light YAMAHA YZF-R125 2016 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZF-R125, Model: YAMAHA YZF-R125 2016Pages: 98, PDF Size: 6.87 MB

Page 49 of 98

Periodic maintenance and adjustment

6-7

6

EAU18732

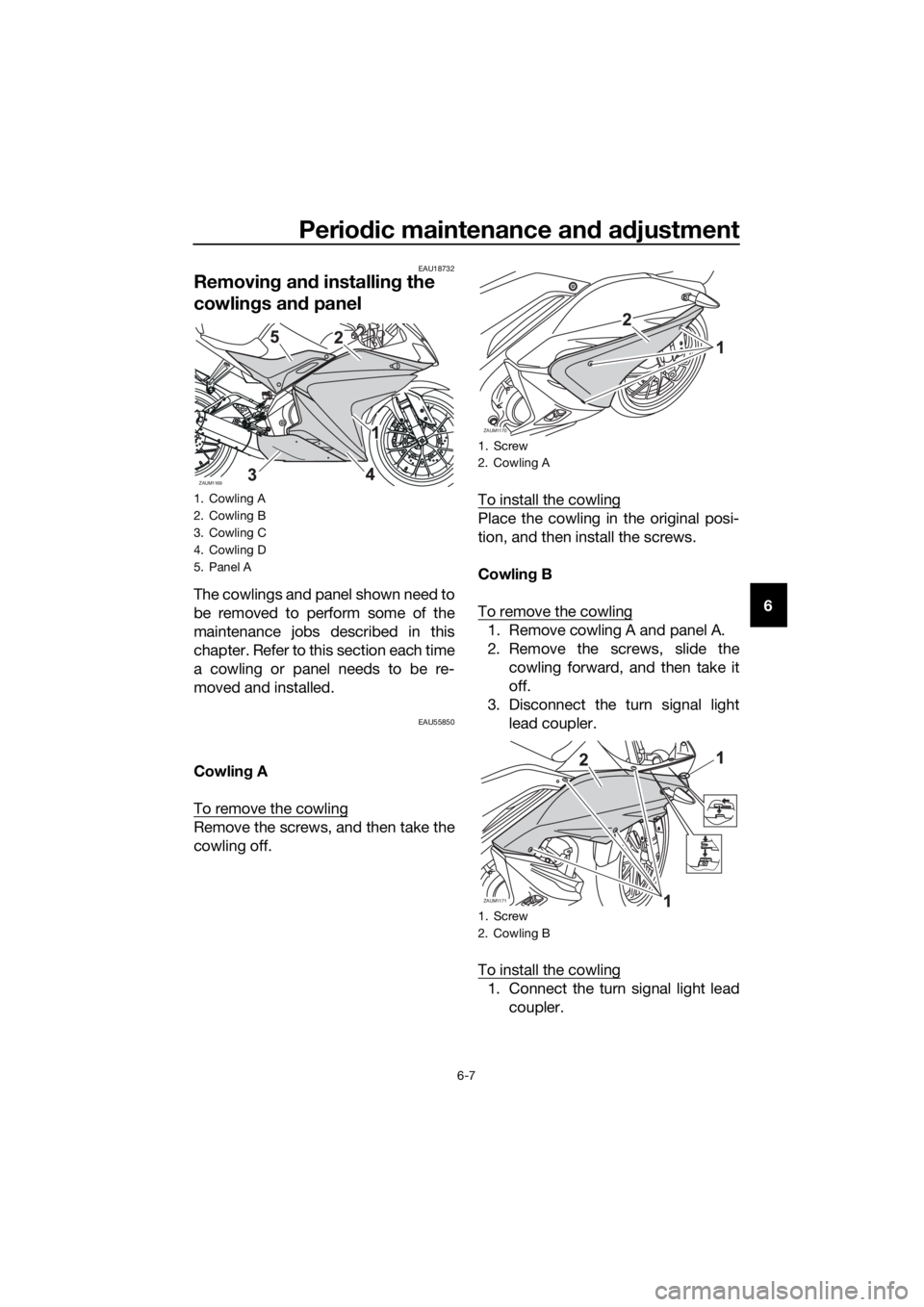

Removing and installing the

cowlings and panel

The cowlings and panel shown need to

be removed to perform some of the

maintenance jobs described in this

chapter. Refer to this section each time

a cowling or panel needs to be re-

moved and installed.

EAU55850

Cowling A

To remove the cowling

Remove the screws, and then take the

cowling off.To install the cowling

Place the cowling in the original posi-

tion, and then install the screws.

Cowling B

To remove the cowling

1. Remove cowling A and panel A.

2. Remove the screws, slide the

cowling forward, and then take it

off.

3. Disconnect the turn signal light

lead coupler.

To install the cowling

1. Connect the turn signal light lead

coupler.

1. Cowling A

2. Cowling B

3. Cowling C

4. Cowling D

5. Panel A

ZAUM1169

1. Screw

2. Cowling A

1. Screw

2. Cowling B

ZAUM1170

ZAUM1171

U5D7E6E0.book Page 7 Wednesday, June 17, 2015 10:25 AM

Page 52 of 98

Periodic maintenance and adjustment

6-10

6To check the spark plug

1. Check that the porcelain insulator

around the center electrode of the

spark plug is a medium-to-light

tan (the ideal color when the vehi-

cle is ridden normally).

TIP

If the spark plug shows a distinctly dif-

ferent color, the engine could be oper-

ating improperly. Do not attempt to

diagnose such problems yourself. In-

stead, have a Yamaha dealer check

the vehicle.

2. Check the spark plug for electrode

erosion and excessive carbon or

other deposits, and replace it if

necessary.

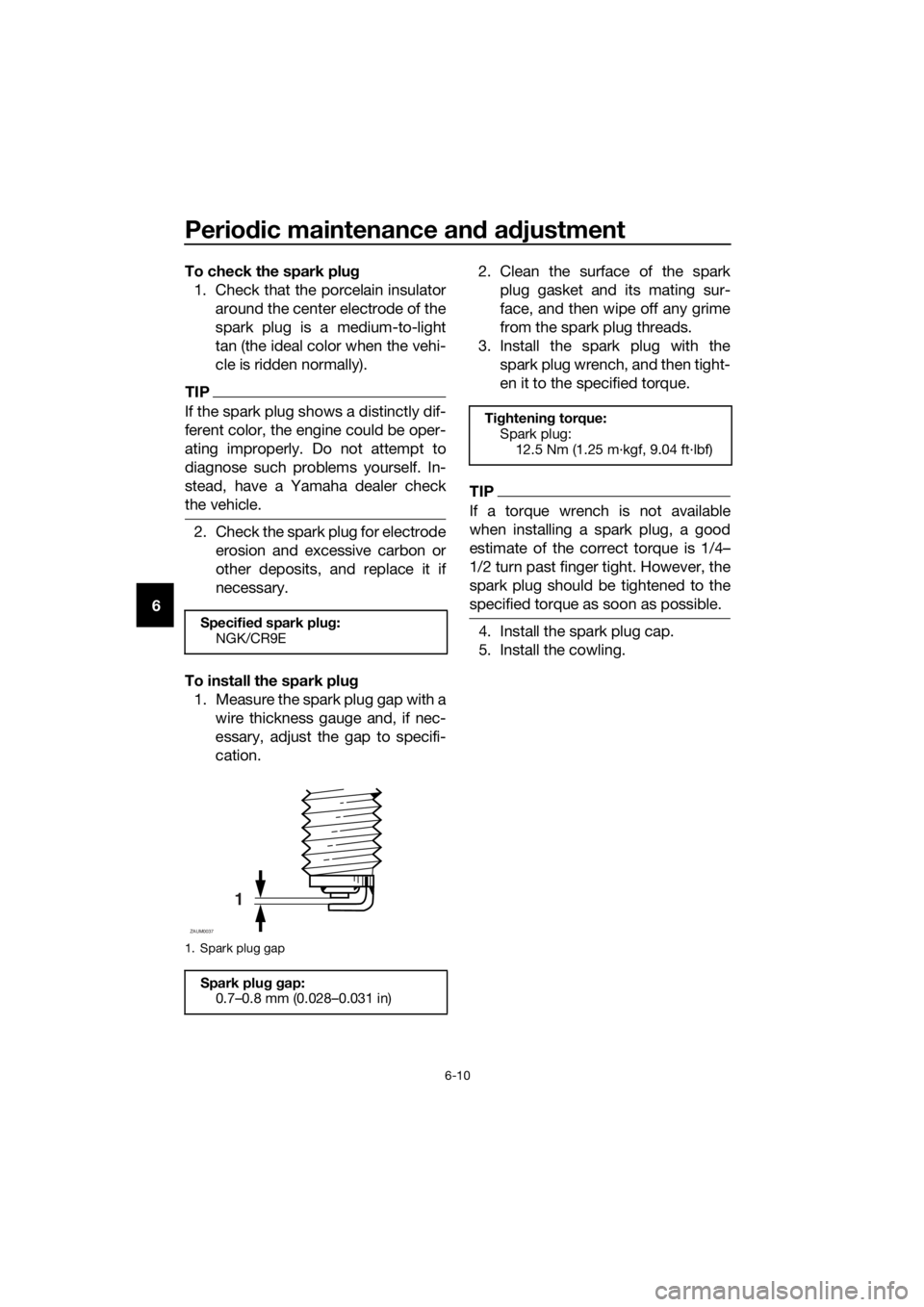

To install the spark plug

1. Measure the spark plug gap with a

wire thickness gauge and, if nec-

essary, adjust the gap to specifi-

cation.2. Clean the surface of the spark

plug gasket and its mating sur-

face, and then wipe off any grime

from the spark plug threads.

3. Install the spark plug with the

spark plug wrench, and then tight-

en it to the specified torque.

TIP

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4…

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.

4. Install the spark plug cap.

5. Install the cowling.Specified spark plug:

NGK/CR9E

1. Spark plug gap

Spark plug gap:

0.7–0.8 mm (0.028–0.031 in)

1

ZAUM0037

Tightening torque:

Spark plug:

12.5 Nm (1.25 m·kgf, 9.04 ft·lbf)

U5D7E6E0.book Page 10 Wednesday, June 17, 2015 10:25 AM

Page 53 of 98

Periodic maintenance and adjustment

6-11

6

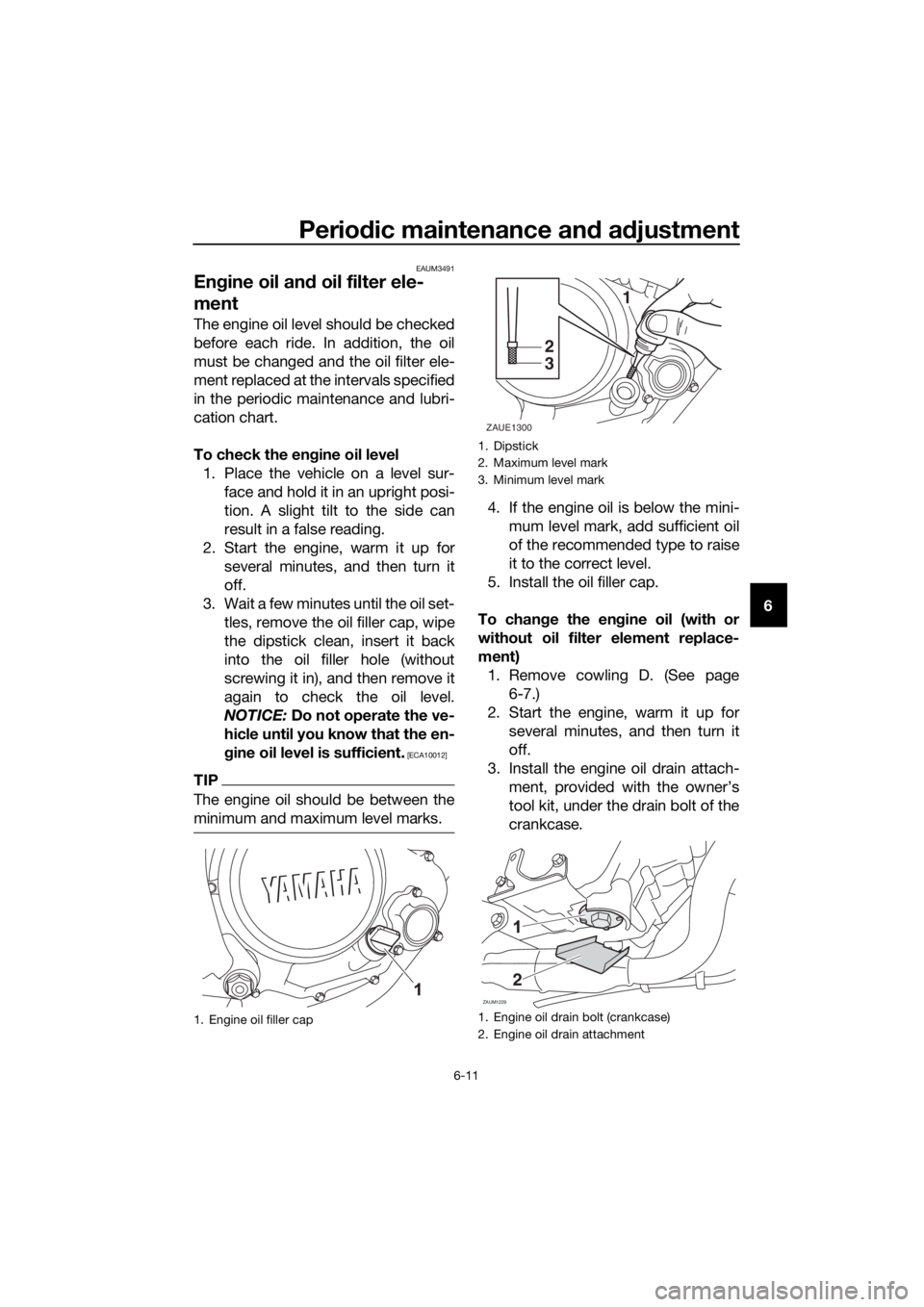

EAUM3491

Engine oil and oil filter ele-

ment

The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart.

To check the engine oil level

1. Place the vehicle on a level sur-

face and hold it in an upright posi-

tion. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Wait a few minutes until the oil set-

tles, remove the oil filler cap, wipe

the dipstick clean, insert it back

into the oil filler hole (without

screwing it in), and then remove it

again to check the oil level.

NOTICE: Do not operate the ve-

hicle until you know that the en-

gine oil level is sufficient.

[ECA10012]

TIP

The engine oil should be between the

minimum and maximum level marks.

4. If the engine oil is below the mini-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Install the oil filler cap.

To change the engine oil (with or

without oil filter element replace-

ment)

1. Remove cowling D. (See page

6-7.)

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Install the engine oil drain attach-

ment, provided with the owner’s

tool kit, under the drain bolt of the

crankcase.

1. Engine oil filler cap

1. Dipstick

2. Maximum level mark

3. Minimum level mark

1. Engine oil drain bolt (crankcase)

2. Engine oil drain attachment

1

2

3

ZAUE1300

ZAUM1229

2

U5D7E6E0.book Page 11 Wednesday, June 17, 2015 10:25 AM

Page 56 of 98

Periodic maintenance and adjustment

6-14

6

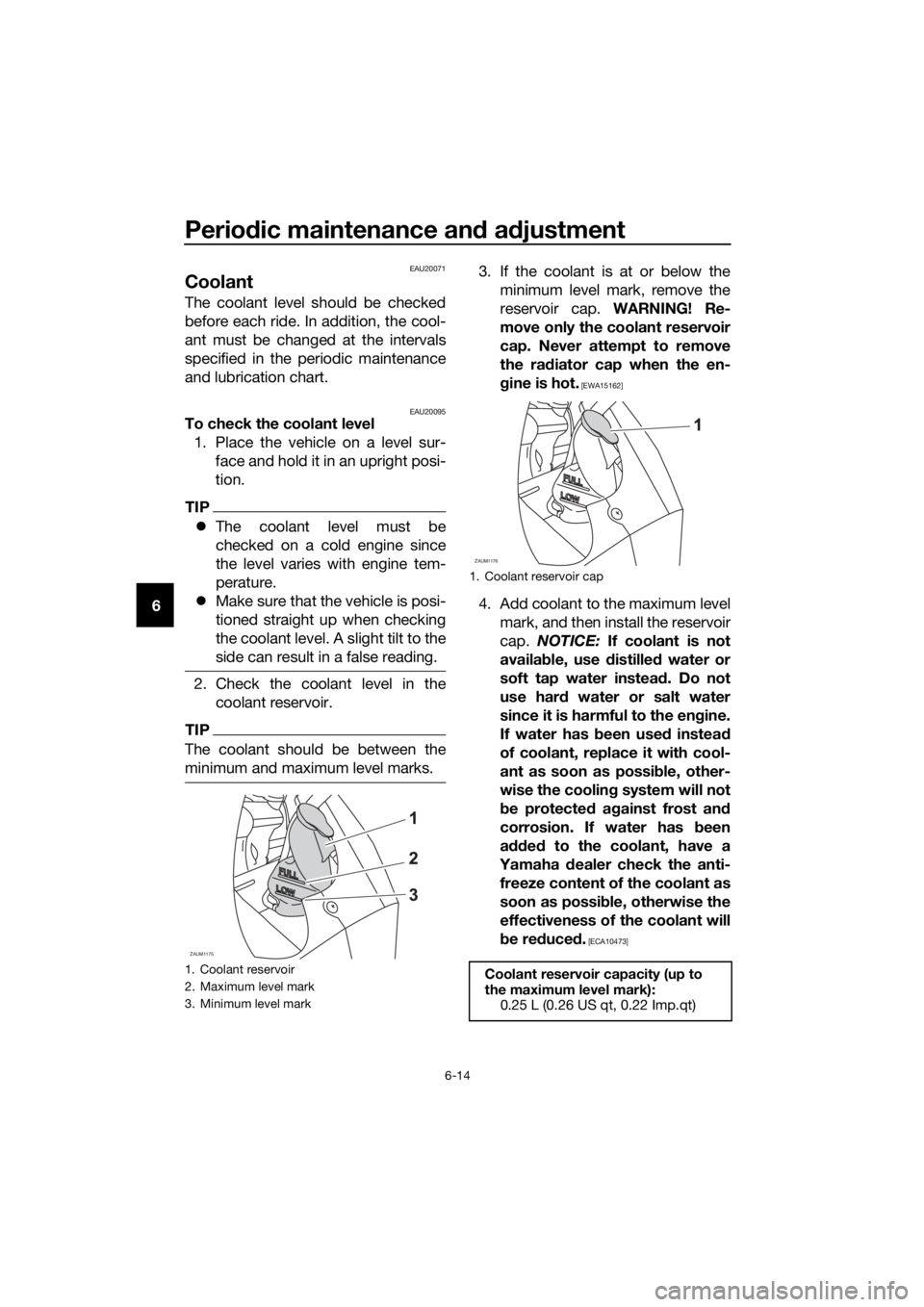

EAU20071

Coolant

The coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU20095To check the coolant level

1. Place the vehicle on a level sur-

face and hold it in an upright posi-

tion.

TIP

The coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.

2. Check the coolant level in the

coolant reservoir.

TIP

The coolant should be between the

minimum and maximum level marks.

3. If the coolant is at or below the

minimum level mark, remove the

reservoir cap. WARNING! Re-

move only the coolant reservoir

cap. Never attempt to remove

the radiator cap when the en-

gine is hot.

[EWA15162]

4. Add coolant to the maximum level

mark, and then install the reservoir

cap. NOTICE: If coolant is not

available, use distilled water or

soft tap water instead. Do not

use hard water or salt water

since it is harmful to the engine.

If water has been used instead

of coolant, replace it with cool-

ant as soon as possible, other-

wise the cooling system will not

be protected against frost and

corrosion. If water has been

added to the coolant, have a

Yamaha dealer check the anti-

freeze content of the coolant as

soon as possible, otherwise the

effectiveness of the coolant will

be reduced.

[ECA10473]

1. Coolant reservoir

2. Maximum level mark

3. Minimum level mark

ZAUM1175

1. Coolant reservoir cap

Coolant reservoir capacity (up to

the maximum level mark):

0.25 L (0.26 US qt, 0.22 Imp.qt)

ZAUM1176

U5D7E6E0.book Page 14 Wednesday, June 17, 2015 10:25 AM

Page 65 of 98

Periodic maintenance and adjustment

6-23

6

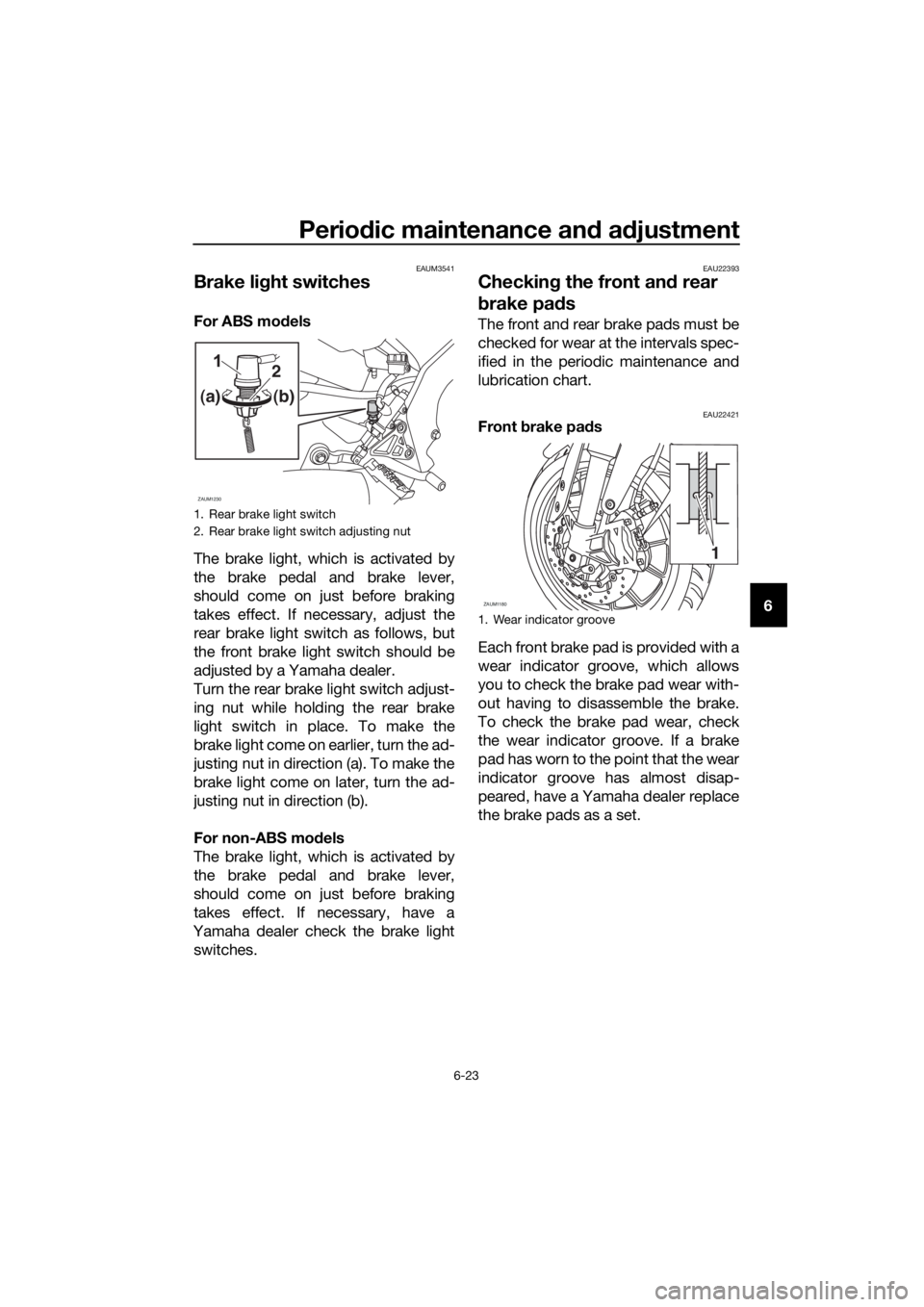

EAUM3541

Brake light switches

For ABS models

The brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, adjust the

rear brake light switch as follows, but

the front brake light switch should be

adjusted by a Yamaha dealer.

Turn the rear brake light switch adjust-

ing nut while holding the rear brake

light switch in place. To make the

brake light come on earlier, turn the ad-

justing nut in direction (a). To make the

brake light come on later, turn the ad-

justing nut in direction (b).

For non-ABS models

The brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, have a

Yamaha dealer check the brake light

switches.

EAU22393

Checking the front and rear

brake pads

The front and rear brake pads must be

checked for wear at the intervals spec-

ified in the periodic maintenance and

lubrication chart.

EAU22421Front brake pads

Each front brake pad is provided with a

wear indicator groove, which allows

you to check the brake pad wear with-

out having to disassemble the brake.

To check the brake pad wear, check

the wear indicator groove. If a brake

pad has worn to the point that the wear

indicator groove has almost disap-

peared, have a Yamaha dealer replace

the brake pads as a set.

1. Rear brake light switch

2. Rear brake light switch adjusting nut

ZAUM1230

2

(a)(b)

1. Wear indicator groove

ZAUM1180

1

U5D7E6E0.book Page 23 Wednesday, June 17, 2015 10:25 AM

Page 76 of 98

Periodic maintenance and adjustment

6-34

6

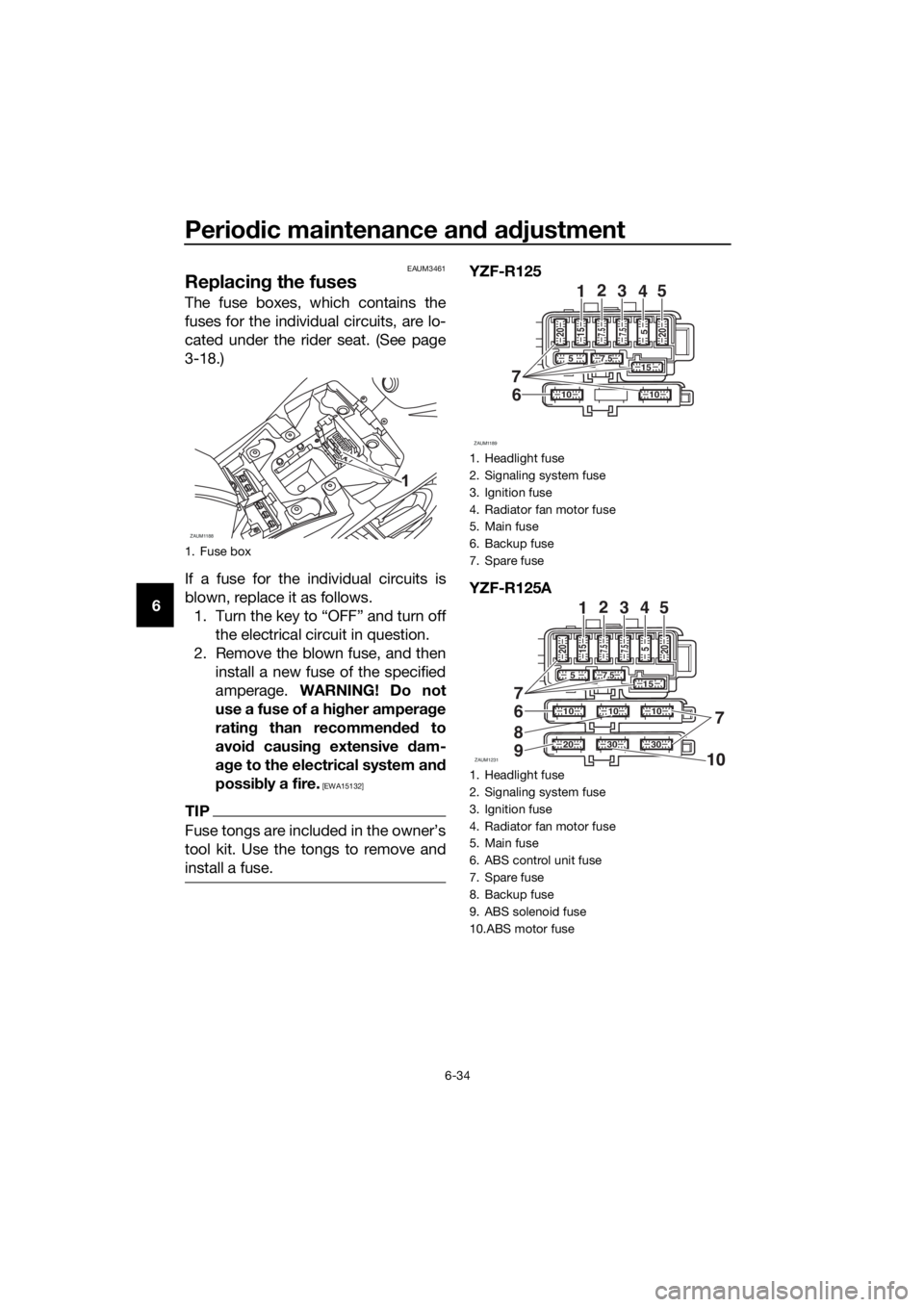

EAUM3461

Replacing the fuses

The fuse boxes, which contains the

fuses for the individual circuits, are lo-

cated under the rider seat. (See page

3-18.)

If a fuse for the individual circuits is

blown, replace it as follows.

1. Turn the key to “OFF” and turn off

the electrical circuit in question.

2. Remove the blown fuse, and then

install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a higher amperage

rating than recommended to

avoid causing extensive dam-

age to the electrical system and

possibly a fire.

[EWA15132]

TIP

tool kit. Use the tongs to remove and

install a fuse.

YZF-R125

YZF-R125A

1. Fuse box

ZAUM1188

1. Headlight fuse

2. Signaling system fuse

3. Ignition fuse

4. Radiator fan motor fuse

5. Main fuse

6. Backup fuse

7. Spare fuse

1. Headlight fuse

2. Signaling system fuse

3. Ignition fuse

4. Radiator fan motor fuse

5. Main fuse

6. ABS control unit fuse

7. Spare fuse

8. Backup fuse

9. ABS solenoid fuse

10.ABS motor fuse

ZAUM1189

1010

157.5

5207.5 7.515 20

5

7

12

3

45

6

ZAUM1231

10

303020

7

8

91010

157.5

207.5 7.515

5 20

5

7

12

3

45

6

U5D7E6E0.book Page 34 Wednesday, June 17, 2015 10:25 AM

Page 77 of 98

Periodic maintenance and adjustment

6-35

6 3. Turn the key to “ON” and turn on

the electrical circuit in question to

check if the device operates.

4. If the fuse immediately blows

again, have a Yamaha dealer

check the electrical system.

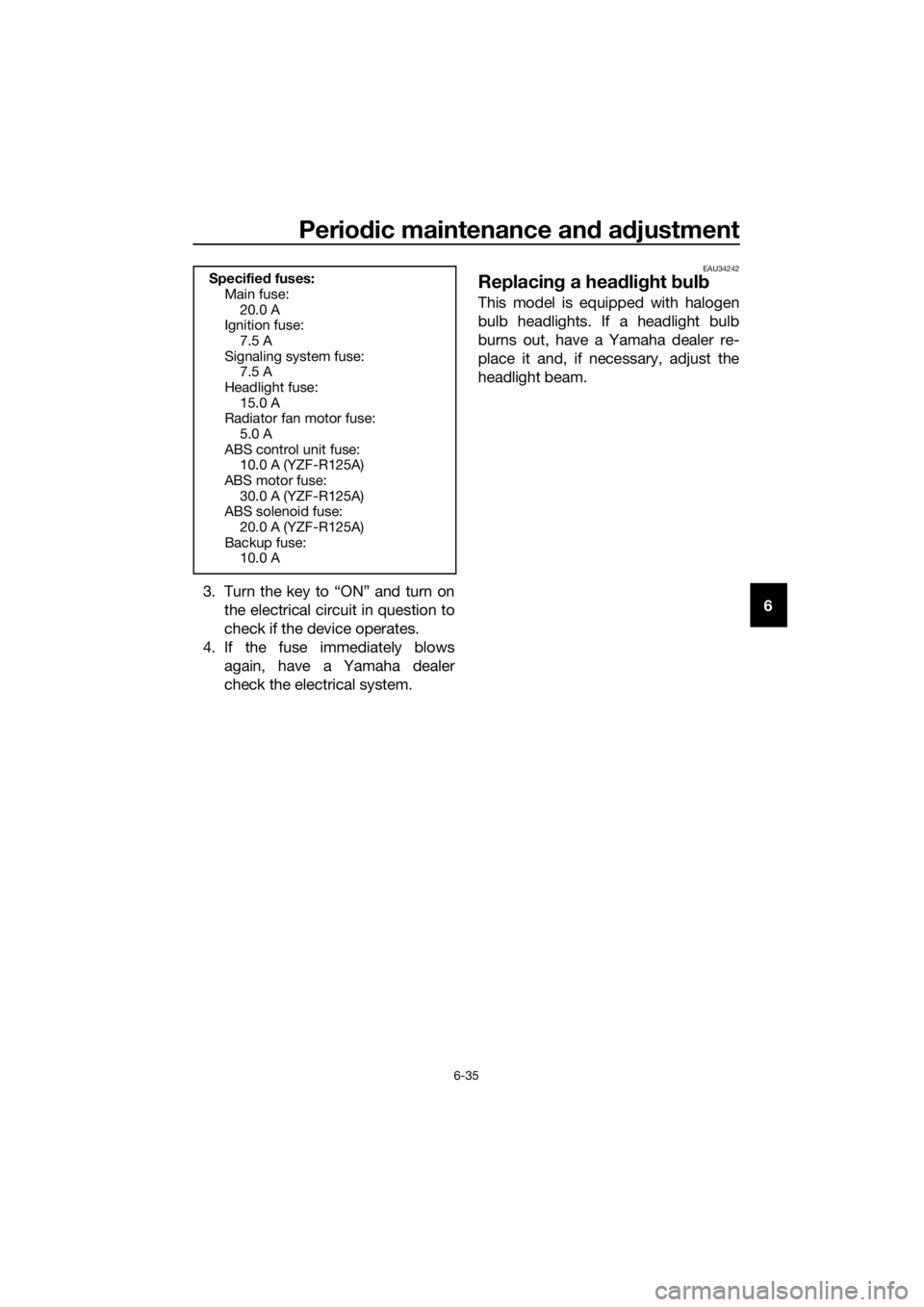

EAU34242

Replacing a headlight bulb

This model is equipped with halogen

bulb headlights. If a headlight bulb

burns out, have a Yamaha dealer re-

place it and, if necessary, adjust the

headlight beam.

Specified fuses:

Main fuse:

20.0 A

Ignition fuse:

7.5 A

Signaling system fuse:

7.5 A

Headlight fuse:

15.0 A

Radiator fan motor fuse:

5.0 A

ABS control unit fuse:

10.0 A (YZF-R125A)

ABS motor fuse:

30.0 A (YZF-R125A)

ABS solenoid fuse:

20.0 A (YZF-R125A)

Backup fuse:

10.0 A

U5D7E6E0.book Page 35 Wednesday, June 17, 2015 10:25 AM

Page 78 of 98

Periodic maintenance and adjustment

6-36

6

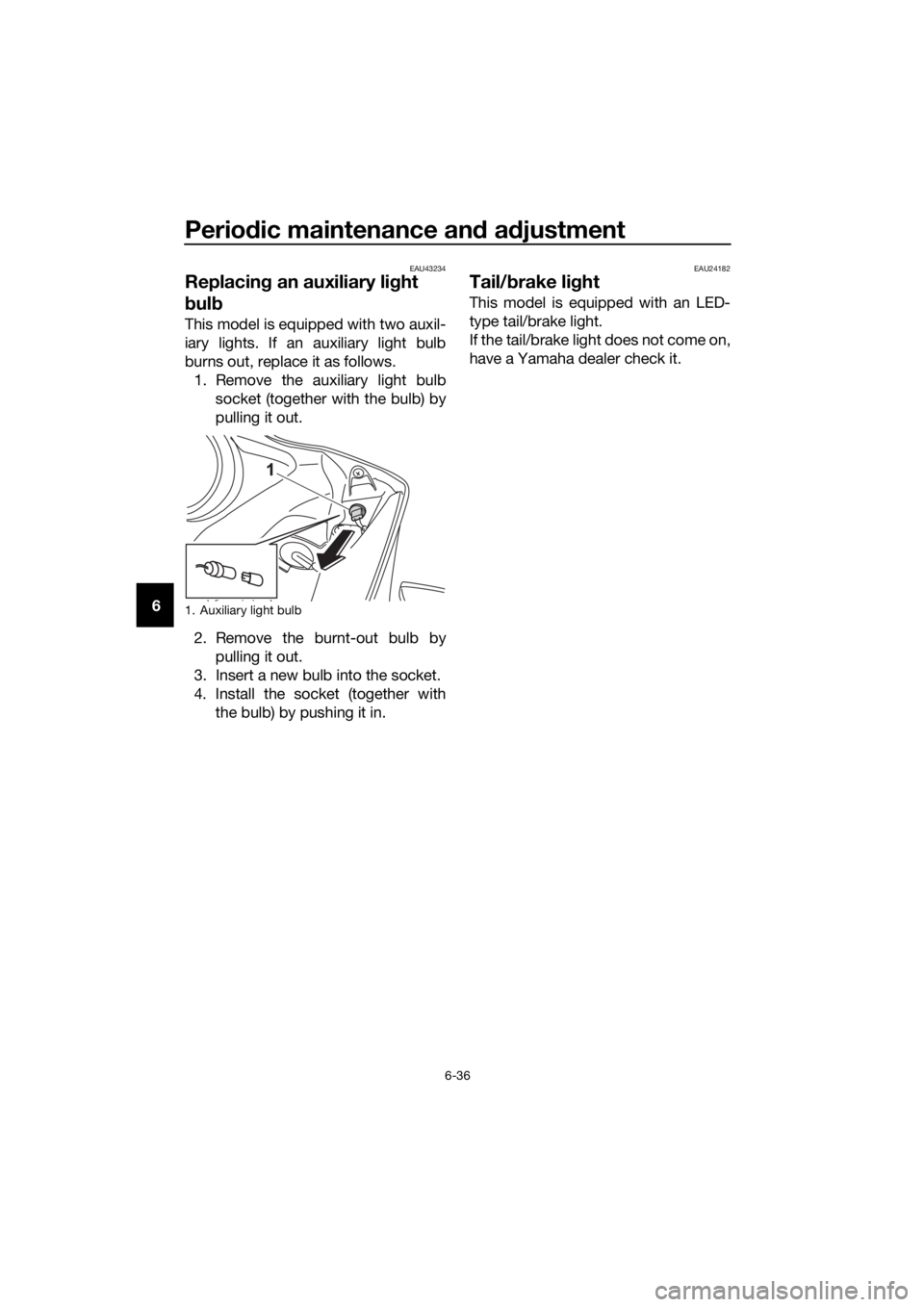

EAU43234

Replacing an auxiliary light

bulb

This model is equipped with two auxil-

iary lights. If an auxiliary light bulb

burns out, replace it as follows.

1. Remove the auxiliary light bulb

socket (together with the bulb) by

pulling it out.

2. Remove the burnt-out bulb by

pulling it out.

3. Insert a new bulb into the socket.

4. Install the socket (together with

the bulb) by pushing it in.

EAU24182

Tail/brake light

This model is equipped with an LED-

type tail/brake light.

If the tail/brake light does not come on,

have a Yamaha dealer check it.

1. Auxiliary light bulb

U5D7E6E0.book Page 36 Wednesday, June 17, 2015 10:25 AM

Page 79 of 98

Periodic maintenance and adjustment

6-37

6

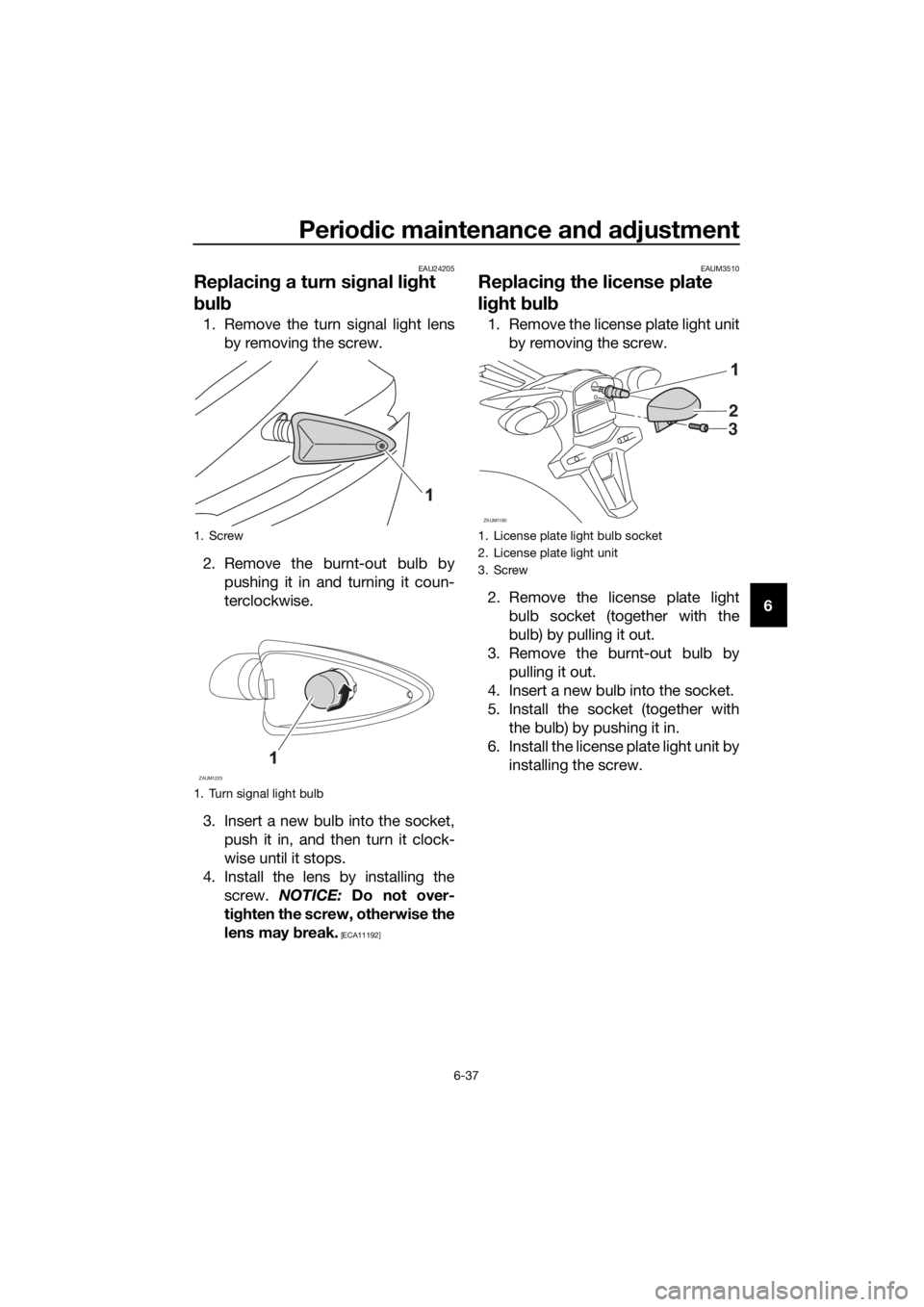

EAU24205

Replacing a turn signal light

bulb

1. Remove the turn signal light lens

by removing the screw.

2. Remove the burnt-out bulb by

pushing it in and turning it coun-

terclockwise.

3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the

screw. NOTICE: Do not over-

tighten the screw, otherwise the

lens may break.

[ECA11192]EAUM3510

Replacing the license plate

light bulb

1. Remove the license plate light unit

by removing the screw.

2. Remove the license plate light

bulb socket (together with the

bulb) by pulling it out.

3. Remove the burnt-out bulb by

pulling it out.

4. Insert a new bulb into the socket.

5. Install the socket (together with

the bulb) by pushing it in.

6. Install the license plate light unit by

installing the screw.

1. Screw

1. Turn signal light bulb

ZAUM1223

1. License plate light bulb socket

2. License plate light unit

3. Screw

ZAUM1190

2

3

U5D7E6E0.book Page 37 Wednesday, June 17, 2015 10:25 AM

Page 83 of 98

Periodic maintenance and adjustment

6-41

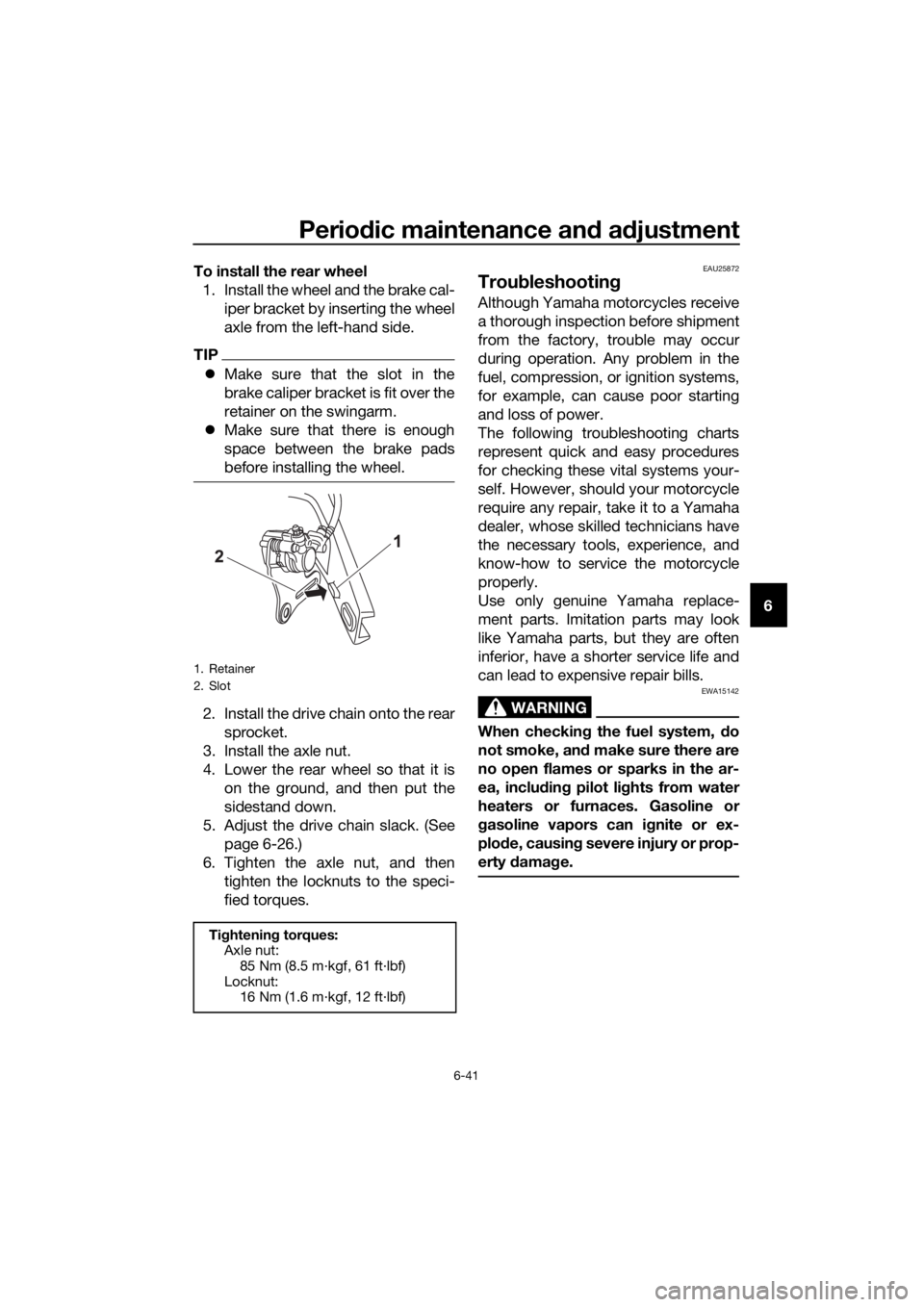

6 To install the rear wheel

1. Install the wheel and the brake cal-

iper bracket by inserting the wheel

axle from the left-hand side.

TIP

Make sure that the slot in the

brake caliper bracket is fit over the

retainer on the swingarm.

Make sure that there is enough

space between the brake pads

before installing the wheel.

2. Install the drive chain onto the rear

sprocket.

3. Install the axle nut.

4. Lower the rear wheel so that it is

on the ground, and then put the

sidestand down.

5. Adjust the drive chain slack. (See

page 6-26.)

6. Tighten the axle nut, and then

tighten the locknuts to the speci-

fied torques.

EAU25872

Troubleshooting

Although Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition systems,

for example, can cause poor starting

and loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWA15142

When checking the fuel system, do

not smoke, and make sure there are

no open flames or sparks in the ar-

ea, including pilot lights from water

heaters or furnaces. Gasoline or

gasoline vapors can ignite or ex-

plode, causing severe injury or prop-

erty damage.

1. Retainer

2. Slot

Tightening torques:

Axle nut:

85 Nm (8.5 m·kgf, 61 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

U5D7E6E0.book Page 41 Wednesday, June 17, 2015 10:25 AM