YAMAHA YZF-R125 2021 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2021, Model line: YZF-R125, Model: YAMAHA YZF-R125 2021Pages: 94, PDF Size: 3.34 MB

Page 51 of 94

Periodic maintenance an d a djustment

6-7

6

EAU72750

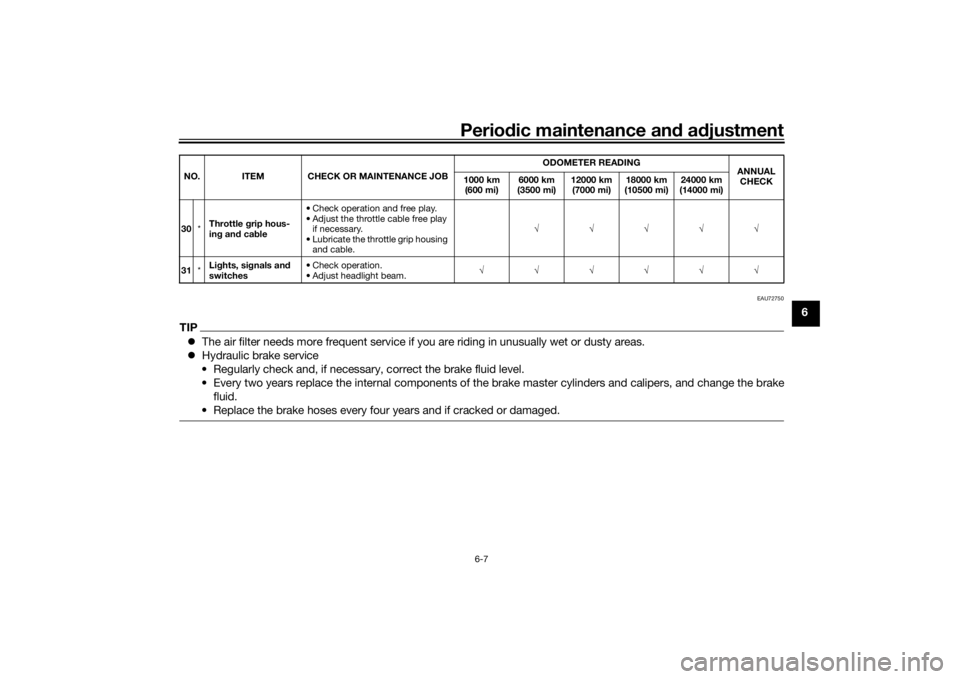

TIP The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

Hydraulic brake service

• Regularly check and, if necessary, correct the brake fluid level.

• Every two years replace the internal components of the brake master cylinders and calipers, and change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.30 *Throttle g

rip hous-

in g an d ca ble • Check operation and free play.

• Adjust the throttle cable free play

if necessary.

• Lubricate the throttle grip housing and cable. √√√√√

31 *Li

ghts, si gnals an d

switches • Check operation.

• Adjust headlight beam.

√√√√√√

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 6000 km

(3500 mi) 12000 km

(7000 mi) 18000 km

(10500 mi) 24000 km

(14000 mi)

UB5GE2E0.book Page 7 Thursday, July 30, 2020 3:08 PM

Page 52 of 94

Periodic maintenance an d a djustment

6-8

6

EAU18782

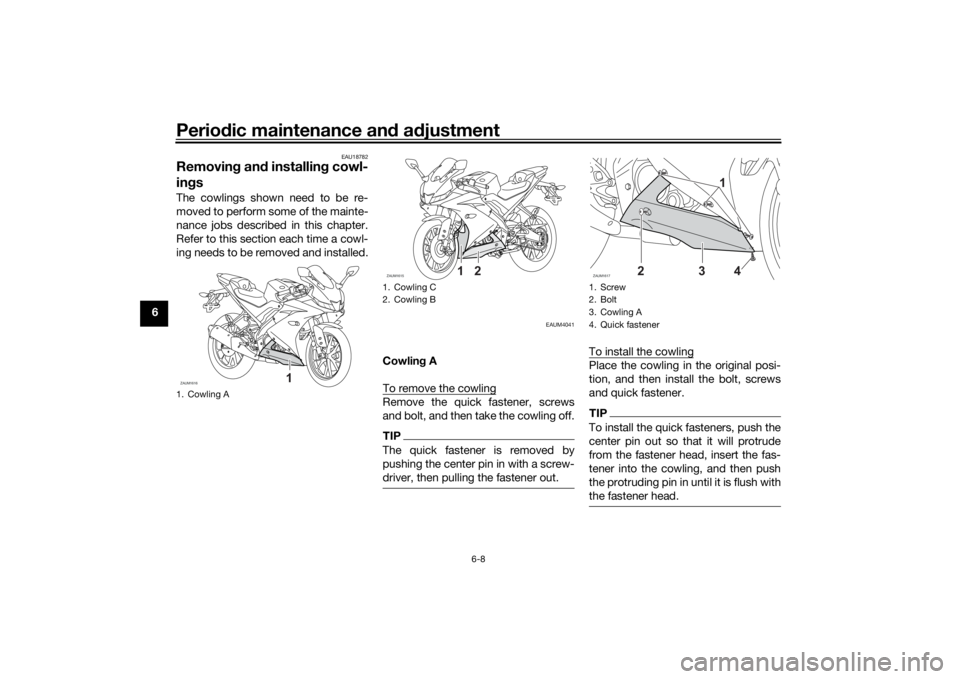

Removin g an d installin g cowl-

in gsThe cowlings shown need to be re-

moved to perform some of the mainte-

nance jobs described in this chapter.

Refer to this section each time a cowl-

ing needs to be removed and installed.

EAUM4041

Cowlin g A

To remove the cowlingRemove the quick fastener, screws

and bolt, and then take the cowling off.TIPThe quick fastener is removed by

pushing the center pin in with a screw-

driver, then pulling the fastener out.

To install the cowlingPlace the cowling in the original posi-

tion, and then install the bolt, screws

and quick fastener.TIPTo install the quick fasteners, push the

center pin out so that it will protrude

from the fastener head, insert the fas-

tener into the cowling, and then push

the protruding pin in until it is flush with

the fastener head.

1. Cowling AZAUM1616

1

1. Cowling C

2. Cowling BZAUM1615

1

2

1. Screw

2. Bolt

3. Cowling A

4. Quick fastenerZAUM1617

3

4

1

2

UB5GE2E0.book Page 8 Thursday, July 30, 2020 3:08 PM

Page 53 of 94

Periodic maintenance an d a djustment

6-9

6

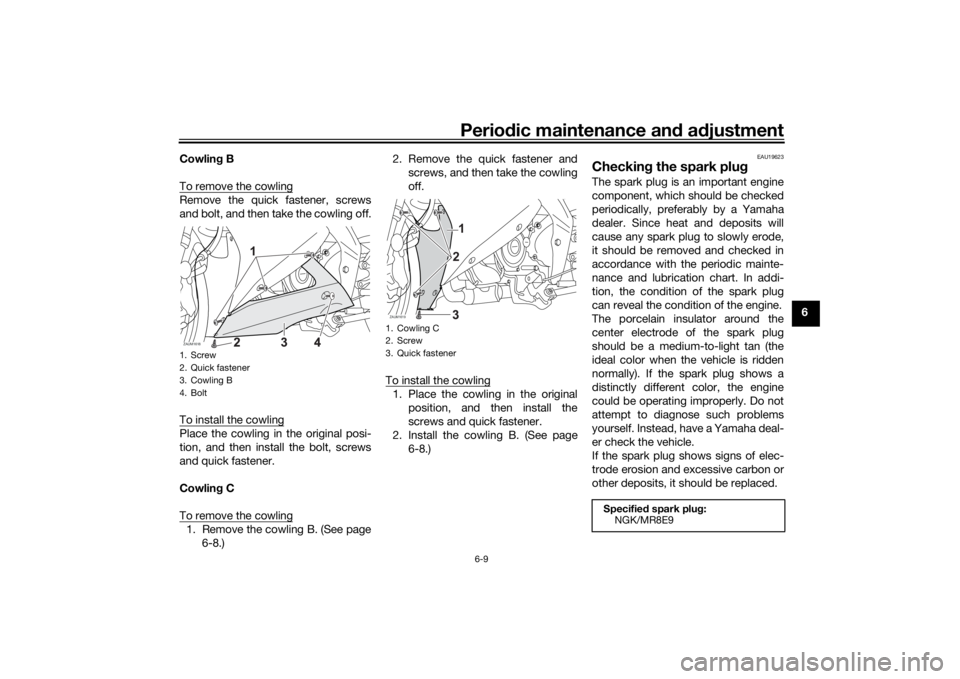

Cowlin

g B

To remove the cowling

Remove the quick fastener, screws

and bolt, and then take the cowling off.

To install the cowlingPlace the cowling in the original posi-

tion, and then install the bolt, screws

and quick fastener.

Cowlin g C

To remove the cowling1. Remove the cowling B. (See page 6-8.) 2. Remove the quick fastener and

screws, and then take the cowling

off.

To install the cowling

1. Place the cowling in the original position, and then install the

screws and quick fastener.

2. Install the cowling B. (See page 6-8.)

EAU19623

Checkin g the spark plu gThe spark plug is an important engine

component, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark plug to slowly erode,

it should be removed and checked in

accordance with the periodic mainte-

nance and lubrication chart. In addi-

tion, the condition of the spark plug

can reveal the condition of the engine.

The porcelain insulator around the

center electrode of the spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally). If the spark plug shows a

distinctly different color, the engine

could be operating improperly. Do not

attempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If the spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced.

1. Screw

2. Quick fastener

3. Cowling B

4. BoltZAUM1618

1

1. Cowling C

2. Screw

3. Quick fastenerZAUM1619

21

Specified spark plu g:

NGK/MR8E9

UB5GE2E0.book Page 9 Thursday, July 30, 2020 3:08 PM

Page 54 of 94

Periodic maintenance an d a djustment

6-10

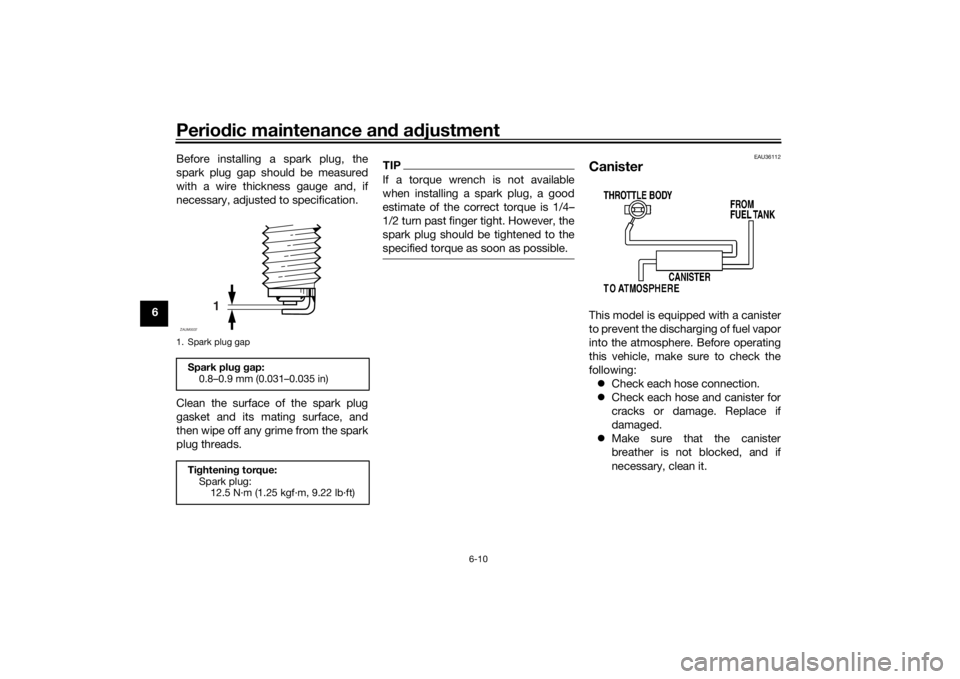

6 Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.

EAU36112

CanisterThis model is equipped with a canister

to prevent the discharging of fuel vapor

into the atmosphere. Before operating

this vehicle, make sure to check the

following:

Check each hose connection.

Check each hose and canister for

cracks or damage. Replace if

damaged.

Make sure that the canister

breather is not blocked, and if

necessary, clean it.

1. Spark plug gapSpark plu g g ap:

0.8–0.9 mm (0.031–0.035 in)

Ti ghtenin g torque:

Spark plug: 12.5 N·m (1.25 kgf·m, 9.22 lb·ft)

1

ZAUM0037

UB5GE2E0.book Page 10 Thursday, July 30, 2020 3:08 PM

Page 55 of 94

Periodic maintenance an d a djustment

6-11

6

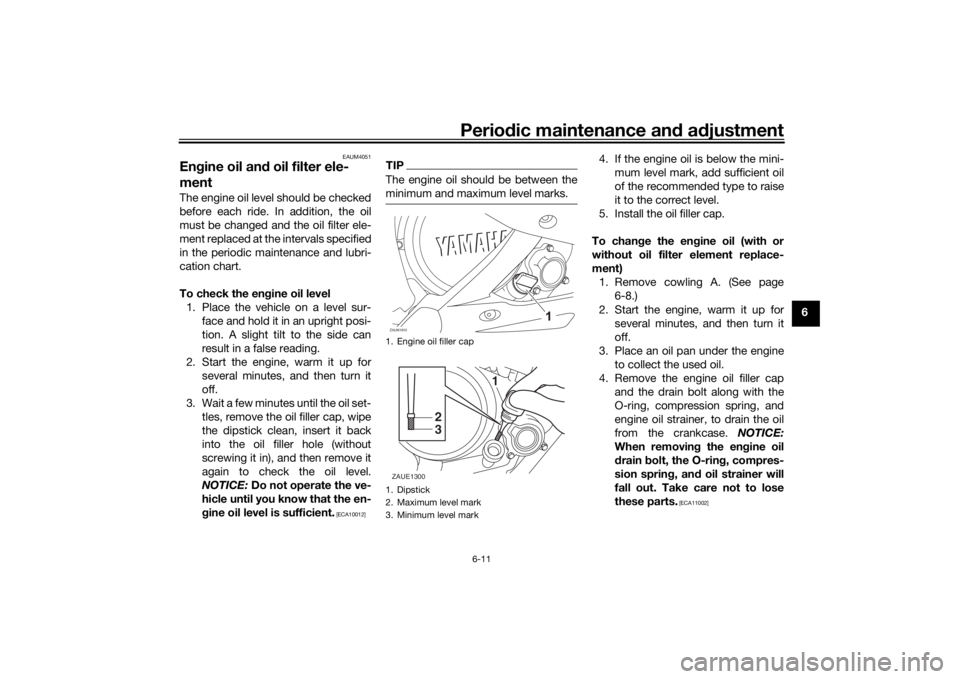

EAUM4051

En gine oil an d oil filter ele-

mentThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart.

To check the en gine oil level

1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes until the oil set- tles, remove the oil filler cap, wipe

the dipstick clean, insert it back

into the oil filler hole (without

screwing it in), and then remove it

again to check the oil level.

NOTICE: Do not operate the ve-

hicle until you know that the en-

g ine oil level is sufficient.

[ECA10012]

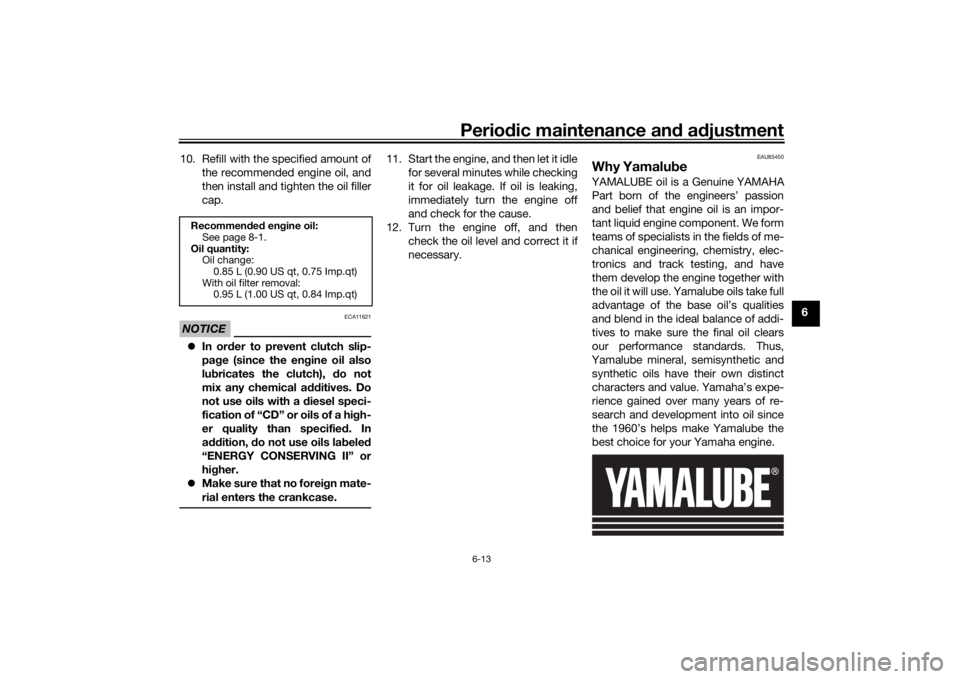

TIPThe engine oil should be between the

minimum and maximum level marks.

4. If the engine oil is below the mini-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Install the oil filler cap.

To chan ge the en gine oil (with or

without oil filter element replace-

ment) 1. Remove cowling A. (See page 6-8.)

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Place an oil pan under the engine to collect the used oil.

4. Remove the engine oil filler cap and the drain bolt along with the

O-ring, compression spring, and

engine oil strainer, to drain the oil

from the crankcase. NOTICE:

When removin g the eng ine oil

d rain bolt, the O-ring , compres-

sion sprin g, an d oil strainer will

fall out. Take care not to lose

these parts.

[ECA11002]

1. Engine oil filler cap

1. Dipstick

2. Maximum level mark

3. Minimum level markZAUM1610

1

2

3

ZAUE1300

UB5GE2E0.book Page 11 Thursday, July 30, 2020 3:08 PM

Page 56 of 94

Periodic maintenance an d a djustment

6-12

6

5. Clean the engine oil strainer withsolvent.

TIPSkip to step 9 when only changing

the oil.

Perform steps 6–8 when replacing

the oil filter element.6. Remove the oil filter element cover

by removing the bolts. 7. Remove and replace the oil filter

element and O-ring. 8. Install the oil filter element cover

by installing the bolts, then tight-

ening them to the specified

torque.

TIPMake sure that the O-ring is properly

seated.9. Install the engine oil strainer, com-pression spring, O-ring and the

engine oil drain bolt, and then

tighten it to the specified torque.

NOTICE: Before installin g the

en gine oil d rain bolt, do not for-

g et to install the O-rin g, com-

pression sprin g, an d oil strainer

in position.

[ECA10422]

1. Engine oil drain bolt

2. O-ring

3. Compression spring

4. Strainer

5. Oil pan

2 3 4

5 1

ZAUE0672

1. Bolt

2. Oil filter element cover

1. Oil filter element

2. O-ring

Ti

ghtenin g torques:

Oil filter element cover bolt: 10 N·m (1.0 kgf·m, 7.4 lb·ft)

Ti ghtenin g torques:

Engine oil drain bolt: 32 N·m (3.2 kgf·m, 24 lb·ft)

UB5GE2E0.book Page 12 Thursday, July 30, 2020 3:08 PM

Page 57 of 94

Periodic maintenance an d a djustment

6-13

6

10. Refill with the specified amount of

the recommended engine oil, and

then install and tighten the oil filler

cap.

NOTICE

ECA11621

In or der to prevent clutch slip-

pa ge (since the en gine oil also

lu bricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a hi gh-

er quality than specifie d. In

a ddition, do not use oils lab eled

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.

11. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

12. Turn the engine off, and then check the oil level and correct it if

necessary.

EAU85450

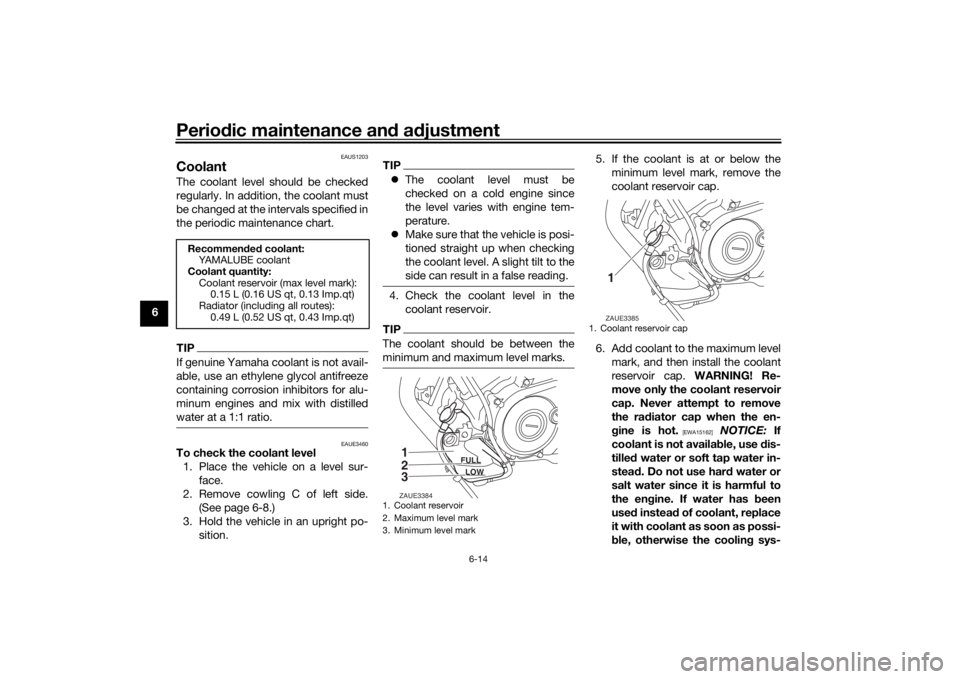

Why Yamalu beYAMALUBE oil is a Genuine YAMAHA

Part born of the engineers’ passion

and belief that engine oil is an impor-

tant liquid engine component. We form

teams of specialists in the fields of me-

chanical engineering, chemistry, elec-

tronics and track testing, and have

them develop the engine together with

the oil it will use. Yamalube oils take full

advantage of the base oil’s qualities

and blend in the ideal balance of addi-

tives to make sure the final oil clears

our performance standards. Thus,

Yamalube mineral, semisynthetic and

synthetic oils have their own distinct

characters and value. Yamaha’s expe-

rience gained over many years of re-

search and development into oil since

the 1960’s helps make Yamalube the

best choice for your Yamaha engine.

Recommen ded en gine oil:

See page 8-1.

Oil quantity: Oil change:

0.85 L (0.90 US qt, 0.75 Imp.qt)

With oil filter removal: 0.95 L (1.00 US qt, 0.84 Imp.qt)

UB5GE2E0.book Page 13 Thursday, July 30, 2020 3:08 PM

Page 58 of 94

Periodic maintenance an d a djustment

6-14

6

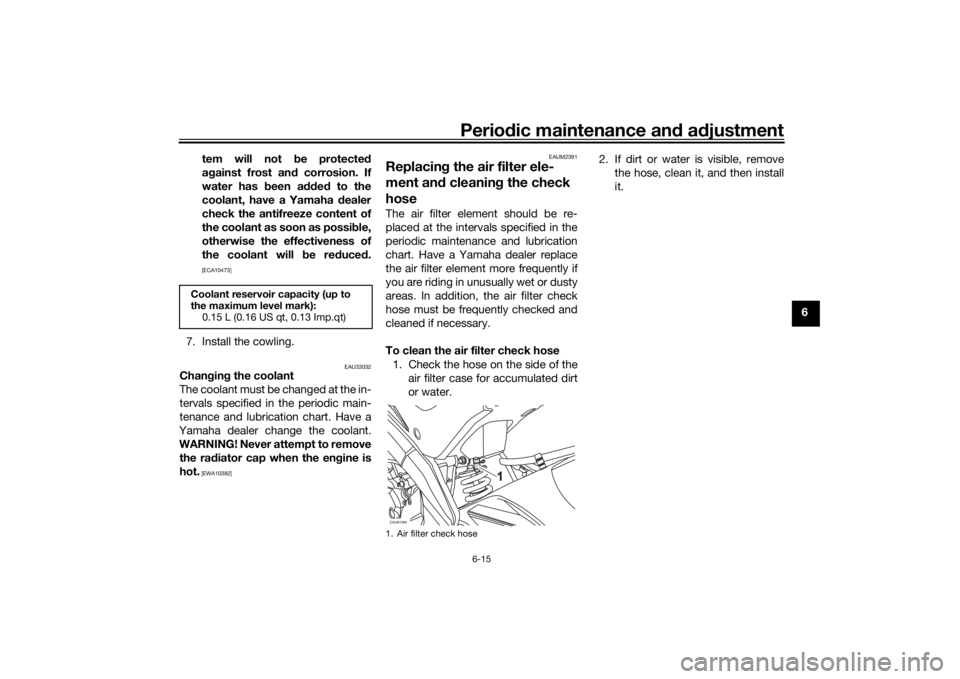

EAUS1203

CoolantThe coolant level should be checked

regularly. In addition, the coolant must

be changed at the intervals specified in

the periodic maintenance chart.TIPIf genuine Yamaha coolant is not avail-

able, use an ethylene glycol antifreeze

containing corrosion inhibitors for alu-

minum engines and mix with distilled

water at a 1:1 ratio.

EAUE3460

To check the coolant level

1. Place the vehicle on a level sur- face.

2. Remove cowling C of left side. (See page 6-8.)

3. Hold the vehicle in an upright po- sition.

TIPThe coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.4. Check the coolant level in the

coolant reservoir.TIPThe coolant should be between the

minimum and maximum level marks.

5. If the coolant is at or below theminimum level mark, remove the

coolant reservoir cap.

6. Add coolant to the maximum level mark, and then install the coolant

reservoir cap. WARNING! Re-

move only the coolant reservoir

cap. Never attempt to remove

the ra diator cap when the en-

g ine is hot.

[EWA15162]

NOTICE: If

coolant is not availa ble, use dis-

tille d water or soft tap water in-

stead . Do not use har d water or

salt water since it is harmful to

the en gine. If water has been

use d instead of coolant, replace

it with coolant as soon as possi-

b le, otherwise the coolin g sys-

Recommen ded coolant:

YAMALUBE coolant

Coolant quantity: Coolant reservoir (max level mark):0.15 L (0.16 US qt, 0.13 Imp.qt)

Radiator (including all routes): 0.49 L (0.52 US qt, 0.43 Imp.qt)

1. Coolant reservoir

2. Maximum level mark

3. Minimum level mark

1

2

3

FULL

LOW

ZAUE3384

1. Coolant reservoir cap

1ZAUE3385

UB5GE2E0.book Page 14 Thursday, July 30, 2020 3:08 PM

Page 59 of 94

Periodic maintenance an d a djustment

6-15

6

tem will not

be protecte d

a g ainst frost an d corrosion. If

water has been a dded to the

coolant, have a Yamaha dealer

check the antifreeze content of

the coolant as soon as possi ble,

otherwise the effectiveness of

the coolant will be re duce d.

[ECA10473]

7. Install the cowling.

EAU33032

Chan gin g the coolant

The coolant must be changed at the in-

tervals specified in the periodic main-

tenance and lubrication chart. Have a

Yamaha dealer change the coolant.

WARNING! Never attempt to remove the ra diator cap when the en gine is

hot.

[EWA10382] EAUM2391

Replacin

g the air filter ele-

ment an d cleanin g the check

hoseThe air filter element should be re-

placed at the intervals specified in the

periodic maintenance and lubrication

chart. Have a Yamaha dealer replace

the air filter element more frequently if

you are riding in unusually wet or dusty

areas. In addition, the air filter check

hose must be frequently checked and

cleaned if necessary.

To clean the air filter check hose

1. Check the hose on the side of the air filter case for accumulated dirt

or water. 2. If dirt or water is visible, remove

the hose, clean it, and then install

it.

Coolant reservoir capacity (up to

the maximum level mark):0.15 L (0.16 US qt, 0.13 Imp.qt)

1. Air filter check hoseZAUM1594

UB5GE2E0.book Page 15 Thursday, July 30, 2020 3:08 PM

Page 60 of 94

Periodic maintenance an d a djustment

6-16

6

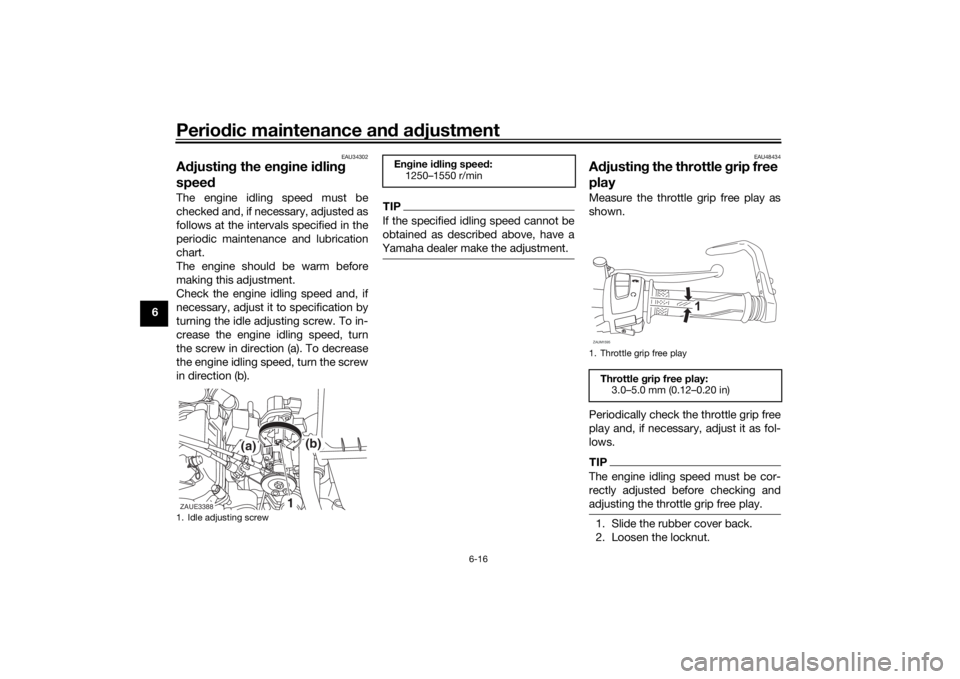

EAU34302

A djustin g the eng ine idlin g

spee dThe engine idling speed must be

checked and, if necessary, adjusted as

follows at the intervals specified in the

periodic maintenance and lubrication

chart.

The engine should be warm before

making this adjustment.

Check the engine idling speed and, if

necessary, adjust it to specification by

turning the idle adjusting screw. To in-

crease the engine idling speed, turn

the screw in direction (a). To decrease

the engine idling speed, turn the screw

in direction (b).

TIPIf the specified idling speed cannot be

obtained as described above, have a

Yamaha dealer make the adjustment.

EAU48434

A djustin g the throttle grip free

playMeasure the throttle grip free play as

shown.

Periodically check the throttle grip free

play and, if necessary, adjust it as fol-

lows.TIPThe engine idling speed must be cor-

rectly adjusted before checking and

adjusting the throttle grip free play.1. Slide the rubber cover back.

2. Loosen the locknut.

1. Idle adjusting screwZAUE3388

(a)

(b)

1

En gine i dlin g spee d:

1250–1550 r/min

1. Throttle grip free playThrottle grip free play:

3.0–5.0 mm (0.12–0.20 in)ZAUM1595

1

UB5GE2E0.book Page 16 Thursday, July 30, 2020 3:08 PM