coolant level YAMAHA YZF-R7 1999 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 1999, Model line: YZF-R7, Model: YAMAHA YZF-R7 1999Pages: 381, PDF Size: 18.88 MB

Page 17 of 381

1 - 5

INSTRUMENT AND CONTROL FUNCTIONS

4 681012

14

x1000r/min

0

1 12

3 3

4

1. Warning light

2. Oil level symbol “ ”

3. Coolant temperature symbol “ ”

4. Engine trouble symbol “ ”

EAU01564

Warning light

This indicator light has three functions.

l

The light will come on and symbol

“ ” will flash if the engine oil

level is low.

If this symbol flashes, stop the en-

gine immediately and fill it with oil

to the specified level.

l

The light will come on and symbol

“ ” will flash if trouble occurs in

a monitoring circuit. In such a

case, take the motorcycle to a

Yamaha dealer to have the self-

diagnostic systems checked.

l

The light will come on and symbol

“ ” will flash if the coolant tem-

perature is too high. The following

chart shows the conditions of the

indicator light, symbol and tem-

perature display in accordance to

coolant temperature.

The light circuit can be checked by the

procedure on page 1-6.

EC000118

CAUTION:

l

Do not run the motorcycle until

you know it has sufficient en-

gine oil.

l

Do not run the motorcycle if the

engine is overheated.

NOTE:

Even if the oil is filled to the specified

level, the indicator light may flicker

when riding on a slope or during sud-

den acceleration or deceleration, but

this is normal.

CB-74ECB-74E

Coolant

temperatureDisplay Conditions What to do

~ 39 ˚CSymbol is on and “LO” is

displayed.OK. Go ahead with riding.

40 ËšC ~ 120 ËšCSymbol is on and temper-

ature is displayed.OK. Go ahead with riding.

121 ËšC ~ 139 ËšCSymbol and temperature

flash.

Warning light comes on.Stop the motorcycle and al-

low it to idle until coolant tem-

perature goes down.

If the temperature does not

go down, stop the engine.

140 ËšC ~ Symbol and message

“HI” flash.

Warning light comes on.Stop the engine and allow it

to cool. Seen page 1-19 if the

engine overheats.

—Symbol and message

“Err” flash.

Warning light comes on.Ask a Yamaha dealer to in-

spect the motorcycle.

C

C

C

C

C

Page 31 of 381

1 - 19

TROUBLESHOOTING CHART

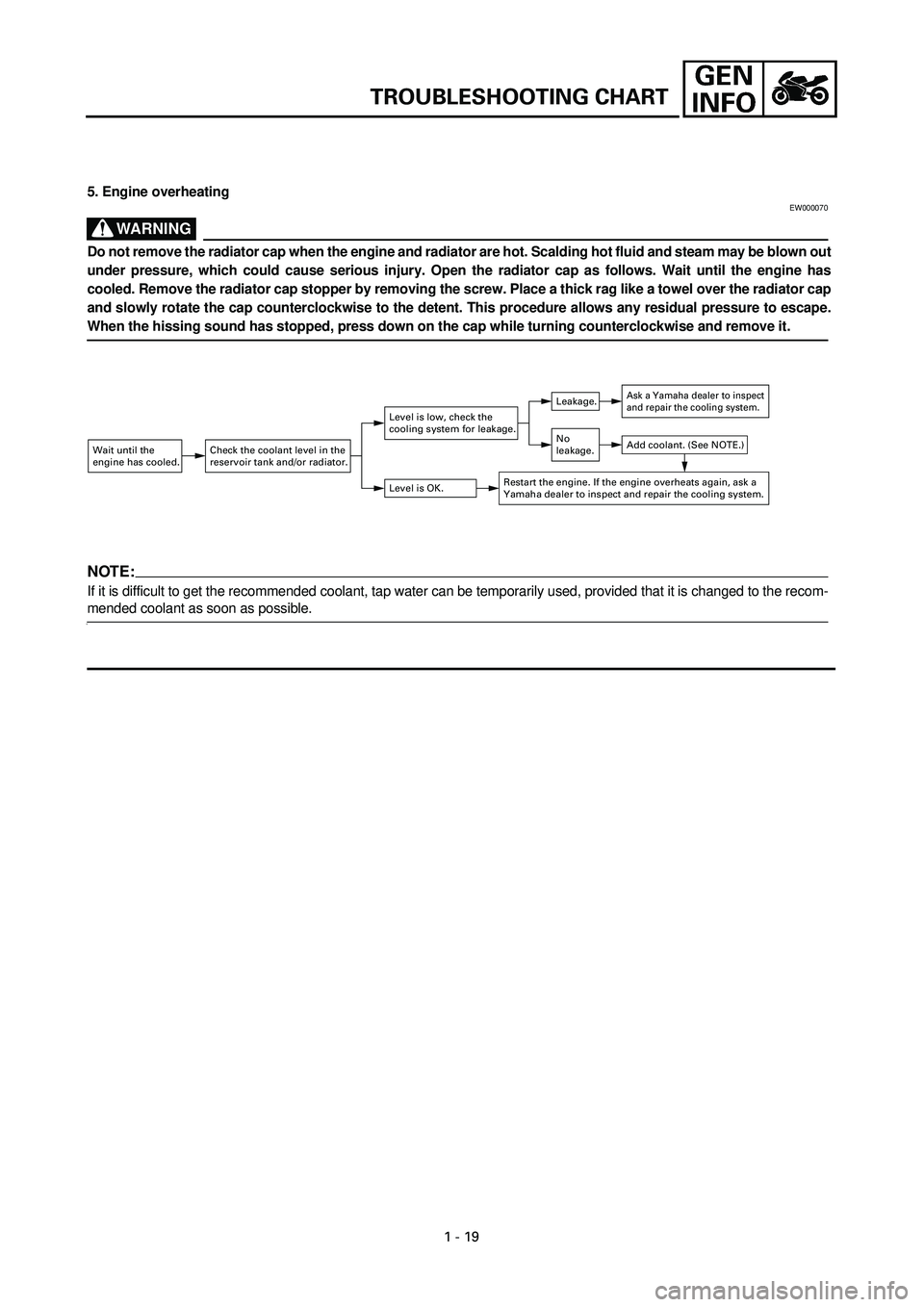

5. Engine overheatingEW000070

WARNING

Do not remove the radiator cap when the engine and radiator are hot. Scalding hot fluid and steam may be blown out

under pressure, which could cause serious injury. Open the radiator cap as follows. Wait until the engine has

cooled. Remove the radiator cap stopper by removing the screw. Place a thick rag like a towel over the radiator cap

and slowly rotate the cap counterclockwise to the detent. This procedure allows any residual pressure to escape.

When the hissing sound has stopped, press down on the cap while turning counterclockwise and remove it.

NOTE:

If it is difficult to get the recommended coolant, tap water can be temporarily used, provided that it is changed to the recom-

mended coolant as soon as possible.

Wait until the

engine has cooled.Check the coolant level in the

reservoir tank and/or radiator.

Level is OK.

Level is low, check the

cooling system for leakage.

No

leakage.

Leakage.Ask a Yamaha dealer to inspect

and repair the cooling system.

Add coolant. (See NOTE.)

Restart the engine. If the engine overheats again, ask a

Yamaha dealer to inspect and repair the cooling system.

Page 66 of 381

2 - 28

SPEC

1Left handlebar switch lead

2Starter cable

3Main relay

4Speed sensor

5Throttle stop screw

6Sidestand switch lead

7Oil level switch lead

8Main switch lead

9Headlight and meter sub-wire har-

ness coupler0Horn lead

AHeadlight and meter sub-wire harness lead

BThrottle cable

CClutch hose

DWire harness (to headlight and meter sub-wire harness)

EWire harness

FFuel tank overflow hose

GWater pump breather hose

HCoolant reservoir breather hose

IAir filter case breather hose

CABLE ROUTING

Page 69 of 381

2 - 31

SPEC

KPickup coil lead

LStator coil lead

MSpeed sensor lead

NSidestand switch lead

OOil level switch lead

PCoolant reservoir breather hose

QWire harness

RWire harness lead (to fall detection

switch coupler)

SWire harness lead (to fuse box)

TStarter motor leadUNeutral switch lead

VGround lead

WCoolant temperature sensor coupler

XThrottle cable

Route the wire harness in front of the ignition coils.

õBe sure that there is no slack in the tail/brake light lead

and rear turn signal leads below the rear fender panel.

‚Align the portions of the wire harness, ground lead and

starter motor lead marked with white tape with the lead

holder.

CABLE ROUTING

Page 71 of 381

3 - 2

CHK

ADJ

PERIODIC MAINTENANCE AND LUBRICATION

INTERVALS

*

Since these items require special tools, data and technical skills, they should be serviced by a

Yamaha dealer.

NOTE:

• The air filter element needs more frequent service if you are riding in unusually wet or

dusty areas.

• Hydraulic brake system

– Replace the brake fluid or clutch fluid after disassembling the master cylinder, caliper cyl-

inder or release cylinder.

– Check the brake fluid or clutch fluid level and add fluid as required.

– Replace the master cylinder, caliper cylinder and release cylinder oil seals every two

years.

– Replace the brake hoses and clutch hose every four years, or if cracked or damaged.

15

*

Chassis fasteners

• Make sure that all nuts, bolts and screws are properly

tightened.

• Tighten if necessary.

Ă–Ă–

16 Sidestand

• Check operation.

• Lubricate and repair if necessary.

Ă–Ă–

17

*

Sidestand switch

• Check operation.

• Replace if necessary.

Ă–Ă–Ă–

18

*

Front fork

• Check operation and for oil leakage.

• Correct accordingly.

Ă–Ă–

19

*

Rear shock

absorber assembly

• Check operation and shock absorber for oil leakage.

• Replace shock absorber assembly if necessary.

Ă–Ă–

20

*

Rear suspension

relay arm and con-

necting arm pivot-

ing points

• Check operation.

• Lubricate with lithium soap base grease every 24,000

km or 24 months (whichever comes first).

Ă–Ă–

21

*

Electronic fuel

injection system

• Check engine idling speed, synchronization and

starter operation.

• Adjust if necessary.

Ă–Ă–Ă–

22 Engine oil

• Check oil level and vehicle for oil leakage.

• Correct if necessary.

• Change. (Warm engine before draining.)

Ă–Ă–Ă–

23Engine oil filter

cartridge

• Replace.

Ă–Ă–

24

*

Cooling system

• Check coolant level and vehicle for coolant leakage.

• Correct if necessary.

• Change coolant every 24,000 km 24 months (which-

ever comes first).

Ă–Ă–

No. ITEM CHECKS AND MAINTENANCE JOBSINITIAL

1,000 km EVERY

6,000 km or

6 months

(whichever

comes first)12,000 km or

12 months

(whichever

comes first)

3

Page 100 of 381

3 - 31

CHK

ADJ

CHECKING THE COOLANT LEVEL

EB303220

CHECKING THE COOLANT LEVEL

1. Stand the motorcycle on a level surface.

NOTE:

• Place the motorcycle on a suitable

stand.

• Make sure that the motorcycle is

upright.

2. Remove:

• bottom cowling

• front cowling

Refer to “COWLINGS”.

3. Check:

• coolant level

The coolant level should be between

the minimum level mark a and maxi-

mum level mark b.

Below the minimum level mark ® Add

the recommended coolant to the

proper level.

ACHTUNG:CAUTION:

• Adding water instead of coolant lowers

the antifreeze content of the coolant. If

water is used instead of coolant, check

and if necessary, correct the antifreeze

concentration of the coolant.

• Use only distilled water. However,

soft water may be used if distilled

water is not available.

4. Start the engine, warm it up for several

minutes, and then turn it off.

5. Check:

• coolant level

NOTE:

Before checking the coolant level, wait a

few minutes until the coolant has set-

tled.

aa b

b

Page 104 of 381

3 - 35

CHK

ADJ

CHANGING THE COOLANT

ACHTUNG:CAUTION:

• Adding water instead of coolant low-

ers the antifreeze content of the cool-

ant. If water is used instead of coolant,

check, and if necessary, correct the

antifreeze concentration of the cool-

ant.

• Use only distilled water. However,

soft water may be used if distilled

water is not available.

• If coolant comes into contact with

painted surfaces, immediately wash

them with water.

• Do not mix different types of anti-

freeze.

11.Install:

• radiator cap

12.Fill:

• coolant reservoir

(with the recommended coolant to the

maximum level mark a)

13.Install:

• coolant reservoir cap

14.Start the engine, warm it up for several

minutes, and then turn it off.

aa

15.Check:

• coolant level

Refer to “CHECKING THE COOLANT

LEVEL”.

NOTE:

Before checking the coolant level, wait a

few minutes until the coolant has set-

tled.

16.Install:

• front cowling

• bottom cowling

Refer to “COWLINGS”.

Page 182 of 381

ENG

4 - 50

OIL PAN AND OIL PUMP

EB411000

OIL PAN AND OIL PUMP

Order Job/Part Q’ty Remarks

Removing the oil pan and oil pumpRemove the parts in the order listed.

Engine oil Drain.

Refer to “CHANGING THE ENGINE

OIL” in chapter 3.

Coolant Drain.

Refer to “CHANGING THE COOLANT”

in chapter 3.

Radiator assembly and water pump

outlet pipeRefer to “RADIATOR AND THERMO-

STAT” and “OIL COOLER” in chapter 5.

Exhaust pipe assembly Refer to “ENGINE”.

1 Oil level switch connector 1 Disconnect.

2 Oil level switch 1

3 Oil level switch lead holder 1

4 Oil pan 1

5 Oil pan gasket 1

6 Dowel pin 2

Page 231 of 381

5 - 12

COOLWATER PUMP

EB503000

WATER PUMP

Order Job/Part Q’ty Remarks

Removing the impeller shaftRemove the parts in the order listed.

Oil/water pump assembly and oil

pump rotorRefer to “OIL PAN AND OIL PUMP” in

chapter 4.

1 Water pump cover 1

2 O-ring 1

3 Pin 2

4 Impeller shaft (along with the impel-

ler)1

NOTE:

• The water pump and oil pump are

combined into one unit (oil/water

pump assembly).

• It is not necessary to remove the

impeller shaft unless the coolant

level is extremely low or coolant

leaks from the oil pan.

Page 337 of 381

8 - 1

–+ELEC

ELECTRICAL COMPONENTS

EB800000

ELECTRICAL

ELECTRICAL COMPONENTS

1

Wire harness

2

Main switch

3

Front brake light switch

4

Ignition coils

5

Clutch switch

6

Throttle position sensor

7

Intake air temperature sensor

8

Intake air pressure sensor

9

Atmospheric pressure sensor

0

Turn signal relay

A

Relay unit

B

ECU

C

CDI unit

D

Fuse box

E

Fall detection switch

F

Starter relay

G

Main fuse

H

Main relay

I

Battery

J

Rectifier/regulator

K

Rear brake light switch

L

Neutral switch

M

Speed sensor

N

Sidestand switch

O

Stator coil assembly

P

Oil level switch

Q

Pickup coil

R

Radiator fan

S

Horn

T

Coolant temperature

sender

U

Thermo switch

V

Camshaft sensor

8