wheel YAMAHA YZF-R6 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZF-R6, Model: YAMAHA YZF-R6 2014Pages: 112, PDF Size: 2.52 MB

Page 79 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-28

6

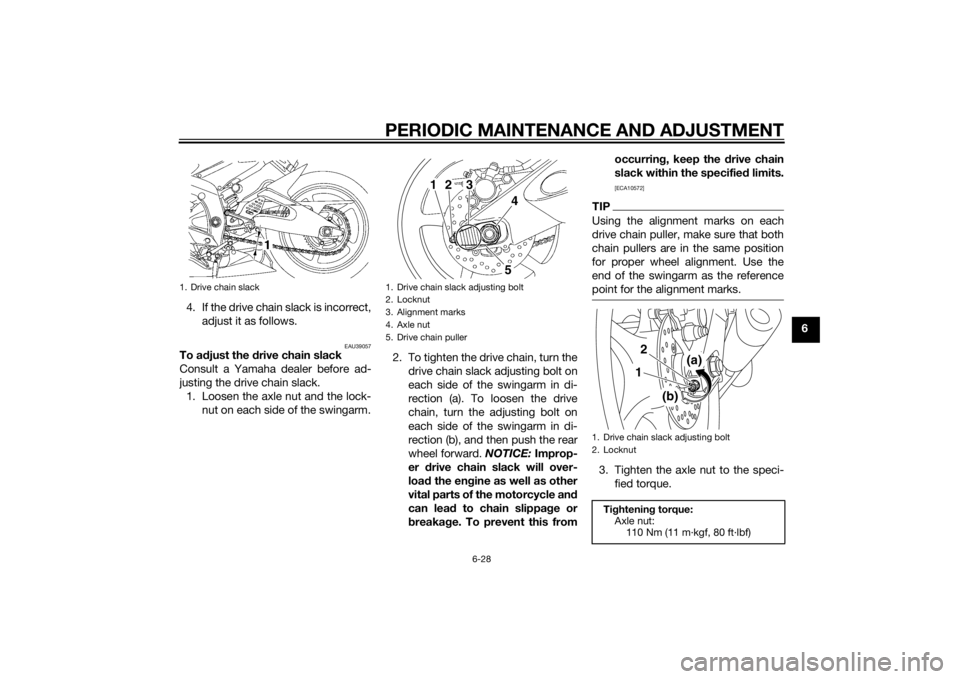

4. If the drive chain slack is incorrect,

adjust it as follows.

EAU39057

To a djust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Loosen the axle nut and the lock- nut on each side of the swingarm. 2. To tighten the drive chain, turn the

drive chain slack adjusting bolt on

each side of the swingarm in di-

rection (a). To loosen the drive

chain, turn the adjusting bolt on

each side of the swingarm in di-

rection (b), and then push the rear

wheel forward. NOTICE: Improp-

er drive chain slack will over-

loa d the en gine as well as other

vital parts of the motorcycle an d

can lea d to chain slippa ge or

b reakag e. To prevent this from occurrin

g, keep the d rive chain

slack within the specified limits.

[ECA10572]

TIPUsing the alignment marks on each

drive chain puller, make sure that both

chain pullers are in the same position

for proper wheel alignment. Use the

end of the swingarm as the reference

point for the alignment marks.3. Tighten the axle nut to the speci-

fied torque.

1. Drive chain slack

1. Drive chain slack adjusting bolt

2. Locknut

3. Alignment marks

4. Axle nut

5. Drive chain puller

45

1

2

3

1. Drive chain slack adjusting bolt

2. Locknut

Tightenin g torque:

Axle nut: 110 Nm (11 m·kgf, 80 ft·lbf)

(a)

(b)

12

U2CXE0E0.book Page 28 Monday, July 29, 2013 2:02 PM

Page 84 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-33

6

NOTICE

ECA10591

If any damage is foun d or the front

fork does not operate smoothly,

have a Yamaha d ealer check or re-

pair it.

EAU23284

Checkin g the steerin gWorn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

chart.

1. Place a stand under the engine to raise the front wheel off the

ground. (See page 6-40 for more

information.) WARNING! To

avoi d injury, securely support

the vehicle so there is no dan ger

of it fallin g over.

[EWA10752]

2. Hold the lower ends of the front

fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steer-

ing.

U2CXE0E0.book Page 33 Monday, July 29, 2013 2:02 PM

Page 85 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-34

6

EAU23292

Checking the wheel bearin gsThe front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer

check the wheel bearings.

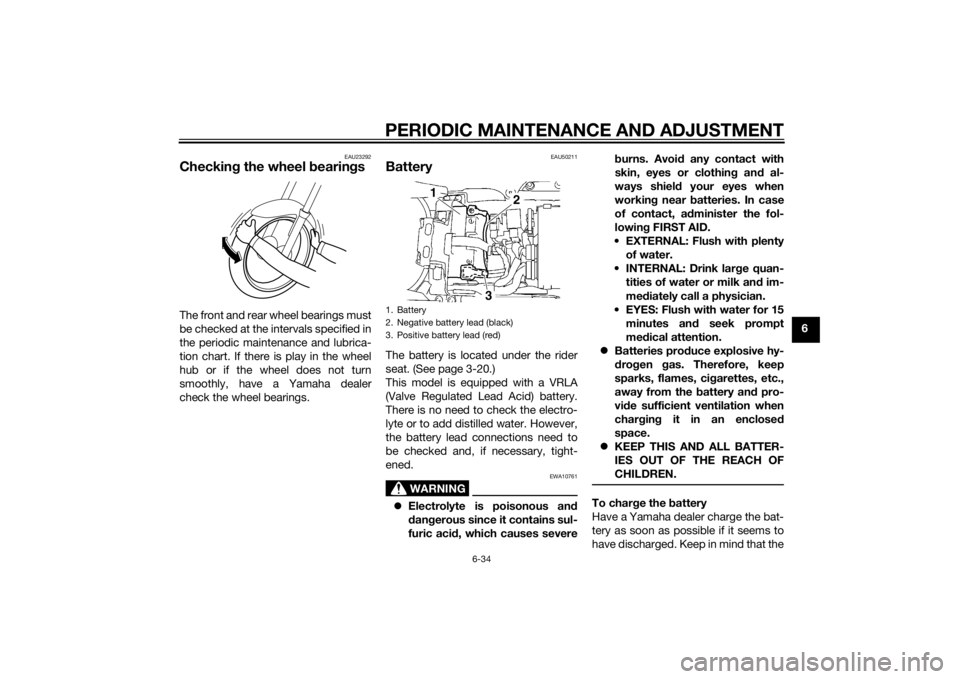

EAU50211

BatteryThe battery is located under the rider

seat. (See page 3-20.)

This model is equipped with a VRLA

(Valve Regulated Lead Acid) battery.

There is no need to check the electro-

lyte or to add distilled water. However,

the battery lead connections need to

be checked and, if necessary, tight-

ened.

WARNING

EWA10761

Electrolyte is poisonous an d

d an gerous since it contains sul-

furic aci d, which causes severe b

urns. Avoi d any contact with

skin, eyes or clothin g an d al-

ways shiel d your eyes when

workin g near b atteries. In case

of contact, ad minister the fol-

lowin g FIRST AID.

EXTERNAL: Flush with plenty of water.

INTERNAL: Drink lar ge quan-

tities of water or milk an d im-

me diately call a physician.

EYES: Flush with water for 15 minutes an d seek prompt

me dical attention.

Batteries pro duce explosive hy-

d ro gen gas. Therefore, keep

sparks, flames, ci garettes, etc.,

away from the battery an d pro-

vi de sufficient ventilation when

char gin g it in an enclose d

space.

KEEP THIS AND ALL BATTER-

IES OUT OF THE REACH OF

CHILDREN.

To char ge the b attery

Have a Yamaha dealer charge the bat-

tery as soon as possible if it seems to

have discharged. Keep in mind that the

1. Battery

2. Negative battery lead (black)

3. Positive battery lead (red)

1

2

3

U2CXE0E0.book Page 34 Monday, July 29, 2013 2:02 PM

Page 91 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-40

6

EAU24351

Supporting the motorcycleSince this model is not equipped with a

centerstand, follow these precautions

when removing the front and rear

wheel or performing other mainte-

nance requiring the motorcycle to

stand upright. Check that the motorcy-

cle is in a stable and level position be-

fore starting any maintenance. A

strong wooden box can be placed un-

der the engine for added stability.

To service the front wheel

1. Stabilize the rear of the motorcy- cle by using a motorcycle stand

or, if an additional motorcycle

stand is not available, by placing a

jack under the frame in front of the

rear wheel.

2. Raise the front wheel off the ground by using a motorcycle

stand.

To service the rear wheel

Raise the rear wheel off the ground by

using a motorcycle stand or, if a motor-

cycle stand is not available, by placing a jack either under each side of the

frame in front of the rear wheel or under

each side of the swingarm.

EAU24361

Front wheel

EAU56350

To remove the front wheel

WARNING

EWA10822

To avoi

d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Loosen the front wheel axle pinch

bolts, the axle bolt, and then the

brake caliper bolts.1. Front wheel axle pinch bolt

U2CXE0E0.book Page 40 Monday, July 29, 2013 2:02 PM

Page 92 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-41

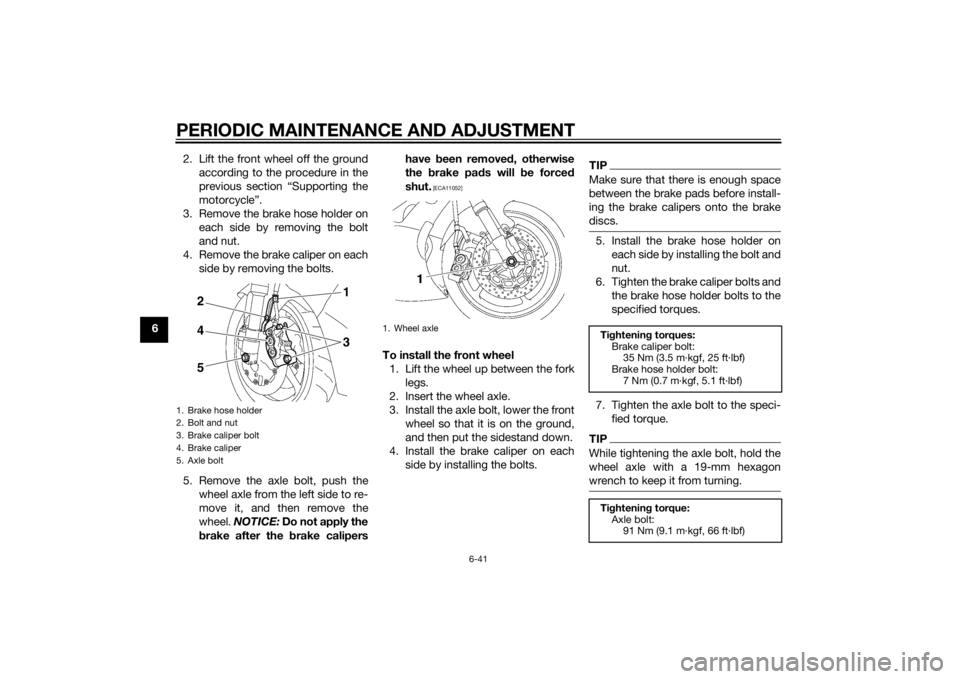

62. Lift the front wheel off the ground

according to the procedure in the

previous section “Supporting the

motorcycle”.

3. Remove the brake hose holder on each side by removing the bolt

and nut.

4. Remove the brake caliper on each side by removing the bolts.

5. Remove the axle bolt, push the wheel axle from the left side to re-

move it, and then remove the

wheel. NOTICE: Do not apply the

b rake after the brake calipers have

been removed , otherwise

the brake pa ds will be forced

shut.

[ECA11052]

To install the front wheel 1. Lift the wheel up between the fork legs.

2. Insert the wheel axle.

3. Install the axle bolt, lower the front wheel so that it is on the ground,

and then put the sidestand down.

4. Install the brake caliper on each side by installing the bolts.

TIPMake sure that there is enough space

between the brake pads before install-

ing the brake calipers onto the brake

discs.5. Install the brake hose holder oneach side by installing the bolt and

nut.

6. Tighten the brake caliper bolts and the brake hose holder bolts to the

specified torques.

7. Tighten the axle bolt to the speci- fied torque.TIPWhile tightening the axle bolt, hold the

wheel axle with a 19-mm hexagon

wrench to keep it from turning.

1. Brake hose holder

2. Bolt and nut

3. Brake caliper bolt

4. Brake caliper

5. Axle bolt

31

2

4

5

1. Wheel axle

Tightenin g torques:

Brake caliper bolt: 35 Nm (3.5 m·kgf, 25 ft·lbf)

Brake hose holder bolt:

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Ti ghtenin g torque:

Axle bolt: 91 Nm (9.1 m·kgf, 66 ft·lbf)

U2CXE0E0.book Page 41 Monday, July 29, 2013 2:02 PM

Page 93 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-42

6

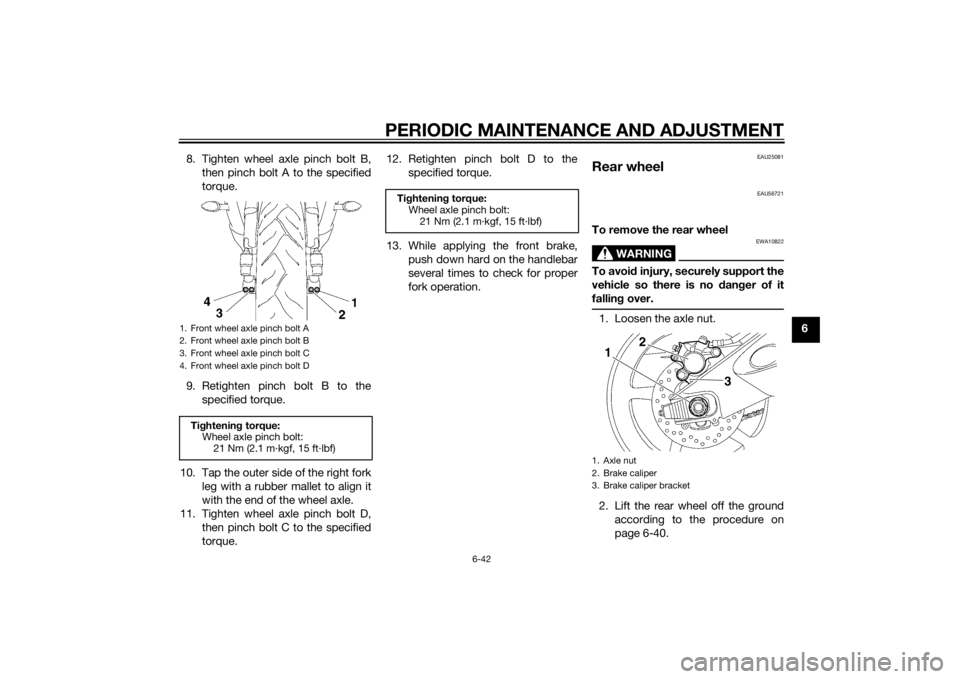

8. Tighten wheel axle pinch bolt B,

then pinch bolt A to the specified

torque.

9. Retighten pinch bolt B to the specified torque.

10. Tap the outer side of the right fork leg with a rubber mallet to align it

with the end of the wheel axle.

11. Tighten wheel axle pinch bolt D, then pinch bolt C to the specified

torque. 12. Retighten pinch bolt D to the

specified torque.

13. While applying the front brake, push down hard on the handlebar

several times to check for proper

fork operation.

EAU25081

Rear wheel

EAU56721

To remove the rear wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Loosen the axle nut.

2. Lift the rear wheel off the ground

according to the procedure on

page 6-40.

1. Front wheel axle pinch bolt A

2. Front wheel axle pinch bolt B

3. Front wheel axle pinch bolt C

4. Front wheel axle pinch bolt DTightenin g torque:

Wheel axle pinch bolt: 21 Nm (2.1 m·kgf, 15 ft·lbf)

Tightenin g torque:

Wheel axle pinch bolt: 21 Nm (2.1 m·kgf, 15 ft·lbf)

1. Axle nut

2. Brake caliper

3. Brake caliper bracket

1

2

3

U2CXE0E0.book Page 42 Monday, July 29, 2013 2:02 PM

Page 94 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-43

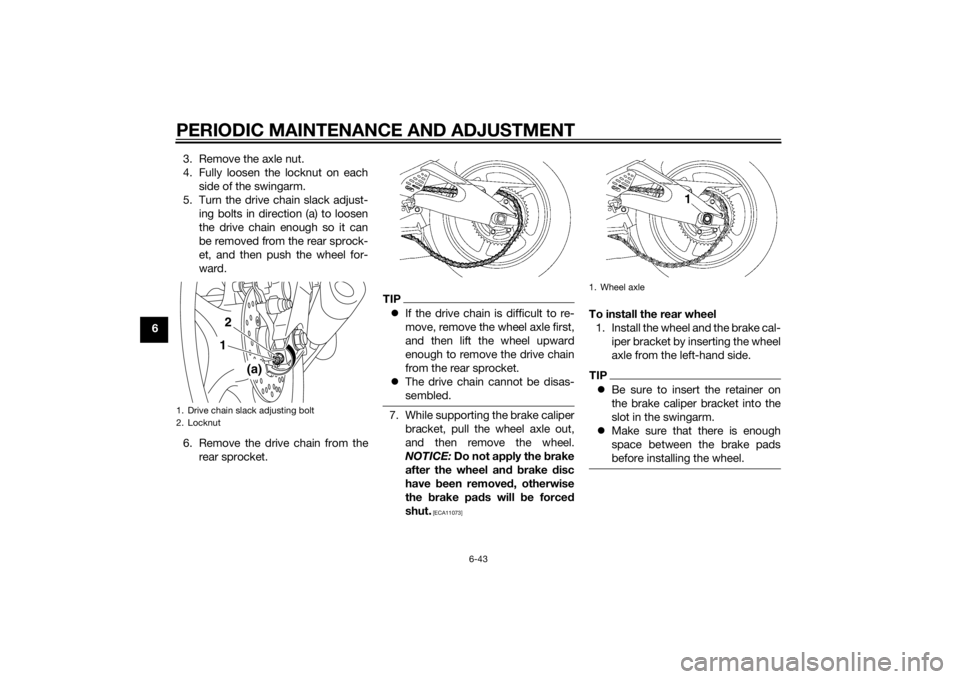

63. Remove the axle nut.

4. Fully loosen the locknut on each

side of the swingarm.

5. Turn the drive chain slack adjust- ing bolts in direction (a) to loosen

the drive chain enough so it can

be removed from the rear sprock-

et, and then push the wheel for-

ward.

6. Remove the drive chain from the rear sprocket.

TIPIf the drive chain is difficult to re-

move, remove the wheel axle first,

and then lift the wheel upward

enough to remove the drive chain

from the rear sprocket.

The drive chain cannot be disas-

sembled.7. While supporting the brake caliper

bracket, pull the wheel axle out,

and then remove the wheel.

NOTICE: Do not apply the brake

after the wheel an d b rake disc

have been removed , otherwise

the brake pa ds will be forced

shut.

[ECA11073]

To install the rear wheel 1. Install the wheel and the brake cal- iper bracket by inserting the wheel

axle from the left-hand side.TIPBe sure to insert the retainer on

the brake caliper bracket into the

slot in the swingarm.

Make sure that there is enough

space between the brake pads

before installing the wheel.

1. Drive chain slack adjusting bolt

2. Locknut

(a)

12

1. Wheel axle

U2CXE0E0.book Page 43 Monday, July 29, 2013 2:02 PM

Page 95 of 112

PERIODIC MAINTENANCE AND ADJUSTMENT

6-44

6

2. Install the drive chain onto the rear

sprocket.

3. Install the axle nut, and then lower the rear wheel so that it is on the

ground, and then put the side-

stand down.

4. Adjust the drive chain slack. (See page 6-27.)

5. Tighten the axle nut to the speci- fied torque.

6. Tighten the drive chain slack ad- justing bolts in direction (b) to their

specified torque. 7. Tighten the locknuts to their spec-

ified torque.

EAU25872

Trou bleshootin gAlthough Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition systems,

for example, can cause poor starting

and loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWA15142

When checkin g the fuel system, d o

not smoke, an d make sure there are

no open flames or sparks in the ar-

ea, inclu din g pilot li ghts from water

1. Retainer

2. SlotTi ghtenin g torque:

Axle nut: 110 Nm (11 m·kgf, 80 ft·lbf)

1. Drive chain slack adjusting bolt

Tightenin g torque:

Drive chain slack adjusting bolt: 2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Ti ghtenin g torque:

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

(b)

1

U2CXE0E0.book Page 44 Monday, July 29, 2013 2:02 PM

Page 99 of 112

MOTORCYCLE CARE AND STORAGE7-1

7

EAU37834

Matte color cautionNOTICE

ECA15193

Some models are equipped with

matte colored finished parts. Be

sure to consult a Yamaha dealer for

a d vice on what prod ucts to use be-

fore cleanin g the vehicle. Usin g a

b rush, harsh chemical pro ducts or

cleanin g compoun ds when cleanin g

these parts will scratch or damag e

their surface. Wax also shoul d not

b e applie d to any matte colored fin-

ishe d parts.

EAU54721

CareWhile the open design of a motorcycle

reveals the attractiveness of the tech-

nology, it also makes it more vulnera-

ble. Rust and corrosion can develop

even if high-quality components are

used. A rusty exhaust pipe may go un-

noticed on a car, however, it detracts

from the overall appearance of a mo-

torcycle. Frequent and proper care

does not only comply with the terms of

the warranty, but it will also keep your

motorcycle looking good, extend its

life and optimize its performance.

Before cleanin g

1. Cover the muffler outlet with a plastic bag after the engine has

cooled down.

2. Make sure that all caps and cov- ers as well as all electrical cou-

plers and connectors, including

the spark plug caps, are tightly in-

stalled.

3. Remove extremely stubborn dirt, like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such prod- ucts onto seals, gaskets, sprock-

ets, the drive chain and wheel

axles. Always rinse the dirt and

degreaser off with water.

Cleanin g

NOTICE

ECA11143

Avoi d usin g stron g aci dic wheel

cleaners, especially on spoked

wheels. If such pro ducts are

use d on har d-to-remove dirt, do

not leave the cleaner on the af-

fected area any lon ger than in-

structed . Also, thorou ghly rinse

the area off with water, immed i-

ately dry it, an d then apply a cor-

rosion protection spray.

Improper cleanin g can d amage

plastic parts (such as cowlin gs,

panels, win dshiel ds, hea dlig ht

lenses, meter lenses, etc.) an d

the mufflers. Use only a soft,

clean cloth or spon ge with wa-

ter to clean plastic. However, if

the plastic parts cannot be thor-

ou ghly cleaned with water, di-

lute d mil d d eter gent with water

may be used . Be sure to rinse

U2CXE0E0.book Page 1 Monday, July 29, 2013 2:02 PM

Page 100 of 112

MOTORCYCLE CARE AND STORAGE

7-2

7off any d

etergent resi due usin g

plenty of water, as it is harmful

to plastic parts.

Do not use any harsh chemical

prod ucts on plastic parts or the

muffler. Be sure to avoi d using

cloths or spon ges which have

b een in contact with stron g or

a b rasive cleanin g prod ucts, sol-

vent or thinner, fuel ( gasoline),

rust removers or inhi bitors,

b rake flui d, antifreeze or elec-

trolyte.

Do not use hi gh-pressure wash-

ers or steam-jet cleaners since

they cause water seepa ge an d

d eterioration in the followin g ar-

eas: seals (of wheel an d swin g-

arm bearin gs, fork an d b rakes),

stora ge compartments, electric

components (couplers, connec-

tors, instruments, switches an d

li g hts), breather hoses an d

vents.

For motorcycles equippe d with

a win dshield : Do not use stron g

cleaners or har d spon ges as

they will cause dullin g

or

scrat

ching . Some cleanin gcompoun

ds for plastic may

leave scratches on the win d-

shield . Test the pro duct on a

small hidden part of the win d-

shield to make sure that it does

not leave any marks. If the win d-

shield is scratche d, use a quality

plastic polishin g compoun d af-

ter washin g.

After normal useRemove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt

and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain, near the sea oron salt-sprayed roadsSince sea salt or salt sprayed on roads

during winter are extremely corrosive

in combination with water, carry out

the following steps after each ride in

the rain, near the sea or on salt-

sprayed roads.

TIPSalt sprayed on roads in the winter

may remain well into spring.1. Clean the motorcycle with cold

water and a mild detergent, after

the engine has cooled down.

NOTICE: Do not use warm wa-

ter since it increases the corro-

sive action of the salt.

[ECA10792]

2. After drying the motorcycle, apply a corrosion protection spray on all

metal, including chrome- and

nickel-plated, surfaces (except the

titanium muffler) to prevent corro-

sion.

Cleaning the windshieldAvoid using any alkaline or strong acid

cleaner, gasoline, brake fluid, or any

other solvent. Clean the windshield

with a cloth or sponge dampened with

a neutral detergent, and after cleaning,

thoroughly wash it off with water. For

additional cleaning, use Yamaha Wind-

shield Cleaner or other quality cleaner.

Some cleaning compounds for plastics

may leave scratches on surfaces of the

U2CXE0E0.book Page 2 Monday, July 29, 2013 2:02 PM