lock YAMAHA YZF-R6 2012 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2012, Model line: YZF-R6, Model: YAMAHA YZF-R6 2012Pages: 112, PDF Size: 2.46 MB

Page 75 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-23

6

EAU33891

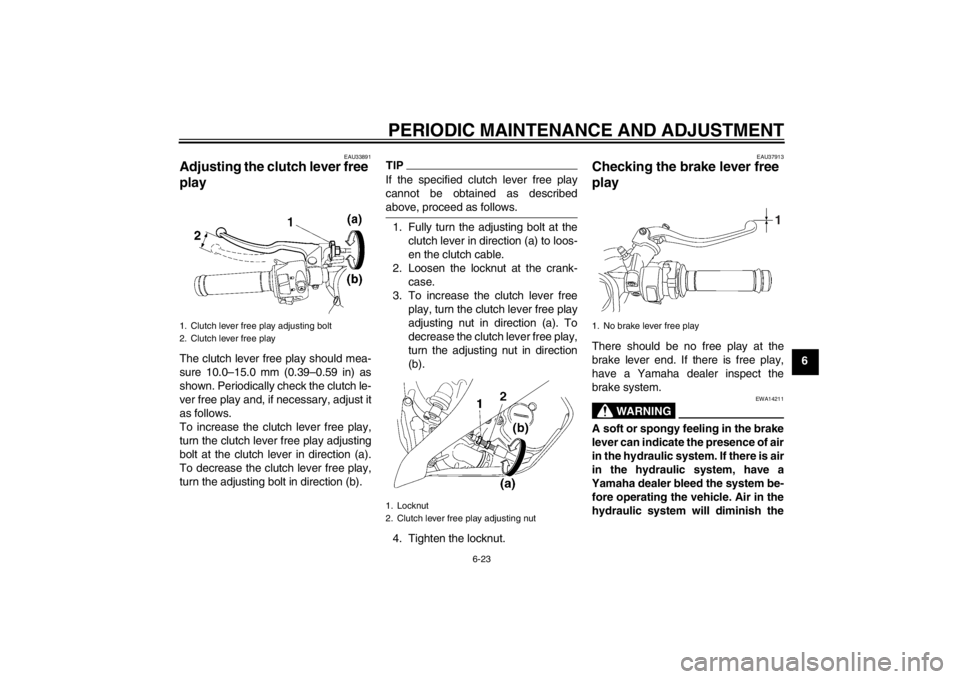

Adjusting the clutch lever free

play The clutch lever free play should mea-

sure 10.0–15.0 mm (0.39–0.59 in) as

shown. Periodically check the clutch le-

ver free play and, if necessary, adjust it

as follows.

To increase the clutch lever free play,

turn the clutch lever free play adjusting

bolt at the clutch lever in direction (a).

To decrease the clutch lever free play,

turn the adjusting bolt in direction (b).

TIPIf the specified clutch lever free play

cannot be obtained as described

above, proceed as follows.1. Fully turn the adjusting bolt at theclutch lever in direction (a) to loos-

en the clutch cable.

2. Loosen the locknut at the crank- case.

3. To increase the clutch lever free play, turn the clutch lever free play

adjusting nut in direction (a). To

decrease the clutch lever free play,

turn the adjusting nut in direction

(b).

4. Tighten the locknut.

EAU37913

Checking the brake lever free

play There should be no free play at the

brake lever end. If there is free play,

have a Yamaha dealer inspect the

brake system.

WARNING

EWA14211

A soft or spongy feeling in the brake

lever can indicate the presence of air

in the hydraulic system. If there is air

in the hydraulic system, have a

Yamaha dealer bleed the system be-

fore operating the vehicle. Air in the

hydraulic system will diminish the

1. Clutch lever free play adjusting bolt

2. Clutch lever free play

1. Locknut

2. Clutch lever free play adjusting nut

1. No brake lever free play

1

U1JSE0E0.book Page 23 Wednesday, July 27, 2011 10:34 AM

Page 78 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-26

6

●

Use only the specified brake flu-

id; otherwise, the rubber seals

may deteriorate, causing leak-

age.

●

Refill with the same type of

brake fluid. Adding a brake fluid

other than DOT 4 may result in a

harmful chemical reaction.

●

Be careful that water does not

enter the brake fluid reservoir

when refilling. Water will signifi-

cantly lower the boiling point of

the fluid and may result in vapor

lock.

NOTICE

ECA17640

Brake fluid may damage painted sur-

faces or plastic parts. Always clean

up spilled fluid immediately.As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake sys-

tem leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brakefluid level goes down suddenly, have a

Yamaha dealer check the cause before further riding.

EAU22731

Changing the brake fluid Have a Yamaha dealer change the

brake fluid at the intervals specified in

the TIP after the periodic maintenance

and lubrication chart. In addition, have

the oil seals of the master cylinders and

calipers as well as the brake hoses re-

placed at the intervals listed below or

whenever they are damaged or leak-

ing.●

Oil seals: Replace every two

years.

●

Brake hoses: Replace every four

years.

U1JSE0E0.book Page 26 Wednesday, July 27, 2011 10:34 AM

Page 79 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-27

6

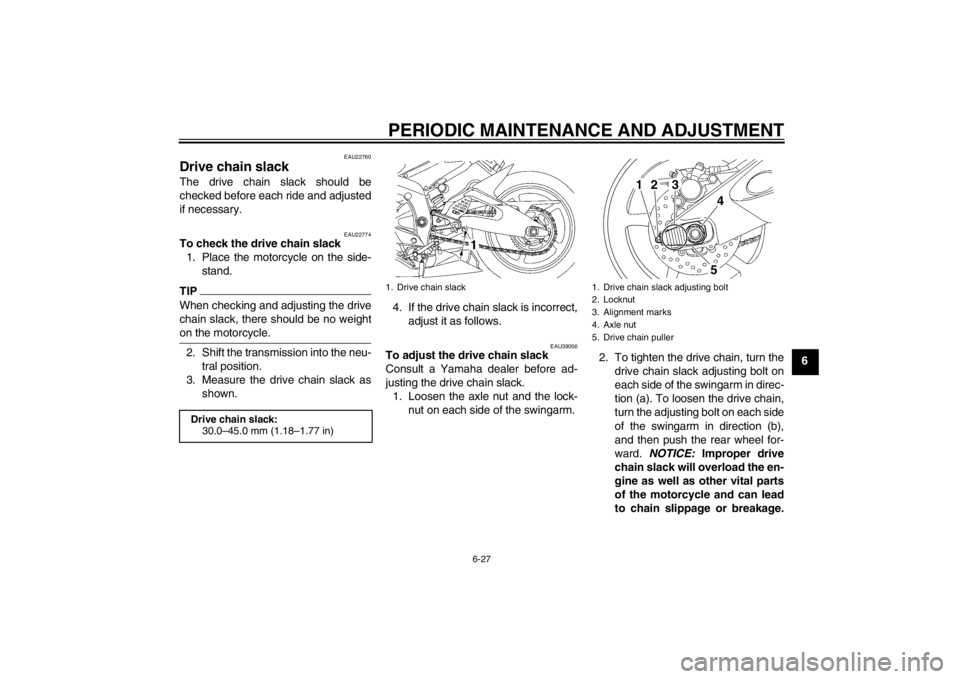

EAU22760

Drive chain slack The drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU22774

To check the drive chain slack1. Place the motorcycle on the side- stand.TIPWhen checking and adjusting the drive

chain slack, there should be no weight

on the motorcycle.2. Shift the transmission into the neu- tral position.

3. Measure the drive chain slack as shown. 4. If the drive chain slack is incorrect,

adjust it as follows.

EAU39056

To adjust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack.1. Loosen the axle nut and the lock- nut on each side of the swingarm. 2. To tighten the drive chain, turn the

drive chain slack adjusting bolt on

each side of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting bolt on each side

of the swingarm in direction (b),

and then push the rear wheel for-

ward. NOTICE: Improper drive

chain slack will overload the en-

gine as well as other vital parts

of the motorcycle and can lead

to chain slippage or breakage.

Drive chain slack: 30.0–45.0 mm (1.18–1.77 in)

1. Drive chain slack

1. Drive chain slack adjusting bolt

2. Locknut

3. Alignment marks

4. Axle nut

5. Drive chain puller

45

1

2

3

U1JSE0E0.book Page 27 Wednesday, July 27, 2011 10:34 AM

Page 80 of 112

![YAMAHA YZF-R6 2012 User Guide PERIODIC MAINTENANCE AND ADJUSTMENT

6-28

6To prevent this from occurring,

keep the drive chain slack with-

in the specified limits.

[ECA10571]

TIPUsing the alignment marks on each

drive chain puller, YAMAHA YZF-R6 2012 User Guide PERIODIC MAINTENANCE AND ADJUSTMENT

6-28

6To prevent this from occurring,

keep the drive chain slack with-

in the specified limits.

[ECA10571]

TIPUsing the alignment marks on each

drive chain puller,](/img/51/54369/w960_54369-79.png)

PERIODIC MAINTENANCE AND ADJUSTMENT

6-28

6To prevent this from occurring,

keep the drive chain slack with-

in the specified limits.

[ECA10571]

TIPUsing the alignment marks on each

drive chain puller, make sure that both

chain pullers are in the same position

for proper wheel alignment. Use the

end of the swingarm as the reference

point for the alignment marks.3. Tighten the axle nut to the speci-

fied torque. 4. Tighten the adjusting bolts in direc-

tion (a) to their specified torque.

5. Tighten the locknuts to their speci- fied torque.

6. Make sure that the drive chain pull- ers are in the same position, the

drive chain slack is correct, and

the drive chain moves smoothly.

EAU23025

Cleaning and lubricating the

drive chain The drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10583

The drive chain must be lubricated

after washing the motorcycle, riding

in the rain or riding in wet areas.1. Clean the drive chain with kero-sene and a small soft brush.

NOTICE: To prevent damaging

the O-rings, do not clean the

drive chain with steam cleaners,

high-pressure washers or inap-

propriate solvents.

[ECA11121]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

engine oil or any other lubri-

cants for the drive chain, as they

1. Drive chain slack adjusting bolt

2. LocknutTightening torque: Axle nut:110 Nm (11 m·kgf, 80 ft·lbf)

(a)

(b)

12

Tightening torque:

Drive chain slack adjusting bolt:2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Tightening torque: Locknut:16 Nm (1.6 m·kgf, 12 ft·lbf)

U1JSE0E0.book Page 28 Wednesday, July 27, 2011 10:34 AM

Page 86 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-34

6battery tends to discharge more quickly

if the vehicle is equipped with optional

electrical accessories.

NOTICE

ECA16521

To charge a VRLA (Valve Regulated

Lead Acid) battery, a special (con-

stant-voltage) battery charger is re-

quired. Using a conventional battery

charger will damage the battery.To store the battery

1. If the vehicle will not be used for more than one month, remove the

battery, fully charge it, and then

place it in a cool, dry place.

NOTICE: When removing the

battery, be sure the key is

turned to “OFF”, then discon-

nect the negative lead before

disconnecting the positive lead.

[ECA16302]

2. If the battery will be stored for more than two months, check it at least

once a month and fully charge it if

necessary.

3. Fully charge the battery before in- stallation. NOTICE: When install-

ing the battery, be sure the key is turned to “OFF”, then con-

nect the positive lead before

connecting the negative lead.

[ECA16840]

4. After installation, make sure that

the battery leads are properly con-

nected to the battery terminals.NOTICE

ECA16530

Always keep the battery charged.

Storing a discharged battery can

cause permanent battery damage.

EAU23706

Replacing the fuses The main fuse, the fuel injection system

fuse, and fuse box 1 are located under

the rider seat. (See page 3-20.)TIPTo access the fuel injection system

fuse, remove the starter relay cover by

pulling it upward.1. Main fuse

2. Fuel injection system spare fuse

3. Starter relay cover

4. Fuel injection system fuse

5. Fuse box 1

6. Backup fuse (for clock and immobilizer sys-tem)

7. Electronic throttle valve fuse

8. Spare fuse

2

1

5

6

3

748

U1JSE0E0.book Page 34 Wednesday, July 27, 2011 10:34 AM

Page 88 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-36

61. Remove the headlight bulb cover

by turning it counterclockwise.

2. Disconnect the headlight coupler. 3. Unhook the headlight bulb holder,

and then remove the burnt-out

bulb.

4. Place a new headlight bulb into po- sition, and then secure it with the

bulb holder.

5. Connect the headlight coupler. 6. Install the headlight bulb cover by

turning it clockwise.

7. Have a Yamaha dealer adjust the headlight beam if necessary.

1. Do not touch the glass part of the bulb.

1. Headlight bulb cover

1

1. Headlight coupler

1. Headlight bulb holder

U1JSE0E0.book Page 36 Wednesday, July 27, 2011 10:34 AM

Page 89 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-37

6

EAU24181

Tail/brake light This model is equipped with an LED-

type tail/brake light.

If the tail/brake light does not come on,

have a Yamaha dealer check it.

EAU24204

Replacing a turn signal light

bulb 1. Remove the turn signal light lensby removing the screw.

2. Remove the burnt-out bulb by pushing it in and turning it counter-

clockwise. 3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the screw. NOTICE: Do not over-

tighten the screw, otherwise the

lens may break.

[ECA11191]

1. Turn signal light lens

2. Screw

21

1. Turn signal light bulb

U1JSE0E0.book Page 37 Wednesday, July 27, 2011 10:34 AM

Page 94 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-42

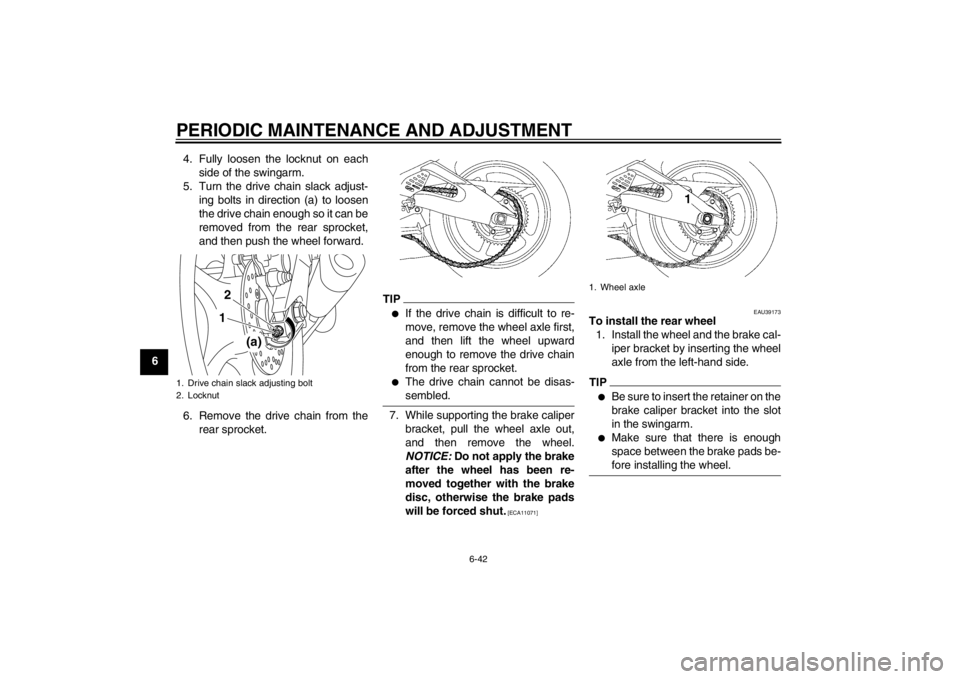

64. Fully loosen the locknut on each

side of the swingarm.

5. Turn the drive chain slack adjust- ing bolts in direction (a) to loosen

the drive chain enough so it can be

removed from the rear sprocket,

and then push the wheel forward.

6. Remove the drive chain from the rear sprocket.

TIP●

If the drive chain is difficult to re-

move, remove the wheel axle first,

and then lift the wheel upward

enough to remove the drive chain

from the rear sprocket.

●

The drive chain cannot be disas-

sembled.

7. While supporting the brake caliperbracket, pull the wheel axle out,

and then remove the wheel.

NOTICE: Do not apply the brake

after the wheel has been re-

moved together with the brake

disc, otherwise the brake pads

will be forced shut.

[ECA11071] EAU39173

To install the rear wheel

1. Install the wheel and the brake cal- iper bracket by inserting the wheel

axle from the left-hand side.TIP●

Be sure to insert the retainer on the

brake caliper bracket into the slot

in the swingarm.

●

Make sure that there is enough

space between the brake pads be-

fore installing the wheel.

1. Drive chain slack adjusting bolt

2. Locknut

(a)

12

1. Wheel axle

U1JSE0E0.book Page 42 Wednesday, July 27, 2011 10:34 AM

Page 95 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-43

6

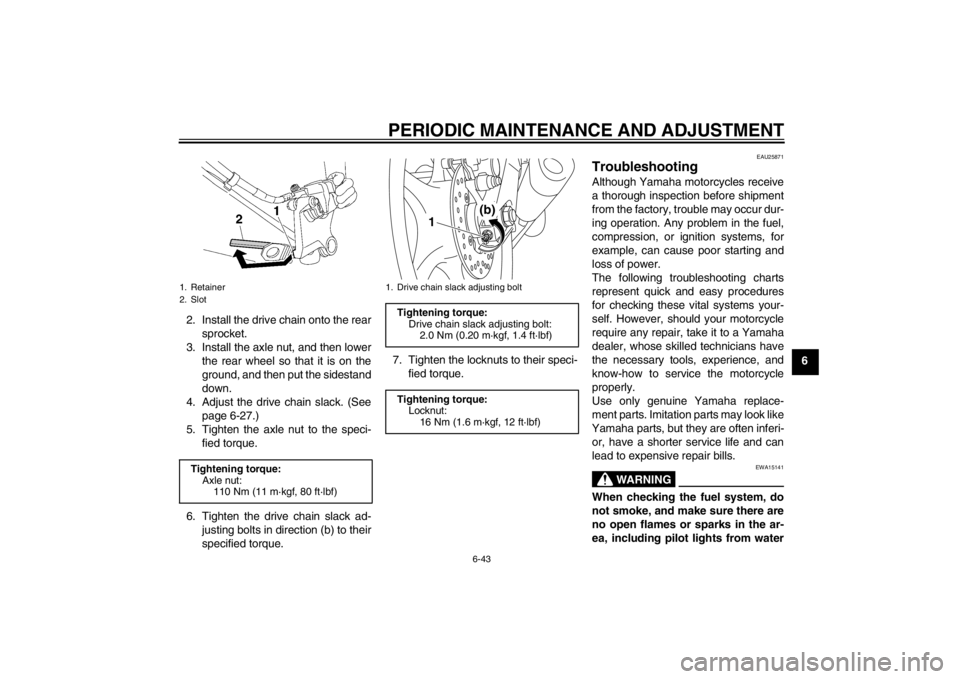

2. Install the drive chain onto the rear

sprocket.

3. Install the axle nut, and then lower the rear wheel so that it is on the

ground, and then put the sidestand

down.

4. Adjust the drive chain slack. (See page 6-27.)

5. Tighten the axle nut to the speci- fied torque.

6. Tighten the drive chain slack ad- justing bolts in direction (b) to their

specified torque. 7. Tighten the locknuts to their speci-

fied torque.

EAU25871

Troubleshooting Although Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur dur-

ing operation. Any problem in the fuel,

compression, or ignition systems, for

example, can cause poor starting and

loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look like

Yamaha parts, but they are often inferi-

or, have a shorter service life and can

lead to expensive repair bills.

WARNING

EWA15141

When checking the fuel system, do

not smoke, and make sure there are

no open flames or sparks in the ar-

ea, including pilot lights from water

1. Retainer

2. SlotTightening torque:Axle nut:110 Nm (11 m·kgf, 80 ft·lbf)

1. Drive chain slack adjusting bolt

Tightening torque: Drive chain slack adjusting bolt:2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Tightening torque: Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

(b)

1

U1JSE0E0.book Page 43 Wednesday, July 27, 2011 10:34 AM

Page 98 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-46

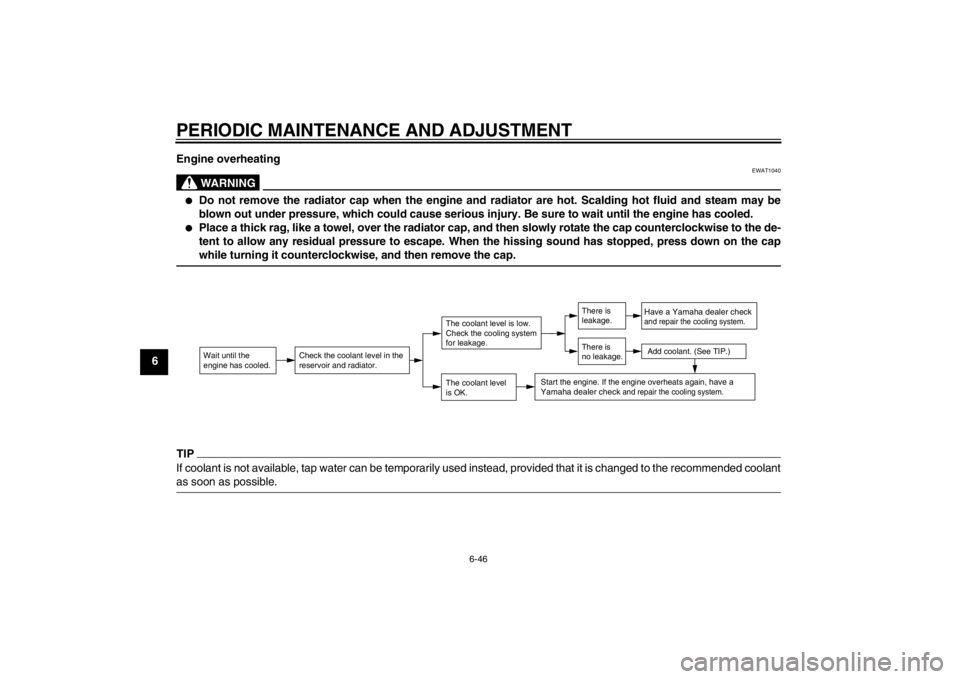

6Engine overheating

WARNING

EWAT1040

●

Do not remove the radiator cap when the engine and

radiator are hot. Scalding hot fluid and steam may be

blown out under pressure, which could cause serious injury. Be sure to wait until the engine has cooled.

●

Place a thick rag, like a towel, over the radiator cap, and then slowly rotate the cap counterclockwise to the de-

tent to allow any residual pressure to escape. When the hissing sound has stopped, press down on the cap

while turning it counterclockwise, and then remove the cap.

TIPIf coolant is not available, tap water can be temporarily used instead, provided that it is changed to the recommended coolant

as soon as possible.

Wait until the

engine has cooled.

Check the coolant level in the

reservoir and radiator.

The coolant level

is OK.The coolant level is low.

Check the cooling system

for leakage.

Have a Yamaha dealer checkand repair the cooling system.Add coolant. (See TIP.)

Start the engine. If the engine overheats again,

have a

Yamaha dealer check

and repair the cooling system.

There is

leakage.

There is

no leakage.

U1JSE0E0.book Page 46 Wednesday, July 27, 2011 10:34 AM