torque YAMAHA YZF-R125 2021 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2021, Model line: YZF-R125, Model: YAMAHA YZF-R125 2021Pages: 94, PDF Size: 3.34 MB

Page 35 of 94

Instrument and control functions

3-20

3

2. Install the passenger seat by in-

stalling and tightening the nut to

the specified torque.

3. Install the plastic cover.

Ri der seat

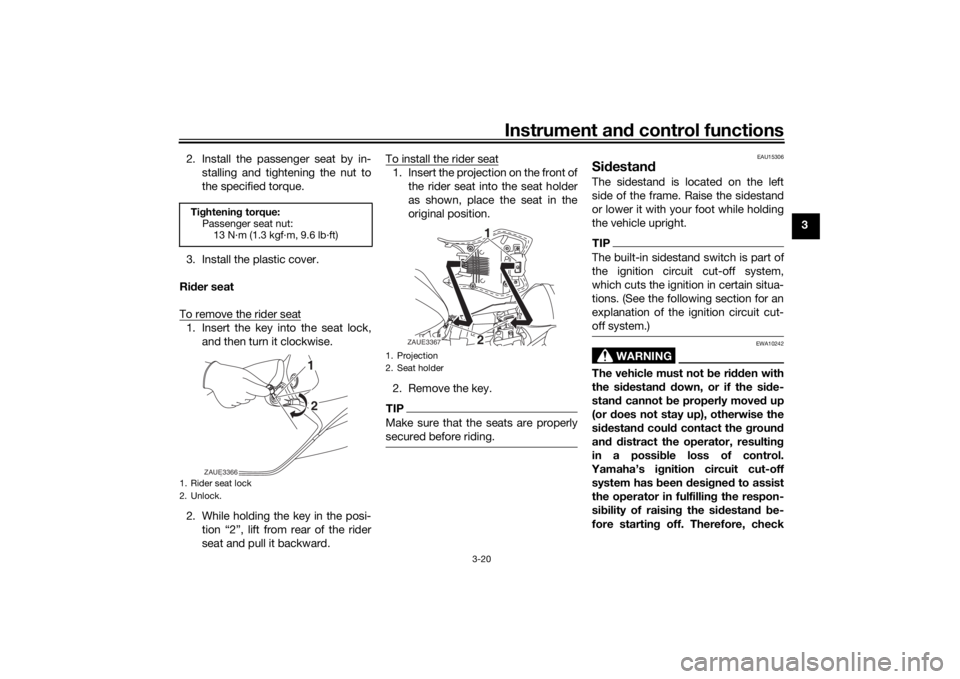

To remove the rider seat

1. Insert the key into the seat lock, and then turn it clockwise.

2. While holding the key in the posi- tion “2”, lift from rear of the rider

seat and pull it backward. To install the rider seat

1. Insert the projection on the front of

the rider seat into the seat holder

as shown, place the seat in the

original position.

2. Remove the key.TIPMake sure that the seats are properly

secured before riding.

EAU15306

Si destan dThe sidestand is located on the left

side of the frame. Raise the sidestand

or lower it with your foot while holding

the vehicle upright.TIPThe built-in sidestand switch is part of

the ignition circuit cut-off system,

which cuts the ignition in certain situa-

tions. (See the following section for an

explanation of the ignition circuit cut-

off system.)

WARNING

EWA10242

The vehicle must not be ri dden with

the si destan d d own, or if the si de-

stan d cannot b e properly move d up

(or does not stay up), otherwise the

si destan d coul d contact the groun d

an d d istract the operator, resultin g

in a possib le loss of control.

Yamaha’s ig nition circuit cut-off

system has been desi gne d to assist

the operator in fulfillin g the respon-

si bility of raisin g the sid estand b e-

fore startin g off. Therefore, check

Ti ghtenin g torque:

Passenger seat nut: 13 N·m (1.3 kgf·m, 9.6 lb·ft)1. Rider seat lock

2. Unlock.

21

ZAUE3366

1. Projection

2. Seat holder

21

ZAUE3367

UB5GE2E0.book Page 20 Thursday, July 30, 2020 3:08 PM

Page 46 of 94

Periodic maintenance an d a djustment

6-2

6

EAU85230

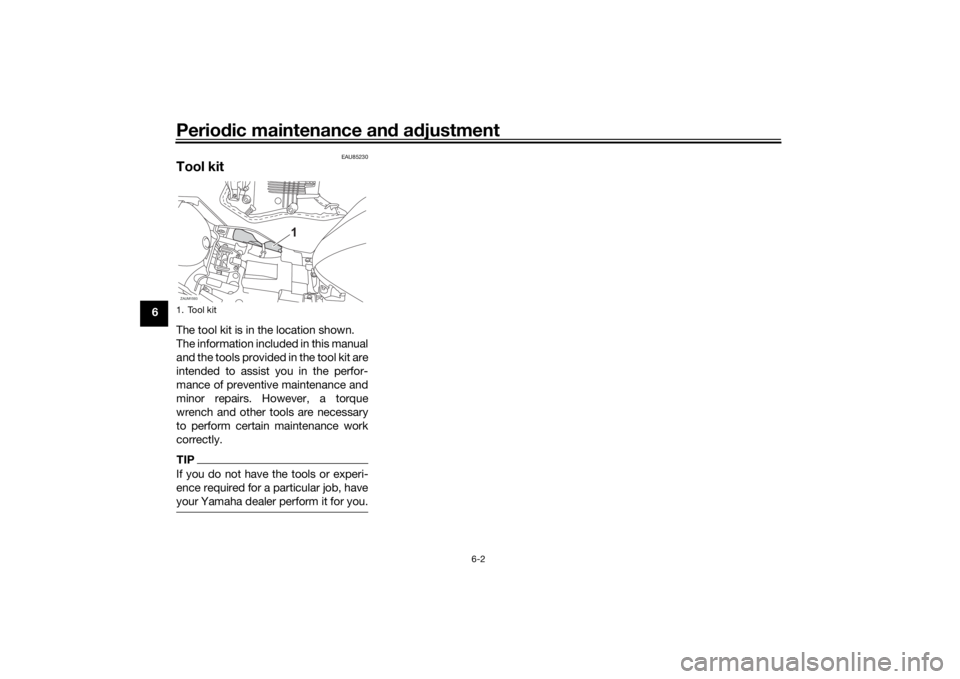

Tool kitThe tool kit is in the location shown.

The information included in this manual

and the tools provided in the tool kit are

intended to assist you in the perfor-

mance of preventive maintenance and

minor repairs. However, a torque

wrench and other tools are necessary

to perform certain maintenance work

correctly.TIPIf you do not have the tools or experi-

ence required for a particular job, have

your Yamaha dealer perform it for you.1. Tool kitZAUM1593

1

UB5GE2E0.book Page 2 Thursday, July 30, 2020 3:08 PM

Page 54 of 94

Periodic maintenance an d a djustment

6-10

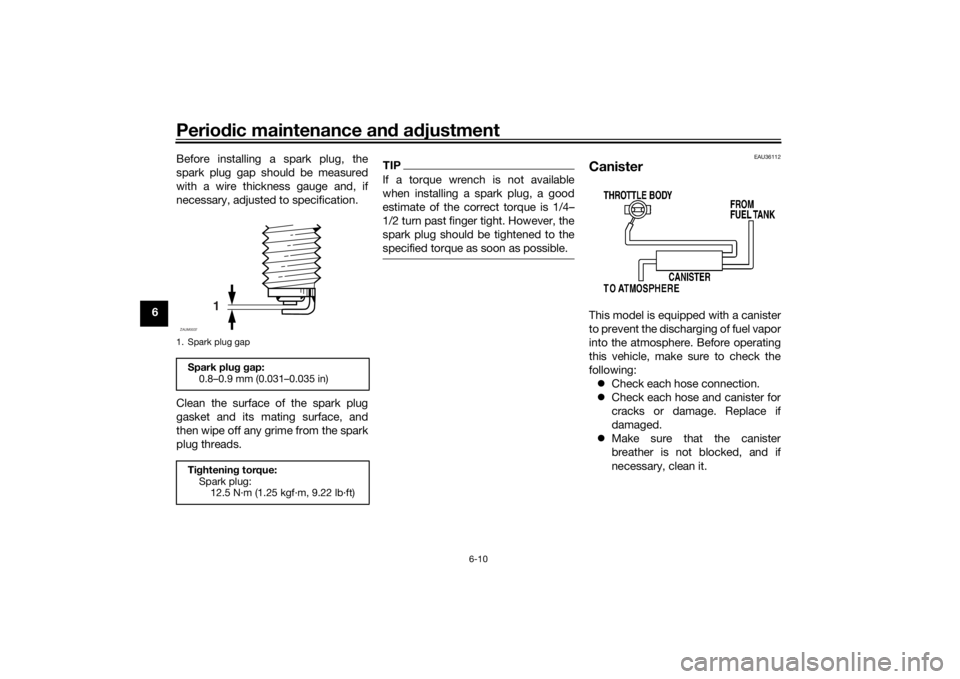

6 Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.

EAU36112

CanisterThis model is equipped with a canister

to prevent the discharging of fuel vapor

into the atmosphere. Before operating

this vehicle, make sure to check the

following:

Check each hose connection.

Check each hose and canister for

cracks or damage. Replace if

damaged.

Make sure that the canister

breather is not blocked, and if

necessary, clean it.

1. Spark plug gapSpark plu g g ap:

0.8–0.9 mm (0.031–0.035 in)

Ti ghtenin g torque:

Spark plug: 12.5 N·m (1.25 kgf·m, 9.22 lb·ft)

1

ZAUM0037

UB5GE2E0.book Page 10 Thursday, July 30, 2020 3:08 PM

Page 56 of 94

Periodic maintenance an d a djustment

6-12

6

5. Clean the engine oil strainer withsolvent.

TIPSkip to step 9 when only changing

the oil.

Perform steps 6–8 when replacing

the oil filter element.6. Remove the oil filter element cover

by removing the bolts. 7. Remove and replace the oil filter

element and O-ring. 8. Install the oil filter element cover

by installing the bolts, then tight-

ening them to the specified

torque.

TIPMake sure that the O-ring is properly

seated.9. Install the engine oil strainer, com-pression spring, O-ring and the

engine oil drain bolt, and then

tighten it to the specified torque.

NOTICE: Before installin g the

en gine oil d rain bolt, do not for-

g et to install the O-rin g, com-

pression sprin g, an d oil strainer

in position.

[ECA10422]

1. Engine oil drain bolt

2. O-ring

3. Compression spring

4. Strainer

5. Oil pan

2 3 4

5 1

ZAUE0672

1. Bolt

2. Oil filter element cover

1. Oil filter element

2. O-ring

Ti

ghtenin g torques:

Oil filter element cover bolt: 10 N·m (1.0 kgf·m, 7.4 lb·ft)

Ti ghtenin g torques:

Engine oil drain bolt: 32 N·m (3.2 kgf·m, 24 lb·ft)

UB5GE2E0.book Page 12 Thursday, July 30, 2020 3:08 PM

Page 70 of 94

Periodic maintenance an d a djustment

6-26

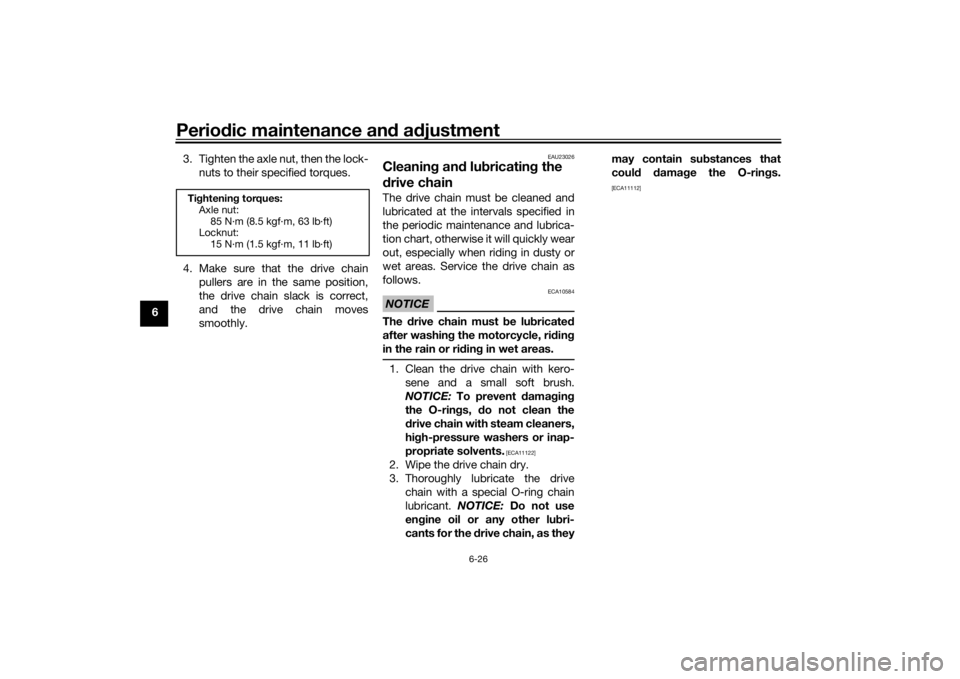

6 3. Tighten the axle nut, then the lock-

nuts to their specified torques.

4. Make sure that the drive chain pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23026

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must b e lubricated

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Clean the drive chain with kero-

sene and a small soft brush.

NOTICE: To prevent d amaging

the O-rin gs, do not clean the

d rive chain with steam cleaners,

hi gh-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

en gine oil or any other lu bri-

cants for the drive chain, as they may contain su

bstances that

coul d damag e the O-rin gs.

[ECA11112]

Ti ghtenin g torques:

Axle nut: 85 N·m (8.5 kgf·m, 63 lb·ft)

Locknut:

15 N·m (1.5 kgf·m, 11 lb·ft)

UB5GE2E0.book Page 26 Thursday, July 30, 2020 3:08 PM