torque YAMAHA YZF-R1M 2020 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2020, Model line: YZF-R1M, Model: YAMAHA YZF-R1M 2020Pages: 136, PDF Size: 16.15 MB

Page 19 of 136

Special features

3-2

3

This traction control system automati-

cally adjusts according to the vehicle’s

lean angle. To maximize acceleration,

when the vehicle is upright a less

amount of traction control is applied.

When cornering, a greater amount of

traction control is applied.

TIP

The traction control system may

engage when the vehicle travels

over a bump.

You may notice slight changes in

engine and exhaust sounds when

the traction control or other YRC

systems engage.

When TCS is turned off, SCS,

LCS, and LIF are also turned off

automatically.

WARNING

EWA15433

The traction control system is not a

substitute for ri din g appropriately

for the con ditions. Traction control

cannot prevent loss of traction d ue

to excessive spee d when enterin g

turns, when acceleratin g har d at a

sharp lean an gle, or while brakin g,

an d cannot prevent front wheel slip-

pin g. As with any vehicle, approach

surfaces that may be slippery with

caution an d avoi d especially slip-

pery surfaces.When the key is turned to “ON”, the

traction control system automatically

turns on. The traction control system

can be turned on or off manually only

when the key is in the “ON” position

and the motorcycle is stopped.TIPTurn the traction control system off to

help free the rear wheel if the motorcy-

cle gets stuck in mud, sand, or other

soft surfaces.

NOTICE

ECA16801

Use only the specifie d tires. (See

pa ge 7-19.) Usin g different size d

tires will prevent the traction control

system from controllin g tire rotation

accurately.SCS

The slide control system regulates en-

gine power output when a sideward

slide is detected in the rear wheel. It

adjusts power output based on data

from the IMU. This system supports

the TCS to contribute to a smoother

ride.

EBM

The engine brake management system

reduces engine torque when deceler-

ating. The fuel injection, ignition timing,

and electronic throttle valve are elec-

tronically adjusted by the ECU. There

are 3 settings to suit the track, riding

conditions, or your personal prefer-

ence.

TCS

UB3LE0E0.book Page 2 Tuesday, July 23, 2019 12:05 PM

Page 69 of 136

Instrument and control functions

4-46

4

3. Tighten the locknut to the speci-

fied torque. NOTICE: Always

ti g hten the locknut ag ainst the

a d justin g rin g, an d then ti ghten

the locknut to the specified

torque.

[ECA22760]

Re boun d d ampin g force

Turn the adjusting bolt in direction (a)

to increase the rebound damping

force.

Turn the adjusting bolt in direction (b)

to decrease the rebound damping

force.

To set the rebound damping force, turn

the adjuster in direction (a) until it

stops, and then count the clicks in di-

rection (b).

TIP When turning the damping force

adjuster in direction (a), the 0 click

position and the 1 click position

may be the same.

When turning the damping force

adjuster in direction (b), it may

click beyond the stated specifica- tions, however such adjustments

are ineffective and may damage

the suspension.

Compression

dampin g force

Fast compression damping forceTurn the adjusting bolt in direction (a)

to increase the compression damping

force.

Turn the adjusting bolt in direction (b)

to decrease the compression damping

force.

To set the compression damping

force, turn the adjuster in direction (a)

until it stops, and then count the turns

in direction (b).

Sprin g preloa d:

Minimum (soft):

Distance A = 77.5 mm (3.05 in)

Standard:

Distance A = 78.5 mm (3.09 in)

Maximum (hard): Distance A = 85.5 mm (3.37 in)

Ti ghtenin g torque:

Locknut:

28 N·m (2.8 kgf·m, 21 lb·ft)

1. Rebound damping force adjusting bolt

Re boun d d ampin g settin g:

Minimum (soft): 23 click(s) in direction (b)

Standard: 12 click(s) in direction (b)

Maximum (hard):

1 click(s) in direction (b)

(a) (b)

1

1. Fast compression damping force adjusting

bolt

1

(a) (b)

UB3LE0E0.book Page 46 Tuesday, July 23, 2019 12:05 PM

Page 71 of 136

Instrument and control functions

4-48

4

higher the spring preload; the

shorter distance A is, the lower the

spring preload.

Use the special wrench in the

tool kit to make the adjust-

ment.

3. Tighten the locknut to the speci-fied torque. NOTICE: Always

ti g hten the locknut ag ainst the

a d justin g rin g, an d then ti ghten

the locknut to the specified

torque.

[ECA22760]

NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn b eyond the

maximum or minimum settin gs.

EAU67050

EXUP systemThis model is equipped with Yamaha’s

EXUP (EXhaust Ultimate Power valve)

system. This system boosts engine

power by means of a valve that con-

trols exhaust flow within the exhaust

chamber.NOTICE

ECA15611

The EXUP system has been set an d

extensively teste d at the Yamaha

factory. Chan gin g these settin gs

without sufficient technical knowl-

e dge may result in poor perfor-

mance of or d amage to the en gine.

1. Spring preload adjusting nut

2. Locknut

1. Distance A

1

(a) (b)

2

1

Sprin

g preloa d:

Minimum (soft):

Distance A = 0.0 mm (0.00 in)

Standard:

Distance A = 4.0 mm (0.16 in)

Maximum (hard): Distance A = 9.0 mm (0.35 in)

Ti ghtenin g torque:

Locknut:

25 N·m (2.5 kgf·m, 18 lb·ft)

UB3LE0E0.book Page 48 Tuesday, July 23, 2019 12:05 PM

Page 83 of 136

Periodic maintenance an d a djustment

7-2

7

EAU67092

Tool kitThe tool kit should be stored separate-

ly from the vehicle. However, there are

some tools located under the seat.

(See page 4-38.)

The information included in this manual

and the tools provided are intended to

assist you in the performance of pre-

ventive maintenance and minor re-

pairs. However, a torque wrench and

other tools are necessary to perform

certain maintenance work correctly.TIPIf you do not have the tools or experi-

ence required for a particular job, have

your Yamaha dealer perform it for you.1. Hexagon wrench

1

UB3LE0E0.book Page 2 Tuesday, July 23, 2019 12:05 PM

Page 94 of 136

Periodic maintenance an d a djustment

7-13

7 Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

NOTICE

ECA10841

Do not use any tools to remove or in-

stall the spark plu

g cap, otherwise

the i gnition coil coupler may get

d amag ed . The spark plu g cap may

b e difficult to remove because the

ru bber seal on the en d of the cap fits

ti g htly. To remove the spark plu g

cap, simply twist it b ack and forth

while pullin g it out; to install it, twist

it back an d forth while pushin g it in.

EAU36112

CanisterThis model is equipped with a canister

to prevent the discharging of fuel vapor

into the atmosphere. Before operating

this vehicle, make sure to check the

following:

Check each hose connection.

Check each hose and canister for

cracks or damage. Replace if

damaged.

Make sure that the canister

breather is not blocked, and if

necessary, clean it.

Specifie d spark plu g:

NGK/LMAR9E-J1. Spark plug gapSpark plu g g ap:

0.6–0.7 mm (0.024–0.028 in)

1

1

Ti ghtenin g torque:

Spark plug (new):

18 N·m (1.8 kgf·m, 13 lb·ft)

Spark plug (after checking):

13 N·m (1.3 kgf·m, 9.6 lb·ft)

1. Canister

2. Canister breather

1

2

UB3LE0E0.book Page 13 Tuesday, July 23, 2019 12:05 PM

Page 96 of 136

Periodic maintenance an d a djustment

7-15

7 4. Install the engine oil drain bolt and

its new gasket, and then tighten

the bolt to the specified torque.

5. Refill with the specified amount of the recommended engine oil.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA11621

In or der to prevent clutch slip-

pa ge (since the en gine oil also

lu bricates the clutch), do not

mix any chemical additives. Do not use oils with a

diesel speci-

fication of “CD” or oils of a hi gh-

er quality than specifie d. In

a ddition, do not use oils la beled

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.

6. Check the oil filler cap O-ring for damage, and replace it if neces-

sary.

7. Install and tighten the oil filler cap. 8. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

TIPAfter the engine is started, the oil pres-

sure and coolant temperature warning

light should go off if the oil level is suf-

ficient.NOTICE

ECA22490

If the oil pressure an d coolant tem-

perature warnin g lig ht flickers or re-

mains on even if the oil level is

correct, immed iately turn the en gine

off an d have a Yamaha d ealer check

the vehicle.9. Turn the engine off, wait a few minutes for the oil level to settle for

an accurate reading, and then

check the oil level and correct it if

necessary.

Tightenin g torque:

Engine oil drain bolt: 23 N·m (2.3 kgf·m, 17 lb·ft)

Recommen ded en gine oil:

Full synthetic

10W-40, 15W-50

Oil quantity: Oil change:3.90 L (4.12 US qt, 3.43 Imp.qt)

With oil filter removal: 4.10 L (4.33 US qt, 3.61 Imp.qt)

1. Engine oil filler cap

2. O-ring

12

UB3LE0E0.book Page 15 Tuesday, July 23, 2019 12:05 PM

Page 97 of 136

Periodic maintenance an d a djustment

7-16

7

To chan

ge the en gine oil an d replace

the oil filter cartri dge

1. Remove cowling A and panel C. (See page 7-9.)

2. Follow steps 1–3 of the “To change the engine oil” section for

the oil draining procedure.

3. Remove the oil filter cartridge with an oil filter wrench.

TIPAn oil filter wrench is available at a

Yamaha dealer.4. Apply a thin coat of clean engine oil to the O-ring of the new oil filter

cartridge.

TIPMake sure that the O-ring is properly

seated.5. Install the new oil filter cartridgewith an oil filter wrench, and then

tighten it to the specified torque

with a torque wrench. 6. Follow steps 4–9 of the “To

change the engine oil” section for

the oil filling procedure.

7. Install the cowling and panel.

1. Oil filter cartridge

2. Oil filter wrench

1

2

1. O-ring

1

1. Torque wrench

Tightenin g torque:

Oil filter cartridge: 17 N·m (1.7 kgf·m, 13 lb·ft)

1

UB3LE0E0.book Page 16 Tuesday, July 23, 2019 12:05 PM

Page 109 of 136

Periodic maintenance an d a djustment

7-28

7

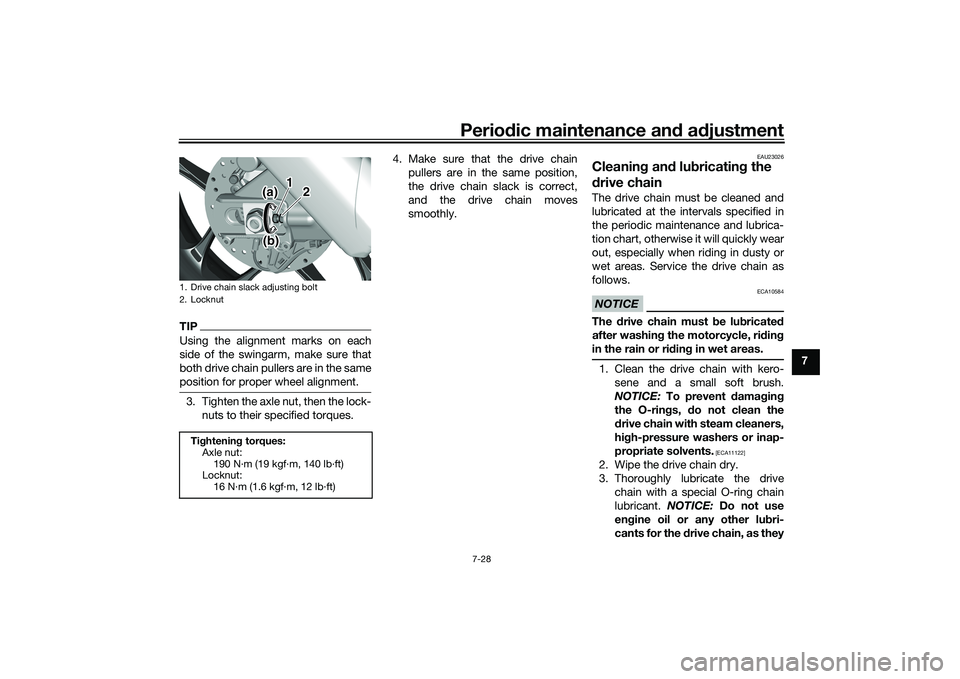

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain pullers are in the same

position for proper wheel alignment.3. Tighten the axle nut, then the lock-

nuts to their specified torques. 4. Make sure that the drive chain

pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23026

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must b e lubricate d

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Clean the drive chain with kero-

sene and a small soft brush.

NOTICE: To prevent d amaging

the O-rin gs, do not clean the

d rive chain with steam cleaners,

hi gh-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

en gine oil or any other lu bri-

cants for the drive chain, as they

1. Drive chain slack adjusting bolt

2. LocknutTi ghtenin g torques:

Axle nut: 190 N·m (19 kgf·m, 140 lb·ft)

Locknut:

16 N·m (1.6 kgf·m, 12 lb·ft)

(a) 1

2

(b)

UB3LE0E0.book Page 28 Tuesday, July 23, 2019 12:05 PM