torque YAMAHA YZF-R6 2017 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: YZF-R6, Model: YAMAHA YZF-R6 2017Pages: 114, PDF Size: 4.2 MB

Page 18 of 114

Special features

3-4

3

EAU79480

Quick shift system

The quick shift system (QS) allows for

full-throttle, clutch lever-less, electron-

ically-assisted upshifts. When the shift

switch detects motion in the shift pedal

(page 4-17), engine power and drive

torque are momentarily adjusted to al-

low the upshift to occur.

TIP

The quick shift system operates

when traveling at least 20 km/h (12

mi/h) with an engine speed of

2000 r/min or higher, and only

when accelerating.

It does not operate when the

clutch lever is pulled.

UBN6E0E0.book Page 4 Wednesday, January 25, 2017 1:28 PM

Page 45 of 114

Instrument and control functions

4-27

4

EAU79931

A djustin g the shock a bsor ber

assem bly

This model is equipped with adjustable

suspension. The spring preload, re-

bound damping force, fast compres-

sion damping force, and slow

compression damping force can be

adjusted.

NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn beyon d the

maximum or minimum settin gs.

Sprin g preloa d

1. Loosen the locknut.

2. To increase the spring preload and thereby harden the suspen-

sion, turn the adjusting nut in di-

rection (a). To decrease the spring

preload and thereby soften the

suspension, turn the adjusting nut

in direction (b).

The spring preload setting is de-

termined by measuring distance

A. The longer distance A is, the

higher the spring preload; the

shorter distance A is, the lower the

spring preload. Use the special wrench and

the extension bar included in

the owner’s tool kit to make

the adjustment. 3. Tighten the locknut to the speci-

fied torque. NOTICE: Always

ti ghten the locknut ag ainst the

a d justin g nut, and then tighten

the locknut to the specifie d

torque.

[ECA10122]

1. Locknut

2. Spring preload adjusting nut

3. Special wrench

4. Extension bar

1. Distance A

Sprin g preloa d:

Minimum (soft):

Distance A = 84.9 mm (3.34 in)

Standard: Distance A = 89.9 mm (3.54 in)

Maximum (hard): Distance A = 92.9 mm (3.66 in)

Ti ghtenin g torque:

Locknut:

28 N·m (2.8 kgf·m, 20 lb·ft)

1

34

2

(a)(b)

1

UBN6E0E0.book Page 27 Wednesday, January 25, 2017 1:28 PM

Page 59 of 114

Periodic maintenance an d a djustment

7-2

7

EAU17303

Emission controls not only function to

ensure cleaner air, but are also vital to

proper engine operation and maximum

performance. In the following periodic

maintenance charts, the services relat-

ed to emissions control are grouped

separately. These services require

specialized data, knowledge, and

equipment. Maintenance, replace-

ment, or repair of the emission control

devices and systems may be per-

formed by any repair establishment or

individual that is certified (if applicable).

Yamaha dealers are trained and equipped to perform these particular

services.

EAU67090

Owner’s tool kit

The owner’s tool kit should be stored

separately from the vehicle. However,

there are two hexagon wrenches

stored under the passenger seat. (See

page 4-23.)

The service information included in this

manual and the tools provided are in-

tended to assist you in the perfor-

mance of preventive maintenance and

minor repairs. However, additional

tools, such as a torque wrench, are

necessary to perform certain mainte-

nance work correctly.

TIP

If you do not have the tools or experi-

ence required for a particular job, have

a Yamaha dealer perform it for you.

1. Hexagon wrench

1

UBN6E0E0.book Page 2 Wednesday, January 25, 2017 1:28 PM

Page 69 of 114

Periodic maintenance an d a djustment

7-12

7

Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

TIP

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.

NOTICE

ECA10841

Do not use any tools to remove or in-

stall the spark plu

g cap, otherwise

the i gnition coil coupler may get

d ama ged . The spark plu g cap may

b e difficult to remove b ecause the

ru bber seal on the en d of the cap fits

ti g htly. To remove the spark plu g

cap, simply twist it b ack and forth

while pullin g it out; to install it, twist

it back an d forth while pushin g it in.

EAU36112

Canister

This model is equipped with a canister

to prevent the discharging of fuel vapor

into the atmosphere. Before operating

this vehicle, make sure to check the

following:

Check each hose connection.

Check each hose and canister for

cracks or damage. Replace if

damaged.

Make sure that the canister

breather is not blocked, and if

necessary, clean it.

1. Spark plug gap

Spark plu g g ap:

0.6–0.7 mm (0.024–0.028 in)

Ti ghtening torque:

Spark plug: 13 N·m (1.3 kgf·m, 9.4 lb·ft)

11

1. Canister

2. Canister breather

2

1

UBN6E0E0.book Page 12 Wednesday, January 25, 2017 1:28 PM

Page 72 of 114

Periodic maintenance an d a djustment

7-15

7

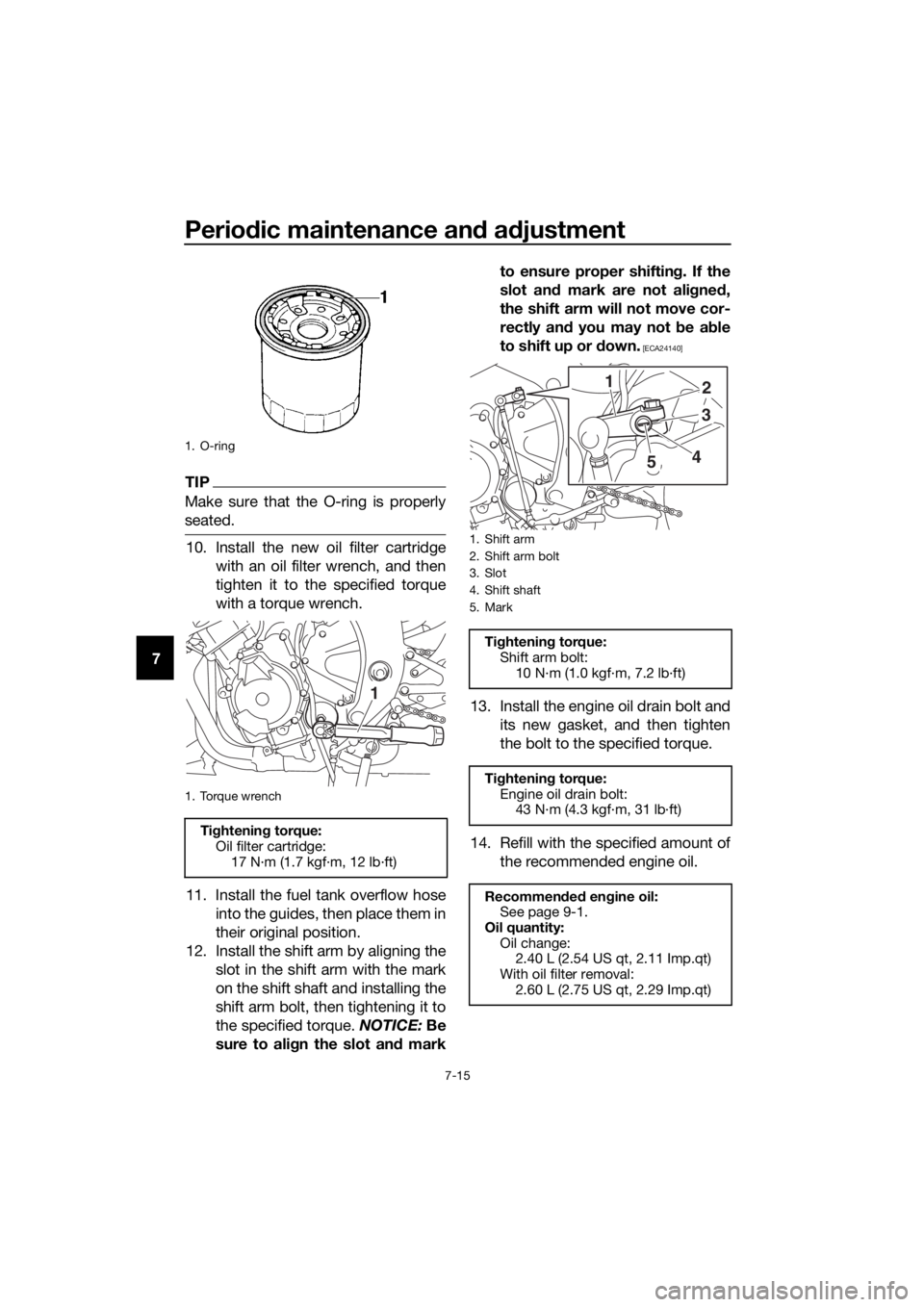

TIP

Make sure that the O-ring is properly

seated.

10. Install the new oil filter cartridge

with an oil filter wrench, and then

tighten it to the specified torque

with a torque wrench.

11. Install the fuel tank overflow hose into the guides, then place them in

their original position.

12. Install the shift arm by aligning the slot in the shift arm with the mark

on the shift shaft and installing the

shift arm bolt, then tightening it to

the specified torque. NOTICE: Be

sure to ali gn the slot an d mark to ensure proper shiftin

g. If the

slot an d mark are not ali gne d,

the shift arm will not move cor-

rectly an d you may not be ab le

to shift up or down.

[ECA24140]

13. Install the engine oil drain bolt and

its new gasket, and then tighten

the bolt to the specified torque.

14. Refill with the specified amount of the recommended engine oil.

1. O-ring

1. Torque wrench

Tightenin g torque:

Oil filter cartridge: 17 N·m (1.7 kgf·m, 12 lb·ft)

1

1. Shift arm

2. Shift arm bolt

3. Slot

4. Shift shaft

5. Mark

Tightening torque:

Shift arm bolt: 10 N·m (1.0 kgf·m, 7.2 lb·ft)

Ti ghtening torque:

Engine oil drain bolt: 43 N·m (4.3 kgf·m, 31 lb·ft)

Recommen ded en gine oil:

See page 9-1.

Oil quantity: Oil change:2.40 L (2.54 US qt, 2.11 Imp.qt)

With oil filter removal: 2.60 L (2.75 US qt, 2.29 Imp.qt)

2

1

3

4

5

UBN6E0E0.book Page 15 Wednesday, January 25, 2017 1:28 PM

Page 75 of 114

Periodic maintenance an d a djustment

7-18

7

5. Install the panel.

EAU79950To chan

ge the coolant

1. Place the vehicle on a level surfa- ce and let the engine cool if neces-

sary.

2. Remove panel B and cowling C. (See page 7-7.)

3. Place a container under the en- gine to collect the used coolant.

4. Remove the radiator cap. WARNING! Never attempt to re-

move the ra diator cap when the

en gine is hot.

[EWA10382]

5. Remove the coolant drain bolt and

its gasket to drain the cooling sys-

tem. 6. Move the hose clamp in the direc-

tion shown, and then disconnect

the radiator hose to drain the radi-

ator.

7. Remove the coolant reservoir by removing the bolts.

8. Remove the coolant reservoir cap, and then turn the coolant reservoir

upside down to empty it.

9. After the coolant is completely drained, thoroughly flush the cool-

ing system with clean tap water.

10. Install the coolant reservoir by in- stalling the bolts.

11. Connect the radiator hose, and then move the hose clamp back to

its original position.

12. Install the coolant drain bolt and its new gasket, and then tighten

the bolt to the specified torque.

13. Pour the recommended coolant into the reservoir to the maximum

level mark, and then install the

coolant reservoir cap.

1. Radiator cap

1. Coolant drain bolt

2. Gasket

3. Radiator hose

4. Hose clamp

1

43

1

2

1. Coolant reservoir cap

2. Coolant reservoir

3. Bolt

Tightenin g torque:

Coolant drain bolt:

10 N·m (1.0 kgf·m, 7.2 lb·ft)

1

2

3

UBN6E0E0.book Page 18 Wednesday, January 25, 2017 1:28 PM

Page 87 of 114

Periodic maintenance an d a djustment

7-30

7

TIP

Using the alignment marks on each

side of the swingarm, make sure that

both drive chain pullers are in the same

position for proper wheel alignment.

3. Tighten the axle nut, then the lock-

nuts to their specified torques.

4. Make sure that the drive chain pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23026

Cleanin g an d lu bricatin g the

d rive chain

The drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.

NOTICE

ECA10584

The drive chain must b e lubricated

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.

1. Clean the drive chain with kero-

sene and a small soft brush.

NOTICE: To prevent d amaging

the O-rin gs, do not clean the

d rive chain with steam cleaners,

hi gh-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

en gine oil or any other lu bri-

cants for the drive chain, as they

may contain su bstances that

coul d damag e the O-rin gs.

[ECA11112]

Ti ghtening torques:

Axle nut: 110 N·m (11 kgf·m, 80 lb·ft)

Locknut: 16 N·m (1.6 kgf·m, 12 lb·ft)

UBN6E0E0.book Page 30 Wednesday, January 25, 2017 1:28 PM