warning YAMAHA YZF-R6 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZF-R6, Model: YAMAHA YZF-R6 2016Pages: 112, PDF Size: 2.57 MB

Page 24 of 112

Instrument and control functions

3-9

3 Clock

The clock uses a 12-hour time system.

To set the clock

1. Turn the key to “ON”.

2. Push both the “SELECT” button

and “RESET” button for two sec-

onds. The hour digits will start

flashing.

3. Push the “RESET” button to set the hours.

4. Push the “SELECT” button, and the minute digits will start flashing.

5. Push the “RESET” button to set the minutes.

6. Push the “SELECT” button to con- firm settings and start the clock. O

dometer, tripmeters, an d stop-

watch

O dometer an d tripmeters

The odometer shows the total distance

traveled by the vehicle.

The tripmeters show the distance trav-

eled since they were last reset.

TIP The odometer will lock at 999999.

The tripmeters will reset and con-

tinue counting after 9999.9 is

reached.During normal operation, push the

“SELECT” button to change the dis-

play between the odometer “ODO”, the tripmeters “TRIP A” and “TRIP B”,

and the stopwatch in the following or-

der:

TRIP A

→ TRIP B → ODO → Stop-

watch → TRIP A

If the fuel level warning light comes on,

the display will automatically change to

the fuel reserve tripmeter “F-TRIP” and

start counting the distance traveled

from that point. In this case, push the

“SELECT” button to change the dis-

play in the following order:

F-TRIP → Stopwatch → TRIP A →

TRIP B → ODO → F-TRIP

To reset a tripmeter, push the “SE-

LECT” button to change the display to

the tripmeter you want to reset, and

then push the “RESET” button for one

second. If you do not reset the fuel re-

serve tripmeter manually, after refuel-

ing and traveling 5 km (3 mi), it will

reset automatically and disappear from

the display.

1. Clock

km/h

TRIP A

1

1. Odometer/tripmeter/fuel reserve tripme- ter/stopwatch

TRIP A

˚C

1

U2CXE2E0.book Page 9 Tuesday, June 9, 2015 5:04 PM

Page 26 of 112

Instrument and control functions

3-11

3

TIP When the air intake temperature is

below –9 °C, “LO” will be dis-

played.

Even when the air intake tempera-

ture is displayed, the coolant tem-

perature warning light comes on if

the engine overheats.

When the key is turned to “ON”,

the coolant temperature is auto-

matically displayed, even if the air

intake temperature was displayed

prior to turning the key to “OFF”.

When the air intake temperature

display is selected, “A” is dis-

played for one second, and then

“A” and the air intake temperature

are displayed.

Self- dia gnosis device

This model is equipped with a self-di-

agnosis device for various electrical

circuits. If a problem is detected in any

of those circuits, the engine trouble

warning light will come on and the dis-

play will indicate an error code. If the

display indicates any error codes, note

the code number and have a Yamaha

dealer check the vehicle.

The self-diagnosis device also detects

problems in the immobilizer system

circuits. If a problem is detected in the

immobilizer system circuits, the immo- bilizer system indicator light will flash

and the display will indicate an error

code.

TIPIf the display indicates error code 52,

this could be caused by transponder

interference. If this error code appears,

try the following:1. Use the code re-registering key to

start the engine.TIPMake sure there are no other immobi-

lizer keys close to the main switch, and

do not keep more than one immobilizer

key on the same key ring! Immobilizer

system keys may cause signal interfer-

ence, which may prevent the engine

from starting.2. If the engine starts, turn it off andtry starting the engine with the

standard keys.

3. If one or both of the standard keys do not start the engine, take the

vehicle, the code re-registering

key and both standard keys to a

Yamaha dealer and have the stan-

dard keys re-registered.

1. Immobilizer system indicator light

2. Engine trouble warning light “ ”

3. Error code display

321

U2CXE2E0.book Page 11 Tuesday, June 9, 2015 5:04 PM

Page 29 of 112

Instrument and control functions

3-14

3

EAU1234H

Han dle bar switchesLeft Ri

ght

EAU12351

Pass switch “ ”

Press this switch to flash the headlight.

EAU12401

Dimmer switch “ / ”

Set this switch to “ ” for the high

beam and to “ ” for the low beam.

EAU12461

Turn si gnal switch “ / ”

To signal a right-hand turn, push this

switch to “ ”. To signal a left-hand

turn, push this switch to “ ”. When

released, the switch returns to the cen- ter position. To cancel the turn signal

lights, push the switch in after it has re-

turned to the center position.

EAU12501

Horn switch “ ”

Press this switch to sound the horn.

EAU12661

En

gine stop switch “ / ”

Set this switch to “ ” before starting

the engine. Set this switch to “ ” to

stop the engine in case of an emergen-

cy, such as when the vehicle overturns

or when the throttle cable is stuck.

EAU12713

Start switch “ ”

Push this switch to crank the engine

with the starter. See page 5-1 for start-

ing instructions prior to starting the en-

gine.

EAU41701

The engine trouble warning light will

come on when the key is turned to

“ON” and the start switch is pushed,

but this does not indicate a malfunc-

tion.

1. Pass switch “ ”

2. Dimmer switch “ / ”

3. Turn signal switch “ / ”

4. Horn switch “ ”

5. Hazard switch “ ”

1. Engine stop switch “ / ”

2. Start switch “ ”

U2CXE2E0.book Page 14 Tuesday, June 9, 2015 5:04 PM

Page 32 of 112

Instrument and control functions

3-17

3

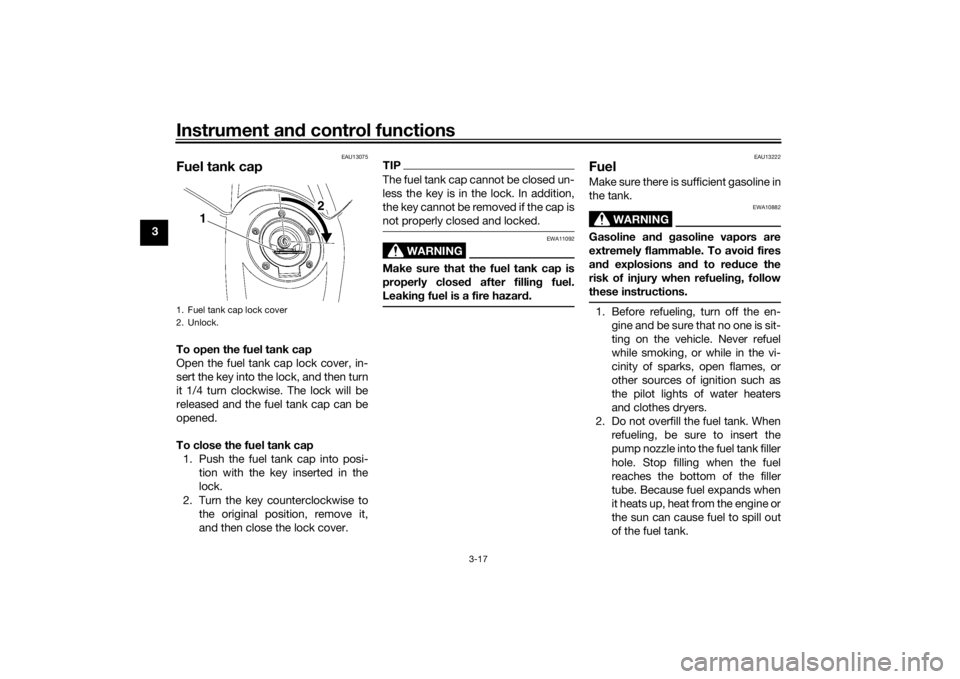

EAU13075

Fuel tank capTo open the fuel tank cap

Open the fuel tank cap lock cover, in-

sert the key into the lock, and then turn

it 1/4 turn clockwise. The lock will be

released and the fuel tank cap can be

opened.

To close the fuel tank cap

1. Push the fuel tank cap into posi- tion with the key inserted in the

lock.

2. Turn the key counterclockwise to the original position, remove it,

and then close the lock cover.

TIPThe fuel tank cap cannot be closed un-

less the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly closed and locked.

WARNING

EWA11092

Make sure that the fuel tank cap is

properly close d after fillin g fuel.

Leakin g fuel is a fire hazar d.

EAU13222

FuelMake sure there is sufficient gasoline in

the tank.

WARNING

EWA10882

Gasoline an d g asoline vapors are

extremely flammab le. To avoid fires

an d explosions an d to re duce the

risk of injury when refuelin g, follow

these instructions.1. Before refueling, turn off the en- gine and be sure that no one is sit-

ting on the vehicle. Never refuel

while smoking, or while in the vi-

cinity of sparks, open flames, or

other sources of ignition such as

the pilot lights of water heaters

and clothes dryers.

2. Do not overfill the fuel tank. When refueling, be sure to insert the

pump nozzle into the fuel tank filler

hole. Stop filling when the fuel

reaches the bottom of the filler

tube. Because fuel expands when

it heats up, heat from the engine or

the sun can cause fuel to spill out

of the fuel tank.

1. Fuel tank cap lock cover

2. Unlock.

1 2

U2CXE2E0.book Page 17 Tuesday, June 9, 2015 5:04 PM

Page 33 of 112

Instrument and control functions

3-18

3

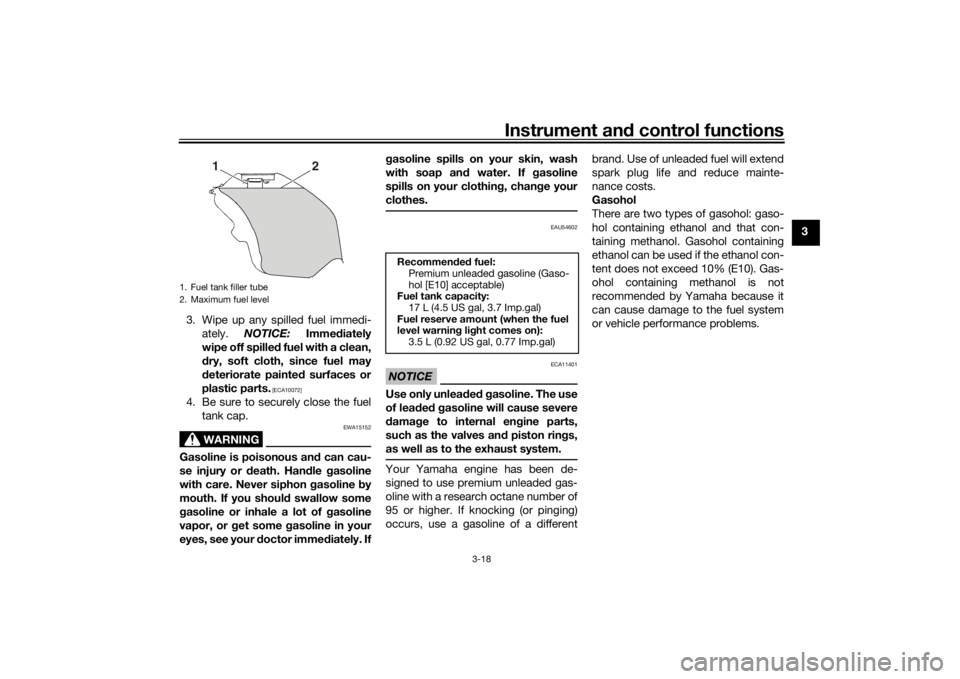

3. Wipe up any spilled fuel immedi- ately. NOTICE: Immediately

wipe off spille d fuel with a clean,

d ry, soft cloth, since fuel may

d eteriorate painte d surfaces or

plastic parts.

[ECA10072]

4. Be sure to securely close the fuel tank cap.

WARNING

EWA15152

Gasoline is poisonous an d can cau-

se injury or death. Han dle gasoline

with care. Never siphon gasoline by

mouth. If you shoul d swallow some

g asoline or inhale a lot of gasoline

vapor, or get some g asoline in your

eyes, see your d octor immediately. If g

asoline spills on your skin, wash

with soap an d water. If gasoline

spills on your clothin g, chan ge your

clothes.

EAU54602

NOTICE

ECA11401

Use only unlea ded g asoline. The use

of lead ed g asoline will cause severe

d amag e to internal en gine parts,

such as the valves an d piston rin gs,

as well as to the exhaust system.Your Yamaha engine has been de-

signed to use premium unleaded gas-

oline with a research octane number of

95 or higher. If knocking (or pinging)

occurs, use a gasoline of a different brand. Use of unleaded fuel will extend

spark plug life and reduce mainte-

nance costs.

Gasohol

There are two types of gasohol: gaso-

hol containing ethanol and that con-

taining methanol. Gasohol containing

ethanol can be used if the ethanol con-

tent does not exceed 10% (E10). Gas-

ohol containing methanol is not

recommended by Yamaha because it

can cause damage to the fuel system

or vehicle performance problems.

1. Fuel tank filler tube

2. Maximum fuel level

2

1

Recommen ded fuel:

Premium unleaded gasoline (Gaso-

hol [E10] acceptable)

Fuel tank capacity:

17 L (4.5 US gal, 3.7 Imp.gal)

Fuel reserve amount (when the fuel

level warnin g li ght comes on):

3.5 L (0.92 US gal, 0.77 Imp.gal)

U2CXE2E0.book Page 18 Tuesday, June 9, 2015 5:04 PM

Page 34 of 112

Instrument and control functions

3-19

3

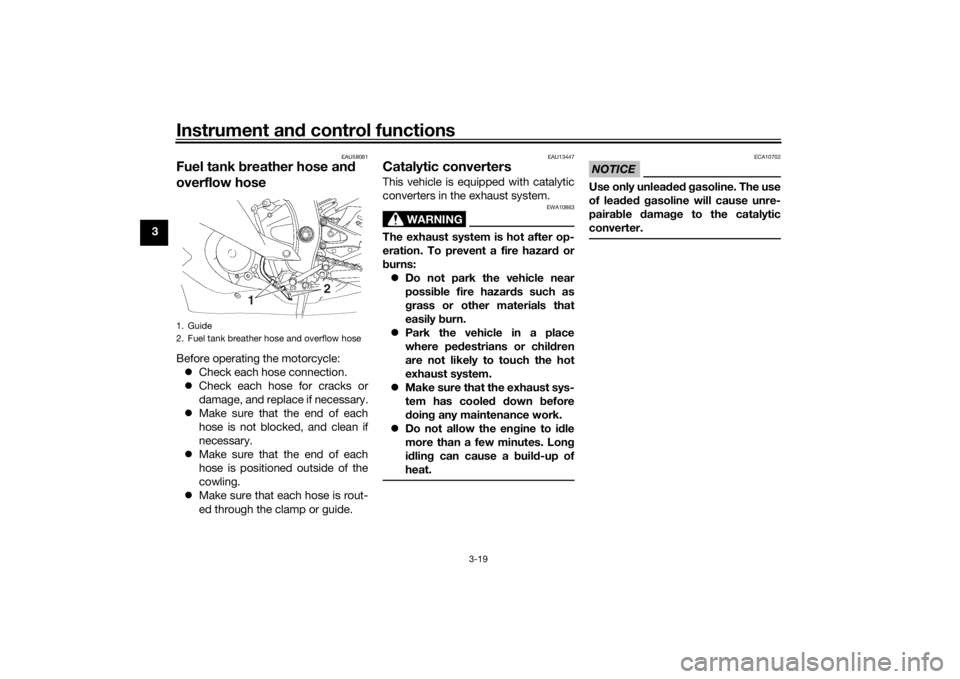

EAU58081

Fuel tank breather hose an d

overflow hoseBefore operating the motorcycle:

Check each hose connection.

Check each hose for cracks or

damage, and replace if necessary.

Make sure that the end of each

hose is not blocked, and clean if

necessary.

Make sure that the end of each

hose is positioned outside of the

cowling.

Make sure that each hose is rout-

ed through the clamp or guide.

EAU13447

Catalytic converters This vehicle is equipped with catalytic

converters in the exhaust system.

WARNING

EWA10863

The exhaust system is hot after op-

eration. To prevent a fire hazar d or

b urns:

Do not park the vehicle near

possi ble fire hazard s such as

g rass or other materials that

easily burn.

Park the vehicle in a place

where ped estrians or chil dren

are not likely to touch the hot

exhaust system.

Make sure that the exhaust sys-

tem has coole d down before

d oin g any maintenance work.

Do not allow the en gine to id le

more than a few minutes. Lon g

i d lin g can cause a b uild-up of

heat.

NOTICE

ECA10702

Use only unlea ded g asoline. The use

of lead ed g asoline will cause unre-

pairab le damag e to the catalytic

converter.

1. Guide

2. Fuel tank breather hose and overflow hose

2

1

U2CXE2E0.book Page 19 Tuesday, June 9, 2015 5:04 PM

Page 36 of 112

Instrument and control functions

3-21

3

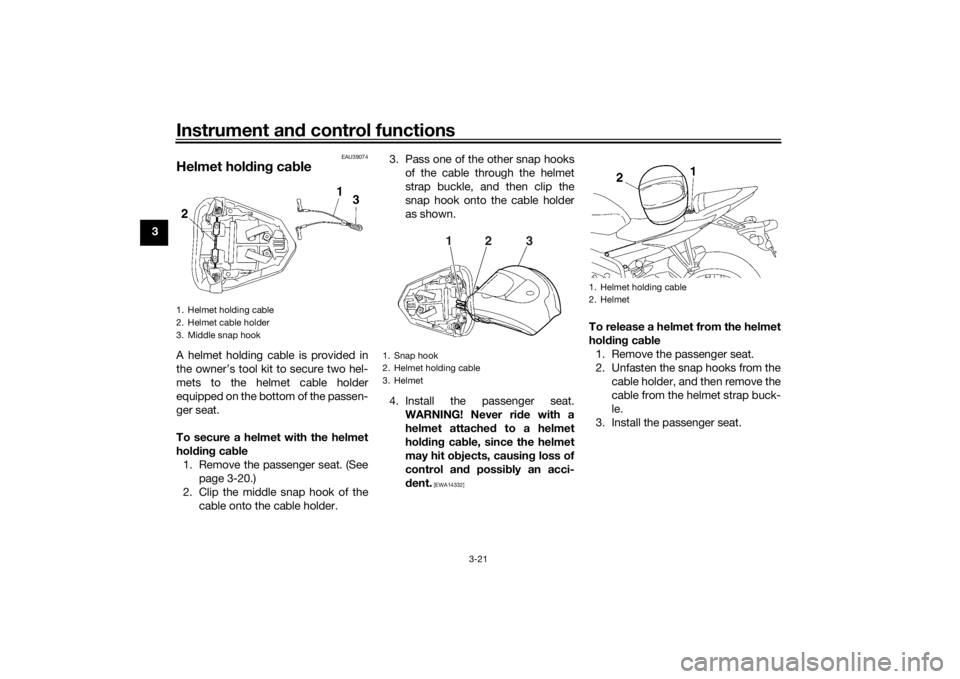

EAU39074

Helmet hold ing ca bleA helmet holding cable is provided in

the owner’s tool kit to secure two hel-

mets to the helmet cable holder

equipped on the bottom of the passen-

ger seat.

To secure a helmet with the helmet

hol din g cab le

1. Remove the passenger seat. (See page 3-20.)

2. Clip the middle snap hook of the cable onto the cable holder. 3. Pass one of the other snap hooks

of the cable through the helmet

strap buckle, and then clip the

snap hook onto the cable holder

as shown.

4. Install the passenger seat. WARNING! Never ri de with a

helmet attached to a helmet

hol din g cab le, since the helmet

may hit o bjects, causin g loss of

control an d possi bly an acci-

d ent.

[EWA14332]

To release a helmet from the helmet

hol din g cab le

1. Remove the passenger seat.

2. Unfasten the snap hooks from the cable holder, and then remove the

cable from the helmet strap buck-

le.

3. Install the passenger seat.

1. Helmet holding cable

2. Helmet cable holder

3. Middle snap hook

1. Snap hook

2. Helmet holding cable

3. Helmet

1

2

3

1. Helmet holding cable

2. Helmet

U2CXE2E0.book Page 21 Tuesday, June 9, 2015 5:04 PM

Page 37 of 112

Instrument and control functions

3-22

3

EAU39672

Rear view mirrorsThe rear view mirrors of this vehicle

can be folded forward or backward for

parking in narrow spaces. Fold the mir-

rors back to their original position be-

fore riding.

WARNING

EWA14372

Be sure to fol d the rear view mirrors

b ack to their ori ginal position before

ri din g.

EAU70520

A djustin g the front fork

WARNING

EWA10181

Always a djust both fork leg s equally,

otherwise poor han dlin g an d loss of

sta bility may result.This front fork is equipped with spring

preload adjusting bolts, rebound

damping force adjusting screws, com-

pression damping force adjusting bolts

(for fast compression damping) and

compression damping force adjusting

bolts (for slow compression damping).NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn b eyond the

maximum or minimum settin gs.Sprin g preloa d

To increase the spring preload and

thereby harden the suspension, turn

the adjusting bolt on each fork leg in di-

rection (a). To decrease the spring pre-

load and thereby soften the

suspension, turn the adjusting bolt on

each fork leg in direction (b). The spring preload setting is deter-

mined by measuring distance A,

shown in the illustration. The shorter

distance A is, the higher the spring pre-

load; the longer distance A is, the lower

the spring preload.

1. Riding position

2. Parking position

2

2

1

2

2

1

1. Spring preload adjusting bolt

1. Distance A

1

(a) (b)

1

U2CXE2E0.book Page 22 Tuesday, June 9, 2015 5:04 PM

Page 41 of 112

Instrument and control functions

3-26

3

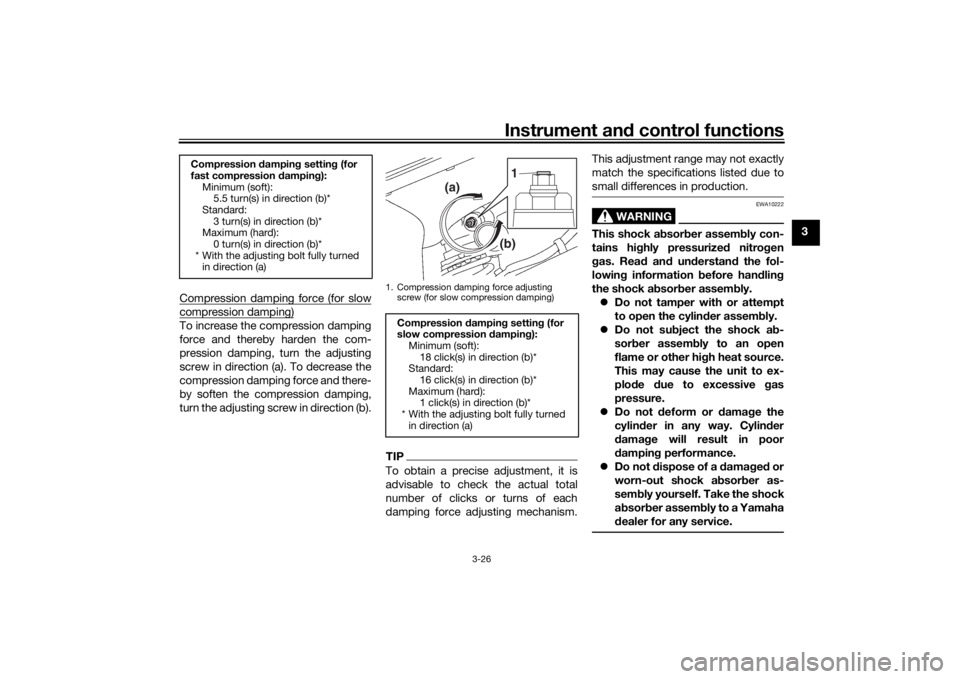

Compression damping force (for slow

compression damping)To increase the compression damping

force and thereby harden the com-

pression damping, turn the adjusting

screw in direction (a). To decrease the

compression damping force and there-

by soften the compression damping,

turn the adjusting screw in direction (b).

TIPTo obtain a precise adjustment, it is

advisable to check the actual total

number of clicks or turns of each

damping force adjusting mechanism. This adjustment range may not exactly

match the specifications listed due to

small differences in production.

WARNING

EWA10222

This shock a

bsor ber assem bly con-

tains hig hly pressurize d nitro gen

g as. Rea d an d un derstan d the fol-

lowin g information before han dlin g

the shock a bsor ber assem bly.

Do not tamper with or attempt

to open the cylind er assembly.

Do not su bject the shock a b-

sor ber assem bly to an open

flame or other hi gh heat source.

This may cause the unit to ex-

plo de due to excessive gas

pressure.

Do not deform or damag e the

cylin der in any way. Cylin der

d ama ge will result in poor

d ampin g performance.

Do not dispose of a d amaged or

worn-out shock a bsor ber as-

sem bly y

ourself. Take the shock

a b sor ber assem bly to a Yamaha

d ealer for any service.

Compression dampin g setting (for

fast compression dampin g):

Minimum (soft): 5.5 turn(s) in direction (b)*

Standard: 3 turn(s) in direction (b)*

Maximum (hard):

0 turn(s) in direction (b)*

* With the adjusting bolt fully turned in direction (a)

1. Compression damping force adjusting

screw (for slow compression damping)

Compression dampin g setting (for

slow compression dampin g):

Minimum (soft):

18 click(s) in direction (b)*

Standard: 16 click(s) in direction (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting bolt fully turned

in direction (a)

1

(a)

(b)

U2CXE2E0.book Page 26 Tuesday, June 9, 2015 5:04 PM

Page 43 of 112

Instrument and control functions

3-28

3

EAU15306

Si destan dThe sidestand is located on the left

side of the frame. Raise the sidestand

or lower it with your foot while holding

the vehicle upright.TIPThe built-in sidestand switch is part of

the ignition circuit cut-off system,

which cuts the ignition in certain situa-

tions. (See the following section for an

explanation of the ignition circuit cut-

off system.)

WARNING

EWA10242

The vehicle must not b e ridden with

the si destan d d own, or if the si de-

stan d cannot b e properly move d up

(or does not stay up), otherwise the

si destan d coul d contact the g round

an d d istract the operator, resultin g

in a possi ble loss of control.

Yamaha’s i gnition circuit cut-off

system has been desi gne d to assist

the operator in fulfilling the respon-

si bility of raisin g the si destan d b e-

fore startin g off. Therefore, check this system re

gularly an d have a

Yamaha dealer repair it if it does not

function properly.

EAU44893

I g nition circuit cut-off systemThe ignition circuit cut-off system

(comprising the sidestand switch,

clutch switch and neutral switch) has

the following functions.

It prevents starting when the

transmission is in gear and the

sidestand is up, but the clutch le-

ver is not pulled.

It prevents starting when the

transmission is in gear and the

clutch lever is pulled, but the side-

stand is still down.

It cuts the running engine when

the transmission is in gear and the

sidestand is moved down.

Periodically check the operation of the

ignition circuit cut-off system accord-

ing to the following procedure.

U2CXE2E0.book Page 28 Tuesday, June 9, 2015 5:04 PM