for-

get to install the O-ring, com-

pression spring, and oil strainer

in position.

[ECA10422]

1. Engine oil drain bolt

2. O-ring

3. Compression spring

4. Strainer

5. Oil pan

1. Bolt

2. Oil filter element cover

1. Oil filter element

2. O-ring

Tightening torques:

Oil filter element cover bolt:

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Tightening torques:

Engine oil drain bolt:

32 Nm (3.2 m·kgf, 23 ft·lbf)

U5D7E5E0.book Page 13 Thursday, August 21, 2014 9:30 AM